- DL manuals

- Zebra

- Printer

- CPM 2030

- Technical Manual

Zebra CPM 2030 Technical Manual

Summary of CPM 2030

Page 1

Zebra® cpm 2030 ticket printer technical manual p1003646-001.

Page 2

P1003646-001 cmp 2030 technical manual 12/18/08 © 2008 zih corp. The copyrights in this manual and the software and/or firmware in the printer described therein are owned by zih corp. Unauthorized reproduction of this manual or the software and/or firmware in the printer may result in imprisonment o...

Page 3

P1003646-001 cpm 2030 technical manual 3 contents 1 introduction...................................................................................................................5 1.1 versions and configurations............................................................................5 1.2 printe...

Page 4

4 cpm 2030 technical manual p1003646-001 12 environmental conditions .........................................................................................36 13 mtbf............................................................................................................................37 14 ti...

Page 5: 1 Introduction

P1003646-001 cpm 2030 technical manual 5 1 introduction the cpm is a ticket printer with versatile ticket handling. It prints text, graphics and bar codes. Finally, it cuts the ticket. The printer can be ordered for 50, 54, 60 or 63 mm wide tickets. The ticket length is variable between 25 mm and 15...

Page 6

6 cpm 2030 technical manual p1003646-001 figure 2. Rear view, cpm 2030 desktop 1.2 printer design figure 3. Printer interior. The cpm prints with direct thermal printing, requiring no consumables other than the pa- per itself. It uses a highly advanced long life print head with built in history cont...

Page 7

P1003646-001 cpm 2030 technical manual 7 to avoid paper jam, the cpm has a straight paper path where tickets pass virtually with- out bending. The straight paper path also enables the use of ticket thickness of up to 0.4 mm. A total of four optical sensors supervise the paper transport through the p...

Page 8

8 cpm 2030 technical manual p1003646-001 1.3.2 power supply the printer mechanism requires +5 vdc 0.3 a, and +24 vdc 2 a continuous, 10 a peak. With a swecoin power supply unit (see ordering information on page 41, and dimensional draw- ing on page 34), just connect the cable from the power supply t...

Page 9: 2 Operation

P1003646-001 cpm 2030 technical manual 9 2 operation 2.1 operator controls green indicator fixed: blinking: flickering: temporarily off: power on & printer ready. Insert ticket. Receiving data. Commands are executed. Yellow indicator fixed: out of paper. Blinking: print command received, but out of ...

Page 10

10 cpm 2030 technical manual p1003646-001 2.3 paper loading the yellow indicator indicates paper out. Press the center button to eject remaining tickets if you want to replace paper stock be- fore paper is out. 2.3.1 paper stock positioning the ticket stock should be oriented with the thermal coatin...

Page 11: 3 Performance

P1003646-001 cpm 2030 technical manual 11 3 performance typical throughput 43 tickets/minute (1.4 s/ticket) when printing already downloaded information on 86 mm tickets, and cutting the tick- ets. Note! – data transfer time is not included in the above throughput. At 9600 bps, typi- cally add 0.3 s...

Page 12: 4 Print

12 cpm 2030 technical manual p1003646-001 4 print data 4.1 general printing method direct, parallel, thermal print ticket width 50, 54, 60 or 63 mm print width 384 pixels = 51.06 mm, centered on ticket width print margins top: 12 mm (can be reduced by reversing the motor, see command !H) bottom: 0 m...

Page 13

P1003646-001 cpm 2030 technical manual 13 4.4 text printing fonts three mono spaced and one proportionally spaced font. Cus- tom designed fonts can be ordered. Character size, w x h font 1 and 3 = 8 x 16 pixels. Font 2 = 16 x 30 pixels. Font 4, width = 4 to 8 pixels depending on character, height = ...

Page 14

14 cpm 2030 technical manual p1003646-001 basic character set the table below shows the basic characters stored in prom on the printer control board. The set contains characters from decimal position 32 (space) through 255. Table 1 character set used from firmware versions 220 note! – decimal 34 / h...

Page 15: 5 Ticket

P1003646-001 cpm 2030 technical manual 15 5 ticket separation 5.1 gapped tickets for specification of gapped tickets, see page 40. Cutter guillotine-type, dc-motor operated, with cam shaft, micro- switch controlled cutter position between print head and ticket exit cutter life expectancy 1 000 000 c...

Page 16: 6 Control

16 cpm 2030 technical manual p1003646-001 6 control board controller 8-bit microcontroller type 80c320 firmware memory 512 kbytes eprom page memory 128 kbytes nonvolatile (battery backed up) ram backup battery cr2025 (3v lithium). Expected life is 7 years. Interface serial: rs232c (v.24) data format...

