- DL manuals

- Zebra

- Printer

- Stripe S400

- Maintenance Manual

Zebra Stripe S400 Maintenance Manual

Summary of Stripe S400

Page 1

S 400 & s 600 maintenance manual.

Page 2: 400/

44895l rev. 1 1/99 i s 400/ s 600 stripe series printer maintenance manual revision 1 registration form =(%5$7(&+12/2*,(6&25325$7,21 to receive maintenance manual revisions and updates, complete this form and fax or mail it to zebra technologies at the fax number or address shown below. Company addr...

Page 3

44895l rev. 1 1/99 ii 127(6.

Page 4

44895l rev. 1 1/99 iii 7$%/(2)&217(176 table of contents................................................................................................................. Iii table of figures ................................................................................................................

Page 5

44895l rev. 1 1/99 iv serial communication signal levels .......................................................................................1-13 centronics® parallel data port ................................................................................................1-13 parallel port inter...

Page 6

44895l rev. 1 1/99 v d ata c able i nstallation ......................................................................................................2-16 p ower o n s elf -t est ................................................................................................................2-17 addi...

Page 7

44895l rev. 1 1/99 vi troubleshooting chart (jammed or stuck labels) ....................................................................3-8 troubleshooting chart (settings or parameter related) ............................................................3-9 troubleshooting chart (cutter related)......

Page 8

44895l rev. 1 1/99 vii label available sensor adjustment.........................................................................................4-27 strip plate adjustment .............................................................................................................4-28 backing rewin...

Page 9

44895l rev. 1 1/99 viii o ptions (f ield i nstallable )..................................................................................................4-65 memory upgrade kit installation instructions ........................................................................4-65 section v - maintena...

Page 10

44895l rev. 1 1/99 ix figure 2-4 roll media loading .........................................................................................................2-9 figure 2-5 fanfold media loading ...................................................................................................2-9 fig...

Page 11

44895l rev. 1 1/99 x figure 4-8 side view of cutter module reassembly .....................................................................4-15 figure 4-9 reassembled cutter module ..........................................................................................4-15 figure 4-10 cutter modul...

Page 12

44895l rev. 1 1/99 xi figure 4-33 print mechanism assembly mounting screw location ..............................................4-44 figure 4-34 printhead assembly removal/installation ..................................................................4-45 figure 4-35 dual-tension ribbon supply disa...

Page 13

44895l rev. 1 1/99 xii table 1-2 media specifications .........................................................................................................1-5 table 1-3 memory specifications .....................................................................................................1-6 ...

Page 14

=(%5$660$,17(1$1&(0$18$/6(&7,21, 44895l rev. 1 1/99 1-1 '(6&5,37,212)(48,30(17 d escription .................................................................................................................................1-2 p rinter o perating m odes ...................................................

Page 15

6(&7,21,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 1-2 ' (6&5,37,21 the zebra stripe s400 and s600 thermal printers are versatile label and ticket printers designed to print high quality bar codes, various sizes and styles of alphanumeric characters, and graphics in either the thermal transfer or d...

Page 16

=(%5$660$,17(1$1&(0$18$/6(&7,21, 44895l rev. 1 1/99 1-3 6 3(&,),&$7,216 $jhqf\$ssurydov • ul 1950 3 rd edition • cispr22-b • csa22.2 no950-95 • en50082-1:1997 • en60950 • meets fcc class b and can.Doc class a rules %du&rghv the following barcodes are available • check digit calculation where applica...

Page 17

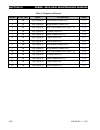

6(&7,21,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 1-4 )rqwv standard printer fonts table 1-1 standard printer fonts 203 dots/inch (8 dots/mm) printhead fonts dot matrix (h x w) (defaults) type* minimum character size (h x w) maximum character/inches a 9 x 5 u-l-d 0.044” x 0.030” 33.3 b 11 x 7 u 0....

Page 18

=(%5$660$,17(1$1&(0$18$/6(&7,21, 44895l rev. 1 1/99 1-5 0hgld&rqvlghudwlrqv table 1-2 media specifications s400 s600 minimum media width 0.75” (19 mm) maximum media width 4.5” (114 mm) maximum media width (cutter installed) 4.0” (102 mm) minimum media length (tear-off) 0.63” (16 mm) minimum media le...

Page 19

6(&7,21,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 1-6 0hpru\ table 1-3 memory specifications s400 s600 flash rom (firmware) 1 mb 1 mb standard dram 1 mb 2 mb available standard flash memory 0 1 mb memory upgrades (options) 4 mb & 8 mb flash modules 4 mb & 8 mb flash modules 0lfursurfhvvru • 32 bit...

Page 20

=(%5$660$,17(1$1&(0$18$/6(&7,21, 44895l rev. 1 1/99 1-7 3ulqwlqj&rqvlghudwlrqv table 1-5 printing specifications s400 s600 resolution 203 dots per inch (8 dots per mm) dot size 0.005” (0.127 mm) minimum print width 0.75” (19 mm) maximum print width 4.09” (104 mm) minimum print length .005” (0.125 mm...

Page 21

6(&7,21,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 1-8 5leerq&rqvlghudwlrqv table 1-7 ribbon specifications s400 & s600 minimum 1.57” (40 mm) ribbon width maximum 4.5” (114 mm) 2:1 media to ribbon roll ratio 984’ (300 m) standard length 3:1 media to ribbon roll ratio 1400’ (427 m) inner diameter 1....

Page 22

=(%5$660$,17(1$1&(0$18$/6(&7,21, 44895l rev. 1 1/99 1-9 &rppxqlfdwlrq,qwhuidfhv • serial port ä rs-232 ä db-9 ä baud rate (110, 300, 600, 1200, 2400, 4800, 9600, 14400, 19200, 28800, 38400, 57600) ä parity (disabled, even, odd) ä stop bits (7 or 8 data bits) ä handshake (xon/xoff or dtr/dsr) ä error...

