- DL manuals

- Zebra

- Software

- 110PAX4

- Maintenance Manual

Zebra 110PAX4 Maintenance Manual

Summary of 110PAX4

Page 1

Zebra ® 110pax4™ print engine maintenance manual.

Page 2

Customer order # 57515l-001 manufacturer part # 57515l-001 rev. 1 © 2005 zih corp. The copyrights in this manual and the label print engine described therein are owned by zebra technologies corporation. Unauthorized reproduction of this manual or the software in the label print engine may result in ...

Page 3

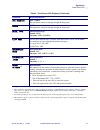

57515l-001 rev. 1 2/2/05 110pax4 maintenance manual iii contents about this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ix who should use this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4

Iv 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 contents standard print engine font matrices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 applicator pin interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 5

Contents 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual v changing password-protected parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 default password value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 disab...

Page 6

Vi 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 contents corrective maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119 print quality adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121 pre...

Page 7

Contents 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual vii 5 • maintenance and assembly drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267 general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269 a • data ...

Page 8

Viii 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 contents notes • ___________________________________________________________________ __________________________________________________________________________ __________________________________________________________________________ ________...

Page 9

57515l-001 rev. 1 2/2/05 110pax4 maintenance manual ix about this document this section provides you with contact information, document structure and organization, and additional reference documents. Contents who should use this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 10: Who Should Use This Document

X 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 about this document who should use this document who should use this document this maintenance manual is intended for use by any person who needs to perform routine maintenance, upgrade, or troubleshoot problems with the print engine. How this do...

Page 11: Contacts

About this document contacts 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual xi contacts you can contact zebra technologies at any of the following: visit us at: http://www.Zebra.Com our mailing addresses: zebra technologies corporation 333 corporate woods parkway vernon hills, illinois 60061.31...

Page 12: Document Conventions

Xii 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 about this document document conventions document conventions the following conventions are used throughout this document to convey certain information: alternate color (online only) cross-references contain hot links to other sections in this ...

Page 13: Related Documents

About this document related documents 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual xiii illustration callouts callouts are used when an illustration contains information that needs to be labeled and described. A table that contains the labels and descriptions follows the graphic. Figure 1 pro...

Page 14

Xiv 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 about this document related documents notes • ___________________________________________________________________ __________________________________________________________________________ _______________________________________________________...

Page 15

57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 1 1 system description this chapter provides an overview of the print engine and its components. Specifications of the print engine and a brief explanation of each main component and its function are included. Contents general . . . . . . . . . . ....

Page 16

Contents (continued) 2 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 system description ac power supply assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 drive system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 17: General

System description general 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 3 general this technical service guide contains information about service and maintenance of zebra’s 110pax4 print engine. The 110pax4thermal transfer print engine consists of the 203 dot/inch and the 300 dot/inch models....

Page 18: Print Engine Exterior View

4 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 system description print engine exterior view print engine exterior view print engines are available in a right-hand configuration (media moves from left to right, figure 1 ) and a left-hand configuration (media moves from right to left, figure 2...

Page 19: Front Panel

System description front panel 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 5 front panel all controls and indicators for the print engine are located on the front of the print engine on the front panel ( figure 3 ). The liquid crystal display (lcd) shows operating status and feature paramete...

Page 20

6 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 system description front panel front panel indicator lights (leds) the front panel lights are described in table 2 . Cancel cancel functions only in pause mode. Pressing cancel has these effects: • cancels the label format that is currently print...

Page 21

System description front panel 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 7 media (yellow) normal operation. Media properly loaded. Out of media. (print engine is paused, lcd displays error message, and pause light is on). — ribbon (yellow) normal operation. Ribbon properly loaded. Ribbon i...

Page 22: Power On/off Switch

8 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 system description power on/off switch power on/off switch the power on/off switch is located on the top of the print engine housing, as shown in figure 4 . When this switch is placed in the on ( i ) position, the power light turns on, and the pr...

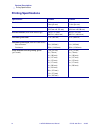

Page 23: General Specifications

System description general specifications 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 9 general specifications physical for installation information, refer to the user guide. Environmental conditions agency approvals . Height 11.8 in. (300 mm) width 9.6 in. (245 mm) depth 18.831 in. (478.31 ...

Page 24

10 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 system description general specifications electrical specifications communications specifications memory power supply universal power supply with power-factor correcting 90–264 vac, 47–63 hz power consumption idle printing 19 w 375 w (maximum) f...

Page 25

System description general specifications 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 11 zebra programming language (zpl ii) bar codes • communicates in printable ascii characters • controlled via mainframe, mini, or pc • downloadable graphics, scalable and bitmap fonts, label templates and ...

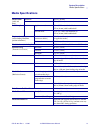

Page 26: Printing Specifications

12 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 system description printing specifications printing specifications specification 112pax4 113pax4 resolution 203 dots per inch (8 dots per mm) 300 dots per inch (12 dots per mm) dot size 0.0049 in. X 0.0049 in. (0.125 mm x 0.125 mm) 0.0033 in. X ...

Page 27: Media Specifications

System description media specifications 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 13 media specifications media width (label and liner) minimum 0.625 in (16 mm) maximum 4.5 in. (114 mm) label length minimum applicator mode 0.5 in. (12.7 mm) with backfeed on 0.25 in. (6 mm) with backfeed of...

Page 28: Ribbon Specifications

14 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 system description ribbon specifications ribbon specifications standard print engine font matrices bit mapped fonts a, b, d, e, f, g, h, and gs are expandable up to 10 times, height and width independent. However, fonts e and h (ocr-b and ocr-a)...

Page 29

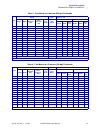

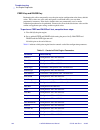

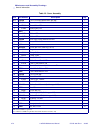

System description standard print engine font matrices 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 15 table 3 • font matrix for 8 dot/mm (203 dpi) printheads font matrix type* character size height width baseline dots inter- character gap cell width font matrix inches millimeters height widt...

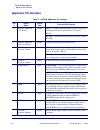

Page 30: Applicator Pin Interface

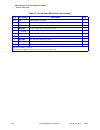

16 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 system description applicator pin interface applicator pin interface table 5 • 110pax4 applicator pin interface pin # signal name signal type functional description 1* signal ground (+5v return) ground jp1 in — ground return for internal +5 powe...

Page 31

System description applicator pin interface 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 17 8 power ground (+28 vdc return) ground interface power ground 9 ribbon low output • if the ribbon low feature is enabled and the amount of ribbon remaining on the supply spool is below a specific thres...