Page 17: 7 Command

P1003646-001 cpm 2030 technical manual 17 7 command set the command set is designed in accordance with industry standards and is enhanced with functions unique to this product. The command language uses only printable ascii characters for easy adaptation to any host system. 7.1 syntax a command stri...

Page 18

18 cpm 2030 technical manual p1003646-001 7.2 summary of commands 7.2.1 system commands can general reset, equivalent to power off/on (takes 20 s to execute) enq status request immediate 19 !C clear all 19 !C a clear all and enable extended acknowledgement 1 19 !F a feed- acceleration and speed 1 22...

Page 19: 8 Command

P1003646-001 cpm 2030 technical manual 19 8 command reference 8.1 system related commands enq status request, immediate the cpm responds by sending one byte to the host computer, indicating the status of the various cpm sensors according to the following table. The enq command is effected immediatel...

Page 20

20 cpm 2030 technical manual p1003646-001 !H c 1 feed reverse !H c n1 feeds the paper in the reverse direction n1 = no. Of pixel lines to feed !P print this command triggers both the printing, cutting and ejecting of a ticket. The print command can also be used to initialize the cpm after power off ...

Page 21

P1003646-001 cpm 2030 technical manual 21 !Sd status request, dip-switch settings the cpm responds with one byte containing 1 bit for each switch. 1 = on, 0 = off. Bit 7 6 5 4 3 2 1 0 dip switch no: 8 7 6 5 4 3 2 1 !U firmware version query 1 the cpm responds by sending the following string: 00905_3...

Page 22

22 cpm 2030 technical manual p1003646-001 !Z burn time 1 the burn time controls the print den- sity. It is used to set the heating so that it is adequate for the thermal paper used as ticket material. Set it to the lowest burn time that gives acceptable print quality. Example: !Z 20 sets burn time 6...

Page 23

P1003646-001 cpm 2030 technical manual 23 top speed top speed is the frequency at which the acceleration stops. A value of 190 sets top speed to 1900 hz. Motor must be set to 2. 1 not used. Must be set to 1. 1 not used. Must be set to 1. 1 not used for graphics printing. Must be set to 1. Space one ...

Page 24

24 cpm 2030 technical manual p1003646-001 8.2.1 text printing !F t format text for printing !F t 1 the parameters are used as follows: !F indicates that this is the start of a print field definition t indicates text mode specifies the way in which the text is to be oriented. This can be either n(ort...

Page 25

P1003646-001 cpm 2030 technical manual 25 example of a command for fixed text: !F t n 150 150 1 1 1 1 "text" example of a command for variable text: !F t n 150 150 1 1 1 1 "%v" text attributes cpm does not handle word processor-like text attributes. In version 4.07 of the firmware, reversed text has...

Page 26

26 cpm 2030 technical manual p1003646-001 8.2.2 graphics printing !F g format graphics for printing cpm can print bit map graphics. Graphic images are stored in the fixed memory area and will therefore be repeated on every ticket until the next !C command is received. Remember, when creating graphic...

Page 27

P1003646-001 cpm 2030 technical manual 27 0 0 0 0 0 0 0 1 0 0 1 1 0 0 0 1 0 1 1 1 1 0 0 1 1 1 1 1 1 1 0 1 0 1 1 1 1 0 0 1 0 0 1 1 0 0 0 1 0 0 0 0 0 0 0 1 1 1 2 2 3 3 5 5 6 6 7 7 8 4 4 1. Create pixel graphics 2. Add empty vertical lines to get full bytes 3. Convert pixels to bits black pixel=1 white...

Page 28

28 cpm 2030 technical manual p1003646-001 8.2.3 printing bar codes !F c format bar code printing bar code printing can be used as a machine readable ticket data carrier note! – to produce sharp code bars, the cpm printer automatically reduces the print speed by approx. 50% when printing tickets with...

Page 29

P1003646-001 cpm 2030 technical manual 29 value 9 = code 128 1 value 11 = code 39 space a space (blank) has to be inserted between the type parameter and the data string. Bar code data this is a block of data to be converted by the cpm and printed in bar code form in accordance with the parameters i...

Page 30: 9 Error

30 cpm 2030 technical manual p1003646-001 9 error codes cpm reports error conditions in the form of error codes. If no error condition exists, the cpm sends an ”ack” (06h) to the host after each received print command !P. An error condition is reported as a nak (15h) followed by a one-character erro...