Page 23

6(&7,21,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 1-10 & 20081,&$7,21 6 3(&,),&$7,216 6huldo'dwd&rppxqlfdwlrq,qwhuidfh2yhuylhz the s400 and s600 printers have a single data terminal equipment (dte) port that supports rs- 232 serial data communications. The rs-232 interface has a 9-pin db-9s connec...

Page 24

=(%5$660$,17(1$1&(0$18$/6(&7,21, 44895l rev. 1 1/99 1-11 56,qwhufrqqhfwlrq the printer is configured as data terminal equipment (dte). Figure 1-2 illustrates the connections required to interconnect the printer with the 9 pin or 25 pin serial port connector on a pc. Figure 1-2 rs-232 connections 25-...

Page 25

6(&7,21,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 1-12 table 1-8 db9p pinout pin description 1 not used. 2 rxd (rs-232 receive data): this is the serial data input to the printer from the host. 3 txd (rs-232 transmit data): this lead is the serial data output from the printer. It is on this lead t...

Page 26

=(%5$660$,17(1$1&(0$18$/6(&7,21, 44895l rev. 1 1/99 1-13 6huldo&rppxqlfdwlrq6ljqdo/hyhov rs-232 transmit and receive data rs-232 data signals are defined as either mark or space while control signals are either on (active-positive voltage) or off (inactive-negative voltage). Although the permitted v...

Page 27

6(&7,21,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 1-14 table 1-9 centronics parallel cable pinout 36-pin connector description 1 strobe – the high to low transition of this input signal will latch the data at the eight data inputs into the printer. 2 – 9 data bits 0 through 7 – parallel data input...

Page 28

=(%5$660$,17(1$1&(0$18$/6(&7,21, 44895l rev. 1 1/99 1-15 ( /(&7521,&6 6 % /2&. ' ,$*5$0 figure 1-4 electronic block diagram main logic board control panel head open sensor media/ ribbon sensor ribbon take-up motor printhead assembly ( 600) s cutter (option) full roll switch (peel option) label avail...

Page 29

6(&7,21,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 1-16 this page left blank intentionally.

Page 30

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-1 23(5$7,21629(59,(: this section contains information and adjustments for an individual to become acquainted with, adjust, test and operate the printer. This information is also found in the user’s guide o perator c ontrols .......................

Page 31

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-2 printer self-test/reset default quick reference chart ..........................................................2-18 cancel key self-test.............................................................................................................

Page 32

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-3 2 3(5$725 & 21752/6 refer to figure 2-1 32:(56wdwxv,qglfdwrujuhhq controlled by the power on/off switch located on the left side of the near the ac power (see figure 2-2). On indicates that primary power is applied to the printer. Off indicate...

Page 33

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-4 '$7$6wdwxv,qglfdwrujuhhq on indicates that the data processing or printing is taking place, but no data is being received. Off indicates that no data is being received or processed. Single flash indicates that the cancel key was pressed and a ...

Page 34

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-5 3$86(.H\ allows the operator to interrupt the printing of a batch of labels. • if the printer is currently printing and the pause key is pressed, printing will stop after the label being printed is completed. • if the printer is not currently ...

Page 35

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-6 figure 2-1 front panel figure 2-2 power on/off switch location ac power cable or communication interface serial cable parallel cable ac power on/off switch.

Page 36

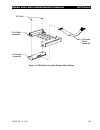

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-7 $ &&(66,1*7+( 3 5,17(5 to access the printer for the loading and unloading of media and ribbon, and for operator adjustments, do the following: 1. Lift on the main door and swing it up and to the left until it rests on top of the right side co...

Page 37

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-8 / 2$',1* 7 +( 0 (',$ note: a media calibration must be performed when media and ribbon (if used) are first installed in the printer, or when a different type of media or ribbon is installed. Note: media widths and thickness vary between applic...

Page 38

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-9 figure 2-4 roll media loading figure 2-5 fanfold media loading head open lever ribbon release button ribbon supply media supply media supply hanger media supply guide media guide closed open media sensor assembly head open lever ribbon release...

Page 39

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-10 figure 2-6 cutter mode media loading figure 2-7 peel-off mode media loading head open lever end of media on top of platen roller cutter module platen roller media guide media sensor assembly media supply hanger media supply guide media supply...

Page 40

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-11 3hho2ii0rgh0hgld/rdglqj 1. Move the head open lever counterclockwise to the open position and raise the printhead. 2. Slide the media guide and the media supply guide as far out from the printer frame as possible. 3. Remove the hold down hook...

Page 41

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-12 5hprylqjwkh/deho%dfnlqj0dwhuldo when the amount of backing material wound on the backing rewind spindle reaches full capacity, the backing rewind spindle full sensor activates, the paper/ribbon led flashes, and the printing pauses. Use the fo...

Page 42

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-13 figure 2-8 media sensor adjustment media sensor adjustment lever media guide.

Page 43

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-14 5 ,%%21 / 2$',1* note: do not load ribbon if the printer is to be used in the direct thermal mode. Caution: do not use ribbon that is narrower than the media. Premature printhead failure may result due to excessive abrasion caused by thermal ...

Page 44

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-15 /rdglqjwkh5leerq note: for direct thermal print method, ribbon is not used and should not be loaded in the printer when performing the media calibration. Note: use ribbon that is wider than the media. The smooth backing of the ribbon protects...

Page 45

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-16 ' $7$ & $%/( , 167$//$7,21 1. Turn the printer off by the power switch. 2. Determine whether you are using a parallel data cable or serial data cable. 3. Follow your computer manufacturer’s instructions for installing data cables to the compu...

Page 46

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-17 3 2:(5 2 1 6 (/) 7 (67 a power on self-test is performed automatically each time the printer is turned on. This test checks for proper initialization of various electronic circuits and establishes starting parameters as those stored in the pr...

Page 47

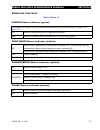

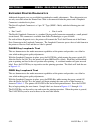

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-18 3ulqwhu6hoi7hvw5hvhw'hidxow4xlfn5hihuhqfh&kduw table 2-1 lists the self-tests and default resets that can be accessed by holding a front panel key or keys and turning the printer power on. The “x” in the four columns on the right indicates wh...