Page 32: Print Engine Options

18 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 system description print engine options print engine options • internal and external zebranet 10/100 print server • advanced counter • 8 mb, 32 mb pcmcia flash card • additional fonts available on pcmcia flash cards • 32 mb, 64 mb, 128 mb, 256 m...

Page 33

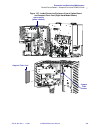

System description main print engine assembly locations 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 19 main print engine assembly locations platen roller see figure 5 . The platen roller provides the frictional force to drive media under the printhead. It also provides the compliant surface ...

Page 34

20 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 system description main print engine assembly locations peel roller assembly see figure 6 . The 110pax4 series peel roller assembly is located farther away from previous assemblies, allowing the label sensors to be located closer to the print li...

Page 35

System description main print engine assembly locations 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 21 ribbon tension control assembly see figure 7 . The ribbon tension control assembly’s main function is to provide appropriate output to the dc motors on the ribbon’s supply and take-up spind...

Page 36

22 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 system description main print engine assembly locations dc power supply assembly see figure 8 . The dc power supply provides power for the printhead, the +5v system power, and the stepper motor drive circuit. Figure 8 • dc power supply assembly ...

Page 37

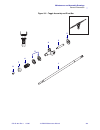

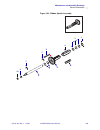

System description main print engine assembly locations 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 23 drive system see figure 10 . The 110pax4 drive system uses a series of pitch timing belts and pulleys. The staged belt drive systems consist of one stage from stepper motor to a compound pu...

Page 38

24 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 system description main print engine assembly locations media sensor see figure 11 . The media sensor uses an led array in a fixed location under the media with a moveable photo transistor above the media in line with the led array. The black ma...

Page 39

System description main print engine assembly locations 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 25 peel bar see figure 12 . The peel bar creates a sharp edge over which the media liner is tensioned to separate and present the label to the applicator’s label transport mechanism. Figure 12...

Page 40

26 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 system description main print engine assembly locations notes • ___________________________________________________________________ __________________________________________________________________________ ______________________________________...

Page 41

57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 27 2 operations this chapter provides the tasks that you must complete and the issues that you must consider before you load and configure your print engine. If you have completed the tasks and resolved issues in the checklist in before you begin o...

Page 42

Contents (continued) 28 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations exit setup mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 changing password-protected parameters. . . . . . . . . . . . . . . . . . . . . . . . ....

Page 43: Installation

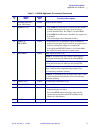

Operations installation 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 29 installation before you begin review this checklist, and resolve any issues before you begin setting up your print engine. unpack and inspect the print engine have you unpacked the print engine and inspected it for dama...

Page 44

30 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations unpack and inspect the print engine unpack and inspect the print engine when you unpack the print engine, save all packing materials and boxes. Inspect the print engine for possible damage incurred during shipment. • inspect the print...

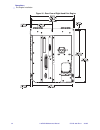

Page 45: Print Engine Installation

Operations print engine installation 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 31 print engine installation this section provides basic information for mounting the print engine into an applicator. The illustrations in this section show the print engine from different angles and include me...

Page 46

32 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations print engine installation figure 14 • front view of right-hand print engine.

Page 47

Operations print engine installation 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 33 figure 15 • right side view of right-hand print engine.

Page 48

34 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations print engine installation figure 16 • rear view of right-hand print engine.

Page 49

Operations print engine installation 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 35 figure 17 • top view of right-hand print engine.

Page 50

36 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations print engine installation install the print engine in an applicator this section provides the basic instructions for installing the print engine into an applicator. To install the print engine into an applicator, complete these steps:...

Page 51

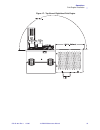

Operations connect the print engine to a power source 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 37 connect the print engine to a power source the power supply in the print engine automatically detects the applied line voltage and works in the 90 to 264 vac, 47 to 63 hz range. Refer to figu...

Page 52

38 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations connect the print engine to a power source power cord specifications depending on how your print engine was ordered, a power cord may or may not be included. If one is not included or if the one included is not suitable for your requi...

Page 53

Operations select a communication interface 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 39 select a communication interface the way that you connect your print engine to a data source depends on the communication options installed in the print engine. See data ports on page 313 for control s...

Page 54

40 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations select a communication interface optional print servers • zebranet wireless print server. For more information on this option, see the zebranet wireless print server user guide (part number 13422l-001). • zebranet 10/100 print server ...

Page 55

Operations select a communication interface 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 41 data cable requirements data cables must be fully shielded and fitted with metal or metallized connector shells. Shielded cables and connectors are required to prevent radiation and reception of electr...

Page 56: Media and Ribbon

42 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations media and ribbon media and ribbon types of media the print engine can use various types of media ( table 1 ). We strongly recommend the use of zebra-brand supplies for continuous high-quality printing. A wide range of paper, polypropy...

Page 57

Operations media and ribbon 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 43 continuous roll media the media is wound on a core and is without gaps, holes, notches, or black marks. This allows the image to be printed anywhere on the label. Fanfold media the media is folded in a zigzag pattern....

Page 58

44 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations media and ribbon load media figure 25 identifies the media-handling components of a right-hand print engine. A left-hand unit contains a mirror image of these components. Figure 26 on page 45 shows the print engine with media loaded. ...

Page 59

Operations media and ribbon 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 45 figure 26 • loaded media to load media, complete these steps: 1. Load media on the media supply reel of the applicator (refer to the applicator’s user guide). 2. Open the media door. 3. See figure 27 . Press the relea...

Page 60

46 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations media and ribbon figure 28 • sliding the outer media guide 5. See figure 29 . Open the printhead assembly by unlatching the printhead latch from the locking pin. Figure 29 • opening the printhead assembly 6. See figure 30 . Thread the...

Page 61

Operations media and ribbon 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 47 figure 30 • threading the media 8. See figure 31 . Position the media so that it is aligned with and just touching the inner media guide. 9. See figure 31 . Position the outer media guide so that it just touches the o...

Page 62

48 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations media and ribbon 10. See figure 27 on page 45 . Press down on the pinch roller assembly until it locks closed. 11. See figure 29 on page 46 . Close the printhead assembly by rotating the printhead latch until it latches onto the locki...

Page 63

Operations media and ribbon 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 49 14. See figure 34 . Rotate the peel roller assembly up until it locks into the closed position. Figure 34 • closed peel roller assembly 15. See figure 33 . Thread the media liner past the lower guide post and around t...

Page 64

50 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations media and ribbon ribbon ribbon is a thin film that is coated on one side with wax or wax resin, which is transferred to the media during the thermal transfer process. The media determines whether you need to use ribbon and how wide th...

