- DL manuals

- 3D Hobby Shop

- Toy

- 33” Extra 330 SC

- Assembly Manual

3D Hobby Shop 33” Extra 330 SC Assembly Manual

Note: For tips, tricks, and important building techniques, please refer to our Build Videos located on the 3D Hobby Shop Website.

The videos are located on the 33” Extra 330 SC product page in the ‘Foamies’ Category.

www.3dhobbyshop.com

3D Hobby Shop

603 FM 2093

STE 1303

Fredericksburg, TX 78624

Ph: (830) 990-6978

33” Extra 330 SC

33” Extra 330 SC

Assembly Guide

Photo by: Eric Runfeldt (PrkFlyrRic)

Photo by: Eric Runfeldt (PrkFlyrRic)

Summary of 33” Extra 330 SC

Page 1

Note: for tips, tricks, and important building techniques, please refer to our build videos located on the 3d hobby shop website. The videos are located on the 33” extra 330 sc product page in the ‘foamies’ category. Www.3dhobbyshop.Com 3d hobby shop 603 fm 2093 ste 1303 fredericksburg, tx 78624 ph:...

Page 2

Intro introduction thank you for purchasing this 3dhobbyshop foam rc aircraft kit. If you have any issues, questions, concerns or problems during assembly, please contact our technical support department online at: www.3dhobbyshop.Com or 1-830-990-6978 10am-5pm central m-f we highly recommend visiti...

Page 3

Intro assembly instructions read completely before starting assembly! Unpack your airplane and examine the components. Check for damage of any kind. If you have damage, please contact 3dhobbyshop to discuss. Please also verify at this time that you also have all of the parts in the kit components se...

Page 4

Step a hinging is one of the most important parts of assembly on an epp foamy, so it is very important to perform this step correctly. If performed incorrectly, your control surfaces may bind and not deflect properly. You will be using welders adhesive to hinge all of the control surfaces on your ai...

Page 5

Step a spread the glue out with a used hobby-blade. Step a-03: hinging - creating the elevator hinge repeat steps a-01 through a-03 for both ailerons as shown step a-04: hinging - aileron hinging.

Page 6

Step a repeat steps a-01 through a-03 for the top half of the rudder only you will hinge the bottom half of the rudder during a later part of the assembly. Step a-05: hinging - rudder hinging (top half) once satisfied, let the elevator, ailerons, and rudder hinges sit for approximately 1-2 hours to ...

Page 7

Step b your horizontal fuselage should now be in 3 pieces (the nose piece, a complete wing, and a rear horizontal fuselage with elevator). Using welders adhesive, glue these three pieces together. Apply a bead of welders adhesive to the rear of the horizontal nose where it meets the front of the win...

Page 8

Step b the wing spar is installed on the bottom of the horizontal fuselage into a pre-cut slot. Start by removing the excess foam from the wing spar slot, and test fit the wing spar in place. Rough up the sides of the carbon spars with a some sand paper or a sanding stick. Then, apply a bead of weld...

Page 9

Step c now, you will attach the lower half of the vertical fuselage to the horizontal fuselage. Apply a bead of welders adhesive to the lower vertical fuselage where it meets the horizontal fuselage, and temporarily install. Remove the vertical fuselage and let the welders adhesive set-up on both si...

Page 10

Step c on the bottom of the horizontal fuselage and on the sides of the vertical fuselage, you will see some small dots along the edges. These small dots are where your carbon braces will attach. Set your fuselage upside down on a flat surface, and start by attaching the two 5” rods from the tips of...

Page 11

Step d start by removing the aileron control horn from the supplied ply-wood hardware kit, and find the slot in the ailerons where the control horns will be installed. Control horns are installed in a similar fashion to the wing spar. Apply a bead of welders adhesive to each side of the bottom of th...

Page 12

Step d apply a generous amount of welders adhesive to the sides and bottom of the aileron servo, and slide it into the pre-cut slot in the top of the horizontal fuselage. Step d-03: servo installation - ailerons using side-cutters, cut a 1.0” piece of piano wire off of the long piece of piano wire i...

Page 13

Step d tape the ailerons to the horizontal fuselage so that they are parallel to the horizontal fuselage. Cut a v-shape out of a piece of scrap ply-wood or card-stock. This piece will be used to protect the foamy in the next step. Step d-05: servo installation - control rods cut two pieces of heat s...

Page 14

Step d center the servo, and verify again that the aileron is parallel to the horizontal fuselage, and then slide the v-shaped protector that you made earlier around the control horn and use a heat gun or lighter to shrink the heat-shrink tubing around the carbon rod and z-bend on both ends. Repeat ...

Page 15

Step d repeat step c-01 to install the top of the vertical fuselage onto the horizontal fuselage. Once installed, ensure the elevator is still able to achieve 45degrees of throw. If it cannot, trim any excess foam necessary to achieve maximum throw. Step d-09: top vertical fuselage installation repe...

Page 16

Step d repeat step c-01 to install the foam part of the motor mount onto the fuselage. Glue should be applied everywhere that the foam motor mount will touch the horizontal and vertical fuselages. Step d-11: top vertical fuselage installation - motor mount this step is optional. If you are installin...

Page 17

Step e to install any bolt-on motor, simply install the x-mount to the back of your motor, center it on the ply-wood motor mount installed in step d-10, and screw in place with small wood screws. To install the recommended hacker a10-9l, first install the phenolic x-mount to the motor. Then, using w...

Page 18

Step e repeat step d-02 to install one of the single-side servo arms onto the elevator servo. Step e-03: electronics installation - elevator servo repeat steps d-03 through d-08 to install the elevator servo and elevator servo pushrod and z-bends. Step e-04: electronics installation - elevator servo.

Page 19

Step e repeat step d-01 to install a long control horn into the left side of the rudder. This is the side opposite of the carbon bracing. Step e-05: electronics installation - rudder servo repeat steps d-02 through d-08 to install the rudder servo and rudder servo pushrod and z-bends. Step e-06: ele...

Page 20

Step e using either bullet connectors or direct-soldering, connect the speed controller to the motor and adhere the speed controller to the fuselage with welders adhesive. Step e-07: electronics installation - speed controller adhere your receiver to the side of the fuselage using welders adhesive. ...

Page 21

Setup congratulations! You have finished assembly of your 33” extra 330 sc. Now it’s time for setup. At this time, you can setup your control throws, exponential and center of gravity. Please refer to the recommended setup sheet at the end of the manual for our setup recommendation. Once you have de...

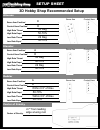

Page 22

Setup sheet 3d hobby shop recommended setup servo arm position : . Control horn position : . High rate throw : . High rate expo : . Low rate throw : . Low rate expo : . Servo arm position : . Control horn position : . High rate throw : . High rate expo : . Low rate throw : . Low rate expo : . Servo ...