- DL manuals

- Zehnder Rittling

- Ventilation

- ComfoAir 70

- Operating And Installation Instructions

Zehnder Rittling ComfoAir 70 Operating And Installation Instructions

Summary of ComfoAir 70

Page 1

Comfoair 70 operating and installation instructions for users and installation technicians.

Page 3

3 legal regulations all rights reserved. This manual has been compiled with the utmost care. Nevertheless, the publisher accepts no liability for damage caused by missing or incorrect details in this manual. We reserve the right at any time and without previous notification to change the content of ...

Page 4

4 contents 1 preface 6 1.1 validity 6 1.2 target group and standard operation 6 1.2.1 qualification of target group 6 1.2.1.1 users 6 1.2.1.2 skilled technicians / installers 6 1.2.2 standard operation of the unit 6 2 introduction and safety 7 2.1 proper use 7 2.1.1.1 comfoair 70 ventilation unit 7 ...

Page 5

5 4.2 installation 18 4.2.1 general installation instructions 18 4.2.2 installation preparations 18 4.2.3 connecting the air ducts (for second room connection) 19 4.2.4 installing the ventilation unit 23 4.2.5 electrical connections 26 4.2.5.1 connection for power supply 26 4.2.5.2 connecting the in...

Page 6

6 1 preface 1.1 validity this document applies to: unit type comfoair 70 series the subject of this manual is the comfoair 70 in its various designs variants. Possible accessories are only described to the extent necessary for appropriate operation in the unit. Please refer to the respective instruc...

Page 7

7 2 introduction and safety the comfoair 70 is built in accordance with current technological standards and accepted safety regulations. The unit is subject to continuing improvement and development. And therefore, is it possible for your unit to deviate slightly from the descriptions in this docume...

Page 8

8 2.2.3 symbols used you will find the following symbols in this document: important note! Caution: risk of affecting the operation of the ventilation system or damaging the unit! Caution: risk of personal injury! 2.3 warranty and liability 2.3.1 warranty provisions for full warranty details please ...

Page 9

9 3 instructions for the user and skilled technician / installer 3.2 product description the comfoair 70 is a decentralized or semi-centralized ventilation unit with waste heat recovery for a healthy, well-balanced, energy-saving, and user-friendly ventilation system. The unit can be used in a singl...

Page 10

10 3.1.1 type label the type label identifies the product and can be found underneath the upper canopy on the polypropylene unit core. You will need the details on the type label for the safe use of the product and to provide information for service. The type label must remain attached to the produc...

Page 11

11 3.3 operating functions and signaling from the control panel icon description explanation fan speed operating mode fan speed 1 (ls1) the selection for the current fan speed (4 fan speeds with preset speeds for each fan) is made by using the (-) / (+) buttons. Touching the (+) button increases the...

Page 12

12 icon description explanation auto led lit automatic operating mode (auto) the automatic function can only be activated with a sensor system module. Touching the (+) button from the currently active ls4 transfers the unit to auto fan speed. Auto fan speed is exited by touching the (-) button, and ...

Page 13

13 icon description explanation led1 and the current ls flash alternately exhaust air operating mode touching the (-) button for 5 seconds while in operating modes ls1 to ls4 activates or deactivates the exhaust air operating mode. The supply air fan is switched off; the exhaust air fan continues to...

Page 14

14 icon description explanation led1 and the current ls flash alternately indication of filter inspection the filters are monitored based on running time. 90 days is the factory preset default. After the filter runtime has elapsed, a notification of a filter inspection is signaled by the filter chan...

Page 15

15 3.3.1.2 functional principle of co 2- and voc sensor system modules the co 2 sensor system module and the voc sensor system module are each combined with a humidity/ temperature sensor. Only one sensor module may be installed in the unit. The co 2 sensor system module and the voc sensor system mo...

Page 16

16 3.4.1 replacing the unit filters the comfoair 70 must not be operated without filters. When changing filters, the unit needs to be set to the standby operating mode. The comfoair 70 has two high-quality, merv 8 (class g4) filters that are installed by default. Retrofitting a pollen filter, merv 1...

Page 17

17 5. Ensure that the directional arrow of the filter label is pointing to the center of the unit, and insert the new filter into the filter compartment. Do not use excessive force when inserting the filter. 6. Insert the filter covers so that the filter compartment is sealed. 7. Proceed in the same...

Page 18

18 4 instructions for skilled installers 4.1 installations requirements the following requirements must be met for the correct installation: installation in accordance with the general and locally-applicable safety and installation regulations from, among others, the power authority, and in accordan...