Page 65

Operations media and ribbon 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 51 adhesive test if you have labels available, perform the adhesive test to determine which side of a ribbon is coated. This method works well for ribbon that is already installed. To perform an adhesive test, complete t...

Page 66

52 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations media and ribbon load ribbon use ribbon with thermal transfer media. The ribbon must be coated on the outside and wider than the media. If the ribbon is narrower than the media, areas of the printhead are unprotected and subject to pr...

Page 67

Operations media and ribbon 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 53 figure 37 • loaded ribbon to load ribbon, complete these steps: 1. See figure 38 . Place a full ribbon roll onto the ribbon supply spindle so the ribbon rotates as shown, and then push the roll toward the print engine...

Page 68

54 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations media and ribbon figure 39 • opening a dancer assembly 4. See figure 40 . Thread the ribbon between the ribbon sensor and the ribbon sensor reflector. Figure 40 • ribbon sensor 5. See figure 41 . Open the printhead assembly by unlatch...

Page 69

Operations media and ribbon 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 55 figure 41 • opening the printhead assembly 6. See figure 42 . Thread the ribbon under the printhead assembly and then up toward the auxiliary roller. Figure 42 • threading ribbon under the printhead assembly 7. See fi...

Page 70

56 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations media and ribbon figure 43 • threading ribbon around rollers 8. See figure 39 on page 54 . On the upper dancer assembly, squeeze the opening tabs to pivot open the dancer arm. 9. See figure 39 on page 54 . Carefully thread the ribbon ...

Page 71

Operations media and ribbon 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 57 remove used ribbon to remove used ribbon, complete these steps: 1. Open the media door. 2. Examine the ribbon. Did the ribbon run out? If... Then... Yes a. Remove the empty core from the ribbon supply spindle. Save th...

Page 72: Parameters Overview

58 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations parameters overview parameters overview after you have installed the media and ribbon and the power-on self test (post) is complete, the front panel displays printer ready . You may now set print engine parameters for your application...

Page 73

Operations parameters overview 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 59 exit setup mode to leave setup mode, complete these steps: 1. Press setup/exit . The lcd displays save changes . 2. Press the left or right oval to display the save options ( table 2 ). 3. Press next to select the ...

Page 74

60 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations changing password-protected parameters changing password-protected parameters certain parameters, including the communication parameters, are password-protected by factory default. The first time that you attempt to change a password-...

Page 75: Front Panel Lcd

Operations front panel lcd 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 61 front panel lcd use the lcd display on the front panel to adjust print engine settings. Table 3 shows parameters in the order in which they are displayed when you press next after entering setup mode. Throughout this p...

Page 76

62 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations front panel lcd adjust backfeed speed if backfeed is on, adjusts the speed at which the label backs up before printing (given in inches per second). • press the right oval to increase the value. • press the left oval to decrease the v...

Page 77

Operations front panel lcd 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 63 set the sensor type this parameter tells the print engine whether you are using media with a web (gap/space between labels, notch, or hole) to indicate the separations between labels or if you are using media with a bl...

Page 78

64 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations front panel lcd set maximum label length this parameter is used during the media portion of the calibration process. Always set maximum label length to a value that is at least 1.0 in. (25.4 mm) greater than the actual label length ( ...

Page 79

Operations front panel lcd 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 65 set early warning for media when this parameter is enabled, the print engine provides warnings when labels are running low. Note • update the number of labels per roll when beginning use of the early warning system. Al...

Page 80

66 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations front panel lcd list fonts • press the right oval to print a label that lists the available fonts in the print engine, including standard print engine fonts plus any optional fonts. Fonts may be stored in ram, flash memory, optional p...

Page 81

Operations front panel lcd 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 67 initialize memory card caution • perform this operation only when it is necessary to erase all previously stored information from the optional pcmcia card or compactflash card. 1. Press the right oval to select yes . (...

Page 82

68 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations front panel lcd print sensor profile the media sensor profile may be used to troubleshoot registration problems that may be caused when the media sensor detects preprinted areas on the media or experiences difficulty in determining we...

Page 83

Operations front panel lcd 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 69 calibrate media and ribbon sensor sensitivity use this procedure to adjust sensitivity of media and ribbon sensors. Important • this procedure must be followed exactly as presented. All of the steps must be performed e...

Page 84

70 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations front panel lcd set serial communications select the communications port that matches the one being used by the host computer. Important • do not change this parameter from the default. The print engine supports only rs-232. This para...

Page 85

Operations front panel lcd 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 71 set protocol protocol is a type of error checking system. Depending on the selection, an indicator may be sent from the print engine to the host computer signifying that data has been received. Select the protocol that...

Page 86

72 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations front panel lcd set communications mode the communication diagnostics mode is a troubleshooting tool for checking the interconnection between the print engine and the host computer. When diagnostics is selected, all data sent from the...

Page 87

Operations front panel lcd 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 73 set format prefix character the format prefix is a two-digit hex value used as a parameter place marker in zpl/zpl ii format instructions. The “h” that is displayed indicates hexadecimal and is not part of the value. T...

Page 88

74 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations front panel lcd select media power-up option this parameter sets the action of the labels when the print engine is turned on. • press the right or left oval to display the choices. Default: calibration selections: feed, calibration, l...

Page 89

Operations front panel lcd 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 75 adjust label top position the label top position adjusts the print position vertically on the label. Positive numbers adjust the label top position further down the label (away from the printhead); negative numbers adj...

Page 90

76 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations front panel lcd set the applicator port determines the action of the applicator port. Note • set this value as suggested by the applicator manufacturer. • off: the applicator port is off. • mode 1: asserts the ~end_print signal low wh...

Page 91

Operations front panel lcd 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 77 select resynch mode this parameter determines how the print engine reacts if the label synchronization is lost and the label top is not where expected. • feed mode—if the label top is not where expected, the print engi...

Page 92

78 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations front panel lcd these parameters are automatically set during the calibration procedure and should be changed only by a qualified service technician. Refer to the zpl ii programming guide for information on these parameters. • press n...

Page 93

Operations front panel lcd 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 79 zebranet ® print server lcd displays the menu options shown in table 4 display only if you have the zebranet 10/100 printserver or the wireless print server installed. Select idle display this parameter selects the lcd...

Page 94

80 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations front panel lcd table 4 • print server lcd displays parameter action/explanation load lan from? 1 this parameter, which serves the same function as the ^np zpl command, specifies whether to use the printer’s or the print server’s ip s...

Page 95

Operations front panel lcd 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 81 mac address 1,3 mac address this parameter cannot be changed through the front panel. Essid 1,3 essid this parameter cannot be changed through the front panel. Auth. Type 1,3 authentication type default: open selection...

