- DL manuals

- 3M

- Glue Gun

- Scotch-Weld Hot Melt Applicator EC

- Owner's Manual

3M Scotch-Weld Hot Melt Applicator EC Owner's Manual

3

Scotch-Weld

™

Hot Melt Applicator EC

Aplicador EC por Fusión en Caliente

Scotch-Weld

™

Applicateur d’adhésif thermo-fusible EC

de Scotch-Weld

™

Adhesive Applicator

Aplicador de adhesivo

Applicateur d’adhésif

Owner’s Manual

Manual del propietario

Manuel de l’utilisateur

Utilice el aplicador con los Adhesivos por Fusión en Caliente Scotch-Weld™ de

3M™ en cartuchos Quadrack™.

Use with 3M™ Scotch-Weld™ Hot Melt Adhesives in Quadrack™ cartridge form.

Utilisez avec l’adhésif thermo-fusible 3M™ Scotch-Weld™ sous forme de cartouche

Quadrack™.

Summary of Scotch-Weld Hot Melt Applicator EC

Page 1

3 scotch-weld ™ hot melt applicator ec aplicador ec por fusión en caliente scotch-weld ™ applicateur d’adhésif thermo-fusible ec de scotch-weld ™ adhesive applicator aplicador de adhesivo applicateur d’adhésif owner’s manual manual del propietario manuel de l’utilisateur utilice el aplicador con los...

Page 2: Table of Contents

Important safety instructions..........................................................................1 grounding instructions ...................................................................................2 unpacking ................................................................................

Page 3: Warning

! ! ! ! Important safety instructions © 3m 2006 1 • save these instructions • read all instructions before using this product 3m™ scotch-weld™ hot melt applicator ec operation and servicing warning to reduce the risk of electrical shock or injury while operating or servicing the 3m scotch-weld hot m...

Page 4: Grounding Instructions

© 3m 2006 2 grounding instructions the 3m ™ scotch-weld ™ hot melt applicator ec must be grounded. If the applicator malfunctions, grounding provides a path of least resistance for electric current to help reduce the risk of electrical shock. This applicator is equipped with a cord having an equipme...

Page 5: Unpacking

© 3m 2006 3 unpacking remove the applicator and temperature modules (attached to the applicator) from their shipping container and inspect for obvious damage. If damaged, do not use and immediately contact your 3m sales representative or your authorized 3m distributor. Features • industrial-grade, a...

Page 6: Caution

© 3m 2006 4 temperature module installation caution use only the proper temperature module for the 3m™ quadrack™ adhesive used. Failure to do so may cause burns or damage applicator. Refer to table 1 for proper module selection for 3m quadrack adhesive used. Important: the 3m™ scotch-weld™ hot melt ...

Page 7: Applicator Startup

Applicator startup © 3m 2006 5 caution use only the proper temperature module for the 3m™ quadrack™ adhesive used. Failure to do so may cause burns or damage applicator. Refer to table 1 in the temperature module installation section for proper module selection for 3m quadrack adhesive used. Caution...

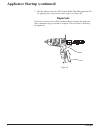

Page 8: Applicator Startup

Applicator startup (continued) caution do not pull adhesive sticks from the rear of the applicator while in operation. Removing adhesive from the rear may cause molten adhesive flow out the rear of the applicator which may cause burns and damage the applicator. 5. Insert 3m scotch-weld hot melt quad...

Page 9: Important:

© 3m 2006 7 applicator startup (continued) 7. Extrude adhesive from the 3m™ scotch-weld™ hot melt applicator ec by applying firm, even pressure to the trigger (see figure e). Important: do not use excessive force while extruding adhesive through the applicator. Slow, continuous trigger actuation is ...

Page 10: Caution

Adjusting trigger stroke and shot size caution avoid contact with hot adhesive and the applicator tip. May cause burns. Wear safety glasses when using. Caution do not pull adhesive stick from the rear of the applicator while in operations. Removing adhesive from the rear may cause molten adhesive to...

Page 11: Caution

© 3m 2006 9 adjusting trigger stroke and shot size (continued) caution avoid contact with hot adhesive and the applicator tip. May cause burns. Wear safety glasses when using. 4. Snap the stroke adjuster into a new position on the entry track (see figure h). • for a shorter stroke or smaller shot si...

Page 12: Caution

Changing to another 3m™ adhesive requiring a different temperature module caution use only the proper temperature module for the 3m quadrack adhesive used. Failure to do so may cause burns or damage applicator. Refer to table 1 in the temperature module installation section for proper module selecti...

Page 13: Important:

© 3m 2006 11 ! Changing to another 3m™ adhesive requiring a different temperature module (continued) install the proper temperature module for the adhesive that has been selected by inserting and tightening the fastener until snug (see figure l). Refer to table 1 on page 4 or the chart on pages 29-3...

Page 14: Shutdown

! Shutdown 1. Turn the applicator off by pressing the rocker switch at the rear of the handle. The red visor on the rocker switch disappears, indicating the applicator is off (see figure m). 2. Immediately, extrude approximately half of a quadrack adhesive stick through the applicator. Important: fo...

Page 15: Preventive Maintenance

© 3m 2006 13 ! Preventive maintenance 1. Inspect the nozzle tip every day before startup. Use a scotch-brite ® pad or equivalent to remove accumulated adhesive or foreign matter from the tip 2. Inspect the adhesive entry track and transport mechanism daily to ensure it is clear of foreign matter and...

Page 16: Avoid:

Operator productivity and comfort avoid: • raised elbow • bent wrist • reaching • bending over these positions can result in irritation of the nerves, muscles, tendons, and cartilage of the shoulder, elbow, wrist, hand and back. Adjust your workstation so you can: • stand or sit erect • keep your el...

