- DL manuals

- A.O. Smith

- Water Heater

- BTX-80 SERIES 100

- Instruction Manual

A.O. Smith BTX-80 SERIES 100 Instruction Manual

1

Instruction Manual

PRINTED 0810

197086-004

Keep thIs Manual In the pocKet on heater for future reference

whenever MaIntenance adjustMent or servIce Is requIred.

power vented Gas Models w/hot surface IGnItIon

Model BtX-80 serIes 100

all technIcal and warrantY questIons: SHOULD BE DIRECTED TO THE LOCAL DEALER FROM WHOM THE WATER HEATER WAS

PURCHASED. IF YOU ARE UNSUCCESSFUL, PLEASE WRITE TO THE COMPANY LISTED ON THE RATING PLATE ON THE WATER HEATER.

coMMercIal Gas water heaters

•

for Your safety

•

AN ODORANT IS ADDED TO THE GAS USED

BY THIS WATER HEATER.

500 Tennessee Waltz Parkway

Ashland City, TN 37015

Low Lead Content

Summary of BTX-80 SERIES 100

Page 1

1 instruction manual printed 0810 197086-004 keep this manual in the pocket on heater for future reference whenever maintenance adjustment or service is required. Power vented gas models w/hot surface ignition model btx-80 series 100 all technical and warranty questions: should be directed to the lo...

Page 2: Approvals

2 safe installation, use and service the proper installation, use and servicing of this water heater is extremely important to your safety and the safety of others. Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and others of ...

Page 3: General Safety Information

3 general safety information.

Page 4: General Safety Information

4 general safety information at least 18" (45.7 cm) above the floor. This will reduce, but not eliminate, the risk.

Page 5: Introduction

5 thank you for purchasing this water heater. Properly installed and maintained, it should give you years of trouble free service. Abbreviations found in this instruction manual: • csa-canadianstandardsassociation • ansi-americannationalstandardsinstitute • nfpa-nationalfireprotectionassociation • a...

Page 6

6 installation requirements for the commonwealth of massachusetts commonwealth of massachusetts for all side wall terminated, horizontally vented power vent, direct vent, and power direct vent gas fueled water heaters installed in every dwelling, building or structure used in whole or in part for re...

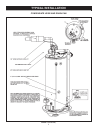

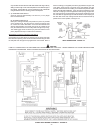

Page 7: Typical Installation

7 typical installation * caution harness has 120 vac. In operation. ** see “planning the vent system”, “condensate” and “blower assembly installation” for more information. *** the side recirculation loop connections may not be used as the primary water inlet and outlet connections. For your conveni...

Page 8: Typical Installation

8 typical installation condensate hose and drain pan figure 1 (continued)..

Page 9: Typical Installation

9 typical installation mixing valves danger water temperature over 125°f (52°c) can cause severe burns instantly resulting in severe injury or death. Children, the elderly and the physically or mentally disabled are at highest risk for scald injury. Feel water before bathing or showering. Temperatur...

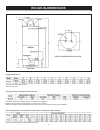

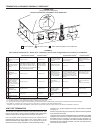

Page 10: Rough-In-Dimensions

10 rough-in-dimensions rough-in-dimensions top/sideinletandoutlet:3/4”npt gasinlet:1/2”npt capacity and gas and electrical characteristics allmodels-maximumsupplypressure:14inchesw.C.(3.48kpa) minimumsupplypressurenaturalgas:5.0inchesw.C.(1.24kpa) minimumpressuremustbemaintainedunderbothloadandnoloa...

Page 11

11 facts to consider about the location carefully choose an indoor location for the new water heater, because the placement is a very important consideration for the safety of the occupants in the building and for the most economical use of the appliance. This water heater is not for use in manufact...

Page 12

12 inanalcoveorcloset,theentirefloormustbecoveredbythepanel. Failuretoheedthiswarningmayresultinafirehazard. Minimum clearances between water heater and combustible constructionare0inchatthesidesandrear,5.5”(14.0cm)fromthe frontand12”(30.5cm)fromtop.(standardclearance.)ifclearances stated on the hea...

