- DL manuals

- Zehnder Rittling

- Fan

- ComfoAir Q

- Installer Manual

Zehnder Rittling ComfoAir Q Installer Manual

Summary of ComfoAir Q

Page 1

Cooling fresh air clean air heating ventilation system zehnder comfoair q installer manual.

Page 2

2 - en foreword read this document carefully before use. With this document you can install, commission and perform the maintenance of the comfoair q in a safe and optimal manner. In this document the comfoair q will be referred to as “the unit”. The unit is subject to continuous development and imp...

Page 3

2 - en en - 3 table of contents foreword ...................................................................................................................................................................... 2 1 safety instructions .......................................................................

Page 4

4 - en 8 maintenance procedures ............................................................................................................................................. 24 8.1 procedure for opening the unit ...........................................................................................

Page 5

4 - en en - 5 1 safety instructions always obey the safety regulations, warnings, comments and instructions given in this document. When the safety regulations, warnings, comments and instructions in this document are not obeyed personal injury or damage to the unit can occur; always obey the ge...

Page 6

6 - en 4 technical specifications q 350 q 450 q 600 performance maximal airflow 350m3/h 450m3/h 600m3/h thermal yield1 92% 90% 89% electrical data maximal power2 including pre-heater 1850w 10.00a 2240w 10.80a 2620w 12.70a maximal power2 excluding pre-heater 180w 1.42a 250w 1.98a 350w 2.77a power sup...

Page 7

6 - en en - 7 4.2 comfoair q 450 1 2 3 5 6 8 9 10 11 0.7 0.9 1.1 1.3 40 43 46 49 52 4 7 0 50 100 150 200 250 0 50 100 150 200 250 300 350 400 450 pst (pa ) qv (m³/h) comfoair q450 gb st sfp (w/l/s) lw (db[a]) qv m³/h pst pa p w cos φ - sfp wh/l/s lw, supply db(a) lw, extract db(a) lw, casing db(a) 1...

Page 8

8 - en 4.4 unit configuration n i a h b b m d n c e c l f g j position part a semi-transparent visor for access to the display and the filter caps. B 2 filter caps for easy access to the filters. C 2 filters for air purification. D cable tray cover for cover and protection of the connected cables. E...

Page 9

8 - en en - 9 4.5 dimension sketch 850 40 160 190 570 123 280,5 725 490 10/25 235 265 250 100 100 850 40 180 200 570 123 280,5 725 490 10/25 235 265 250 100 100 comfoair q 350 comfoair q 450 / comfoair q 600

Page 10

10 - en 4.6 service parts the service parts mentioned below can be ordered as a special service set from zehnder. Each set will be supplied with its own service instruction explaining how to replace the part. Please check the pricelist of the supplier for the article codes and prices of all availabl...

Page 11

10 - en en - 11 4.7 wiring diagram main board legend: meaning code meaning code orientation: right orientation: left pe green / yellow display display screen display screen n / bu blue rf not applicable not applicable l / bk brown or black vv pre-heater pre-heater wh white byp modulating by-pass act...

Page 12

12 - en 4.8 wiring diagram option box (optional) technical specifications code meaning interface umax imax lmax-wiring 1 bathroom switch digital 3.3vdc 1ma 30m 2 external filter error sensor digital 3.3vdc 1ma 30m 3 standby switch digital 3.3vdc 1ma 30m 4a not applicable analog 3.3vdc 1ma 30m 4b not...

Page 13

12 - en en - 13 5 installation procedures 5.1 installation on the wall ≥250mm ≥1065mm 635mm 1 2 1 2 install the unit against a wall with a minimum mass of 200 kg/m2. The given height is an indication. The selected type of condensation drain and air ducts will determine the exact height. Attach the m...

Page 14

14 - en 5.2 installation on the floor 1100 mm 250 mm 1 example of instruction 2 use a zehnder mounting frame on the floor (available as an optional extra) for walls with a mass of less than 200 kg/m2. This will reduce contact noise as much as possible. Install the mounting frame as instructed in its...

Page 15

14 - en en - 15 5.3 installation of the condensation drain r min 90mm 1 1/4“ 32mm l min 90mm 1 1/4“ 32mm erv the condensation created by the unit must be drained off frost-free, at a gradient and incorporate an air seal. To drain the condensation from the unit, two zehnder bayonet connections are lo...

Page 16

16 - en 5.5 installation of the air ducts air duct systems zehnder comfopipe (plus) zehnder comfowell zehnder comfoflat zehnder comfotube flexalen spiro pipe the unit can be installed with any standard non flexible air duct system or with a special zehnder air duct system. When installing a zehnder ...