Page 96: Calibrate The Print Engine

82 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations calibrate the print engine calibrate the print engine calibrate the print engine when it is first put into service. Calibration allows the print engine to establish the proper settings for the specific media and ribbon used in your ap...

Page 97

Operations calibrate the print engine 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 83 calibrating sensor sensitivity the “media and ribbon sensor calibration” procedure includes the following functions: • prompts the user to load just the liner in the media sensor path and remove the ribbon f...

Page 98

84 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations calibrate the print engine • media sensor—the “paper out” value equals a certain percentage of 5 volts. This is hard-coded at 75% (5 volts × 75% = 3.75 volts). The ribbon sensor value is calculated and indicated on the print configura...

Page 99: Toggle Positioning

Operations toggle positioning 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 85 toggle positioning proper toggle positioning is important for proper print quality. The toggle should be positioned approximately midway across the width of the media. To adjust the toggle, complete these steps: 1. ...

Page 100

86 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations printhead pressure adjustment printhead pressure adjustment before adjusting the printhead pressure, check that the toggle is positioned correctly. See toggle positioning on page 85 . You may need to adjust the printhead pressure in t...

Page 101: Power Fuse Replacement

Operations power fuse replacement 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 87 power fuse replacement the print engine uses a metric-style fuse (5 × 20 mm iec) rated for 5 amps at 250 volts that bears the certification mark of a known international safety organization (see figure 21 on pag...

Page 102

88 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 operations power fuse replacement notes • ___________________________________________________________________ __________________________________________________________________________ ____________________________________________________________...

Page 103

57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 89 3 troubleshooting this section contains tables showing symptom, diagnosis, and action columns. These tables help the technician to diagnose print engine faults and determine the repair needed. This chapter provides you with information about lcd...

Page 104: Troubleshooting Checklists

90 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 troubleshooting troubleshooting checklists if you encounter any problems that cannot be corrected with the aid of this manual, contact zebra’s technical support immediately to minimize or avoid print engine downtime. Technical support can also a...

Page 105: Lcd Error Messages

Troubleshooting lcd error messages 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 91 lcd error messages the lcd displays messages when there is an error. See table 6 for lcd errors, the possible causes, and the recommended solutions. Table 6 • lcd error messages lcd display/ print engine condit...

Page 106

92 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 troubleshooting lcd error messages print engine stops and error light flashes. Caution • the printhead may be hot enough to cause severe burns. Allow the printhead to cool. Caution • observe proper electrostatic safety precautions when handling ...

Page 107: Memory Errors

Troubleshooting memory errors 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 93 memory errors the memory errors in table 7 indicate that the print engine does not have enough memory to perform the function shown on the second line of the lcd. Table 7 • memory errors problem/lcd display possible...

Page 108: Print Quality Problems

94 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 troubleshooting print quality problems print quality problems table 8 identifies problems with print quality, the possible causes, and the recommended solutions. Table 8 • print quality problems problem possible cause recommended solution genera...

Page 109

Troubleshooting print quality problems 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 95 wrinkled ribbon ribbon fed through the machine incorrectly. See load ribbon on page 52 . Incorrect burn temperature. Set the darkness to the lowest possible setting for good print quality. See adjust print ...

Page 110

96 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 troubleshooting print quality problems misregistration and misprint of one to three labels media sensor is not positioned correctly. Place media sensor in proper position. The platen roller is dirty. Clean the platen roller according to the inst...

Page 111: Communications Problems

Troubleshooting communications problems 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 97 communications problems table 9 identifies problems with communications, the possible causes, and the recommended solutions. Table 9 • communications problems problem possible cause recommended solution a ...

Page 112

98 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 troubleshooting miscellaneous print engine problems miscellaneous print engine problems table 10 identifies miscellaneous problems with the print engine, the possible causes, and the recommended solutions. Table 10 • miscellaneous print engine p...

Page 113

Troubleshooting miscellaneous print engine problems 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 99 the ribbon light is on even though ribbon is loaded correctly. The print engine was not calibrated for the label being used. Perform the calibration procedure in calibrating media and ribbon se...

Page 114: Print Engine Diagnostics

100 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 troubleshooting print engine diagnostics print engine diagnostics self tests and other diagnostics provide specific information about the condition of the print engine. The most commonly used are the power-on and the cancel self tests. Power-on...

Page 115

Troubleshooting print engine diagnostics 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 101 cancel self test the cancel self test prints a configuration label, which tells you the settings for the print engine stored in configuration (eeprom) memory ( figure 51 ). The settings may be changed ei...

Page 116

102 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 troubleshooting print engine diagnostics pause self test this self test can be used to provide the test labels required when making adjustments to the print engine’s mechanical assemblies. Figure 52 shows a sample printout. To perform a pause s...

Page 117

Troubleshooting print engine diagnostics 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 103 feed self test the labels printed during this print quality test depend on the dot density of the printhead. • 300 dpi print engines: 7 labels are printed at the 2 ips and 8 ips print speeds. • 203 dpi p...

Page 118

104 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 troubleshooting print engine diagnostics feed key and pause key performing this self test temporarily resets the print engine configuration to the factory default values. These values are active only until power is turned off unless you save th...

Page 119

Troubleshooting print engine diagnostics 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 105 format prefix configuration, zpl, and webview delimiter character configuration, zpl, and webview zpl mode configuration, zpl, and webview media power up configuration, zpl, and webview head close config...

Page 120

106 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 troubleshooting print engine diagnostics communications diagnostics test do not perform the following test until all configuration and calibration parameters have been set. For configuration information, see front panel lcd on page 61 . This te...

Page 121

57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 107 4 preventive and corrective maintenance this section provides various levels of print engine maintenance required for optimum performance. This section also provides information on cleaning and general maintenance, replacement of major assembli...

Page 122

Contents (continued) 108 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance applicator interface board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245 ac power supply board . . . . . . . . . . . . . . . . . . . . . ...

Page 123

57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 109 safety information this section identifies general and specific safety information for the 110pax4 print engine. Contents equipment safety tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 124: Equipment Safety Tips

110 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance safety information—equipment safety tips equipment safety tips • the ac power plug and iec 320 connectors on all zebra printers must bear the certification mark of at least one of the international safety o...

Page 125

Preventive and corrective maintenance safety information—equipment safety tips 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 111 • ribbons used in the printers must be as wide as or wider than the media. If the ribbon is narrower than the media, areas of the printhead will be unprotected and s...

Page 126: Personal Safety Tips

112 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance safety information—personal safety tips personal safety tips caution • risk of explosion if battery is replaced by an incorrect type, or in the wrong polarity. Important • beware of “pinch points” on the pr...

