- DL manuals

- Zebra

- Printer

- TTPM3

- Service Manual

Zebra TTPM3 Service Manual

Summary of TTPM3

Page 1

Zebra® ttpm3™ kiosk ticket printer/encoder service manual p1011350-001.

Page 2

P1011348-001 ttpm2™ selection guide 2/18/09 © 2009 zih corp. The copyrights in this manual and the software and/or firmware in the printer described therein are owned by zih corp. Unauthorized reproduction of this manual or the software and/or firmware in the printer may result in imprisonment of up...

Page 3

March, 09 ttpm3 - service manual 3 contents 1 introduction .............................................................................................5 1.1 about this manual............................................................................................5 1.2 updating .....................

Page 4

4 ttpm3 - service manual march 2009 6 replacement parts ............................................................................. 39 6.2 desktop version, final assembly................................................................... 40 6.3 modules ................................................

Page 5: 1 Introduction

March, 09 ttpm3 - service manual 5 1 introduction 1.1 about this manual this manual describes the design and function of the ttpm3 ticket printer/encoder, which creates credit-card-wide documents with magnetic encoding and thermal printing. The manual also contains maintenance instructions and repla...

Page 6: 2 Product

6 ttpm3 - service manual march 2009 2 product presentation ttpm3 ticket printer/encoder creates credit-card-wide tickets with magnetic encoding and thermal printing. 2.1 document printing ttpm3 uses the direct thermal printing technique and can print the entire surface of the ticket with text, bar c...

Page 7

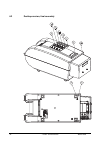

March, 09 ttpm3 - service manual 7 input 1 (lower) input 2 (upper) interface connector power switch power inlet (24v) ticket output control panel figure 1. Desktop printer figure 2. Oem printer mechanism.

Page 8

8 ttpm3 - service manual march 2009 the figure below shows the main parts of the oem-type printer/encoder unit with attached front load mechanism. Items in the figure, but not pointed to belong to the basic module. Output module input module magnetic stripe module cutter module control board assy ba...

Page 9: 3 Functional

March, 09 ttpm3 - service manual 9 3 functional description the ttpm3 connects to a host computer, for example a workstation or a pc, through the rs232 serial interface or optional ethernet. The host controls the operation of the ttpm3 by means of software commands. A microprocessor on the control b...

Page 10

10 ttpm3 - service manual march 2009 3.1.1 document paths see figure 4. The ttpm3 can handle the following document path combinations: two software-selectable paths for fanfold or roll stock. One path for a fanfold or roll stock and one single-document path with override function. Lower document pat...

Page 11

March, 09 ttpm3 - service manual 11 3.1.3 cutting module see figure 4. The knife in the cutting module moves by means of a dc-motor (u) with a combined carrier and cam wheel (ae). The motor runs in one direction only during normal cutting operations. A micro-switch sensor (v) detects when the knife ...

Page 12

12 ttpm3 - service manual march 2009 printhead module assy micro switches actuator arm adjustment plate lock screw eccentric cam wheel sw97093b print platen front load module figure 6. Printhead lifting mechanism design (optional) 3.2.2 function feeding the document in when the paper presence sensor...

Page 13

March, 09 ttpm3 - service manual 13 the document is fed through the front load input/output module into the ordinary “output module” now also serving as an input device. A leaf spring ensures that the document is kept pressed against the running feed belts to get sufficient friction. Sw97096-r2 docu...

Page 14

14 ttpm3 - service manual march 2009 feeding the document out returning the document through the input/output module (can also be fed out through the rear document path) is the reverse of feeding the document in. Note that the document is guided out through the horizontal path (see arrow). Sw97098 d...

Page 15

March, 09 ttpm3 - service manual 15 alternatively, the document can be fed out downward into a waste bin or similar. This is affected by a software command that actuates the solenoid that pushes the link upward and pivots the input module so that the document is guided downward and out. Sw97099-r1 d...

Page 16

16 ttpm3 - service manual march 2009 3.3 control board see figure 12. Ttpm3 functional block diagram on page 19 and the logic diagram in chapter 5. 3.3.1 microprocessor system the main parts of the microprocessor system are 80c420 processor 2mb flashprom 128 k ram two programmable i/o ports 3.3.2 me...

Page 17

March, 09 ttpm3 - service manual 17 3.3.5 cutting the dc-motor first turns in one direction to perform the cutting. The cam wheel actuates the micro-switch sensor when the mechanism reaches its home position again. At this moment, the motor is forced to a quick stop as the drive circuit for turning ...

