- DL manuals

- A.O. Smith

- Water Heater

- 197835-001

- Instruction Manual

A.O. Smith 197835-001 Instruction Manual

1

Instruction Manual

PRINTED IN THE U.S.A 1208

197835-001

Keep thIs Manual In the pocKet on heater for future reference

whenever MaIntenance adjustMent or servIce Is requIred.

power vent/power dIrect vent Gas Models

wIth hot surface IGnItIon

all technIcal and warrantY questIons: SHOULD BE DIRECTED TO THE LOCAL DEALER FROM WHOM THE WATER HEATER WAS

PURCHASED. IF YOU ARE UNSUCCESSFUL, CALL THE TECHNICAL SUPPORT PHONE NUMBER SHOWN ON THE WATER HEATER LABELING.

resIdentIal Gas water heaters

•

for Your safety

•

AN ODORANT IS ADDED TO THE GAS USED

BY THIS WATER HEATER.

Ashland City, TN 37015

www.hotwater.com

Summary of 197835-001

Page 1

1 instruction manual printed in the u.S.A 1208 197835-001 keep this manual in the pocket on heater for future reference whenever maintenance adjustment or service is required. Power vent/power direct vent gas models with hot surface ignition all technical and warranty questions: should be directed t...

Page 2

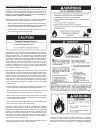

2 safe installation, use and service your safety and the safety of others is extremely important in the installation, use and servicing of this water heater. Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and others of a poten...

Page 3: General Safety

3 general safety.

Page 4: General Safety

4 general safety.

Page 5: Introduction

5 thank youforpurchasingthiswaterheater.Properlyinstalledand maintained,itshouldgiveyouyearsoftroublefreeservice. Abbreviations found in this instruction manual: • csa-canadianstandardsassociation • ansi-americannationalstandardsinstitute • nfpa-nationalfireprotectionassociation • asme-americansocie...

Page 6

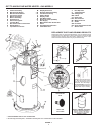

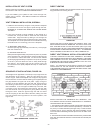

6 * caution harness has 120 vac. In operation. ** see “planning the vent system,” “installation of vent system” and “condensate” for more information. Figure 1. Vacuum relief valve *install per local codes m display enclosure ** n exhaust elbow assembly ** o condensate tubing p off/on switch q displ...

Page 7: Installation Considerations

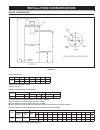

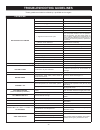

7 rough-in-dimensions model units a b c d e f 100 inches 68.50 49.25 22.00 15.75 3.00 8.00 cm 174 125.09 55.88 40.00 7.62 20.32 top/side inlet and outlet: 3/4” npt gas inlet: 1/2” npt capacity, gas and electrical characteristics model approximatecapacity manifold pressure electrical characteristics ...

Page 8

8 forallsidewallterminated,horizontallyventedpowervent,directvent,andpowerdirectventgasfueledwaterheaters installedineverydwelling,buildingorstructureusedinwholeorinpartforresidentialpurposes,includingthoseowned oroperatedbythecommonwealthandwherethesidewallexhaustventterminationislessthanseven(7)fe...

Page 9

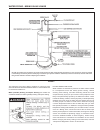

9 figure 2. Water piping - mixing valve usage this appliance has been design certified as complying with americannationalstandard/csastandardforwaterheatersand is considered suitable for: water (potable) heating and space heating:all models are consideredsuitableforwater(potable)heatingandspaceheati...

Page 10

10 facts to consider about the location carefully choose an indoor location for the new water heater, because theplacementisaveryimportantconsiderationforthesafetyofthe occupantsinthebuildingandforthemosteconomicaluseofthe appliance. This water heater is not for use in manufactured (mobile) homes or...

Page 11

11 inanalcoveorcloset,theentirefloormustbecoveredbythepanel. Failuretoheedthiswarningmayresultinafirehazard. Minimum clearances between the water heater and combustible constructionare0inchatthesidesandrear,5.5”(14.0cm)fromthefront and12”(30.5cm)fromthetop.(standardclearance.)ifclearances stated on ...

Page 12

12 afreeareaofonesquareinchper1000btu/hr(22cm 2 /kw)ofthe totalinputofallappliancesintheenclosure,butnotlessthan100 squareinches(645cm 2 ). Iftheconfinedspaceiswithinabuildingoftightconstruction,airfor combustionandventilationmustbeobtainedfromoutdoors.When directlycommunicatingwiththeoutdoorsorcomm...

Page 13

13 closed water systems watersupplysystemsmay,becauseofcoderequirementsorsuch conditionsashighlinepressure,amongothers,haveinstalleddevices suchaspressurereducingvalves,checkvalves,andbackflowpreventers. Devicessuchasthesecausethewatersystemtobeaclosedsystem. Thermal expansion aswaterisheated,itexpa...