Page 17: Troubleshooting

© 3m 2006 15 ! Troubleshooting this part of the owner’s manual is divided into three sections to assist in evaluating possible operating difficulties with your 3m™ scotch-weld™ hot melt applicator ec. If the applicator will not heat, refer to: condition 1: applicator will not heat page 16 if the app...

Page 18: Troubleshooting (Continued)

Troubleshooting (continued) condition 1: applicator will not heat important: troubleshooting steps should be conducted only by a qualified electrician or service person. 1. Turn the applicator on by pushing the on/off switch to the “on” position, indicated by the visible red visor of the switch (see...

Page 19: Troubleshooting (Continued)

© 3m 2006 17 ! Troubleshooting (continued) condition 1: applicator will not heat 3. Check to make sure that power cord is plugged in and that the electrical outlet has power. If there is no power, contact an electrician. If outlet has correct power, proceed to the next step. 4. Disconnect the power ...

Page 20: Troubleshooting (Continued)

Troubleshooting (continued) condition 1: applicator will not heat ho tm elt a pp lic ato re c 3 sc otc h-w eld ™ 9. To remove the trigger (see figure q): a. Use a small screwdriver to remove the e-ring from the pin at the base of the trigger. B. Remove the trigger pin. C. Remove the trigger and spri...

Page 21: Troubleshooting (Continued)

© 3m 2006 19 ! Troubleshooting (continued) condition 1: applicator will not heat 12. Inspect all terminal block connections for loose or disconnected wires by making certain the screws in each terminal block are securing the wires. If any connections are loose or have pulled out of the terminal bloc...

Page 22: Troubleshooting (Continued)

Troubleshooting (continued) condition 1: applicator will not heat important: applicator must be cooled to room temperature for step 14. 14. Check continuity of the thermistor. First, disconnect the thermistor lead from terminal number 1 of the upper terminal block (tb2) (see figure s). Using an ohmm...

Page 23: Troubleshooting (Continued)

© 3m 2006 21 troubleshooting (continued) condition 1: applicator will not heat b. Using the ohmmeter, check for continuity between terminal number 2 (white wire from cord) on the lower terminal block tb1 and the ac neutral terminal on the applicator plug (see figures t and u). If the measurements in...

Page 24: Troubleshooting (Continued)

! Troubleshooting (continued) condition 2: dripping nozzle caution avoid contact with hot adhesive and the applicator tip. May cause burns. Wear safety glasses when using. Warning do not pull adhesive stick from the rear of the applicator while in operation. Removing adhesive from the rear may cause...

Page 25: Troubleshooting (Continued)

© 3m 2006 23 troubleshooting (continued) condition 2: dripping nozzle f. Immediately (before the applicator cools), use a blunt object to gently push the adhesive stick approximately one inch into the applicator so the white sleeve is empty (see figure v). Allow the applicator to cool to room temper...

Page 26: Troubleshooting (Continued)

! Troubleshooting (continued) condition 3: low or no adhesive flow caution use only the proper temperature module for the 3m™ quadrack™ adhesive used. Failure to do so may cause burns or damage applicator. Refer to table 1 in the temperature module installation section for proper module selection fo...

Page 27: Troubleshooting (Continued)

© 3m 2006 25 troubleshooting (continued) condition 3: low or no adhesive flow 5. If the transport mechanism does not move freely on the track or if the arms of the mechanism do not open and close freely, clean the transport mechanism (steps 5a-5d). A. Extrude the remaining adhesive from the entry tr...

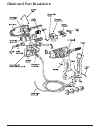

Page 28: Illustrated Part Breakdown

Illustrated part breakdown © 3m 2006 26.

Page 29: Ec Parts Kits

© 3m 2006 27 3m™ scotch-weld™ hot melt applicator ec parts kits each parts kit is shipped with illustrated instructions 3m stock number description contents 62-9680-9733-7 thermistor kit trigger pin e-ring thermistor assy heat block inserts (1 set) handle screws (6) spring end clip 62-9680-9730-3 he...

Page 30: Accessories

Accessories 3m stock number description 62-9921-0066-9 .090 inch fluted tip 62-9922-0066-7 .063-inch fluted tip 62-9940-6920-1 .125-inch fluted tip 62-9946-6980-2 .072-inch brass extension 62-9725-9930-2 mini-extension tip, .072-inch opening 62-9726-9930-0 “t” tip w/adapter 62-9727-9930-8 “l” tip w/...

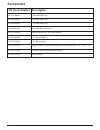

Page 31

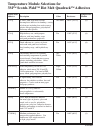

© 3m 2006 29 temperature module selections for 3m™ scotch-weld™ hot melt quadrack™ adhesives scotch-weld temperature adhesive description color resistance module 3731 q a 100% solid, high heat resistant off-white 265°f (129°c) (5) thermoplastic adhesive for bonding a variety of substrates including ...

Page 32: Important Notice

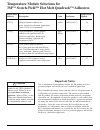

Temperature module selections for 3m™ scotch-weld™ hot melt quadrack™ adhesives scotch-weld temperature adhesive description color resistance module 3779 q high performance adhesive for amber 300°f (149°c) (5) many electrical or electronic applications. Meets ul 94 v-o requirements. 3789 q high perf...

Page 33: Warranty and Repair

© 3m 2006 31 warranty and repair during warranty period contact your nearest 3m sales branch or authorized 3m™ scotch-weld™ hot melt adhesive distributor. After warranty period the 3m™ scotch-weld™ hot melt applicator ec has been engineered to be durable and reliable. Recognizing that it will eventu...