Page 19

19 observe the respective enclosed instructions on professional installation when installing the wall mounting pipe (available separately). Use the mounting template in order to transfer all centerings for the holes onto the inner wall surface. A 110 or 220 vac main power supply connection is requir...

Page 20

20 3. Attach the comfoflex ducting to the rear duct wall adapter and seal with ul 181a rated duct tape. 4. To ensure proper alignment of the rear duct wall adapter to the ca 70 unit, the adapter(s) must be located per the template on page 40. Outer sheathing wall studs 5. Remove the outer male-threa...

Page 21

21 8. With your other hand, engage and thread the outer ring into the adapter until it is seated flush with the surface of the drywall. 9. Using the self-adhesive foam sealing tape provided with the adapter, form a gasket with the tape on the surface of the outer ring. This will provide a seal betwe...

Page 22

22 6. Reaching through the side duct opening that is to be converted to a rear duct connection, carefully push the epp rear duct plug out of the epp body as shown below. 7. Using the duct plug just removed from the rear of the epp body, carefully press into the side opening so that it is sealed. Not...

Page 23

23 the air ducts in a second room connection have an effect on the airflow balance of the ventilation unit. The balance adjustment must be conducted in accordance with the system characteristic curve by a skilled technician. 3.2.4 installing the ventilation unit prior to starting work, ensure that t...

Page 24

24 6. Screw the wall bracket to the inner wall, and take care to ensure that the main power supply line and, if present, the cable for the external control device, are guided through the area of the cable entry point. If the inner wall surfaces are uneven, or it is not vertical, then the wall bracke...

Page 25

25 13. Push the unit into the wall mounting pipe as far as it will go, taking into account the electrical connections. Take care to ensure that the lower side of the epp housing rests on the wall bracket. If necessary, push the upper frame of the wall bracket slightly upwards. In the final mounting ...

Page 26

26 instructions for skilled installers 4.2.5 electrical connections electrical connections are to be completed in accordance with the existing standards specific to the relevant country, and must only be performed by qualified personnel! 4.2.5.1 connection for power supply prior to starting work, en...

Page 27

27 4. Push the connections into the connection box and install the cover. 5. Connect the wires of the low-voltage, secondary-side cable of the power supply to the 24 v x6 terminal on the main control board. The low-voltage, secondary side of the power supply is polarity-dependant color coded power s...

Page 28

28 4.2.5.2 connecting the internal control panel the internal control panel must be connected to the control board using the ribbon cable. 1. First, plug the connector of one end of the cable (in the position shown) into the designated x9 socket on the control board. 2. Plug the connector of the oth...

Page 29

29 2. Press the sensor system module into the recess of the epp housing, bearing in mind the cable routing. 3. Put the upper epp housing section on the lower epp housing. Install the sensor cable at the rear and side in the designated cable recess on the epp housing sections to that the cable ends i...

Page 30

30 4.2.6 configurable operating modes 4.2.6.1 configuration of automatic operating mode the dip switch mode sw1 can be used to configure the automatic operating mode for various functionality. The use of the bathroom function requires the installation of the humidity sensor system module (dip switch...

Page 31

31 2. Place the back cover into the contour of the epp housing unit on the outer wall side. The side air passage louvers on the back cover are directed downwards. 3. Transfer the center points of the slotted holes onto the outside wall surface. The partition between the outdoor air and exhaust air g...

Page 32

32 4.3 maintenance and repair by the skilled technician if regular maintenance work is not carried out on the comfoair 70, this will affect the functionality of the user- friendly ventilation system. It is vital that an esd armband be worn during work on the electrical system, in order to protect th...

Page 33

33 4. Remove the filter cover and the filter from the upper filter compartment. 5. Remove the upper part of the epp housing, pulling in an upward direction. The enthalpy exchanger can now be pulled out of the lower part of the epp housing. 6. Clean the enthalpy exchanger if needed: in doing so, proc...

Page 34

34 4.3.2 replacing the fans to change the fans, the unit must be completely pulled out of the wall. In doing so, proceed as follows: 1. Disconnect the ca 70 from the power supply voltage. 2. Perform steps 2. And 3. As described in 3.3.1. 3. Remove the plug on the ribbon cable from the control panel....

Page 35

35 4.4 visualization of fault notifications the unit control system is equipped with an internal system for recognizing faults. A fault notification is visualized through the flashing of the red “fault led” and a coded failure prediction using led1-4. As a reaction to a fault status, the fans are sh...

Page 36

36 sound data housing emission sound pressure level l p in [db(a)], free-field conditions with 10 ft. (3 m.) clearance fan speed standard 1 adjoining room connection 2 adjoining room connections on the outside fs1 11.0 9.2 2.9 22.3 fs2 23.6 16.3 16.0 35.0 fs3 29.4 24.3 16.2 42.0 fs4 36.4 31.2 22.7 5...

