- DL manuals

- Zapi

- Inverter

- AC-2

- User Manual

Zapi AC-2 User Manual

Summary of AC-2

Page 1

Electronic • oleodynamic • industrial equipments construction via parma, 59 – 42028 – poviglio (re) – italy tel +39 0522 960050 (r.A.) – fax +39 0522 960259 e-mail: zapi@zapispa.It – web: www.Zapispa.It en user manual ac-2 inverter.

Page 2

Copyright © 1975-2006 zapi s.P.A. All rights reserved the contents of this publication is a zapi s.P.A. Property; all related authorizations are covered by copyright. Any partial or total reproduction is prohibited. Under no circumstances will zapi s.P.A. Be held responsible to third parties for dam...

Page 3: Contents

Contents 1 introduction ...................................................................................................................5 2 specification ...................................................................................................................6 2.1 technical specificatio...

Page 4

6.2 description of console “restore” function ........................................................... 50 6.3 description of “alarms” menu ............................................................................... 52 6.4 description of console “program vacc” function............................

Page 5: 1 Introduction

1 introduction within the zapimos family, the ac-2 inverter is the model suitable for control of 3.0 kw to 8.0 kw motors. It has been expressly designed for battery electric traction. It is fit for electric truck, golf cars, utility cars. Adezp0ae - ac-2 inverter - user manual page - 5/64.

Page 6: 2 Specification

2 specification 2.1 technical specifications inverter for ac asynchronous 3-phase motors regenerative braking functions can-bus interface digital control based upon a microcontroller voltage:....................................................................... 24 - 36 - 48 - 72 – 80 – 96 v maximum...

Page 7

Function request (for ex.: running request) is made. 2.3.2 accelerator unit the accelerator unit can consist of a potentiometer or an hall effect device. It should be in a 3-wire configuration. Cpot (e1) signal ranges from 0 to 10 v. Potentiometer value should be in the 0.5 – 10 kohm range; generall...

Page 8: 2.4

Chapter 5.4 for more explanation. 2.3.4 speed feedback the motor control is based upon the motor speed feedback. The speed transducer is an incremental encoder, with two phases shifted at 90°. The encoder can be of different types: - power supply: +5 v or +12 v - electric output: open collector ( np...

Page 9: 2.6 Diagnosis

- regenerative release braking based upon deceleration ramps. - regenerative braking when the accelerator pedal is partially released (deceleration). - direction inversion with regenerative braking based upon deceleration ramp. - regenerative braking and direction inversion without contactors: only ...

Page 10: 2.7 Thermal Consideration

2.7 thermal consideration - the heat generated by the power block must be dissipated. For this to be possible, the compartment must be ventilated and the heat sink materials ample. - the heat sink material and system should be sized on the performance requirement of the machine. Abnormal ambient air...

Page 11

- an intrinsic protection is present inside the logic when the voltage on the battery power connection overtakes 40% more than the battery nominal voltage or if the key is switched off before the battery power line is disconnected. Adezp0ae - ac-2 inverter - user manual page - 11/64.

Page 12: Safety And Protection

3 u safety and protection zapi controllers are designed according to the pren954-1 specifications for safety related parts of control system and to uni en1175-1 norm. The safety of the machine is strongly related to installation; length, layout and screening of electrical connections have to be care...

Page 13: 4 Installation

4 installation install the controller with the base-plate on a flat metallic surface that is clean and unpainted. Apply a light layer of thermo-conductive grease between the two surfaces to permit better heat dissipation. Ensure that the wiring of the cable terminals and connectors is carried out co...

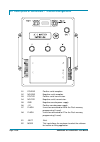

Page 14

4.4 description of connectors - traction configuration a1 pclrxd positive serial reception. A2 nclrxd negative serial reception. A3 pcltxd positive serial transmission. A4 ncltxd negative serial transmission. A5 gnd negative console power supply. A6 +12 positive console power supply. A7 flash it mus...

Page 15

Configuration: mode: open (not connected) traction inverter mode: close (connected with a5) pump inverter c1 can-l low level can-bus voltage i/o. C2 can-l-out low level can-bus voltage i/o. C3 can-h high level can-bus voltage i/o. C4 can-h-out high level can-bus voltage i/o. D1÷d6 incremental encode...

Page 16

Input. F6 ptherm input for motor temperature sensor. F7 cm common of fw / bw / sr / pb / seat / inching fw / inching bw / exclusive hydro / enable microswitches. F8 nlc negative of main contactor coil. F9 nbrake output for driving a brake or an hydraulic steering contactor coil; it drives the load t...

