- DL manuals

- Zebra

- Printer

- DA402

- User Manual

Zebra DA402 User Manual

Summary of DA402

Page 1

User s guide ' t 402 stripe series thermal transfer printer ®.

Page 2

Rev. 3 customer order # 52007l manufacturer part # 52007lb user s guide ' t 402 stripe series thermal transfer printer ® awards for publication excellence.

Page 3

Proprietary statement this manual contains proprietary information of zebra technologies corporation. It is intended solely for the information and use of parties operating and maintaining the equipment described herein. Such proprietary information may not be used, reproduced, or disclosed to any o...

Page 4

I have determined that the zebra printers identified as the stripe series 402 and 402 ® da t manufactured by: zebra technologies corporation 333 corporate woods parkway vernon hills, illinois 60061-3109 u.S.A. Have been shown to comply with the applicable technical standards of the fcc for home, off...

Page 6

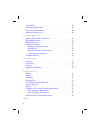

Contents introduction hello! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 what’s in the box . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 unpacking and inspection . . . . . . . . . . . . . . . . . . . . . . . . 2 reporting damage . . . . . . . . . . . . . . . . ....

Page 7

Using zpl ii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 adjusting the print width . . . . . . . . . . . . . . . . . . . . . . . 30 adjusting the print darkness . . . . . . . . . . . . . . . . . . . . . . 30 adjusting the print speed . . . . . . . . . . . . . . . . . . . . . . . 3...

Page 8

Introduction hello! Thank you for choosing the zebra t 402 printer. This rugged little printer is certain to become a productive and efficient addition to your workplace! N this user’s guide gives you all the information you will need to operate and maintain the printer. N to create and print label ...

Page 9

Unpacking and inspection in spect the printer for pos si ble ship ping dam age: n check all exterior surfaces for damage. N raise the top cover (refer to “loading the media” on page 5) and inspect the media compartment for damage. In case ship ping is re quired, save the car ton and all pack ing ma ...

Page 10

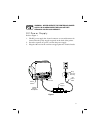

Warning: never operate the printer and power supply in an area where they can get wet. Personal injury could result! Dc power supply refer to figure 1. 1. The dc power supply has a barrel connector on one end that must be inserted into the power supply receptacle on the back of the printer. 2. Inser...

Page 11

Printer overview 4 printhead tear bar peel bar sensor housing release lever (2) feed button cutter option media guide adjuster printhead release lever platen roller media guides cutter unit status led media hanger media supply guides bottom slot ribbon core supply spindle take-up spindle figure 2.

Page 12

Getting ready to print loading the media you can op er ate this printer in three dif fer ent modes: tear-off, peel-off, or with a cutter. N tear-off mode allows you to tear off each label (or a strip of labels) after it is printed. N in peel-off mode, the backing material is peeled away from the lab...

Page 13

2. Insert one end of the media hanger into one of the media supply guides (refer to figure 4). 3. Place the roll of media onto the media hanger. 4. Place the second media supply guide onto the other end of the media hanger (refer to figure 4). Notes: the media roll must be centered on the media hang...

Page 14

7 labels tags figure 5 printhead release lever printhead 1 2 figure 6.

Page 15

9. Refer to figure 7. Thread the media through the media guides. Note: if the media guides must be changed to accommodate the width of the media, turn the green media guide adjuster (refer to figure 7). The media guides should just touch, but not restrict, the edges of the roll. 10. Continue to thre...

Page 16

9 mounting slot mounting slot figure 8 printhead arrow arrow figure 9.

Page 17

Peel-off mode 1. Unlatch the top cover by pressing the two green release levers (refer to figure 10). Then, lift the top cover to expose the media compartment. 2. Insert one end of the media hanger into one of the media supply guides (refer to figure 11 ). 3. Place the roll of media onto the media h...

Page 18

11 1 2 3 smooth side of media supply guide media hanger media supply guide textured side marked "out" figure 11 printhead release lever printhead 1 2 figure 12.

Page 19

8. Refer to figure 13. Thread the media through the media guides. Note: if the media guides must be changed to accommodate the width of the media, turn the green media guide adjuster (refer to figure 13). The media guides should just touch, but not restrict, the edges of the media roll. 9. Continue ...

Page 20

13 feed button bottom slot peel-off feed slot figure 15 mounting slot mounting slot figure 14.

Page 21

13. Gently pull the label backing to remove any slack in the media. 14. Close the printhead by pressing down at both arrows (refer to figure 16 ). 15. Close the top cover. Activate the label taken sensor by pushing in on the top of the sensor housing until it locks into position (refer to figure 17 ...

Page 22

15 printhead arrow arrow figure 16 sensor housing figure 17.

Page 23

Cutter mode (optional) 1. Unlatch the top cover by pressing the two green release levers (refer to figure 18). Then, lift the top cover to expose the media compartment. 2. Insert one end of the media hanger into one of the media supply guides (refer to figure 19 ). 3. Place the roll of media onto th...

Page 24

17 printhead release lever printhead 2 1 figure 20 1 2 3 smooth side of media supply guide media hanger media supply guide textured side marked "out" figure 19.