Page 31: 10 Power

P1003646-001 cpm 2030 technical manual 31 10 power requirements 10.1 cpm 2030 desktop supply voltage 115 vac or 230 vac, switch selectable supply current up to 4a at 115 vac, and 2a at 230 vac fuse 5x20 mm 3.15a / 250v slow blow. Replacement fuse inside power cable receptacle power consumption 50–19...

Page 32: Dimensions and Weight

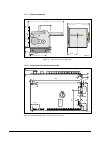

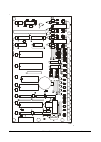

32 cpm 2030 technical manual p1003646-001 11 dimensions and weight 11.1 cpm 2030 oem printer figure 13 . Cpm 2030 oem dimensions.

Page 33

P1003646-001 cpm 2030 technical manual 33 11.1.1 printer mechanism sw97141 191 mm 114 m m 23 m m 11 mm 81 mm 12 m m 67 m m 124 mm 49 mm ∅4.2mm 124 m m figure 14 . Print mechanism from cpm 2030 11.1.2 control board for printer mechanism 230 4 6 6.5 5 15 31 10 0 37.5 5 11 .5 13 5 20 38 20 e- pr om 1, ...

Page 34

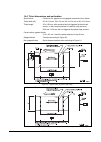

34 cpm 2030 technical manual p1003646-001 11.1.3 power supply for cpm 2030 oem printer mechanism 15 9 mm 23 5. 5 m m m3 (3x) 25 14.5 27 20 2. 5 54 110 mm ty pe la be l 500 sw97128 figure 16. Power supply 01035-002 dimensions. All measurements are in mm..

Page 35

P1003646-001 cpm 2030 technical manual 35 11.2 cpm 2030 desktop 35 m m 25,5 mm 25 2 mm 211 mm 41 mm 13 m m 10 7 mm 125 mm 118 mm 70 m m 10 7 m m 70 mm front view top view rear view ri g h t v ie w 145 mm 33 mm sw97138 40 mm 100 mm 7 mm figure 17. Dimension drawing for cpm 2030 desktop printer. All m...

Page 36: 12 Environmental

36 cpm 2030 technical manual p1003646-001 right view sw97142 90 mm 125 mm ~270 —350 mm ~3 50 mm 80 mm fanfold ticket stock 365 mm figure 18. Approximate space required around the cpm 2030 printer 11.3 weight cpm 2030 oem: 2.7 kg cpm 2030: 6.1 kg 12 environmental conditions temperature operation +5 °...

Page 37: 13 Mtbf

P1003646-001 cpm 2030 technical manual 37 13 mtbf complete unit approximately 1.4 years for the typical user profile given below. User profile: operational 12 month/year. Average 30 000 tick- ets /month. Average printing density 20 % black. Clean- ing of printer every 2 months. Mtbf for cpm componen...

Page 38: 14 Ticket

38 cpm 2030 technical manual p1003646-001 14 ticket stock 14.1 ticket base material material paper, 100 % chemical pulp, no ground wood permitted laminate (triplex) plastic (pvc) stiffness 18–36 g/cm (in grain direction) thickness paper and laminate: 0.18–0.40 mm, 170–210 g/m² plastic (pvc): 0.18–0....

Page 39

P1003646-001 cpm 2030 technical manual 39 14.3 tof detection (if used) general black marks or holes can be used to position the paper before cutting. There shall be one mark or hole for each ticket to be printed. The size and position is given below. Print side for black marks opposite side to therm...

Page 40

40 cpm 2030 technical manual p1003646-001 14.4 ticket dimensions and perforation stock format fanfold or roll, gapped or non-gapped consecutive form tickets. Ticket width (w) 50 +0/–0.4 mm, 54 ± 0.2 mm, 60 +0/–0.4 mm or 63 +0/–0.4 mm ticket length 25 to 156 mm, with synchronized cut triggered by bla...

Page 41: 15 Ordering

P1003646-001 cpm 2030 technical manual 41 15 ordering information the following printer versions where released when this manual was printed if you need another configuration, or any other modifications, contact swecoin, or a swecoin repre- sentative. Order- ing no. Version cpm 2030 desktop evaluati...

Page 42: 16 Fault

42 cpm 2030 technical manual p1003646-001 16 fault finding the cpm informs the host of some error symptoms with status reports and error codes. Error codes are only sent if dip-switch 6 is on. See dip-switches on page 16, and “er- ror codes” on page 30. The lamps in the lid indicate errors requiring...

Page 43

P1003646-001 cpm 2030 technical manual 43 symptom only one self-test ticket can be done. When you press the print button again, only blank tickets are produced. Action check the setting of dip-switch 4, "auto clear". If it is on, this is the correct behavior. If dip-switch 4 is off, test the printer...