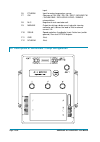

Page 17

A1 pclrxd positive serial reception. A2 nclrxd negative serial reception. A3 pcltxd positive serial transmission. A4 ncltxd negative serial transmission. A5 gnd negative console power supply. A6 +12 positive console power supply. A7 flash it must be connected to a8 for the flash memory programming (...

Page 18: 4.6 Encoder Installation

(ch) with a 10 a fuse in series. F2 paux positive of the auxiliary output. F3 phydro positive for the hydraulic steering contactor. F4 4th speed input for fourth speed request; it is active high. F5 safety if not connected to -batt the mc coil power output will be disabled. It can also be used as a ...

Page 19

4) connection of encoder with open collector output: +12 v power supply. Very important it is necessary to specify in the order the type of encoder used, in terms of power supply, electronic output and n° of pulses for revolution, because the logic unit must be set in the correct way by zapi. Adezp0...

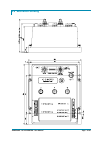

Page 20

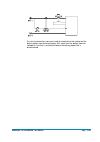

4.7 description of power connections view of the power bars: -batt negative of the battery. +batt positive of the battery. U; v; w connection bars of the three motor phases; follow this sequence and the indication on the motor. Page - 20/64 adezp0ae - ac-2 inverter - user manual.

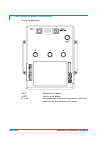

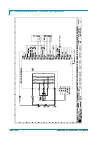

Page 21: 4.8 Mechanical Drawing

4.8 mechanical drawing adezp0ae - ac-2 inverter - user manual page - 21/64.

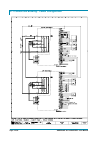

Page 22

4.9 connection drawing - traction configuration page - 22/64 adezp0ae - ac-2 inverter - user manual.

Page 23

4.10 connection drawing - pump configuration adezp0ae - ac-2 inverter - user manual page - 23/64.

Page 24

4.11 connection drawing - combi configuration page - 24/64 adezp0ae - ac-2 inverter - user manual.

Page 25: Digital Console

5 programming & adjustments using digital console 5.1 adjustments via console adjustment of parameters and changes to the inverter’s configuration are made using the digital console. The console is connected to the “a” connector of the inverter. 5.2 description of console & connection digital consol...

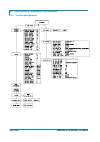

Page 26

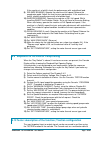

5.3 description of standard console menu 5.3.1 traction configuration page - 26/64 adezp0ae - ac-2 inverter - user manual.

Page 27: 5.4 Function Configuration

5.3.2 pump configuration 5.4 function configuration 5.4.1 traction using the config menu of the programming console, the user can configure adezp0ae - ac-2 inverter - user manual page - 27/64.

Page 28

The following functions (see "operational feature" chapter for an explanation of "hydraulic steering function"): submenu "set options" 1) hour counter - running: the counter registers travel time only. - key on: the counter registers when the "key" switch is closed. 2) battery check - on: the batter...

Page 29

- analog: an analog motor thermal sensor is connected between f6 and f12 (the curve can be customized on a customer request). - none: no motor thermal sensor switch is connected. 9) aux function - on/off: if this option is programmed on the traction inverter applies maximum braking and traction torq...

Page 30

Vacc" function. 8) adjustment #04 this parameter determines the motor temperature level at which the “motor temperature” alarm is signalled. The range is from 70 °c to 160 °c with 10 °c steps. This parameter must be adjusted only if the “set temperature” (menu “set option”) parameter is programmed “...

Page 31

Aux output stop on ramp f9 output behaviour on a slope brake on -it drives the coil of a electromagnetic brake. -the hydraulic steering function request is sent to the pump inverter by the can-bus link. The truck is electrically hold on a slope; when the time set by ""auxiliary time"" parameter is e...

Page 32

- off: the battery discharge level check is carried out but no alarm is signalled. Very important: in the combi system (pump + traction), the battery discharge calculation for the complete system is carried out by the traction inverter; the information about the pump inverter consumption is sent on ...

Page 33

“set option”) parameter is programmed “analog”. 7) adjustment #03 this parameter isn’t used. 8) adjustment #02 it adjusts the lower level of the battery discharge table. 9) adjustment #01 it adjusts the upper level of the battery discharge table. 10) load hm from mdi for an explanation of this point...

