Summary of Tiger performance T-310SSL

Page 2

Introduction – safety warnings serial number location using and filling the sba cylinder information 2nd stage pre-use check post-use care maintenance specifications service record notes pages 1 2 5-11 12 13 14 15 15 16 17 18 table of contents:.

Page 3: Danger

Copyright: this manual is copyrighted with all rights reserved. It may not be copied, translated or reproduced in any physical or electronic medium without the consent of zeagle systems, inc. This owner’s manual uses signal words recommended by the american national standards institute (see ansi z53...

Page 4: Congratulations

2 congratulations your new zeagle/tiger sba (survival breathing apparatus) has been designed and manufactured to the highest possible standards of performance and reliability. With the reasonable care outlined in this manual it will provide you with many years of diving enjoyment. Safety information...

Page 5: Caution

3 caution sba products are subject to conditions of extreme wear and corro- sion. Inspection and maintenance are required to ensure continued performance. Tiger performance recommends that you have your regulator inspected and serviced once a year on the anniversary date of its purchase. Sba service...

Page 6: Caution

4 caution 1. The high-pressure outlets (hp ports) are distinctly larger than the low-pressure outlets. Only devices with fittings, hoses and compo- nents designed for the full tank pressure that the regulator will be subjected to, such as pressure gauges, are to be installed in these ports. 2. Durin...

Page 7: Sba First Stage & Valve

5 sba first stage & valve the compact sba body, is a combination of on-off valve, quick- disconnect filling attachment, and a simple rugged flow-by piston first stage. The tiger performance sba screws directly into a 3000 psi cylinder and is much lighter and more compact than the separate valve and ...

Page 8

6 during storage, when the valve hand wheel (fig. 2) is turned off (clockwise), tank pressure is applied to the backside of the safety relief burst disc, but not the hp (high pressure) gauge port or the regulator section of the sba. When breathing air is needed or a reading of tank pressure using th...

Page 9: Warning

7 filling the tiger performance sba the cylinder attached to the sba can be filled using either the transfiller or the filling whip adapter shown in fig. 3 depending on the source of the air. The 330- 6052 transfiller is used to connect the valve of a standard yoke scuba cylinder to the fill probe t...

Page 10: Warning

8 filling the tiger performance sba using the 330-6052 transfiller as described on the previous page, the 330-6052 transfiller is used when the source of air is a standard scuba cylinder with a yoke style valve. This process only works when the scuba cylinder’s pressure is higher than the pressure i...

Page 11

9 attach the other end of the transfiller to the yoke valve in a full scuba cylinder (fig. 5). Fig. 5 since the valve hand wheel on the sba is fully open (fig. 6) the hp pressure gauge on the sba will now be showing the small cylinder’s pressure. Fig. 6.

Page 12: To Streaming Video)

10 check that all bleed collar on the filling system are closed (see fig. 7). Open the scuba cylinder valve. You will hear the humming sound of the check valve in the sba’s fill probe opening and the air moving from the high pressure source into the small cylinder. When the pressures are equalized, ...

Page 13: Filling Whip Adapter

11 if a scuba air compressor is available, then the filling whip adapter shown below would be the preferred method of filling the sba. The 330-fa52-aa filling whip adapter (fig 8), is attached to the sba in the same manner described earlier for the transfiller. Turn the sba’s valve handwheel fully c...

Page 14: Never

The tiger performance sba comes standard with a 9.25” (23.5 cm) long cylinder that when filled to its 3000 psi (207 bar) rated pressure holds a volume of air which if allowed to exit the cylinder will expand to a volume of 2.0 cubic feet (56.6 liters). This volume of air will give the user about 20 ...

Page 15

13 320-rg6l second stage features the tiger performance sba compact second stage (fig. 10) is a light yet affective device for delivering good control and airflow to the user. It’s simplicity of design ensure rugged reliable performance. After the valve hand wheel on the 1st stage is turned on (fig....

Page 16: Caution

14 if you hear any leaks, turn the tank valve off. Do not use the sba until the source of the leak has been found and corrected by an authorized tiger performance sba service technician. Caution pre-use check 1. Before using the tiger performance sba, check to be sure that the black fill probe cap i...

Page 17: Maintenance

15 it is essential that your regulator is checked at least once every two years by an authorized tiger performance regulator technician. Unusually heavy use, or use in dirty or contaminated water may result in the need for more frequent service. A service record has been provided at the end of this ...

Page 18: B. Second Stage Regulator

2nd stage weight (2nd only, no hose) 35” (88.9 cm) standard hose weight 20” (50.8 cm) optional hose weight materials: cover case poppet seat o-rings diaphragm exhaust valve mouthpiece .26 lb. (.12 kg) no hose .39 lb. (.17 kg.) .36 lb. (.16 kg) flexible thermoplastic thermoplastic elastomer buna-n el...

Page 19

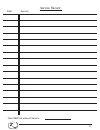

17 service record date: service: date sba first entered service:.

Page 20

18 notes: the date of purchase and contact information for the source should be written on this page. A copy of the issue receipt could also be stapled to this page for future records..

Page 21

Zeagle systems inc. U.S.A. The t-310ssl sba (survival breathing apparatus) is distributed exclusively by tiger performance products, inc. 525 bullis road west seneca, new york 14224 usa office: 1-716-674-8545 fax: 1-716-674-7497 p/n 175-1656 revision - nov. 2011 © 2011 zeagle systems, inc..