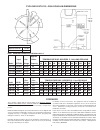

1 a division of a.O. Smith corporation mc bee, south carolina place these instructions adjacent to heater and notify owner to keep for future reference. Printed in u.S.A. 0307 part no. 197727-000 cyclone xi model bth 120-250(a) series 100 and 101 commercial gas water heater gas-fired power burner fo...

2 these designs comply with the current edition of the american national standard for gas water heaters, volume iii, ansi z21.10.3 / csa 4.3 as an automatic circulating tank water heater, and automatic storage water heaters. Detailed installation diagrams are found in this manual. These diagrams wil...

3 danger this water heater is equipped with an adjustable thermostat to control water temperature. Hot water temperatures required for automatic dishwasher and laundry use can cause scald burns resulting in serious personal injury and/ or death. The temperature at which injury occurs varies with the...

4 water temperature be set for the lowest temperature which satisfies your hot water needs. This will also provide the most energy efficient operation of the water heater and minimize scale formation. Setting the water heater temperature at 120°f/49°c will reduce the risk of scalds. Some states requ...

5 locating the heater warning there is a risk in using fuel burning appliances such as gas water heaters in rooms, garages or other areas where gasoline, other flammable liquids or engine driven equipment or vehicles are stored, operated or repaired. Flammable vapors are heavy and travel along the f...

6 if the confined space is within a building of tight construction, air for combustion and ventilation must be obtained from outdoors. When directly communicating with the outdoors through vertical ducts, two permanent openings, located in the above manner, shall be provided. Each opening shall have...

7 for all side wall terminated, horizontally vented power vent, direct vent, and power direct vent gas fueled water heaters installed in every dwelling, building or structure used in whole or in part for residential purposes, including those owned or operated by the commonwealth and where the side w...

8 figure 5a. U.S. Power vent canadian power vent figure 5b. Caution to prevent exhausting products from circulating to the air intake in windy/cold areas, the maximum practical distance between these two terminals is recommended..

9 figure 6a. U.S. Direct vent canadian direct vent figure 6b. Caution to prevent exhausting products from circulating to the air intake in windy/cold areas, the maximum practical distance between these two terminals is recommended..

10 important the vent system must terminate so that proper clearances are maintained as cited in local codes or the current editions of the national fuel gas code, ansi z223.1/nfpa 54 or the natural gas and propane installation code, can/csa-b149.1. Do not terminate the exhaust vent terminal over pu...

11 5. Glue the intake vent terminal to the section of the pipe. 6. Slide the wall plate over the pipe to stop against intake vent terminal. 7. Place a bead of caulking (not supplied) around the gap between the pipe and the wall. Place some of the caulking on the back of the plate to hold it against ...

12 note: for water heaters in locations with high ambient temperatures (above 100°f or 38°c) and/or insufficient dilution air, it is recommended that cpvc or abs pipe and fittings (must use supplied vent terminal) be used. 4. It is important that condensate not be allowed to buildup in the exhaust v...

13 low gas pressure switch (see figure 12) the low gas switch (lgs) is a single-pole, normally open pressure switch that will close its contacts when a rising pressure of 5.0 in. (1.25kpa) w.C. Is encountered. The contacts will open when the pressure falls below the fixed set point of 4.8"wc (1.18kp...

14 warning the heater is not intended for operation at higher than 10.5" (2.59 kpa) water column supply gas pressure. Higher gas supply pressures require supplemental reducing service regulation. Exposure to higher gas supply pressure may cause damage to the gas controls which could result in fire o...

15 disconnect the appliance and its manual gas shutoff valve from the gas supply piping system during any supply pressure testing exceeding 1/2 psig (3.45kpa). Gas supply line must be capped when disconnected from the heater. For test pressures of 1/2 psig (3.45kpa) or less, the appliance need not b...

16 conditioner must be installed if the above conditions exist. Malfunctions caused by a poor electrical supply are not covered under your warranty. The controller is wired to the heater as shown in figure 15. The model and rating plate provides the electrical information needed to size the complete...

17 using the electronic controller 1. Overview interaction with the water heater controller is done through an up, a down, and three operation buttons. These buttons are illustrated to the right. Operation of the three lower buttons is defined immediately above them on the screen. The [up] and [dn] ...