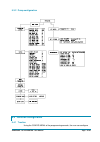

Page 34

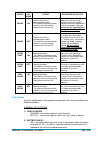

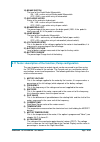

Flow chart showing how to make changes to options menu. 1) opening zapi menu. Ac2 zapi v0.0 48v 350a 00000 2) press top left & right buttons to enter set menu. % ' % ' ' ' 3) the display will show: set model. Config menu set model 4) press roll up or roll down button until set model menu appears. % ...

Page 35

Flow chart showing how to make changes to adjustments menu. 1) opening zapi menu. Ac2 zapi v0.0 48v 350a 00000 2) press top left & right buttons to enter config menu. % ' % ' ' ' 3) the display will show: set model. Config menu set model 4) press roll up or roll down button until adjustments menu ap...

Page 36

Flow chart showing how to use the set battery type adjustment 1) opening zapi menu. Ac2 zapi v0.0 48v 350a 00000 2) press top left & right buttons to enter config menu. % ' % ' ' ' 3) the display will show: set model. Config menu set model 4) press roll up button until adjustments menu appears. % ' ...

Page 37

Flow chart showing how to carry out adjustment battery operation by console. 1) opening zapi menu. Ac2 zapi v0.0 48v 350a 00000 2) press top left & right buttons to enter config menu. % ' % ' ' ' 3) the display will show: set model. Config menu set model 4) press roll up button until adjustments men...

Page 38

5.5 parameter regulation: traction configuration in addition to the input configuration, parameter modification is made directly by zapi on customer specifications, or by the customer, making the adjustments using the programming console. The following parameters can be modified: 1) acceleration del...

Page 39

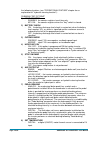

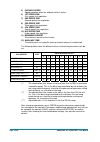

Programmed level parameter unit 0 1 2 3 4 5 6 7 8 9 acceleration delay (*) sec. 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 release braking (**) sec. 5.5 5.0 4.5 4.0 3.5 3.0 2.5 2.0 1.5 1.0 invers. Braking (**) sec. 5.5 5.0 4.5 4.0 3.5 3.0 2.5 2.0 1.5 1.0 pedal braking (**) sec. 5.5 5.0 4.5 4.0 3.5 3.0 ...

Page 40

5) cutback speed speed reduction when the cutback switch is active. 6) 1st speed fine first speed, fine regulation. 7) 2nd speed fine second speed, fine regulation. 8) 3rd speed fine third speed, fine regulation. 9) 4th speed fine fourth speed, fine regulation. 10) hyd speed fine hydro speed, fine r...

Page 41

Flow chart showing how to make programme changes using digital console fitted with eprom ck ultra. 1) opening zapi display. Ac2 zapi v0.0 48v 350a 00000 2) press enter to go into the general menu. ' % ' ' ' ' 3) the display will show: main menu parameter change 4) press enter to go into the paramete...

Page 42

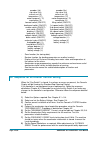

Encoder (hz) encoder (hz) slip value (hz) slip value (hz) current rms (a) current rms (a) temperature (°c) temperature (°c) motor temperat. (°c) motor temperature (°c) accelerator (v) accelerator (v) forward switch (on/off) lifting switch (on/off) backward switch (on/off) 1st speed switch (on/off) e...

Page 43

If the machine is a forklift, check the performance with and without load. 9) release braking. Operate the machine at full speed. Release the accelerator pedal. Adjust the level to your requirements. If the machine is a forklift, check the performance with and without load. 10) inversion braking. Op...

Page 44

Read voltage, current and temperature. The following definition listing shows the relative measurements: 1) motor voltage this is the voltage supplied to the motor by the inverter; it is expressed as a percentage of the full voltage (which depends of the battery voltage). 2) frequency this is the fr...

Page 45

16) brake switch the level of the pedal brake microswitch. - on / +vb = active entry of brake pedal microswitch. - off / gnd = non active entry of microswitch. 17) exclusive hydro status of the exclusive hydro input. - on / +vb = active entry of closed switch. - off / gnd = non active entry of open ...

Page 46

9) lifting switch status of the lifting switch. - on / +vb = active entry of closed switch. - off / gnd = non active entry of open switch. 10) 1st speed switch status of the first speed switch of the pump. - on / +vb = active entry of closed switch. - off / gnd = non active entry of open switch. 11)...

Page 47

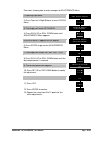

Flow chart showing how to use the tester function of the digital console. 1) opening zapi display. Ac2 zapi v0.0 48v 350a 00000 2) press enter to go into the general menu. ' % ' ' ' ' 3) the display will show: main menu parameter change 4) press roll up or roll down button until tester menu appear o...