Page 48

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-19 table 2-1 self-test and calibration quick reference chart operator description pause key feed key cancel key mode key 3 cancel key self-test – produces a printer configuration label printout x 3 pause key self-test – produces test printouts f...

Page 49

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-20 important: use full width media when performing the self-tests. Labels less than full width will lose printing on the right side. Printing may run on to the next label when using short labels. &$1&(/.H\6hoi7hvw this self-test prints a listing...

Page 50

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-21 3$86(.H\6hoi7hvw this self-test can be used to provide the test labels (see figure 2-13 ) required when making adjustments to the printer’s mechanical assemblies. These test labels can also be used during the configuration mode adjustments. T...

Page 51

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-22 figure 2-13 pause key self-test printout figure 2-14 feed key self-test printout positive value: press feed key ( ) “3” times during print darkness adjustment negative value: press cancel key ( ) “2” times during print darkness adjustment s t.

Page 52

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-23 02'(.H\6hoi7hvw note: the printer data cable must be connected to the host computer during this self-test. This self-test places the printer in a communications diagnostics mode. In this mode, the printer prints the ascii characters and their...

Page 53

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-24 figure 2-15 mode key self-test printout table 2-2 factory default values parameter default value backfeed default baud 9600 calibration auto darkness 10 data bits 8 bits/character error detection on handshake xon/xoff head close calibration l...

Page 54

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-25 & $/,%5$7,21 $xwr&doleudwlrq the auto calibration occurs whenever the printer is turned on or when the printhead is opened and closed (with the printer turned on). During this procedure, the printer automatically determines the media type, la...

Page 55

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-26 7. Turn the power switch on. 8. After the calibrate led goes out, release the pause, feed, and cancel buttons. 9. When the printhead led flashes, reload the ribbon. 10. Make sure the media sensor is properly positioned. 11. Close the printhea...

Page 56

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-27 the zpl ii programming guide contains information on instructions that may be sent to the printer to disable the mode key and set specific label format values for each of these parameters. If you are not using zpl ii, refer to the instruction...

Page 57

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-28 figure 2-16 cancel key self test printout (configuration label) figure 2-17 feed key self-test printout.

Page 58

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-29 7hvwlqj3ulqw'dunqhvv3$86(.H\6hoi7hvw0hwkrg another method of testing print darkness, with a test label that contains a large amount of printing, is done by performing the pause key self-test. First, you must determine how you want to proceed ...

Page 59

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-30 4. While the printer is paused, pressing the cancel key a third time alters the self-test again. Now each time the pause key is pressed the printer prints 50 labels at speed 6 ips up to a maximum of 9999 labels. To conserve labels, you would ...

Page 60

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-31 7hdu2ii3rvlwlrq$gmxvwphqw this procedure sets the end-of-label position relative to the tear-off plate or cutter. The media stopping position is adjustable in increments of four dot rows at a time. The possible adjustment range is +/- 80 dot ...

Page 61

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-32 7rsriwkh/deho3rvlwlrq$gmxvwphqw this procedure positions the printing on the label relative to the top edge of the label. Make this adjustment if the printing is too close or too far away from the top or bottom edge of the label. 1. Press the...

Page 62

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-33 figure 2-19 adjusting the print of the top of the label.

Page 63

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-34 5 287,1( $ '-8670(176 3ulqwkhdg3uhvvxuh$gmxvwphqw if the printing is too light on one side of the label, or if media with a different thickness is used, the printhead pressure may need to be adjusted in order to provide the best print quality...

Page 64

=(%5$660$,17(1$1&(0$18$/6(&7,21,, 44895l rev. 1 1/99 2-35 %dfnlqj5hzlqg3rzhu5roohu$gmxvwphqw note: the rewind power roller is only present on printers with the peel-off option. This roller is pre-set during manufacture for proper operation with most applications. Only adjust this roller when necessa...

Page 65

6(&7,21,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 2-36 figure 2-21 backing rewind power roller backing material rewind power roller power roller adjustment edge guide mark up down.

Page 66

=(%5$660$,17(1$1&(0$18$/6(&7,21,,, 44895l rev. 1 1/99 3-1 7528%/(6+227,1* ,qwklvvhfwlrq t roubleshooting c harts ........................................................................................................3-1 led quick reference chart ........................................................

Page 67

6(&7,21,,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 3-2 /('4xlfn5hihuhqfh&kduw table 3-1 is a quick reference troubleshooting chart based on the status of the leds after the power on self-test has been completed (or attempts to complete) or during operation of the printer. Using the legend at the ...

Page 68

=(%5$660$,17(1$1&(0$18$/6(&7,21,,, 44895l rev. 1 1/99 3-3 7urxeohvkrrwlqj&kduw3ureohpvzlwk/(',qglfdwlrqv table 3-2 lists a number of problems or conditions that may be encountered with the printer. These condition or problems generally have led indications as listed in table 3-1 . Table 3-2 troubles...

Page 69

6(&7,21,,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 3-4 table 3-2 troubleshooting chart (problems with led indications) (continued) # symptom diagnosis action 7 calibrate, position, darken and data leds off but all other leds on. Firmware error. Download and install firmware. 8 calibrate, position...

Page 70

=(%5$660$,17(1$1&(0$18$/6(&7,21,,, 44895l rev. 1 1/99 3-5 table 3-2 troubleshooting chart (problems with led indications) (continued) # symptom diagnosis action the pause button was accidentally or intentionally pushed. Push the pause button to resume operation. 13 printer stops and pause led on. No...

Page 71

6(&7,21,,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 3-6 7urxeohvkrrwlqj&kduw3ulqwru3ulqw4xdolw\5hodwhg3ureohpv table 3-3 troubleshooting chart (print or print quality related problems) symptom diagnosis action printhead dirty. Clean the printhead. Print quality problems. Check print quality dots m...