Page 18

18 ttpm3 - service manual march 2009 3.3.7 power supply the power supply unit (psu) is of the switched mode type and supplies +24v to the control board. A transistor on the control board switches on the +24 v when motors, solenoids and printhead is to be used and keeps it off when the printer is idl...

Page 19

March, 09 ttpm3 - service manual 19 addr. Latch chip select d0—d7 d0—d7 a0—a15 printer stepper motor encoding stepper motor cutter motor upper entry solenoid lower entry solenoid output solenoid cutter motor drive circuit solenoid drivers a8—a15 a0—a7 lower entry input sensor upper entry input senso...

Page 20: 4 Maintenance

20 ttpm3 - service manual march 2009 4 maintenance warning! Danger of injury! Depending on the position of the crank mechanism in the cutter module, the cutting knife may start moving when the printer is switched on. Keep hands away! Caution! The power supply should be switched off before you discon...

Page 21

March, 09 ttpm3 - service manual 21 = apply on thread: loctite 243 threadlocker, medium strength, removable, and oil tolerant = grease = oil = red laquer sealant figure 13. Lubricating a ttpm3.

Page 22

22 ttpm3 - service manual march 2009 4.2 fault finding the ttpm3 informs the host of some error symptoms by means of status reports and error codes (if not disabled with parameter n6). The indicators on the control panel indicate errors requiring assistance of the operator. Both parameter settings a...

Page 23

March, 09 ttpm3 - service manual 23 symptom only one self-test ticket can be done. When you press the print button again, only blank tickets are produced. Action check the setting of parameter n7, "clear memory after print". If it is on, this is the correct behavior. If n7 is off, test the printer w...

Page 24

24 ttpm3 - service manual march 2009 cover remove the four screws holding the printer mechanism to the bottom of the cover. Lift the printer-mechanism out of the cover. Print module open the printhead and clean the printhead resistor-line with alcohol. Check the plastic cogwheels for wear. Check for...

Page 25

March 2009 ttpm3 - service manual 25 4.4 parts removal and replacement whenever modules are loosened, removed or replaced, a complete adjustment and verification cycle must be performed. Note 1! — this is essential for the reliability of the printer and should never be overlooked! Note 2! — only tec...

Page 26

26 ttpm3 - service manual march 2009 4.4.3 firmware the firmware is the software that controls the ttpm3. It is stored in a flash prom and can be updated from the host computer. How to do this is described in the technical manual. You can download firmware from www.Zebra.Com . 4.4.4 cover removal 1....

Page 27

March 2009 ttpm3 - service manual 27 4.4.5 printhead module removal 1. Disconnect the printhead cable from the printhead. 2. Remove the two circlips from the shaft attaching the printhead support plate to the output module. 3. Pull the printhead engagement arm forwards to relieve the printhead and t...

Page 28

28 ttpm3 - service manual march 2009 4.4.8 magnetic stripe module removal 1. Remove the printer/encoder unit from the cabinet as described above. 2. Remove the input module as described above. 3. Disconnect the two cables from the control board connector j3. 4. Remove the four screws securing the ma...

Page 29

March 2009 ttpm3 - service manual 29 4.4.10 control board when you order a control board as replacement parts it is configured with firmware and parameter settings suitable for the factory. Removal 1. Remove the printer/encoder unit from the cabinet as described above. 2. Disconnect all cables from ...

Page 30

30 ttpm3 - service manual march 2009 4.4.11 front load module removal sw98076 figure 14. Removing the frontload module assembly 1. Disconnect the frontload cable connectors j11 and j20 from the control board (remember to mark the houses with no,). 2. Remove one screw on each side of the front load m...

Page 31: 5 Adjustments

March 2009 ttpm3 - service manual 31 5 adjustments whenever modules are loosened, removed or replaced, a complete adjustment and verification cycle must be performed. Note 1! — this is essential for the reliability of the printer and should never be overlooked! Note 2! — only technicians having the ...

Page 32

32 ttpm3 - service manual march 2009 5.2 ticket path adjustment gauge 54.3mm stop screw cutout of printer seen from front fixed guide adjustable guide stop screw correct! Ticket path width adjustment press and tighten stop screw lightly stop screw if you press and tighten stop screw hard bend guide ...

Page 33

March 2009 ttpm3 - service manual 33 5.2.1 rear 1. Loosen 1.5-mm allen-screws g and h keeping the rear ticket guide plate in position. Widen the ticket path by pushing the loose guide plate toward the right hand side of the ttpm3. Figure 17. Adjusting the rear ticket path 2. Insert the gauge through...