Page 37

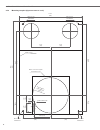

37 4.5.2 dimensions 15” (380mm) 17-5/16” (440mm) 3-1/4” (82mm) 2-3/8” (60mm) 2-3/8” (60mm) 5-11/16” (145mm) 4-1/4” (107mm) 3-15/16” (100mm) 10-13/16” (275mm) 10-13/16” - 23-5/8" (275mm - 600mm) 26” (660mm) 14-13/16” (376mm) 7-7/16” (189mm) outdoor air exhaust air supply air extract air 2" (50mm) 5-1...

Page 38

38 4.5.3 mounting template (figure not true to scale) 17.28” (439) bore hole for wall bracket bore hole for wall bracket 5.39” (137) 5.39” (137) 19.8” (503) 4.41” (112) 7.75” (197) 4.69” (119) 7.75” (197) 5.24” (133) 25.9” (658) 17.87” (454) 2.76” (70) 2.0” (51) 1.57” (40) 0.59” (15) bore hole for w...

Page 39

39 4.5.4 wiring schematic terminal diagram ca 70 premium 1 stand 11.05.17 version premium 1 intake air t1 / isolating flap 1 / fan 1 supply air exhaust air fan 2 / isolating flap 2 extract air sensor phi / voc phi / co2 dip-switch sw1 switch no. Function factory setting 1 voc / co2 sensor active on ...

Page 40

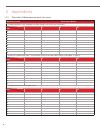

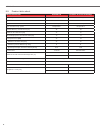

40 5 appendices 5.1 checklist a maintenance work for users maintenance work enter date in quarter 1. Change both filters in the ventilation unit (filter change cycle at least every 6 months) i ii iii iv 20... 20... 20... 20... 20... 20... 20... 20... 20... 20... 2. Exhaust air supplementary filter /...

Page 41

41 5.2 checklist b maintenance work for skilled technicians maintenance work enter result the listed maintenance work must be carried out in accordance with the components actually available. Comments on status using informal protocol no. Components annually result 20____ 20____ 20____ 20____ 20____...

Page 42

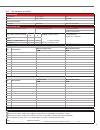

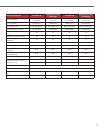

42 5.3 commissioning and turnover protocol customer data last name: first name: tel.: street: city / state: zip code: construction project: unit type: serial no.: year of construction: completeness no. Components description result 1 supply air duct (if accessible) installed as planned cleaning inst...

Page 43

43 5.4 air volume protocol customer data last name: first name: tel.: street: city / state: zip code: construction project: unit type: serial no.: year of construction: measurement data meausuring instrument used: faults during operation: indoor temperature: outdoor temperature: filter status when m...

Page 44

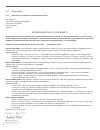

44 5.5 product data sheet model identification comfoair 70 comfoair 70 sensor technology unit configuration unit only unit only type of ventilator bi-directional bi-directional type of drive motor ecm, multi-speed ecm, variable speed type of heat recovery system recuperation recuperation thermal eff...

Page 45

45 model identification comfoair 70 comfoair 70 sensor technology comfoair 70 comfoair 70 sensor technology unit configuration 1 remote room connection 1 remote room connection 2 remote room connections 2 remote room connections type of ventilator bi-directional bi-directional bi-directional bi-dire...

Page 46: 35 Cfm

46 5.6 product label produced for the comfoair 70 are product labels of various energy efficiency labels in accordance with the energy related products directive 2009/125/ec, depending on the application of the unit. The product label applicable for the ventilation system is based on the installatio...

Page 47: 30 Cfm

47 1 room installation 30 cfm 30 cfm 2 room installation.

Page 48

48 5.7 conformity 5.7.1 declaration of conformity of the european union manufacturer: paul wärmerückgewinnung gmbh august-horsch-straße 7 08141 reinsdorf germany eu declaration of conformity we hereby declare that the product/series named in the following, by virtue of its conception and design, as ...

Page 49

49 5.7.2 eac certificate of the eurasian economic union manufacturer: paul wärmerückgewinnung gmbh august-horsch-straße 7 08141 reinsdorf germany eac certificate we hereby declare that the product/series named in the following, by virtue of its conception and design, as well as in terms of the confi...

Page 50

Zehnder north america · 6 merrill industrial dr., suite 7 · hampton, nh 03842 · usa t 603-601-8544 · info@zehnderamerica.Com · www.Zehnderamerica.Com © zehnder north america, v ersion 1.8 september 2017, english, subject to change without notice.