Page 14

14 figures2and10showthetypicalattachmentofthewaterpipingto thewaterheater.Thewaterheaterisequippedwith3/4inchnpt water connections. Note: if using copper tubing, solder tubing to an adapter before attaching the adapter to the water heater connections. Do not solder the water lines directly to the wa...

Page 15

15 the temperature-pressure relief valve must be manually operatedatleastonceayear,seefigure28.Cautionshouldbe takentoensurethat(1)nooneisinfrontoforaroundtheoutlet ofthetemperature-pressurereliefvalvedischargeline,and(2) thewatermanuallydischargedwillnotcauseanybodilyinjury orpropertydamagebecauset...

Page 16

16 sediment traps asedimenttrapshouldbeinstalledasclosetothegasinletofthewater heateraspracticalatthetimeofwaterheaterinstallation.Thesediment trapshouldbeeitherateefittingwithacappednippleinthebottom outletorotherdevicerecognizedasaneffectivesedimenttrap. Contaminantsinthegaslinesmaycauseimproperop...

Page 17

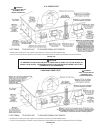

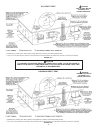

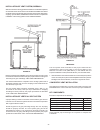

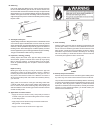

17 figure 15b. U.S. Power vent canadian power vent warning vent hood(s) may be extremely hot during operation. Warning vent hood(s) may be extremely hot during operation. Figure 15a. Caution to prevent exhausting products from circulating to the air intake in windy/cold areas, the maximum practical ...

Page 18

18 figure 15d. U.S. Direct vent canadian direct vent warning vent hood(s) may be extremely hot during operation. Warning vent hood(s) may be extremely hot during operation. Figure 15c. Caution to prevent exhausting products from circulating to the air intake in windy/cold areas, the maximum practica...

Page 19

19 planning the vent system plantherouteoftheventsystemfromtheexhaustelbowtothe plannedlocationoftheventterminal. 1. Layouttotalventsystemtouseaminimumofventpipeandelbows. 2. Thiswaterheateriscapableofventingfluegasesequivalentto 25’(7.6m)of2”pipe,65’(19.8m)of3”pipe,or128’(39.0m)of 4”pipeaslistedint...

Page 20

20 installation of vent system beforebeginninginstallationofpipingsystemthoroughlyread thesectionofthismanualventpipepreparation. If you are installing your system so that it vents through roof, please refer to section titled installation of vertical vent system. Vent terminal installation, sidewall...

Page 21

21 installation sequence forinstallationsinthecityoflosangeles,californiacategoryiv pvcpipesuchasthatmanufacturedbybrownlinepipecompany, mustbeusedasventpipematerial. Caution vent terminals supplied with heater must be used. Note: before beginning installation of any vent pipe read the vent pipe man...

Page 22

22 installation of vent system, sidewall withtherouteoftheventingsystemandselectionofmaterialscompleted, asdiscussedinthesectionofthismanualtitledplanningthevent system,thethroughthewallventterminalinplaceandthefirstsection ofpiping,uptofirstelbow,installedatthebloweritistimetocompletethe installati...

Page 23

23 thisconcentricventterminationkitmaybeusedwith3or4inchdiameter pipesystems.Whenconnectingtoa4in.Diameterpipesystema3x4 inchfieldsuppliedreduceristobeinstalledattheintakeandexhaust connectionoftheconcentricventterminationkit. Safety considerations installingandservicingwaterheatingequipmentcanbehaz...

Page 24

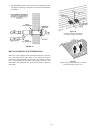

24 5. Secureassemblytoroofstructureasshowninfigureeusing fieldsuppliedmetalstrappingorequivalentsupportmaterial. Note: ensure termination height is above the roof surface or anticipated snow level (1 ft. In u.S.A. Or 1-1/2 ft. In canada) as shown in figure c. 6. Install rain cap and small diameter p...

Page 25

25 8. Operateheaterthrough1heatcycletoensurecombustion-airand ventpipesareproperlyconnectedtoconcentricventtermination connections. Figure g. Multi-concentric vent terminations whentwoormoreappliancesaredirectedventedwithconcentric vent terminations near each other, each appliance must be individual...

Page 26

26 vent pipe preparation 1. Initial preparation. A.)make sure the solvent cement you are planning to use isdesignedforthespecificapplicationyouareattempting. B.)knowthephysicalandchemicalcharacteristicsandlimitationsofthe pvcandcpvcpipingmaterialsthatyouareabouttouse. C.)knowthereputationofyourmanuf...

Page 27

27 b. Deburring useaknife,plasticpipedeburringtool,orfiletoremoveburrsfrom theendofsmalldiameterpipe.Besuretoremoveallburrsfrom aroundtheinsideaswellastheoutsideofthepipe.Aslightchamfer (bevel)ofabout10°-15°shouldbeaddedtotheendtopermiteasier insertionofthepipeintotheendofthefitting.Failuretochamfer...