Page 48: 6 Other Functions

6 other functions 6.1 description of the console “save” function the save function allows the operator to transmit the parameter values and configuration data of the controller into the console memory. It is possible to load 64 different programmes. The information saved in the console memory can th...

Page 49

12) press out to return to the opening zapi display. ' ' ' ' % ' adezp0ae - ac-2 inverter - user manual page - 49/64.

Page 50

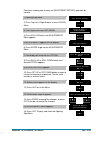

6.2 description of console “restore” function the restore param function allows transfer of the console’s stored data into the memory of the controller. This is achieved in a fast and easy way using the method previously used with the save param. Function. The data that is available via the restore ...

Page 51

12) you can see the items that are being stored in the inverter memory whilst the restore routine is happening. Storing acceler. Delay 13) when finished the console displays: main menu restore param. 14) press out to return to the opening zapi display. ' ' ' ' % ' adezp0ae - ac-2 inverter - user man...

Page 52

6.3 description of “alarms” menu the microprocessor in the controller remembers the last five alarms that have occurred. Items remembered relative to each alarm are: the code of the alarm, the number of times the particular alarm occurred, the hour meter count, and the controller temperature. This f...

Page 53

6.4 description of console “program vacc” function this function looks for and remembers the minimum and maximum potentiometer wiper voltage over the full mechanical range of the pedal. It enables compensation for non symmetry of the mechanical system between directions. The operation is performed b...

Page 54

15) when finished, the console shows: main menu program vacc 16) press out again to return to the opening zapi menu. ' ' ' ' % ' page - 54/64 adezp0ae - ac-2 inverter - user manual.

Page 55: Traction Configuration

7 ac-2 inverter diagnostic - traction configuration the alarms are signalled by a diagnostic led. 1 blink: logic failure ("watchdog", "eeprom ko", "logic failure #1", "logic failure #2", "logic failure #3", "check up needed"). 2 blinks: running request on start-up or error in seat sequence, double d...

Page 56

4) logic failure #2 fault in the hardware section of the logic board which manages the phase' s voltage feedback. Replace the logic board. 5) logic failure #3 fault in the hardware section of the logic board which manages the hardware current protection. Replace the logic board. 6) check up needed t...

Page 57

A) the charging resistance is opened; if it is opened. B) the charging circuit has a failure. C) there is a problem on the power modules. 12) vmn low, vmn high the test is carried out during initial diagnosis and in standby. Possible causes: a) problem with the motor connections or the motor power c...

Page 58

- contactor closed the controller checks if the lc contact is closed when the coil isn’t driven, trying to discharge the capacitor bank. If they don’t discharge, the fault condition is entered. It is suggested to check the contactor contact, if it is mechanically stuck or pasted. 19) aux output ko t...

Page 59: Configuration

8 ac-2 inverter diagnostic - pump configuration the alarms are signalled by a diagnostic led. 1 blink: logic failure ("watchdog", "eeprom ko", "logic failure #1", "logic failure #2", "logic failure #3"). 2 blinks: running request on start-up, error in seat sequence or encoder problem ("incorrect sta...

Page 60

4) logic failure #2 fault in the hardware section of the logic board which manages the phase' s voltage feedback. Replace the logic board. 5) logic failure #3 fault in the hardware section of the logic board which manages the hardware current protection. Replace the logic board. 6) incorrect start t...

Page 61

Possible causes: a) the potentiometer is not correctly calibrated; b) the potentiometer is defective. 12) stby i high test carried out in standby. Check if the current is 0. If not verified, an alarm is signalled which inhibits machine operations. Possible causes: a) current sensor failure; b) logic...

Page 62

18) motor temperature this warning is signalled if the motor temperature switch opens digital sensor or if the analog signal overtakes the cut-off level. If it happens when the motor is cold, check the wiring. If all is ok, replace the logic board. 19) thermic sensor ko the range of inverter tempera...

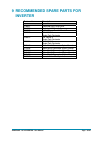

Page 63: Inverter

9 recommended spare parts for inverter part number description c16507 protected 500 a strip fuse. C16505 protected 355 a strip fuse. C16520 6.3 a 20 mm control circuit fuse c29523 sw 180 80 v single pole contactor c29522 sw 180 48 v single pole contactor c29508 sw 180 24 v single pole contactor c124...

Page 64

10 periodic maintenance to be repeated at times indicated check the wear and condition of the contactors’ moving and fixed contacts. Electrical contacts should be checked every 3 months. Check the foot pedal or tiller microswitch. Using a suitable test meter, confirm that there is no electrical resi...