Page 127

57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 113 preventive maintenance an operator or technician may perform preventive maintenance, which consists of: • visual inspection • regular cleaning of the printhead, platen roller, peel roller, and pinch roller • general cleaning of the print engine...

Page 128: Lubrication

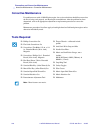

114 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance preventive maintenance—tools required for preventive maintenance tools required for preventive maintenance recommended preventive maintenance schedule lubrication 47362* zebra preventative maintenance kit...

Page 129: Cleaning The Exterior

Preventive and corrective maintenance preventive maintenance—cleaning the exterior 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 115 cleaning the exterior • clean the exterior surfaces of the 110pax4 print engine with a lint-free cloth. • do not use solvents or harsh cleaning agents. • if the ...

Page 130

116 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance preventive maintenance—cleaning the printhead and rollers figure 55 • printhead and platen roller cleaning cleaning the rollers to clean the rollers, complete these steps: 1. Check the platen roller for stu...

Page 131

Preventive and corrective maintenance preventive maintenance—cleaning the peel bar and media path 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 117 cleaning the peel bar and media path in case of a label jam, the peel bar and peel roller can be accessed for cleaning. To clean the peel bar and ...

Page 132

118 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance preventive maintenance—cleaning the peel bar and media path figure 57 • side view of ribbon sensor locations (right-hand model shown) 5. Reload ribbon and media. 6. Close and latch the printhead locking lev...

Page 133

57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 119 corrective maintenance this section outlines adjustments and alignments for the 110pax4 print engine. Contents print quality adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121 printhea...

Page 134: Corrective Maintenance

120 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance corrective maintenance—corrective maintenance corrective maintenance if a problem occurs with a 110pax4 print engine, the service technician should first ensure that the unit is being used properly, and the...

Page 135: Print Quality Adjustments

Preventive and corrective maintenance corrective maintenance—print quality adjustments 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 121 print quality adjustments there are five interrelated adjustments for obtaining optimum print quality and increased printhead life: • printhead parallelism •...

Page 136

122 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance corrective maintenance—print quality adjustments 4. Print a pause key self test by holding down pause while turning the print engine power on (l). The preliminary speed for the pause test label is 2 inches ...

Page 137

Preventive and corrective maintenance corrective maintenance—print quality adjustments 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 123 3. Adjust the parallel location of the uppermost test label print lines by turning very slightly one of the two horizontally positioned parallelism adjustmen...

Page 138

124 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance corrective maintenance—print quality adjustments printhead balance adjustment the balance hub position is adjustable to produce an even pressure across the full width of the printhead and platen roller. 1. ...

Page 139

Preventive and corrective maintenance corrective maintenance—print quality adjustments 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 125 6. Balance the printhead pressure by turning the hub adjusting screw with an allen wrench. 7. When even print quality is achieved, tighten the hub locking sc...

Page 140

126 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance corrective maintenance—print quality adjustments 3. With full width media installed, move the toggle to the center of the printhead. 4. Set the darkness configuration parameter value to achieve the optimum ...

Page 141

Preventive and corrective maintenance corrective maintenance—print quality adjustments 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 127 printhead pressure adjustment using lower printhead pressure and darkness settings can extend printhead life. If printing is too light on one side, a thick m...

Page 142

128 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance corrective maintenance—print quality adjustments strip plate adjustment the strip plate position is a very important part of the total printhead adjustment procedure. The strip plate is factory adjusted for...

Page 143: Print Darkness Adjustment

Preventive and corrective maintenance corrective maintenance—print darkness adjustment 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 129 print darkness adjustment due to differences in types of media and ribbon and wear on thermal printhead elements, it may be necessary to adjust the darkness ...

Page 144: Adjusting The Sensors

130 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance corrective maintenance—adjusting the sensors adjusting the sensors this section describes how to adjust the media sensors. Transmissive media sensor position the transmissive media sensor senses either the ...

Page 145

Preventive and corrective maintenance corrective maintenance—adjusting the sensors 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 131 ribbon sensor position figure 66 shows the location of the ribbon sensor in the bottom inside of print mechanism housing. Because the ribbon sensor is mounted in...

Page 146: Adjusting The Media Tracking

132 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance corrective maintenance—adjusting the media tracking adjusting the media tracking this section includes instructions for adjusting the upper pinch roller, the elastomer pinch roller, and the media tracking c...

Page 147

Preventive and corrective maintenance corrective maintenance—adjusting the media tracking 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 133 5. Was the force required approximately equal? 6. If the inner media strip required more force to remove, the adjustment cam must be rotated clockwise. If...

Page 148

134 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance corrective maintenance—adjusting the media tracking adjusting the elastomer pinch roller to adjust the elastomer pinch roller, complete these steps: 1. Run a pause test, and observe how the labels print in ...

Page 149

Preventive and corrective maintenance corrective maintenance—adjusting the media tracking 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 135 figure 69 • pressure adjustment (left-hand model shown) upper pinch roller assembly adjustment cam (shaded) cam screw upper pinch roller mounting screw up...

Page 150

136 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance corrective maintenance—adjusting the media tracking media tracking cam adjustment there is a cam that can be used to correct media tracking. Perform this adjustment only as a last resort and only after chec...

Page 151: Maintaining Spindles

Preventive and corrective maintenance corrective maintenance—maintaining spindles 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 137 5. Tighten the phillips screw to secure the cam in position. Maintaining spindles ribbon spindles in the pax print engine are maintenance free. Note • zebra does ...

Page 152

138 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance corrective maintenance—routine referral procedures (rrps) routine referral procedures (rrps) routine referral procedures are commonly used steps that are performed often during corrective maintenance. These...

Page 153

Preventive and corrective maintenance corrective maintenance—routine referral procedures (rrps) 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 139 open the rear enclosure 7. See figure 73 . Remove the seven electronics enclosure cover mounting screws. Lift up on the electronics enclosure cover ...

Page 154

140 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance corrective maintenance—routine referral procedures (rrps) 9. See figure 74 . From inside the front of the print engine, remove the two recessed rear enclosure mounting screws with star washers. Figure 74 • ...

Page 155

Preventive and corrective maintenance corrective maintenance—routine referral procedures (rrps) 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 141 rrp no. 2: close and reinstall print engine in applicator close the rear enclosure 1. Carefully swing the electronics enclosure closed. 2. Ensure th...

Page 156

142 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance corrective maintenance—routine referral procedures (rrps) notes • ___________________________________________________________________ ________________________________________________________________________...