Page 34

34 ttpm3 - service manual march 2009 5.2.2 front ttpm3 without front load option 1. Loosen 1.5-mm hexagonal (allen) screws j and k keeping the front ticket guide plate in position. Widen the ticket path by pushing the loose guide plate toward the right hand side of the ttpm3. 2. Insert the gauge und...

Page 35

March 2009 ttpm3 - service manual 35 5.3 magnetic head pressure rollers adjustment w rite h ea d re ad h ea d rotate freely without ticket hard to turn with ticket move roller up&down to adjust figure 19. Adjusting the magnetic head pressure rollers to properly encode tickets of a specific thickness...

Page 36

36 ttpm3 - service manual march 2009 5.4 solenoids solenoids create a linear movement that the ttpm uses to engage and disengage ticket feed. A solenoid consists of a coil with a hole in it, and a plunger. When voltage is applied to the coil, the plunger is pulled into the hole by the magnetic field...

Page 37

March 2009 ttpm3 - service manual 37 5.4.3 adjusting output solenoid no ticket should be inserted! 1) loosen the two screws holding the solenoid coil 2) press and hold down the plunger 3) move the coil towards the plunger using the screwdriver, and tighten the screw. Press down on plunger adjust lif...

Page 38

38 ttpm3 - service manual march 2009 5.5 printers with front load sw99011 front eccentric cam wheel lock screw actuator arm 0. 5 mm front 0.5 mm adjustment plate 1. Check with a feeler gauge that the distance between the actuator arm and the micro switch housing (the frame around the knob) is 0.5mm....

Page 39: Replacement Parts

March 2009 ttpm3 - service manual 39 6 replacement parts this chapter lists the replacement parts available for the ttpm3. The number of replacement parts is restricted due to the division of the product into easily replaceable modules. Desktop version, final assembly ..................................

Page 40

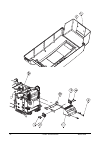

40 ttpm3 - service manual march 2009 6.2 desktop version, final assembly.

Page 41

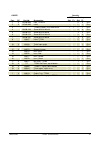

March 2009 ttpm3 - service manual 41 quantity cover oem desktop pos. Sp part no. Designation std fl std fl 1 x 02349-000 foot, sj 5514 - - 4 4 pcs. 2 x 02382-000 label, - - 1 1 pcs. 3 - ttpm3 encode / print mechanism 1 1 1 1 pcs. 4 09100-168 screw mrx-h m2x10 - - 4 4 pcs. 5 09100-222 screw mrx-h m3x...

Page 42

42 ttpm3 - service manual march 2009.

Page 43

March 2009 ttpm3 - service manual 43 quantity cover oem desktop pos. Sp part no. Designation std fl std fl 1 x 02349-000 foot, sj 5514 - - 4 4 pcs. 2 x 02382-000 label - - 1 1 pcs. 3 02712-000 ttpm3 tr. 1-3 loco/hico fl3 - - 1 1 pcs. 4 09100-168 screw mrx-h m2x10 - - 4 4 pcs. 5 09100-222 screw mrx-h...

Page 44

44 ttpm3 - service manual march 2009 6.3 modules mag-roller 01674-005 must always be fitted with the grove facing upwards!.

Page 45

March 2009 ttpm3 - service manual 45 quantity modules oem desktop pos. Sp part no. Designation std fl std fl 3 x 01695-000 printhead module assy 1 1 1 1 pcs. 4 01721-000 screw mrt 8.8 m2.5x8 2 2 2 2 pcs. 5 02276-000 washer brb 2.7x8x0.8 2 2 2 2 pcs. 6 x 02309-000 spacer 1 1 1 1 pcs. 7 x 02435-000 sh...

Page 46

46 ttpm3 - service manual march 2009 modules, continued….

Page 47

March 2009 ttpm3 - service manual 47 modules quantity oem desktop pos. Sp part no. Designation std fl std fl 3 x 01695-000 printhead module assy 1 1 1 1 pcs. 4 01721-000 screw mrt 8.8 m2.5x8 2 2 2 2 pcs. 5 02276-000 washer brb 2.7x8x0.8 2 2 2 2 pcs. 6 x 02309-000 spacer 1 1 1 1 pcs. 7 x 02435-000 sh...

Page 48

48 ttpm3 - service manual march 2009 6.4 input module.