Page 13

13 such a condition often will result in a yellow, luminous burner flame, causing sooting of the combustion chamber, burners and flue tubes and creates a risk of asphyxiation. Do not install the water heater in a confined space unless an adequate supply of air for combustion and ventilation is broug...

Page 14

14 figure 7. The water heater shall have clearances of at least 1 inch (25mm)fromthesidesandbackand6inches(150mm)fromthe front of the appliance. The opening shall directly communicate with the outdoors or shall communicate through a vertical or horizontal duct to the outdoors or spaces that freely c...

Page 15: Danger

15 this water heater should not be connected to any heating systems or component(s)usedwithanon-potablewaterheatingappliance. All piping components connected to this unit for space heating applications should be suitable for use with potable water. Toxic chemicals, such as those used for boiler trea...

Page 16

16 thermal expansion aswaterisheated,itexpands(thermalexpansion).Inaclosedsystem the volume of water will grow when it is heated. As the volume of water grows there will be a corresponding increase in water pressure due to thermal expansion. Thermal expansion can cause premature tank failure(leakage...

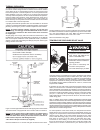

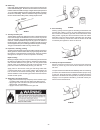

Page 17: Caution

17 discharge opening must not be blocked or reduced in size under anycircumstances.Excessivelength,over30feet(9.14m),or use of more than four elbows can cause restriction and reduce the discharge capacity of the valve. No valve or other obstruction is to be placed between the temperature-pressure re...

Page 18

18 agaslineofsufficientsizemustberuntothewaterheater.Consult thecurrenteditionofnationalfuelgascode(ansiz223.1/nfpa 54)orthenaturalgasandpropaneinstallationcode(can/csa b149.1)andyourgassupplierconcerningpipesize. There must be: • areadilyaccessiblemanualshutoffvalveinthegassupplyline serving the wa...

Page 19

19 never use this water heater unless it is completely full of water. To preventdamagetothetank,thetankmustbefilledwithwater.Water mustflowfromthehotwaterfaucetbeforeturning“on”gastothe water heater. Tofillthewaterheaterwithwater: 1. Close the water heater drain valve by turning handle to the right ...

Page 20

20 termination clearances sidewall power vent v x vent terminal air supply inlet area where terminal is not permitted v v a g v fixed closed fixed closed operable operable v c b b b b f b v v a j v h m x x v v k b e d l power vent (using room air for combustion) exterior clearances for sidewall vent...

Page 21

21 planning the vent system plan the route of the vent system from the discharge of the blower to the planned location of the vent terminal. Refer to vaa instruction on page 25 while planning the vent system. 1. Layout total vent system to use a minimum of vent pipe and elbows. 2. Thiswaterheaterisc...

Page 22

22 thecondensatetrapmaybeprimedbyfillingthecondensate u-assembly with tap water while the water heater is not operating. The system is fully primed when the water level reaches the adaptor connected into the tee. In most installations the water heater will self-primethecondensatetrapduringthefirstfu...

Page 23

23 caution label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing. Power vent wiring schematic - figure 19. May be easier to mark both the inside and outside wall. Align holes by drilling a hol...

Page 24

24 installation of vent system, sidewall with the route of the venting system and selection of materials completed, as discussed in the section of this manual titled planning the vent system,thethroughthewallventterminalinplaceandthefirstsection ofpiping,uptofirstelbow,installedatthebloweritistimeto...

Page 25

25 vent attenuation assembly installation instructions the ventattenuationassembly (vaa) is designed to provide a reduction in fan noise created in the blower wheel. This installation of this vaa is optional. Review directions thoroughly prior to installing the new vaa. Please contact the manufactur...

Page 26

26 barb, use a wire tie or hose clamp (not supplied with kit) and secure. 6. Take the other end of the flexible tubing and slide it through the hose clamp on the jacket top cover and install it into one of the four barb fittings in vent pipe assembly #2. 7. Onceinstalledalongwiththerestoftheventconf...