Page 157

57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 143 print system this section provides replacement, conversion, and installation procedures for the 110pax4 print system, including the following: • printhead • toggle assembly contents printhead replacement . . . . . . . . . . . . . . . . . . . . ...

Page 158: Printhead Replacement

144 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance print system—printhead replacement printhead replacement tools required installation instructions remove the old printhead assembly 1. Turn off ( o ) the printer and disconnect the ac power cord. 2. Open th...

Page 159

Preventive and corrective maintenance print system—printhead replacement 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 145 figure 75 • view of the printhead from inside the front cover 6. See figure 76 . While holding the printhead, remove the power connector, and then the printhead data conne...

Page 160

146 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance print system—printhead replacement figure 76 • front view of printhead connections 2. See figure 77 . Fit the new printhead into the mounting bracket by aligning the printhead alignment posts into the print...

Page 161

Preventive and corrective maintenance print system—printhead replacement 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 147 3. Verify the printhead is seated properly, and then carefully guide the printhead mounting screw into the printhead’s aluminum body. After the screw is aligned properly, ...

Page 162: Printhead Conversion

148 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance print system—printhead conversion printhead conversion tools required installation instructions printhead replacement 1. See figure 78 . Hold the printhead from underneath and loosen the printhead mounting ...

Page 163

Preventive and corrective maintenance print system—printhead conversion 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 149 2. See figure 79 . While holding the printhead, remove the power connector first, and then the printhead data connector. 3. Remove the old printhead. Figure 79 • printhead ...

Page 164

150 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance print system—printhead conversion figure 80 • printhead alignment (right-hand model shown) 4. Verify the printhead is seated properly, and then carefully guide the printhead mounting screw into the printhea...

Page 165

Preventive and corrective maintenance print system—printhead conversion 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 151 figure 81 • rear view of print engine 2. Remove the stepper motor belt tensioner pulley. 3. Walk the stepper motor belt off of the compound pulley. 4. Turn the print engine...

Page 166

152 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance print system—printhead conversion figure 82 • stepper motor pulley adjustment 11. See figure 83 . Place the new belt around the stepper motor pulley. 12. Ensure the stepper motor standoff is positioned prop...

Page 167

Preventive and corrective maintenance print system—printhead conversion 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 153 figure 83 • removal and installation of stepper motor and belt l 14. See figure 81 on page 151 . Walk the other end of the belt onto the compound pulley. Replace the steppe...

Page 168: Toggle Assembly

154 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance print system—toggle assembly toggle assembly tools required installation instructions removing the toggle assembly 1. To remove the print engine from the applicator and open the electronics enclosure, compl...

Page 169

Preventive and corrective maintenance print system—toggle assembly 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 155 3. Remove the two screws that secure the head-open sensor mounting bracket to the mainframe. Flip both brackets straight down to avoid damage to the head open flag. 4. See figur...

Page 170

156 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance print system—toggle assembly 10. See figure 86 . Remove the four mounting screws that secure the end plate. 11. Remove the c-clip in the plastic bushing. 12. Insert a flat blade screwdriver behind the end p...

Page 171

Preventive and corrective maintenance print system—toggle assembly 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 157 installing the new toggle assembly 1. See figure 86 . Slide the new toggle assembly onto the new toggle shaft. 2. On the toggle shaft, install the two c-clips that retain the to...

Page 172

158 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance print system—toggle assembly notes • ___________________________________________________________________ __________________________________________________________________________ __________________________...

Page 173

57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 159 drive system this section provides replacement and installation procedures for the 110pax4 print system, including the following: • belts • pulleys • stepper motor • ribbon motor and gears contents belts . . . . . . . . . . . . . . . . . . . . ...

Page 174: Belts

160 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—belts belts tools required installation instructions remove the print engine from the applicator 1. To remove the print engine from the applicator and open the electronics enclosure, complete r...

Page 175

Preventive and corrective maintenance drive system—belts 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 161 figure 87 • drive belts on right-hand and left-hand models remove the old belts auxiliary roller drive belt right-hand print engine left-hand print engine platen roller drive belt auxilia...

Page 176

162 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—belts 1. Loosen one of the slack side idler pulley mounting screws, and then remove the second screw. Figure 88 • locate the idler pulleys (right-hand model shown) if you have... Then... A righ...

Page 177

Preventive and corrective maintenance drive system—belts 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 163 figure 89 • locate the idler pulleys (left-hand model shown) 2. Loosen the two screws securing the stepper motor belt tensioner pulley located alongside of the stepper motor. 3. Raise the...

Page 178

164 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—belts figure 90 • locate the platen pulley and the cable support bracket (right-hand model shown) figure 91 • locate the platen pulley and the cable support bracket (left-hand model shown) 10. ...

Page 179

Preventive and corrective maintenance drive system—belts 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 165 11. See figure 92 or figure 93 . Remove the wire track bracket mounting screw. 12. Remove the two mounting screws securing the head open sensor bracket. 13. Swing the two brackets up and ...

Page 180

166 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—belts 14. See figure 94 or figure 95 . Remove the c-clip and platen bearing on the platen shaft from the front of the print engine. Figure 94 • remove platen roller c-clip and bearing (right-ha...

Page 181

Preventive and corrective maintenance drive system—belts 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 167 figure 96 • remove the platen pulley 16. Slide the platen roller out of the platen pulley. 17. Remove the auxiliary roller drive belt. Install the new replacement belts 1. See figure 97 ....

Page 182

168 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—belts figure 97 • platen pulley belt separator 2. See figure 96 . Slide the platen pulley onto the platen roller. 3. Align the flats of the platen roller with the set screws of the platen pulle...

Page 183

Preventive and corrective maintenance drive system—belts 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 169 figure 98 • view of belt path 6. See figure 99 . Reinstall the cable support bracket. Insert the tab in the hole above the mounting hole in the main frame, align the mounting holes, and t...

Page 184

170 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—belts figure 99 • locate the locator hole and tab 7. See figure 92 on page 165 or figure 93 on page 165 . Reinstall the head open and wire track brackets. 8. Install the pinch/peel belt; the be...

Page 185: Compound Pulley

Preventive and corrective maintenance drive system—compound pulley 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 171 compound pulley tools required 1. To remove the print engine from the applicator and open the electronics enclosure, complete rrp no. 1 on page 138 . Installation instructions r...

Page 186

172 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—compound pulley figure 100 • rear view of print engine (right-hand model shown) figure 101 • rear view of print engine (left-hand model shown) compound pulley & mounting screws stepper motor be...

Page 187

Preventive and corrective maintenance drive system—compound pulley 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 173 4. Raise the tensioner pulley as high as it will go, and then snug one of the screws. 5. Loosen the compound pulley mounting screws to relieve the belt tension. 6. Use a flat-bl...