Page 49

March 2009 ttpm3 - service manual 49 input module quantity oem desktop pos. Sp part no. Designation std fl std fl 1 x 02205-000 spacer drm 3260x9 2 2 2 2 pcs. 2 x 02206-000 roller shaft 1 1 1 1 pcs. 3 x 02207-000 bearing 6 6 6 6 pcs. 4 x 02208-000 feed roller assy. 3 3 3 3 pcs. 5 x 02211-000 roller ...

Page 50

50 ttpm3 - service manual march 2009 6.5 magnetic encoding module mag. Stripe module assy, tr 1-3, lc/hc quantity oem desktop pos. Sp part no. Designation std fl std fl 1 x 09018-217 screw sk6ss m3x3 2 2 2 2 pcs. 2 09100-220 screw mrx-h m3x6 3 3 3 3 pcs. 3 x 102858 mag. Amplification board, 3 track,...

Page 51

March 2009 ttpm3 - service manual 51 6.7 printhead module assembly 01695-000 printhead module assy quantity oem desktop pos. Sp part no. Designation std fl std fl 1 01256-000 printhead label 1 1 1 1 pcs. 2 x 01694-900 pressure plate assy 1 1 1 1 pcs. 3 x 02254-000 spacer, cylindrical 1 1 1 1 pcs. 4 ...

Page 52

52 ttpm3 - service manual march 2009 6.8 output module = 100891 oil atf dexron ii.

Page 53

March 2009 ttpm3 - service manual 53 output module quantity oem desktop pos. Sp part no. Designation std fl std fl 1 02203-000 side plate, front 2 2 2 2 pcs. 2 02205-000 spacer drm 3260x9 2 2 2 2 pcs. 3 x 02206-000 roller shaft 2 2 2 2 pcs. 4 x 02207-000 bearing 4 4 4 4 pcs. 5 x 02208-000 feed rolle...

Page 54

54 ttpm3 - service manual march 2009 6.9 cutter module = 100890 grease hasco z260 = 100905 loctite 243 threadlock.

Page 55

March 2009 ttpm3 - service manual 55 cutter module quantity oem desktop pos. Sp part no. Designation std fl std fl 1 x 00549-060 cutter support (fixed cutter blade) 1 1 1 1 pcs. 2 x 00555-000 hub 5mm 2 2 2 2 pcs. 3 x 00555-001 hub 6.5mm 2 2 2 2 pcs. 4 x 00556-000 pressure plate 1 1 1 1 pcs. 5 x 0055...

Page 56

56 ttpm3 - service manual march 2009 front load module sensor cable under this shaft = 100891 oil atf dexron ii.

Page 57

March 2009 ttpm3 - service manual 57 front load module quantity oem desktop pos. Sp part no. Designation std fl std fl 1 x 00251-000 bearing, plastic 2 2 pcs. 2 x 00358-000 cable clamp 1 1 pcs. 3 01268-000 tie-wrap, 71×1.8mm 1 1 pcs. 4 01332-000 tube spacer drm 2550x5 2 2 pcs. 5 x 02261-000 cog whee...

Page 58

58 ttpm3 - service manual march 2009 6.10 basic module basic module quantity oem desktop pos. Sp part no. Designation std fl std fl 1 00359-000 washer brb 3.2x8x1 2 2 2 2 pcs. 2 x 00375-000 cog wheel 1 1 1 1 pcs. 3 x 00628-000 cutter arm support 0 1 0 1 pcs. 4 x 00629-000 cam wheel 0 1 0 1 pcs. 5 x ...

Page 59

March 2009 ttpm3 - service manual 59 basic module quantity oem desktop pos. Sp part no. Designation std fl std fl 12 x 02242-002 platen assy 1 1 1 1 pcs. 13 x 02244-000 fastening plate 1 1 1 1 pcs. 14 x 02245-000 bottom plate 1 1 1 1 pcs. 15 x 02257-000 hub 1 1 1 1 pcs. 16 x 02259-000 cog wheel, pla...

Page 60: Contacts

About this document contacts 8 p1003639-001 ttp8000 technical manual 2/18/09 contacts technical support via the internet is available 24 hours per day, 365 days per year. Web site: www.Zebra.Com e-mail back technical library: e-mail address: emb@zebra.Com subject line: emaillist self service knowled...

Page 62

Zebra technologies international, llc 333 corporate woods parkway vernon hills, illinois 60061.3109 u.S.A t: +1 847 793 2600 toll-free +1 800 423 0422 f: +1 847 913 8766 zebra technologies europe limited dukes meadow millboard road bourne end buckinghamshire, sl8 5xf, uk t: +44 (0)1628 556000 f: +44...