Page 72

=(%5$660$,17(1$1&(0$18$/6(&7,21,,, 44895l rev. 1 1/99 3-7 table 3-3 troubleshooting chart (print or print quality related problems) (continued) symptom diagnosis action fine gray lines on blank labels at angles wrinkled ribbon. See wrinkled ribbon symptom chart media was pulled when motor was not mo...

Page 73

6(&7,21,,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 3-8 7urxeohvkrrwlqj&kduw:ulqnohg5leerq table 3-4 troubleshooting chart (wrinkled ribbon) symptom diagnosis action ribbon fed through printer incorrectly load ribbon correctly. Incorrect darkness setting. Set the darkness to the lowest setting pos...

Page 74

=(%5$660$,17(1$1&(0$18$/6(&7,21,,, 44895l rev. 1 1/99 3-9 7urxeohvkrrwlqj&kduw6hwwlqjvru3dudphwhu5hodwhg table 3-6 troubleshooting chart (settings or parameter related) symptom diagnosis action parameters are set or saved incorrectly reload the factory defaults, calibrate the printer and then cycle ...

Page 75

6(&7,21,,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 3-10 7urxeohvkrrwlqj&kduw&xwwhu5hodwhg table 3-7 troubleshooting chart (cutter related) symptom diagnosis action in cutter mode, skewed or stuck labels. Cutter is dirty. Clean cutter module. Cutter is dirty. Clean cutter. The cutter is not cuttin...

Page 76

=(%5$660$,17(1$1&(0$18$/6(&7,21,,, 44895l rev. 1 1/99 3-11 6 $03/( / $%(/6 the following pages contain samples of labels to be used with the preceding troubleshooting charts. These labels illustrate conditions that could be seen if mechanical adjustments are necessary. Zebra type 3p media stock and ...

Page 77

6(&7,21,,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 3-12 unacceptable label: darkness set too low. Printhead positioned correctly toggles balanced (equal pressure on left and right sides). Unacceptable label: darkness set very low. Printhead positioned correctly toggles balanced (equal pressure on...

Page 78

=(%5$660$,17(1$1&(0$18$/6(&7,21,,, 44895l rev. 1 1/99 3-13 unacceptable label: darkness set properly. Printhead too far forward. • “scratch flowers” on black area (washed out appearance). • printhead needs to be moved rearward. • walk out wrinkle with feed button and readjust. Toggles balanced (equa...

Page 79

6(&7,21,,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 3-14 unacceptable label: darkness set properly. Printhead position. • correct on right side. • way too far back on left side. Noisy printing. • breakup on trailing edges of horizontal bars. • splotchy on left side toggles balanced (equal pressure...

Page 80

=(%5$660$,17(1$1&(0$18$/6(&7,21,,, 44895l rev. 1 1/99 3-15 unacceptable label: darkness set properly. Printhead position. • correct on right side. • way too far forward on left side. Noisy printing. • breakup on trailing edges of horizontal bars. • splotchy on left side toggles balanced (equal press...

Page 81

6(&7,21,,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 3-16 3 5,17(5 6 7$786 6 (16256 the printer contains several status sensors. These sensors alert the operator to various conditions by either stopping the printing or turning on an led. Sensor what it monitors how it works printhead sensor checks ...

Page 82

=(%5$660$,17(1$1&(0$18$/6(&7,21,,, 44895l rev. 1 1/99 3-17 ) $&725 $ 66,67$1&( should any problem be encountered which cannot be corrected with the aid of this manual, and you have internet access, you should check out zip support . If you cannot solve your problem via zip support or do not have int...

Page 83

6(&7,21,,,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 3-18 this page left blank intentionally.

Page 84

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-1 35(9(17,9($1'&255(&7,9(0$,17(1$1&( 352&('85(6 e quipment s afety t ips ..............................................................................................................4-3 p ersonal s afety t ips .....................................

Page 85

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-2 removing the front door ........................................................................................................4-35 removing the rear cover .........................................................................................

Page 86

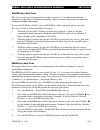

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-3 ( 48,30(17 6 $)(7 7 ,36 after reviewing each procedure, place a check in the box. ❏ the ac power plug and iec 320 connectors on all zebra printers must bear the certification mark of at least one international safety organization listed below....

Page 87

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-4 ( 48,30(17 6 $)(7 7 ,36 & 217,18(' ❏ to insure optimum printhead life, observe proper electrostatic safety precautions (i.E.; esd wrist straps) when removing, handling and replacing the printhead. ❏ zebra recommends using solvent containing 70...

Page 88

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-5 3 (5621$/ 6 $)(7 7 ,36 ❏ do not wear any jewelry (rings, watches, etc.) and loose clothing when servicing the printers. ❏ beware of “pinch points” on the printers. Be especially careful of: • opening and closing of covers. • printhead • rewind...

Page 89

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-6 3 5(9(17,9( 0 $,17(1$1&( 6 &+('8/( &ohdqlqj²*hqhudo caution: use only the cleaning agents described in the following procedures. Damage may occur if the incorrect cleaning agents are used on this printer. Exterior – the exterior surfaces of th...

Page 90

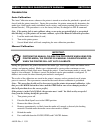

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-7 table 4-1 recommended cleaning schedule area method interval printhead clean with a solution of 70% isopropyl alcohol and 30% distilled water. Platen roller clean with a solution of 70% isopropyl alcohol and 30% distilled water. Media sensor a...

Page 91

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-8 3ulqwkhdgdqg3odwhq5roohu&ohdqlqj3urfhgxuh 1. Open the main door and front door (see figure 4-1). Open the printhead by turning the locking lever counter-clockwise. 2. Remove the media and ribbon if present. 3. Use a cleaning swab to wipe the p...

Page 92

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-9 figure 4-2 printhead cleaning.

Page 93

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-10 &ohdqlqjwkh&xwwhu0rgxoh the cutter module is an option available on the s400/s600 that requires periodic cleaning to remove paper dust and gummed label residue. The following procedure should be performed, as scheduled in table 4-1 , by the o...

Page 94

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-11 figure 4-3 cutter catch tray location figure 4-4 cutter connector and mounting screw label catch tray cutter module cutter cable connector mounting screw.