Page 188

174 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—compound pulley figure 103 • platen roller pulley and the cable support bracket (left-hand model shown) 11. Walk the platen roller drive belt off of the platen pulley and remove it from the com...

Page 189

Preventive and corrective maintenance drive system—compound pulley 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 175 figure 105 • head open sensor and wire track brackets (left-hand model shown) 13. Remove the two mounting screws securing the head open sensor bracket. 14. Swing the two bracket...

Page 190

176 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—compound pulley figure 106 • view of belt paths 4. See figure 107 . Reinstall the cable support bracket. Insert the tab in the hole above the mounting hole in the main frame, align the mounting...

Page 191

Preventive and corrective maintenance drive system—compound pulley 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 177 figure 107 • locator hole and tab 5. Reinstall the compound pulley assembly. 6. See figure 104 on page 174 or figure 105 on page 175 . Reinstall the head open and wire track bra...

Page 192: Stepper Motor Pulley

178 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—stepper motor pulley stepper motor pulley tools required installation instructions 1. To remove the print engine from the applicator and open the electronics enclosure, complete rrp no. 1 on pa...

Page 193

Preventive and corrective maintenance drive system—stepper motor pulley 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 179 figure 108 • rear view of print engine (right-hand model shown) figure 109 • rear view of print engine (left-hand model shown) compound pulley & mounting screws stepper mot...

Page 194

180 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—stepper motor pulley 4. Raise the tensioner pulley as high as it will go, and then snug one of the screws. 5. See figure 110 . Turn the print engine until it rests with the media door face down...

Page 195

Preventive and corrective maintenance drive system—stepper motor pulley 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 181 install the new stepper motor pulley and belt 1. See figure 111 . Place the new stepper motor pulley on the shaft. Make sure there is a 3/16 in. (4.76 mm) gap between the p...

Page 196: Stepper Motor

182 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—stepper motor stepper motor tools required installation instructions 1. To remove the print engine from the applicator and open the electronics enclosure, complete rrp no. 1 on page 138 . Remov...

Page 197

Preventive and corrective maintenance drive system—stepper motor 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 183 figure 112 • rear view of print engine (right-hand model shown) figure 113 • rear view of print engine (left-hand model shown) compound pulley & mounting screws stepper motor belt...

Page 198

184 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—stepper motor 4. Raise the tensioner pulley as high as it will go, and then snug one of the screws. 5. Turn the print engine until it rests with the media door face down. 6. See figure 114 . Re...

Page 199

Preventive and corrective maintenance drive system—stepper motor 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 185 figure 115 • stepper motor pulley adjustment 2. See figure 115 . While holding the stepper motor belt around the stepper motor pulley, place the new stepper motor onto the standof...

Page 200: Ribbon Take-Up Motor

186 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—ribbon take-up motor ribbon take-up motor tools required installation instructions 1. To remove the print engine from the applicator and open the electronics enclosure, complete rrp no. 1 on pa...

Page 201

Preventive and corrective maintenance drive system—ribbon take-up motor 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 187 figure 116 • dc motor power wires 3. See figure 117 . Remove the three take-up dc motor bracket mounting screws. Ribbon take-up motor ribbon take-up motor right-hand print ...

Page 202

188 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—ribbon take-up motor figure 117 • remove the mounting screws 4. Remove the ribbon take-up dc motor bracket assembly from the print engine. 5. Cut the cable tie. 6. See figure 118 on page 189 . ...

Page 203

Preventive and corrective maintenance drive system—ribbon take-up motor 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 189 figure 118 • locate the dc motor control board dc motor control board corrugated tubing cable clamp cable clamp left-hand print engine right-hand print engine dc motor cont...

Page 204

190 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—ribbon take-up motor 8. See figure 119 . Loosen the two screws in the mounting slots of the rear enclosure. 9. Remove the two other mounting screws from the rear enclosure. This provides access...

Page 205

Preventive and corrective maintenance drive system—ribbon take-up motor 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 191 10. Slide the motor control board to the side, align the two screws with the enlarged holes of the mounting slots, and then pull the board out of the enclosure. 11. See fig...

Page 206

192 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—ribbon take-up motor install the new dc ribbon take-up motor 1. See figure 117 on page 188 . Install the new dc motor bracket assembly onto the mainframe, aligning the three mounting holes with...

Page 207: Ribbon Supply Motor

Preventive and corrective maintenance drive system—ribbon supply motor 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 193 ribbon supply motor tools required installation instructions 1. To remove the print engine from the applicator and open the electronics enclosure, complete rrp no. 1 on page...

Page 208

194 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—ribbon supply motor figure 121 • ribbon supply dc motor and power wires 3. Follow the ribbon supply encoder wires to the first cable clamp. Take note of the routing of the wires. 4. Remove the ...

Page 209

Preventive and corrective maintenance drive system—ribbon supply motor 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 195 figure 122 • remove the mounting screws 6. Remove the ribbon supply dc motor bracket from the print engine. 7. See figure 123 on page 196 . Cut the cable tie. 8. Follow the ...

Page 210

196 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—ribbon supply motor figure 123 • locate the dc motor control board dc motor control board corrugated tubing cable clamp cable clamp left-hand print engine right-hand print engine dc motor contr...

Page 211

Preventive and corrective maintenance drive system—ribbon supply motor 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 197 10. See figure 124 . Loosen the two screws in the mounting slots of the rear enclosure. 11. Remove the two other mounting screws from the rear enclosure. This provides acces...

Page 212

198 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—ribbon supply motor 12. Slide the motor control board to the side, align the two screws with the enlarged holes of the mounting slots, and then pull the board out of the enclosure. 13. See figu...

Page 213

Preventive and corrective maintenance drive system—ribbon supply motor 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 199 9. See figure 121 on page 194 . Install the two power connectors to the rear of the ribbon supply dc motor. The black wire connects to the positive (+) terminal on the right...

Page 214

200 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance drive system—ribbon supply motor notes • ___________________________________________________________________ __________________________________________________________________________ ______________________...

Page 215

57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 201 roller system this section provides replacement and installation procedures for the 110pax4 print system, including the following: • pinch roller • peel roller • auxiliary roller contents pinch roller . . . . . . . . . . . . . . . . . . . . . ....

Page 216: Pinch Roller

202 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance roller system—pinch roller pinch roller tools required installation instructions 1. To remove the print engine from the applicator and open the electronics enclosure, complete rrp no. 1 on page 138 . Remove...