18 3. Adjusting the operating set point the operating set point of this water heater determines the regulated temperature for the water in the tank. This parameter is adjusted in the temperature menu. Items in this menu allow you to monitor different temperature readings in the tank along with adjus...

19 4. Changing the display units the display interface to the heater has the option of selecting between degrees fahrenheit and degrees celsius for temperature displays. This can be found in the “display settings” menu. Also in this menu, you may adjust how the backlight operates and the contrast of...

20 action: to get to the current fault information screen, press menu. Display: action: press the down button to highlight "current fault" and press select. Display: action: press the down button for more information. Display: 7. Viewing the fault history the controller for this water heater will st...

21 5. Check the vent system seams and joints and ensure that there is no discharge of flue products into the room. 6. Check the input rate. For appliance installation locations with elevations above 6500 feet (1982 meters) refer to high altitude installations section of this manual. A. Attach a pres...

22 warning under no circumstances should the input exceed the rate shown on the heater rating plate. Over firing could result in damage or sooting of the heater. Cathodic protection caution hydrogen gas can be produced in a hot water system served by this heater that has not been used for a long per...

23 for your safety read before operating warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. Bth 120 models only..

24 for your safety read before operating warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. Bth 150 models only. Operating instructions turn off gas to appliance.

25 operating instructions turn off gas to appliance for your safety read before operating warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. Bth 199/250 models only. Operating instructions turn off gas to...

26 figure 16. To dissolve and remove the more stubborn mineral deposits, a.O. Smith un•lime® professional delimer should be used. A.O. Smith un•lime® professional delimer is an easy to handle patented food grade acid formulated specifically for lime scale removal from all types of water using equipm...

27 drain valve and access panels the heaters are equipped with a 3/4" drain valve. An access panel covers the cleanout opening in the tank which is sealed by a gasket and cover, figure 25. Relief valve at least twice a year, the temperature and pressure relief valve should be checked to ensure that ...

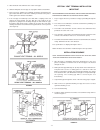

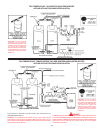

28 one temperature - one heater horizontal storage tank forced circulation with or without building recirculation danger temperature setting should not exceed safe temperature at fixtures. See water temperature control warning on page 4. If higher preheat temperatures are necessary to obtain adequat...

29 * pipe relief valve to open drain. Note: if tempered water is recirculated, return line should be connected at point “a”. Install in accordance with local codes. Two temperature - one heater high temperature with or without building recirculation danger temperature setting should not exceed safe ...

30 two temperature - two heaters high temperature with or without building recirculation two temperature - three heaters (two pre-heaters/one booster heater) with or without building recirculation must be identical heaters for multiple heater installation see manifold kit specifications, page 33. Ca...

31 * pipe relief valve to open drain ** 140°f (60°c) to 150°f (66°c) should be maximum water temperature maintained in the pre-heaters. 120°f (49°c) should be the minimum temperature of water in the pre- heaters. Connect circulating line from fixtures, if used, to cold water supply line of pre-heate...

32 note 1: toggle switch controls 180°f (82°c) water circulation. Install on or close to dishwasher. Toggle switch must be closed (on) during the rinse operation and open (off) when dishwasher is not operating or when on long standby. Note 2: install line temperature control in an uninsulated tee be...

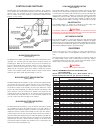

33 manifold kits precision cut type “l” all copper a.O. Smith manifold kits assure water flow balance of all units. Without this balance, the full water heating and storage potential of the system cannot be achieved. Plus, the units with the higher water flow may have a shortened life. Dimensions sh...

34 checklist and service information important the installer may be able to observe and correct certain problems which might arise when the unit is put into operation or when it is re-fired after a prolonged shutdown. However, it is recommended that only qualified servicemen, using appropriate test ...

35 motor will not run 1. Confirm 120v ac to the controller. Also, to verify correct polarity, check for 120 v ac between hot supply and ground. If there is no voltage, check for a loose connection where it connects to the controller. 2. If there is 120 volts to the controller, check for loose connec...

36 model bth limited warranty a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this water heater. 1. The tank if the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potable ...

37 notes:.

38 notes:.

39 notes:.

40 a.O. Smith water products company 500 tennessee waltz parkway ashland city, tn 37015 phone: 1-800-433-2545 fax: 1-800-433-2515 www.Aosmithwaterheaters.Com / email: parts@hotwater.Com.