Page 95

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-12 figure 4-5 cutter module removal mounting posts cutter module mounting slots.

Page 96

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-13 2. Disassemble the cutter module. A. Hold the cutter module as shown in figure 4-6. Put your thumbs on the two wire spring loops and your index fingers on the top of the rear cutter blade guard. It may help to lay the cutter module on a table...

Page 97

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-14 3. Clean the cutter module. A. Remove any label material that has adhered to the cutter parts and use a small brush to remove any paper dust from the cutter module. B. If pressure sensitive media has been used, use a lint-free cloth soaked in...

Page 98

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-15 figure 4-8 side view of cutter module reassembly figure 4-9 reassembled cutter module rear cutter blade guard rear cutter blade guard cutter side panel cutter side panel metal pin wire spring wire spring loop pin slot.

Page 99

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-16 5. Reinstall the cutter module. A. Refer to figure 4-10. Position the cutter module above the cutter mounting posts. Press down on the cutter module until the mounting slots engage the mounting posts on the printer. B. Refer to figure 4-4 . T...

Page 100

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-17 / 8%5,&$7,21 caution: no lubricating agents of any kind should be used on this printer! If used, some commercially available lubricants will damage the finish and the mechanical parts..

Page 101

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-18 ' ,$*1267,&6 3ulqwhu6hoi7hvw5hvhw'hidxow4xlfn5hihuhqfh&kduw table 4-2 lists the self-tests and default resets that can be accessed by holding a front panel key or keys and turning the printer power on. The “x” in the four columns on the right...

Page 102

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-19 table 4-2 self-test and calibration quick reference chart operator description pause key feed key cancel key mode key 3 cancel key self-test – produces a printer configuration label printout x 3 pause key self-test – produces test printouts f...

Page 103

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-20 table 4-3 sequence of formats format # of labels speed test function figure 1 20 6 ips (speed d) left ribbon wrinkle test 4-12 2 20 6 ips (speed d) right ribbon wrinkle test 4-13 3 20 6 ips (speed d) bar code wrinkle test (code – 39) 4-14 4 1...

Page 104

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-21 figure 4-11 pause & cancel key test printout figure 4-12 test, formats 1 and 8 figure 4-13 test, formats 2 and 9.

Page 105

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-22 figure 4-14 test, formats 3 and 10 figure 4-15 test, formats 4 and 11 figure 4-16 test, formats 5 and 12.

Page 106

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-23 figure 4-17 test, formats 6 and 13 figure 4-18 test, formats 7 and 14.

Page 107

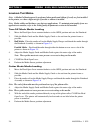

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-24 ( ;7(1'(' 3 5,17(5 ' ,$*1267,&6 additional diagnostic tests are available for printhead assembly adjustments. These diagnostic tests are only accessible when the printer data cable is disconnected from the printer and a loopback connector is ...

Page 108

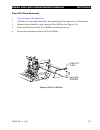

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-25 0 (&+$1,&$/ $ '-8670(176 3ulqwkhdg3rvlwlrq$gmxvwphqw 1. Make sure the printer is loaded with full width media and ribbon, and has had a media calibration performed with this combination of media and ribbon. 2. Turn printer power off. 3. Remov...

Page 109

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-26 printhead position locking screw printhead adjustment slot printhead position locking screw printhead adjustment slot strip plate braided ground strap braided ground strap 15. If labels are printing properly, press the pause key to stop print...

Page 110

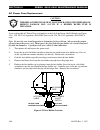

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-27 /deho$ydlodeoh6hqvru$gmxvwphqw the label sensor functions only when the printer is set to peel-off mode. This mode requires that the peel-off option be in stalled in the printer. This sensor is not installed on printers without the peel-off o...

Page 111

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-28 6wuls3odwh$gmxvwphqw the ribbon strip plate position can be adjusted to provide proper tracking and separation of the ribbon from the media after printing. If the ribbon does not track properly, or if ribbon wrinkle problems are experienced, ...

Page 112

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-29 %dfnlqj5hzlqg6slqgoh$gmxvwphqw refer to figure 4-22 and follow the procedures below to adjust the backing rewind spindle tension. 1. Turn the printer off and remove all media and ribbon. 2. Tape the end of the 30” long mylar tape (zebra part ...

Page 113

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-30 ( /(&75,&$/ $ '-8670(176 3ulqwkhdg9rowdjh$gmxvwphqw caution: the printhead voltage adjustment is critical to the life of the printhead. Do not use this adjustment in an attempt to increase the printing darkness. When a printhead or power supp...

Page 114

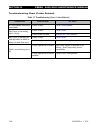

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-31 table 4-4 printhead voltage values (s400 only) printhead voltage formula: resistance Ω voltage vdc resistance Ω voltage vdc 935 to 945 22.2 1092 to 1110 24.0 946 to 963 22.4 1111 to 1129 24.2 964 to 981 22.6 1130 to 1148 24.4 982 to 999 22.8 ...

Page 115

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-32 figure 4-23 printhead voltage adjustment potentiometer location power supply board (access rv2 through cut-out in base) ground wire rv2.

Page 116

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-33 &xwwhu9rowdjh$gmxvwphqw warning: use caution around cutter blades. Keep fingers away from blades. The voltage applied to the printhead is the same voltage applied to the cutter module. The specific voltage applied to the cutter motor is contr...

Page 117

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-34 figure 4-24 properly adjusted cutter sensor figure 4-25 home position potentiometer side plate edge embossed line sensor disc outer cover home position potentiometer home position potentiometer.

Page 118

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-35 & 255(&7,9( 0 $,17(1$1&( 7rrov5htxluhg 7/32 open end wrench screwdriver, phillips no. 2 metric allen wrench set spring scale, 2200 gram and 1000 gram screwdriver, ¼” flat blade .010 shim or feeler gauge screwdriver, phillips no. 1 .020 shim o...

Page 119

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-36 figure 4-26 opening main and front doors figure 4-27 door and cover disassembly rear cover front door main door 1 2 tab main door front door.