Page 27

27 vent pipe preparation 1. Initial preparation a. Make sure the solvent cement you are planning to use is designedforthespecificapplicationyouareattempting. B. Know the physical and chemical characteristics and limitations of the pvc and cpvc piping materials that you are about to use. C. Know the ...

Page 28

28 b. Deburring useaknife,plasticpipedeburringtool,orfiletoremoveburrsfromthe end of small diameter pipe. Be sure to remove all burrs from around the insideaswellastheoutsideofthepipe.Aslightchamfer(bevel)ofabout 10°-15°shouldbeaddedtotheendtopermiteasierinsertionofthepipe intotheendofthefitting.Fai...

Page 29

29 for your safety read before operating warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. A. This appliance does not have a pilot. It is equipped with an ignition device which automatically lights the b...

Page 30: Temperature Regulation

30 it is recommended that lower water temperatures be used to avoid the risk of scalding. It is further recommended, in all cases, that the watertemperaturebesetforthelowesttemperaturewhichsatisfies yourhotwaterneeds.Thiswillalsoprovidethemostenergyefficient operation of the water heater. Short repe...

Page 31: For Your Information

31 for your information start up conditions smoke/odor it is not uncommon to experience a small amount of smoke and odor during the initial start-up. This is due to burning off of oil from metal parts, and will disappear in a short while. Strange sounds possible noises due to expansion and contracti...

Page 32: Periodic Maintenance

32 venting system inspection at least once a year a visual inspection should be made of the venting system. You should look for: 1. Obstructions which could cause improper venting. The combustion andventilationairflowmustnotbeobstructed. 2. Damage or deterioration which could cause improper venting ...

Page 33: Danger

33 the anode rod is used to protect the tank from corrosion. Most hot water tanksareequippedwithananoderod.Thesubmergedrodsacrifices itself to protect the tank. Instead of corroding tank, water ions attack andeatawaytheanoderod.Thisdoesnotaffectwater’stasteorcolor. The rod must be maintained to keep...

Page 34: Leakage Checkpoints

34 leakage checkpoints neverusethiswaterheaterunlessitiscompletelyfilledwithwater. Topreventdamagetothetank,thetankmustbefilledwithwater. Watermustflowfromthehotwaterfaucetbeforeturning“on”gas to the water heater. A *condensation may be seen on pipes in humid weather or pipe connections may be leaki...

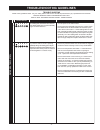

Page 35: Troubleshooting Guidelines

35 troubleshooting guidelines trouble shooting pleasecheckguidelinesbelow.Foryoursafety,waterheaterserviceshouldbeperformedonlybyaqualifiedservicetechnician. Readthegeneralsafetyinformationsectionfirst. Intelli-vent troubleshooting chart - user control problem solution inadequate or no earth ground ...

Page 36: Troubleshooting Guidelines

36 troubleshooting guidelines trouble shooting pleasecheckguidelinesbelow.Foryoursafety,waterheaterserviceshouldbeperformedonlybyaqualifiedservicetechnician. Readthegeneralsafetyinformationsectionfirst. Intelli-vent troubleshooting chart - user control problem solution ignition/flame failure. 6 the ...

Page 37: Troubleshooting Guidelines

37 troubleshooting guidelines trouble shooting pleasecheckguidelinesbelow.Foryoursafety,waterheaterserviceshouldbeperformedonlybyaqualifiedservicetechnician. Readthegeneralsafetyinformationsectionfirst. Intelli-vent troubleshooting chart - user control problem solution 15 # led status b c d e f 1. T...

Page 38: Troubleshooting Guidelines

38 theseguidelinesshouldbeutilizedbyaqualifiedserviceagent. Troubleshooting guidelines troubleshooting guidelines.

Page 39

39 limited warranty a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this water heater. 1. The tank if the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potable water ther...

Page 40

40 500 tennessee waltz parkway, ashland city, tn 37015 technicalsupport:800-527-1953•parts:800-433-2545•fax:800-644-9306 www.Hotwater.Com copyright © 2010 a. O. Smith corporation. All rights reserved..