Page 25

8. Refer to figure 21. Thread the media through the media guides. Note: if the media guides must be changed to accommodate the width of the media, turn the green media guide adjuster (refer to figure 21). The media guides should just touch, but not restrict, the edges of the roll 9. Refer to figure ...

Page 26

19 mounting slot mounting slot figure 22 printhead arrow arrow figure 23.

Page 27

Fanfold media fanfold media loads from the outside of the printer. 1. Thread the media through the access slot in the back of the printer (refer to figure 24 ). 2. Open the top cover. 3. Release the printhead by pulling the printhead release lever toward you (refer to figure 24, “1” ). 4. Lift the p...

Page 28

21 access slot printhead release lever printhead 1 2 figure 24 media guide adjuster media guides peel bar arrow arrow figure 25.

Page 29

Loading the ribbon figure 26 shows the location of the ribbon supply spindle, ribbon take-up spindle, and ribbon supply slot. 1. Open the top cover. 2. Install an empty ribbon core (notched end to the right) as shown in figure 27 . This becomes the ribbon take-up spindle. 3. Remove the tape that sec...

Page 30

23 supply spindle ribbon core notch figure 27 printhead take-up spindle figure 28.

Page 31

10. Close the printhead by pressing down at both arrows. 11. Close the top cover and turn on the printer or press the feed button if the printer is already on (see “auto calibration” on page 25 for more information). Removing the ribbon 1. Open the printhead. 2. Cut the ribbon below the ribbon take-...

Page 32

Auto calibration note: if you are using pre-printed labels, pre-printed label backing, or continuous media, see “manual calibration” on page 34. An auto calibration is performed when the printer is turned on (if media is loaded) or after an error is cleared. When it is auto calibrating, the printer ...

Page 33

Operator controls refer to figure 30. Power switch n press to turn on and turn off the printer. Caution: the power should be turned off be fore con nect ing or dis con nect ing the com mu ni ca tions and power ca bles. Feed button n forces the printer to feed one blank label. N when printing, puts t...

Page 34

Printing a test label be fore you con nect the printer to your com puter, make sure that the printer is in proper work ing or der. You can do this by print ing a configuration la bel: 1. Make sure the media is properly loaded and the top cover of the printer is closed. Then, turn the printer power o...

Page 35

Parallel interface requirements the required cable (ieee 1284-compliant is recommended) must have a standard 36-pin parallel connector on one end, which is plugged into the parallel port located on the back of the printer (refer to figure 31). The other end of the parallel interface cable connects t...

Page 36

Communicating with the printer via the serial port serial communications between the printer and the host computer can be set by either autobaud synchronization or the ^sc command. Autobaud autobaud synchronization allows the printer to automatically match the communications parameters of the host c...

Page 37

Using zpl ii for information about creating labels using zpl ii, refer to the zpl ii programming guide or visit our web site at www.Zebra.Com . Adjusting the print width print width must be calibrated when: n you are using the printer for the first time. N there is a change in the width of the media...

Page 38

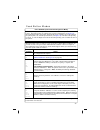

Troubleshooting what the status led is telling you resolutions: 1. The printer is not receiving power. N have you turned on the printer power? N check power connections from the wall outlet to the power supply, and from the power supply to the printer. 2. The printer is on. 3. The printer has failed...

Page 39

5. The media or ribbon is not loaded. N load a roll of media or ribbon, following the instructions in “loading the media” on page 5 or “loading the ribbon” on page 22. Then, press the feed button to resume printing. The printhead is open. N close the top cover. Then, press the feed button to resume ...

Page 40

There are long tracks of missing print (blank vertical lines) on several labels. N the printhead is dirty. Clean the printhead according to the instructions on page 39. N the printhead elements are damaged. Replace the printhead (see “replacing the printhead” on page 44). The printing does not start...

Page 41

Manual calibration a manual calibration should be performed whenever you are using pre-printed labels (or label backing) or if the printer will not correctly auto calibrate. 1. Turn on the printer power. 2. Remove approximately 6” (152 mm) of labels from a section of backing material. Load the media...

Page 42

Troubleshooting tests printing a configuration label to print out a list ing of the printer’s cur rent con figu ra tion (an exam ple is shown in fig ure 33), re fer to the one-flash sequence in “feed but ton modes” on page 37. Recalibration re cali brate the printer if it starts to dis play un usual...

Page 43

Resetting the factory default values some times, re set ting the printer to the fac tory de faults solves some of the prob lems. Fol low the four-flash sequence in struc tions in “feed but ton modes” on page 37. Communications diagnostics if there is a problem transferring data between the computer ...

Page 44

Feed button modes 37 power off mode (communications diagnostics mode) with the printer power off, press and hold the feed button while you turn on the power. The printer prints out a listing of its current configuration (see figure 33 ). After printing the label, the printer automatically enters a d...

Page 45

38.

Page 46

Maintenance cleaning caution: use only the clean ing agents in di cated. Ze bra tech nolo gies cor po ra tion will not be re spon si ble for dam age caused by any other clean ing ma te ri als used on this printer. If necessary, refer to figure 2 for part locations. Lubrication caution! No lu bri cat...