Page 120

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-37 7hdu2ii3odwh5hprydo 1. Open (or remove) the main door. 2. Grab the tab on top of the front door and carefully pull down until it rests on the desktop. 3. Remove the two 5mm hex screws from the tear-off plate (see figure 4-28). 4. Push up on t...

Page 121

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-38 &rqwuro3dqho$vvhpeo\5hprydo caution: observe proper electrostatic safety precautions when removing, handling and replacing printed circuit boards. 1. Turn printer off and remove the power cord. 2. Remove the front door. 3. Remove the rear cov...

Page 122

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-39 figure 4-29 control panel assembly control panel ribbon cable strain relief control panel cover.

Page 123

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-40 0dlq/rjlf%rdug5hprydo caution: observe proper electrostatic safety precautions when removing, handling and replacing printed circuit boards. 1. Turn printer off and remove the power cord. 2. Remove the printer data cable (if connected). 3. Re...

Page 124

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-41 j1 serial port j10 full roll switch assembly j2 parallel port j11 media/ribbon sensor assembly j3 ribbon take-up motor assembly j12 control panel assembly j4 printhead assembly (s600) j13 not used j5 printhead assembly (s400) j14 option conne...

Page 125

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-42 3ulqw0hfk$vvhpeo\5hprydo 1. Turn printer off and remove the power cord. 2. Remove the printer data cable (if connected). 3. Remove the media and ribbon. 4. Remove the main door, front door and rear cover . 5. Remove the main logic board. 6. L...

Page 126

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-43 3ulqwkhdg$vvhpeo\5hprydo 1. Turn printer off and remove the power cord. 2. Remove the printer data cable (if connected). 3. Remove the main door, front door and rear cover. 4. Remove the two phillips head screws holding the strip plate to the...

Page 127

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-44 figure 4-32 braided ground strap location figure 4-33 print mechanism assembly mounting screw location print mech assembly braided ground straps print mech assembly mounting screw cut-out printhead cable braided ground strap.

Page 128

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-45 figure 4-34 printhead assembly removal/installation printhead assembly m3 nuts printhead cable assembly print mech assembly.

Page 129

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-46 5leerq6xsso\6slqgoh'lvdvvhpeo\ refer to figure 4-35 1. Turn printer off and remove the power cord. 2. Remove the printer data cable (if connected). 3. Remove any media and ribbon. 4. Ensure the dual tension ribbon supply spindle outer spindle...

Page 130

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-47 5leerq6xsso\6slqgoh5hsodfhphqw 1. Perform the “ ribbon supply spindle disassembly ” procedures. 2. Use an emery cloth to remove burrs and nicks on the ribbon supply spindle shaft. 3. Slide the ribbon supply spindle sub-assembly on the ribbon ...

Page 131

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-48 7. Once the cup and spring assembly is tightened, remove the shim/feeler gauge. The ribbon supply spindle sub-assembly should have some “play” on the shaft. When rotated in a counter-clockwise direction, the ribbon supply spindle sub-assembly...

Page 132

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-49 11. Replace the c-clip in the grove found on the shaft (see figure 4-38 ). 12. Place a .020 shim or feeler gauge between the spindle assembly and the ribbon supply spindle sub-assembly (see figure 4-38 ). 13. Slide the outer spindle on the sh...

Page 133

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-50 .020 shim or feeler gauge placed between ribbon supply spindle sub-assembly and spindle assembly c-clip cup and spring assembly 1.5 mm allen head set screws outer spindle figure 4-38 spindle assembly installation figure 4-39 spindle assembly ...

Page 134

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-51 0hgld6hqvru$vvhpeo\5hprydo caution: observe proper electrostatic safety precautions when removing, handling and replacing printed circuit boards. 1. Turn printer off and remove the power cord and the printer data cable (if connected). 2. Remo...

Page 135

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-52 figure 4-41 media sensor assembly figure 4-42 main drive belt replacement and adjustment media sensor assembly upper media guide assembly 10 00 90 0 80 0 70 0 60 0 in c h e s 1 2 3 shoulder bolt and idler pulley spring scale stepper motor pla...

Page 136

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-53 0dlq'ulyh%how5hprydo5hsodfhphqwdqg$gmxvwphqwiru3ulqwhuv :lwkrxwwkh3hho2ii2swlrq caution: observe proper electrostatic safety precautions when removing, handling and replacing printed circuit boards. 1. Turn printer off and remove the power co...

Page 137

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-54 0dlq'ulyh%how5hzlqg6slqgoh'ulyh%how5hprydo5hsodfhphqw dqg$gmxvwphqwiru3ulqwhuv(txlsshg:lwkwkh3hho2ii2swlrq caution: observe proper electrostatic safety precautions when removing, handling and replacing printed circuit boards. 1. Turn printer ...

Page 138

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-55 figure 4-43 peel-off drive belt adjustment i n c h e s 1 2 3 2 2 0 0 2 0 0 0 1 8 0 0 1 6 0 0 1 4 0 0 2 2 0 0 2 0 0 0 1 8 0 0 1 6 0 0 1 4 0 0 1/4" shoulder bolt & idler pulley for rewind spindle belt adjustment rewind spindle belt tension 2300...

Page 139

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-56 3odwhq5roohu5hsodfhphqw 1. Turn printer off and remove the power cord and the printer data cable (if connected). 2. Remove media and ribbon. 3. Remove the main door, rear cover and control panel assembly . 4. Remove the main logic board and m...

Page 140

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-57 figure 4-44 platen roller replacement figure 4-45 platen roller platen pulley main drive belt shoulder bolt & idler pulley ground chain assembly platen roller platen bearings outboard guides /inboard the bearings pictured here are installed t...

Page 141

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-58 5leerq7dnh8s0rwru5hsodfhphqw 1. Turn printer off and remove the power cord and the printer data cable (if connected). 2. Remove media and ribbon. 3. Remove the main door and rear cover. 4. Remove the main logic board. 5. Remove the main drive...