Page 28

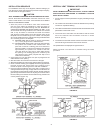

28 controls and switches thismodelisprovidedwiththreepressureswitches.Theseswitches areessentialtothesafeandproperoperationoftheunit.Allswitches arewiredinseries.Thecontrollerissetuptoshuttheunitdown wheneverthereisafailureofanyoftheswitches.Itisimportantto understandthepurposeofeachswitch. Figure 1...

Page 29

29 caution label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing. Power vent wiring schematic - figure 24. This water heater is polarity sensitve. Before applying electricity to this heater be...

Page 30

30 up operating set point status: heating menu help 120 f dn off gas o n warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. A. Thisappliancedoesnothaveapilot.Itisequippedwith anignitiondevicewhichautomati...

Page 31: Temperature Regulation

31 the water temperature is controlled using the temperature controlonthedisplayatthefrontoftheunit(seefigure1). Thiscontrolutilizesatemperatureprobetodeterminethetank temperature.Theprimarytemperatureprobeislocatedatthe topofthetank. Thetemperaturemaybeadjustedfrom90°f/32°cto160°f/71°c. Thethermost...

Page 32

32 using the electronic controller 1. Overview interactionwiththewaterheatercontrollerisdonethroughanup,adown,andthreeoperationbuttons.Thesebuttonsareillustratedtothe right.Operationofthethreelowerbuttonsisdefinedimmediatelyabovethemonthescreen.The[up]and[dn]buttonsareusedtonavigate throughthemenusa...

Page 33

33 3. Adjusting the operating set point the operating set pointofthiswaterheaterdeterminestheregulated temperatureforthewaterinthetank.Thisparameterisadjustedinthe temperaturemenu.Itemsinthismenuallowyoutomonitordifferent temperaturereadingsinthetankalongwithadjustingtheoperating set point. Action: ...

Page 34

34 3. Changing the display units thedisplayinterfacetotheheaterhastheoptionofselectingbetween degreesfahrenheitanddegreescelsiusfortemperaturedisplays.This canbefoundinthe“displaysettings”menu.Alsointhismenu,youmay adjusthowthebacklightoperatesandthecontrastofthelcdscreen. Action: fromthemainmenu,pr...

Page 35

35 action: togettothecurrentfaultinformationscreen,press menu. Display: action: press the downbuttontohighlight"currentfault"andpressselect. Display: action: press the downbuttonformoreinformation. Display: 6. Viewing the fault history the controller for this water heater will store a history of ten...

Page 36: For Your Information

36 for your information start up conditions smoke/odor itisnotuncommontoexperienceasmallamountofsmokeand odorduringtheinitialstart-up.Thisisduetoburningoffofoil frommetalparts,andwilldisappearinashortwhile. Thermal expansion water supply systems may, because of such events as high line pressure, fre...

Page 37: Periodic Maintenance

37 venting system inspection atleastonceayearavisualinspectionshouldbemadeoftheventing system.Youshouldlookfor: 1.Obstructionswhichcouldcauseimproperventing.Thecombustion andventilationairflowmustnotbeobstructed. 2.Damageordeteriorationwhichcouldcauseimproperventingor leakageofcombustionproducts. Be...

Page 38

38 installedinsuitablearea:toinsuresufficientventilationand combustionairsupply,properclearancesfromthewaterheatermust bemaintained.See“factstoconsideraboutlocation”section. Combustible materials such as clothing, cleaning materials, or flammableliquids,etc.Mustnotbeplacedagainstoradjacentto thewate...

Page 39: Leakage Checkpoints

39 leakage checkpoints neverusethiswaterheaterunlessitiscompletelyfilledwithwater. Topreventdamagetothetank,thetankmustbefilledwithwater. Watermustflowfromthehotwaterfaucetbeforeturning“on”gas to the water heater. A *condensationmaybeseenonpipesinhumidweatherorpipe connectionsmaybeleaking. B.*theano...

Page 40: Troubleshooting Guidelines

40 problems not enough hot water 1.)blowerwillnotrun. A.“on/off”controlswitchturnedoff. Turnswitchtothe“on”position. B.Blowerunplugged. Plugblowerbackinto115vacoutlet. C.Nopoweratoutlet. Repairservicetooutlet. D.Thermostatdefective. Replacethermostat. E. Control harness defective. Replacecontrolharn...

Page 41: Notes

41 notes.

Page 42: Notes

42 notes.

Page 43

43 this warranty is applicable to the original owner only if theglasslinedtankinthiswaterheatershallproveuponexaminationby(the warrantor)tohaveleakedduringthewarrantyperiodinnormalresidential use,duetonaturalcorrosionfrompotablewatertherein,thewarrantorwill furnishtheoriginalownerareplacementwaterhe...

Page 44

44 500tennesseewaltzparkway,ashlandcity,tn37015 phone:800-527-1953fax:800-433-2515 www.Hotwater.Com.