Page 47

40 7 5 8 6 1 2 3 4 figure 35.

Page 48

Parts list refer to figure 35 . 41 item number description part number 1 ribbon detector sensor kit (set of 3) 105903-026 2 printhead assembly (4”) 105950-020 printhead cable (set of 5) 105903-028 3 media gap sensor kit (4”) (set of 2) 105903-029 4 stepper motor 105903-132 5 blackline media sensor k...

Page 49

42 4 5 6 7 1 2 3 figure 36.

Page 50

Refer to figure 36 . 43 item number description part number 1 print mechanism assembly 105903-131 2 upper frame w/ribbon handler kit 105903-049 3 lower frame kit 105903-050 4 rubber foot kit (set of 100) 105903-019 5 option port cover (set of 20) 105903-051 6 media roll holder kit (set of 5) 105903-...

Page 51

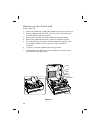

Replacing the printhead refer to figure 37. 1. Release the printhead by pulling the printhead release lever toward you. 2. Lift the printhead until you feel it “lock” into place. Be careful not to force the printhead past this position! 3. Remove the screw that secures the printhead to the upper fra...

Page 52

Specifications note: printer specifications are subject to change without notice. Printing specifications ribbon specifications 45 print density 203 dots/inch (8 dots/mm) print speed (per second) tear-off and cutter: 1.5” (38 mm), 2” (51 mm), and 2.5” (64 mm) peel-off: 1.5” (38 mm) and 2” (51 mm) pr...

Page 53

Label/tag specifications 46 label/tag width 1.12” to 4.65” (28 mm to 118 mm) label/tag length 0.38” to 22” (10 mm to 559 mm) with standard memory 0.5” (13 mm) to 22” (559 mm) in peel-off mode interlabel gap 0.08” to 0.16” (2 mm to 4 mm) recommended: 0.118” (3 mm) label/tag thickness .003” to .0075” ...

Page 54

Font/bar code specifications physical/environmental/electrical specifications 47 fonts available ü cg triumvirate bold condensed scaleable smooth (0) ü zebra fonts a-h, gs, p-v ü ibm code page 850 international symbols bar codes available (1d) ü codabar (supports ratios of 2:1 to 3:1) ü code 11 ü co...

Page 55

Agency approvals n ul 544 medical equipment standard part 42.5 n csa 22.2 no. 950-95 canadian safety standard n iec 950/en 60950 international safety standard n fcc class b n ul 1950 domestic safety standard, 3rd ed. N canadian doc class a n en50082-1:1997 international immunity standard n en55022 c...

Page 56

Serial (rs-232) connector technical information notes: the maximum current available through the serial and/or parallel port is not to exceed a total of 0.75 amps. When xon/xoff handshaking is selected, data flow is controlled by the ascii control codes dc1 (xon) and dc3 (xoff). The dtr control lead...

Page 57

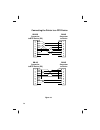

50 connecting the printer to a dte device db-25s connector to dte device (pc) db-9s connector to dte device (pc) db-9p connector to printer db-9p connector to printer 2 3 4 5 6 7 8 20 22 1 2 3 4 5 6 7 8 9 txd txd rxd rxd rts rts cts cts dsr dsr gnd gnd dcd dcd dtr dtr 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7...

Page 58

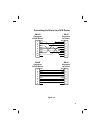

51 connecting the printer to a dce device db-25s connector to dce device db-9s connector to dce device db-9p connector to printer db-9p connector to printer 2 3 4 5 6 7 8 20 22 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 txd txd txd txd rxd rxd rxd rxd rts rts cts cts cts cts rts rts dsr d...

Page 59

Parallel interface technical information note: the maximum current available through the serial and/or parallel port is not to exceed a total of 0.75 amps. 52 pin no. Description 1 nstrobe/hostclk 2-9 data bits 1-8 10 nack/ptrclk 11 busy/ptrbusy 12 perror/ackdatareq 13 select/xflag 14 nautofd/hostbu...

Page 60

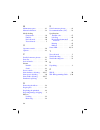

A ad just ments print dark ness . . . . . . . . 30 print speed . . . . . . . . . 30 print width . . . . . . . . . 30 agency ap prov als . . . . . . . . 48 auto cali bra tion . . . . . . . . . 25 auto baud . . . . . . . . . . . . 29 c cali bra tion auto . . . . . . . . . . . . . 25 man ual . . . . . ...

Page 61

M main te nance parts . . . . . . . . 41 man ual cali bra tion . . . . . . . 34 me dia load ing cut ter mode . . . . . . . . . 16 fan fold . . . . . . . . . . . 20 peel- off mode . . . . . . . . 10 tear- off mode . . . . . . . . 5 o op era tor con trols . . . . . . . . 26 op tions . . . . . . . . . ...

Page 62

Customer order #52007l manufacturer part #52007lb © zebra technologies corporation zebra house the valley centre, gordon road high wycombe buckinghamshire hp13 6eq, uk telephone +44 (0)1494 472872 facsimile +44 (0)1494 450103 zebra technologies europe limited zebra technologies corporation 333 corpo...