Page 142

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-59 6whsshu0rwru5hsodfhphqw 1. Turn printer off and remove the power cord and the printer data cable (if connected). 2. Remove media and ribbon. 3. Remove the main door and rear cover. 4. Remove the main logic board. 5. Remove the main drive belt...

Page 143

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-60 figure 4-48 stepper motor (electronics side) stepper motor power supply board (j1) (access through cut-out in base stepper motor cable ground wire.

Page 144

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-61 caution: observe proper electrostatic safety precautions when removing, handling and replacing printed circuit boards. 3rzhu6xsso\%rdug5hprydo 1. Turn printer off and remove the power cord and the printer data cable (if connected). 2. Remove ...

Page 145

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-62 8. Replace the main logic board . 9. Reconnect all ribbon cable connectors and wire harness connectors to the main logic board . 10. Reconnect power cord and perform a printhead voltage adjustment procedure . 11. Replace the rear cover and ma...

Page 146

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-63 figure 4-50 power supply assembly exploded view power supply board power supply base power supply base mounting screw power supply board mounting screws.

Page 147

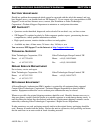

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-64 $&3rzhu)xvh5hsodfhphqw caution: the replacement fuse must have the ratings specified below. Serious damage may occur if a higher rated fuse is installed. A user replaceable ac power fuse is located just to he left of the power on/off switch (...

Page 148

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-65 2 37,216 ) ,(/' , 167$//$%/( 0hpru\8sjudgh.Lw,qvwdoodwlrq,qvwuxfwlrqv caution: observe proper electrostatic safety precautions when removing, handling and replacing printed circuit boards. 1. Turn printer off and remove the power cord. 2. Rem...

Page 149

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-66 15. Push the main logic board straight down until connector j8 has seated completely onto the power supply board. 16. Reinstall the three 5mm hex screws securing the main logic board to the printer main frame. 17. Reconnect all ribbon cable c...

Page 150

=(%5$660$,17(1$1&(0$18$/6(&7,21,9 44895l rev. 1 1/99 4-67 main logic board mounting screw mounting screws memory board figure 4-52 sample main logic board & memory board figure 4-53 memory board installation main logic board mounting screw mounting screws memory board.

Page 151

6(&7,21,9=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 4-68 figure 4-54 sample before and after configuration labels (8 mb memory board installed).

Page 152

=(%5$660$,17(1$1&(0$18$/6(&7,219 44895l rev. 1 1/99 5-1 0$,17(1$1&($1'$66(0%/ c over a ssemblies ......................................................................................................................5-2 l ogic b oard and c ontrol p anel ..................................................

Page 153

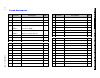

2 & 29(5 $ 66(0%/,(6 # part no. Description qty 1 44114 screw m4.2 x 1.41 x 8 hi-lo hex 3 2 44185m front door retention clip 1 3 44075-1 rear cover 1 44076-5 front door (s400) 1 4 44076-4 front door (s600) 1 44070-3 main door (standard) 1 5 44070-4 main door (quick release) 1 # part no. Description ...

Page 154

3 &ryhu$vvhpeolhv =( %5$ 6 6 0$,17(1 $1& (0 $18$/ 6(&7,21 9 44895l rev. 1 1/99 5-3 1 2 3 4 5.

Page 155

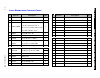

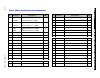

4 / 2*,& % 2$5'$1' & 21752/ 3 $1(/ # part no. Description qty 1 44114 screw m4.2 x 1.41 x 8 hi-lo hex 3 2 44506m (a) front panel assembly 1 (b) front panel cover (includes 1 front door retention clip, 2 m4.2 x 1.41 x 8 hi-lo hex screws 3 44071-400m and 1 m4 x 10 hex screw) 1 4 44053 screw m3 x .6 x ...

Page 156

5 /rjlf%rdugdqg&rqwuro3dqho =( %5$ 6 6 0$,17(1 $1& (0 $18$/ 6(&7,21 9 44895l rev. 1 1/99 5-5 1 2 3 4 5 6 7 8 9 10 12 13 14 1 8 11 15 a b c.

Page 157

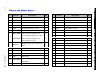

6 5 ,%%21$1' 0 (',$ 6 833/ # part no. Description qty 1 10432 screw, m4 x .7 1 2 30251 washer .836 x .390 x .048 1 3 44043m (a) rtu motor assy 1 4 44198m cable, motor rtu 1 5 44481 ground chain assy 1-3/8” 1 6 44046-2 bevel gear, 60t 1 44052-400m ribbon take-up spindle assy 1 (tear-off and cutter op...

Page 158

7 5leerqdqg0hgld6xsso\ =( %5$ 6 6 0$,17(1 $1& (0 $18$/ 6(&7,21 9 44895l rev. 1 1/99 5-7 1 2 6 7 8 9 10 11 12 13 2 11 18 19 17 3 4 5 14 15 16 20 a b c.

Page 159

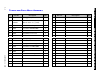

8 7 2**/($1' 3 5,17 0 (&+ $ 66(0%/ # part no. Description qty 1 44329-400m (a) toggle assy 1 44180m (b) print mech assy (s400) 1 2 44204m (b) print mech assy (s600) 1 3 77687 braided ground strap 1 4 44482 screw m3 x 20 din7500c 1 5 01448 screw 1 6 44484 screw m4.2 x 1.41 x 25 1 7 44339 hex standoff...

Page 160

9 7rjjohdqg3ulqw0hfk$vvhpeo\ =( %5$ 6 6 0$,17(1 $1& (0 $18$/ 6(&7,21 9 44895l rev. 1 1/99 5-9 a b a b 1 1 2 2 3 4 5 6 7 8 9 10 11 12 print mech and mounting hardware only. See print mech and printhead assembly section for printhead assy and printhead cable 13 13 13 5 14.

Page 161

10 3 5,17 0 (&+$1' 3 5,17+($' $ 66(0%/ # part no. Description qty 44999m (a) printhead assy (s400) 1 1 44998m (a) printhead assy (s600) 1 44180m (b) print mech assy (s400) 1 2 44204m (b) print mech assy (s600) 1 44527 printhead cable assy (s400) 1 3 44920 printhead cable assy (s600) 1 # part no. Des...