Page 217

Preventive and corrective maintenance roller system—pinch roller 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 203 4. Loosen one of the slack side idler pulley mounting screws, and then remove the second screw. 5. Loosen the two screws securing the stepper motor belt tensioner pulley located a...

Page 218

204 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance roller system—pinch roller figure 128 • rear view of print engine (left-hand print engine shown) 6. Raise the tensioner pulley as high as it will go, and then snug one of the screws. 7. Loosen the compound ...

Page 219

Preventive and corrective maintenance roller system—pinch roller 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 205 figure 129 • label guide shelf plate mounting screws 13. Loosen and remove the screw and washer that retain the peel roller bearing. 14. While holding the pulley at the rear of th...

Page 220

206 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance roller system—pinch roller 9. Reinstall the screw removed earlier from the slack side idler pulley and tighten both screws. Ensure the pinch/peel belt rides on the top of the slack side idler pulley. 10. Lo...

Page 221: Peel Roller

Preventive and corrective maintenance roller system—peel roller 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 207 peel roller tools required installation instructions 1. To remove the print engine from the applicator and open the electronics enclosure, complete rrp no. 1 on page 138 . Remove p...

Page 222

208 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance roller system—peel roller figure 130 • peel roller latch and roller assembly (right-hand model shown) 4. See figure 131 . Loosen, but do not remove, the belt tensioner pulley mounting screws, and then relie...

Page 223

Preventive and corrective maintenance roller system—peel roller 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 209 figure 131 • rear view of the peel roller pulley 6. See figure 132 . Loosen and remove the four screws that secure the label guide shelf plate. Remove the plate. Figure 132 • remov...

Page 224

210 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance roller system—peel roller install the new peel roller 1. See figure 133 . Slide the new peel roller with bearing into the inner main frame. Install the outer bearing and secure it to the peel roller assembl...

Page 225

Preventive and corrective maintenance roller system—peel roller 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 211 test and adjust the peel roller 1. Set up and run some labels through the print engine while watching to see if the labels run parallel to the main frame of the print engine. 2. De...

Page 226: Auxiliary Roller

212 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance roller system—auxiliary roller auxiliary roller tools required installation instructions 1. To remove the print engine from the applicator and open the electronics enclosure, complete rrp no. 1 on page 138 ...

Page 227

Preventive and corrective maintenance roller system—auxiliary roller 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 213 2. Remove the adjustment hub set screw (right-hand side set screw for left-hand print engine, left-hand side set screw for right-hand print engine). 3. Remove the c-clip from ...

Page 228

214 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance roller system—auxiliary roller 4. If the label printing is lighter or no printing is observed on one side of the label as compared with the other, continue to step 8 . If printing is even, printhead balance...

Page 229

57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 215 printed circuit boards this section provides replacement and installation procedures for the 110pax4 print system, including the following: • pcmcia card and compact flash card, wireless pcmcia board • print server • main logic board • applicat...

Page 230: Pcmcia Card

216 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance printed circuit boards—pcmcia card pcmcia card tools required installation instructions 1. Turn off ( o ) the printer or print engine and disconnect the ac power cord and data cables, if required. 2. See fi...

Page 231

Preventive and corrective maintenance printed circuit boards—pcmcia card 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 217 figure 137 • notch location 3. Insert the pcmcia card until it is fully seated into the interface. The card-eject button will pop out. 4. Reinstall the option card shield ...

Page 232: Wireless Pcmcia Board

218 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance printed circuit boards—wireless pcmcia board wireless pcmcia board tools required installation instructions 1. To remove the print engine from the applicator and open the electronics enclosure, complete rrp...

Page 233

Preventive and corrective maintenance printed circuit boards—wireless pcmcia board 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 219 figure 139 • removal and installation of pcb access panel from print engine 4. Which model print engine do you have? Pcb access panel pcb access panel screws (6)...

Page 234

220 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance printed circuit boards—wireless pcmcia board for the right-hand print engine 1. Disconnect the cables from j1 and j2 of the motor control board. Note the orientation of the wires: yellow is j1 and white is ...

Page 235

Preventive and corrective maintenance printed circuit boards—wireless pcmcia board 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 221 figure 141 • main logic board electrical connections table 13 • main logic board electrical connections connector description p2 door-open sensor p3 head-open se...

Page 236

222 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance printed circuit boards—wireless pcmcia board 4. See figure 141 . If you have a 10/100 printserver installed, you must remove the two screws securing the 10/100 ps board and unplug the ribbon cable attached ...

Page 237

Preventive and corrective maintenance printed circuit boards—wireless pcmcia board 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 223 for the left-hand print engine 1. See figure 141 . If you have a 10/100 printserver installed, remove the two screws securing the 10/100 ps board and unplug the ...

Page 238

224 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance printed circuit boards—wireless pcmcia board figure 144 • removing or installing main logic board 5. See figure 145 . Carefully remove the three hex screws and spacers that secure the mlb and the pcmcia boa...

Page 239

Preventive and corrective maintenance printed circuit boards—wireless pcmcia board 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 225 hex screws and spacers hex screws and spacers hex screws hex screw spacer nuts nut pcmcia board (back side) main logic board pcb access panel pcb access panel pc...

Page 240

226 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance printed circuit boards—wireless pcmcia board installation of the wireless pcmcia board assembly 1. See figure 146 . Align the connectors on the pcmcia board with the connectors on the mlb. Support both boar...

Page 241

Preventive and corrective maintenance printed circuit boards—wireless pcmcia board 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 227 11. See figure 141 on page 221 and figure 142 on page 222 . If you had an internal 10/100 print server installed, complete the following steps: a. Plug the ribbo...

Page 242: Tools Required

228 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance printed circuit boards—compact flash and pcmcia cards compact flash and pcmcia cards tools required installation instructions 1. To remove the print engine from the applicator and open the electronics enclo...

Page 243

Preventive and corrective maintenance printed circuit boards—compact flash and pcmcia cards 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 229 figure 147 • inside electronics enclosure view of option board and compact flash card (right-hand model shown) option board (shown shaded) compact flash...

Page 244

230 110pax4 maintenance manual 57515l-001 rev. 1 2/2/05 preventive and corrective maintenance printed circuit boards—compact flash and pcmcia cards figure 148 • inside electronics enclosure view of option board and compact flash card (left-hand model shown) 4. To reinstall the print engine into the ...

Page 245

Preventive and corrective maintenance printed circuit boards—compact flash and pcmcia cards 57515l-001 rev. 1 2/2/05 110pax4 maintenance manual 231 initialize flash memory 1. Press setup/exit to enter the configuration mode. 2. Press plus (+) until init flash mem. Is displayed. 3. Press select and e...

Page 246