Page 17

16 - en en - 17 5.6 installation of the valves and/or grilles example valve example grille install supply and extract valves and/or supply and extract grilles (e.G. In an open living kitchen) at least 1m from each other. This will prevent the supply air short circuiting with the extract air; use...

Page 18

18 - en 6 commissioning procedures zehnder recommends cleaning the air ducts before commissioning the unit when the dwelling is being occupied. This will prevent damage to the furniture from building dust blown out of the air ducts. 1 2 3 connect the power to the unit. Open the semi-transparent viso...

Page 19

18 - en en - 19 7 operation 7.1 overview of the display auto sensor shift menu tu 14:02 a b c e d position part a status indicator led light. B universal button. The function depends on the current text on the display. C up button to: increase fan speed; increase value; select the previous ite...

Page 20

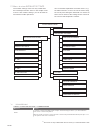

20 - en 7.3 menu structure installer settings 7.3.1 commissioning > menu > installer settings > commissioning menu item function start to start the commissioning wizard. In the chapter “commissioning procedures” you can find attention points for the commissioning wizard. When the unit has never been...

Page 21

20 - en en - 21 7.3.2 main board settings > menu > installer settings > main board settings menu item function ventilation presets to set the airflow of the position switch. preset a: set the airflow of the absent position (default comfoair q 350: 20 l/s) (default comfoair q 450: 20 l/s) (default ...

Page 22

22 - en 7.3.3 option box settings3 > menu > installer settings > option box settings3 menu item function switch-on delay to set the time (delay timer) before the air volume will switch to preset 3 after closing the bathroom switch contact. (default: 5 min) if the bathroom switch is stopped within th...

Page 23

22 - en en - 23 menu item function 0-10v 43 to set the control options of the fourth 0-10v input. Input at 0% to set the required input signal to get 0% output signal from the unit; (default: 0v) if positive control is necessary the input at 0% must be lower than the input at 100%: if negative contr...

Page 24

24 - en 8 maintenance procedures follow all maintenance procedures given in this chapter and in the user manual. If the maintenance is not performed periodically the performance of the ventilation system will ultimately be compromised. In this chapter you can find a separate subchapter for each main...

Page 25

24 - en en - 25 8.2 maintenance of the casing inspect the unit casing at least once every 4 years. 1 2 3 remove the front cover as instructed in the chapter procedure for opening the unit: open the semi-transparent visor; change the unit to service mode; disconnect the power to the unit; rem...

Page 26

26 - en 8.4 maintenance of the fans inspect the fans at least once every 4 years. 1 2 3 remove the heat exchanger as instructed in the maintenance instruction of the heat exchanger: open the semi-transparent visor; change the unit to service mode; disconnect the power to the unit; remove the...

Page 27

26 - en en - 27 8.5 maintenance of the modulating by-pass valves inspect the modulating by-pass valves at least once every 4 years. 1 2 3 remove the heat exchanger as instructed in the maintenance instruction of the heat exchanger: open the semi-transparent visor; change the unit to service mode...

Page 28

28 - en 8.7 maintenance of the condensation drain inspect the condensation drain at least once every 4 years. 1 example siphon 2 example siphon 3 disconnect the condensation drain. Perform the next checks on the condensation drain siphon: check whether the drain is still open by adding water to th...

Page 29

28 - en en - 29 8.9 procedure for ending the maintenance 1 during installation: set the unit in service mode when the modulating by-pass valves are blocking the installation of the heat exchanger; tighten all screws manually (max. 1.5 nm); place all cables in their guiding channels; place th...

Page 30

30 - en 9. Malfunction procedures always disconnect the power supply of the unit before you start working on the unit. The unit can cause personal injury when it is open while running. Make sure the unit cannot switch back on by accident. Always take esd-inhibiting measures when dealing with electro...

Page 31

30 - en en - 31 9.3 how to gain access to the main power fuse of the unit 1 2 3 open the semi-transparent visor. Pull the cable tray cover forwards. Remove the 6 screws of the cable tray. Carefully lift up the cable tray. 9.4 how to change the location of the pre-heater 1 2 3 open the semi-transpare...

Page 32

32 - en 9.5 how to gain access to the top-section sensor 1 2 3 remove the heat exchanger as instructed in the maintenance instruction of the heat exchanger: open the semi-transparent visor; change the unit to service mode; disconnect the power to the unit; remove the 3 screws of the front co...

Page 33

32 - en en - 33 9.7 how to gain access to the mid-section sensor 1 1 2 2 3 remove the modulating by-pass valve as instructed in its relevant chapter: open the semi-transparent visor; change the unit to service mode; disconnect the power to the unit; remove the 3 screws of the front cover; ...