Page 162

11 3ulqw0hfkdqg3ulqwkhdg$vvhpeo\ =( %5$ 6 6 0$,17(1 $1& (0 $18$/ 6(&7,21 9 44895l rev. 1 1/99 5-11 b 2 a a 1 3 1.

Page 163

12 0 (',$ 6 (1625$1' 5 ,%%21 * 8,'( # part no. Description qty 1 44011 media guide 1 2 44466 ground cable 1 3 44482 screw, m3 x 20 din7500c 1 44140-400m upper media guide plate assy 1 (tear-off and cutter option only) 44140-402m upper media guide plate assy 1 4 (peel-off option only) 44135-400m (a) ...

Page 164

13 0hgld6hqvrudqg5leerq*xlgh =( %5$ 6 6 0$,17(1 $1& (0 $18$/ 6(&7,21 9 44895l rev. 1 1/99 5-13 8 7 6 3 2 5 6 4 1 9 10 11 13 14 15 this end of the ground strap attaches to the print mech assy a b b 12 8.

Page 165

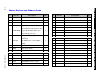

14 ' 5,9( 6 # part no. Description qty 44023-0m stepper motor (tear-off and 1 cutter option only) 44023-2m stepper motor (peel-off option 1 1 only) 2 44216 screw m4.2 x 1.41 x 13 1 3 44177 tear plate ground strap 1 4 44019 idler shaft 1 idler pulley, 20t (tear-off and 5 44025 cutter option only) 1 w...

Page 166

15 'ulyh6\vwhp =( %5$ 6 6 0$,17(1 $1& (0 $18$/ 6(&7,21 9 44895l rev. 1 1/99 5-15 1 2 3 4 5 6 7 8 9 10 11 12.

Page 167

16 3 /$7(1$1' 3 2:(5 6 833/ # part no. Description qty 1 44282 tear off plate 1 2 44015 platen bearing 2 3 44120 outboard guide 1 44182 platen roller (s400) 1 4 44214 platen roller (s600) 1 5 44121 inboard guide 1 6 44114 screw m4.2 x 1.41 x 8 hi-lo hex 2 7 44484 screw m4.2 x 1.41 x 25 1 8 44004-400...

Page 168

17 3odwhqdqg3rzhu6xsso\ =( %5$ 6 6 0$,17(1 $1& (0 $18$/ 6(&7,21 9 44895l rev. 1 1/99 5-17 1 2 3 4 5 6 7 8 9 10 2 the bearings (item #2) pictured here are installed this way for the 400 only. For the 600, rotate the bearings 180 degrees (turn upside down). S s.

Page 169

18 3 ((/ 2 )) 2 37,21 ) 5217 9 ,(: # part no. Description qty 1 44191 ground chain assy 1 2 44218 backing rewind hook 1 3 44284m (d) media take-up spindle assy 1 4 44391 anti-static brush 1 5 44398m (c) lower guide rod kit 1 6 44383 ground cable assy 1 7 44349m (b) upper media rod kit 1 8 44463m (a)...

Page 170

19 3hho2ii2swlrq)urqw9lhz =( %5$ 6 6 0$ ,17(1$1& (0 $18$/ 6(&7,21 9 44895l rev. 1 1/99 5-19 a b c d a b b c c d 1 2 3 4 5 6 7 8 3 5 7 8 6.

Page 171

20 3 ((/ 2 )) 2 37,21 5 ($5 9 ,(: # part no. Description qty 1 44216 screw m4.2 x 1.41 x 13 1 2 44358m (c) media take-up idler assy 1 (b) upper idler assy (peel-off 3 44359m option only) 1 4 44368m (d) carrier idler assy 1 5 44536m (a) take label sensor assy 1 6 44665m full roll switch assy 1 7 4518...

Page 172

21 3hho2ii2swlrq5hdu9lhz =( %5$ 6 6 0$,17(1$1&(0$18$/ 6(& 7 ,219 44895l rev. 1 1/99 5-21 b a b a a f d c e e e f 1 2 3 4 5 6 7 8 9 10 11 12 13 5 5 3 9 10 14 15 16 17 9 17 18.

Page 173

22 & 877(5 2 37,21 # part no. Description qty 1 44710m cutter maint kit 1 2 44986 catch tray 1 3 44437m cutter mounting maint kit 1 4 10432m plate mounting maint kit 1 5 10432 screw, m4 x .7 x 12 1 6 07257 washer .438 x .188 x .036 1 7 06223 cable clamp .188 1 8 44674 cable 8 cond din (cutter cable)...

Page 174

23 &xwwhu2swlrq =( %5$ 6 6 0$,17(1 $1& (0 $18$/ 6(&7,21 9 44895l rev. 1 1/99 5-23 1 a b c the cutter option field installable. The parts displayed below are for repairing the factory installed option. These parts cannot be installed on non-cutter option units. Is not note: 2 4 3 5 6 7 8 9.

Page 175

6(&7,219=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 5-24 this page left blank intentionally.

Page 176

=(%5$660$,17(1$1&(0$18$/6(&7,219, 44895l rev. 1 1/99 6-1 0,6&(//$1(286,1)250$7,21$1' $33(1',&(6 this section is used to file various documents. Some of which may not have been originally included with the manual. This includes (if applicable): • additional information provided that does not fit in a...

Page 177

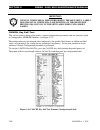

6(&7,219,=(%5$660$,17(1$1&(0$18$/ 44895l rev. 1 1/99 6-2 $6&,,& 2'( & +$57 american standard code for information interchange hex char hex char hex char hex char 00 nul 20 space 40 @ 60 ‘ 01 soh 21 ! 41 a 61 a 02 stx 22 “ 42 b 62 b 03 etx 23 # 43 c 63 c 04 eot 24 $ 44 d 64 d 05 enq 25 % 45 e 65 e 06...