Page 44: 17 Maintenance

44 cpm 2030 technical manual p1003646-001 17 maintenance 17.1 lubrication when serviced, it is a good rule to clean and lubricate the printer. All bearings for the platen and the cog wheels should be lubricated with oil, for example dexron iii automatic gearbox oil. The outer surface of the cam whee...

Page 45

P1003646-001 cpm 2030 technical manual 45 17.2.2 cutting module (a) dc motor (b) cam wheel (c) micro switch fixed blade moving blade the knife in the cutting module moves by means of a dc-motor (a) with a combined car- rier and cam wheel (b). The motor runs in one direction only during normal cuttin...

Page 46: 18 Drawings

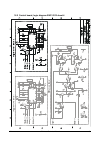

46 cpm 2030 technical manual p1003646-001 18 drawings control board interconnections page 46 control board, logic diagram swc-2210 sheets 1—4 47 18.1 control board interconnections j24 j12 j6 j7 j8 j9 j21 86 mm cut sensor 110 mm cut sensor paper-end sensor black mark sensor indicator and ticket feed...

Page 47

P1003646-001 cpm 2030 technical manual 47 18.2 control board, logic diagram swc-2210 (part no 02448-901) sheet 1.

Page 48

48 cpm 2030 technical manual p1003646-001.

Page 49

P1003646-001 cpm 2030 technical manual 49 18.3 control board, logic diagram swc-2210 sheet 2.

Page 50

50 cpm 2030 technical manual p1003646-001.

Page 51

P1003646-001 cpm 2030 technical manual 51 18.4 control board, logic diagram swc-2210 sheet 3.

Page 52

52 cpm 2030 technical manual p1003646-001.

Page 53

P1003646-001 cpm 2030 technical manual 53 18.5 control board, logic diagram swc-2210 sheet 4.

Page 54

54 cpm 2030 technical manual p1003646-001.

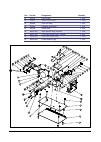

Page 55: 19 Replacement

P1003646-001 cpm 2030 technical manual 55 19 replacement parts figure 23. Replacement parts, cpm2030

Page 56

56 cpm 2030 technical manual p1003646-001 19.1 final assembly pos. Part no. Designation quantity 1 00358-000 cable clamp 1 pcs. 2 00375-000 cog wheel 1 pcs. 3 00515-000 hub 1 pcs. 4 00634-000 printer chassis 1 pcs. 5 00637-054 rod 2 pcs. 6 00705-000 distance washer 1 pcs. 7 00839-054 ticket guide pl...

Page 57

P1003646-001 cpm 2030 technical manual 57 pos. Part no. Designation quantity 41 102035 light shield 1 pcs. 42 102887 spacer db 5x10x1 1 pcs. 43 102888 free arm assy 1 pcs. 44 102890 pressure plate assy 1 pcs. 45 103109 guide plate 1 pcs. 46 10620-200 opto sensor assy 390 ohm 1 pcs. 47 10632-190 fork...

Page 58

58 cpm 2030 technical manual p1003646-001 19.2 cutter module 10803-060 = grease = oil pos part no. Designation quantity 1 00549-060 cutter support 1 pcs. 2 00550-060 print mech. Support 1 pcs. 3 00551-060 cutter blade, moving 1 pcs. 4 00555-000 hub 5mm 2 pcs. 5 00555-001 hub 6.5mm 2 pcs. 6 00556-000...

Page 59

P1003646-001 cpm 2030 technical manual 59 19.3 cutter motor assy. 10622-003 part no. Designation quantity 102056 dc motor rhv 158.12.30 1 pcs. 10622-002 cable assy, cutter motor 1 pcs. 09100-220 screw mrx-h m3x6 3 pcs. 00372-000 micro switch, gold plated xcg3-81 1 pcs. 00552-060 motor bracket 1 pcs....

Page 60: 20 Index

60 cpm 2030 technical manual p1003646-001 20 index a accessories .................. 41 ack/nak...................... 30 ambient light................... 7 b bar code ....................... 12 bar-code....................... 28 battery .......................... 16 bmp-files ...................... 2...

Page 62

Zebra technologies international, llc 333 corporate woods parkway vernon hills, illinois 60061.3109 u.S.A t: +1 847 793 2600 toll-free +1 800 423 0422 f: +1 847 913 8766 zebra technologies europe limited dukes meadow millboard road bourne end buckinghamshire, sl8 5xf, uk t: +44 (0)1628 556000 f: +44...