Page 34

34 - en 9.8 malfunction alerts on the display of the unit auto sensor shift menu tu 14:02 when there is a malfunction in the unit the led next to the display of the unit will flash. When accessing the display the corresponding malfunction code will be displayed. Code meaning airflow_eha error the ex...

Page 35

34 - en en - 35 9.9 malfunction alerts on the comfosense c when a malfunction code appears on the comfosense c the corresponding malfunction code will also appear on the display of the unit. 9.10 malfunction alerts on the comfoswitch c you can find a filter led on the comfoswitch c. When it is neces...

Page 36

36 - en 9.14 what to do in the event of a malfunction alert (troubleshooting) malfunction code airflow_eha error / airflow_sup error. The exhaust / supply airflow is not reaching its set point. Question answer action 1 is one or more of the valves and/or grilles blocked? Yes 1. Set the valves and/or...

Page 37

36 - en en - 37 malfunction code fan_eha error / fan_sup error. The exhaust / supply air fan has a malfunction. Question answer action 1 not applicable not applicable 1. Disconnect the power from the unit. 2. Access the control pcb as instructed in the chapter “how to gain access to the control pcb”...

Page 38

38 - en malfunction code humid_eta error / humid_oda error the extract / outdoor air humidity sensor is detecting an incorrect humidity. Question answer action 1 is the humidity protection on?5 yes 1. Increase the ventilation to maximum. 2. Reset the errors as instructed in the chapter “how to reset...

Page 39

38 - en en - 39 malfunction code option_box connect error. No communication between the option box and the unit. Question answer action 1 not applicable not applicable 1. Access the comfonet connectors as instructed in the chapter “how to gain access to the comfonet connectors on the unit”. 2. Go to...

Page 40

40 - en malfunction code gound_heat_temp error / postheat_temp error the temperature sensor of the comfofond-l q / post-heater is detecting an incorrect temperature. Question answer action 1 is the temperature in the comfofond-l q / comfohood / post-heater between -40°c and +70°c. Yes 1. Solve the p...

Page 41

40 - en en - 41 malfunction code preheat_pres error. There is no communication between the pre-heater and the unit. Question answer action 1 not applicable not applicable 1. Disconnect the power from the unit. 2. Access the control pcb as instructed in the chapter “how to gain access to the control ...

Page 42

42 - en malfunction code sensor_eta error / sensor_oda error. The extract / outdoor air sensor has a malfunction. Question answer action 1 not applicable not applicable 1. Disconnect the power from the unit. 2. Access the control pcb as instructed in the chapter “how to gain access to the control pc...

Page 43

42 - en en - 43 malfunction code sensor_eha error / sensor_sup error. The exhaust / supply air sensor has a malfunction. Question answer action 1 not applicable not applicable 1. Disconnect the power from the unit. 2. Access the control pcb as instructed in the chapter “how to gain access to the con...

Page 44

44 - en malfunction code tempcontrol_sup error the modulating by-pass actuators have a malfunction. Question answer action 1 not applicable not applicable 1. Inspect the modulating by-pass valves as instructed in the chapter “maintenance of the modulating by-pass valves”. 2. Remove the modulating by...

Page 45

44 - en en - 45 9.15 what to do in the event of a malfunction (or problem) without a malfunction alert (troubleshooting) problem: the display and fans of the unit are off. Question answer action 1 is the mains power connected? Yes 1. Open the semi-transparent visor. 2. Pull the cable tray cover forw...

Page 46

46 - en problem: there is too much noise. Question answer action 1 is the noise a whistling noise? Yes locate the air gap and seal it. No go to the next question. 2 is the noise a slurping noise? Yes 1. Check the condensation drain. 2. Go to the next question. No go to question 4. 3 has the condensa...

Page 47

46 - en en - 47 10 available operating devices appearance example name remark zehnder comfosense c 67 you can connect the comfosence c directly to the unit via a comfonet connection. Zehnder comfoswitch c 67 you can connect the comfoswitch c directly to the unit via a comfonet connection. Zehnder co...

Page 48

48 - en 11 optional ancillaries appearance example name remark zehnder comfofond-l q a connected option box is necessary to control the comfofond-l q. Zehnder comfocool q600 you can connect the comfocool q600 directly to the unit via a comfonet connection. Zehnder comfoair q pre-heater you can insta...

Page 49

48 - en.

Page 52

Quic k ins tal lat ion g uid e ple ase r efe r to t he f ull i nst alla tio n ma nu al f or d eta ile d in sta lla tion and comm issi oning in fo rm ati on. Leg en d: cod e mea nin g r su pp ly a nd e xtr ac t air t o th e rig ht s id e l su pp ly a nd e xtr ac t air t o th e le ft s id e erv en tha...