1 a division of a.O. Smith corporation mc bee, south carolina stratford (ontario) canada www.Hotwater.Com place these instructions adjacent to heater and notify owner to keep for future reference. Printed in u.S.A. 0903 part no. 195792-000 supersedes part no. 195049-000 cyclone xhe ® model bth 300a ...

2 these designs comply with the latest version of the american national standard for gas water heaters, volume iii, ansi z21.10.3 / csa 4.3 as an automatic circulating tank water heater, and automatic storage water heaters. Detailed installation diagrams are found in this manual. These diagrams will...

Danger this water heater is equipped with an adjustable thermostat to control water temperature. Hot water temperatures required for automatic dishwasher and laundry use can cause scald burns resulting in serious personal injury and/or death. The temperature at which injury occurs varies with the pe...

4 the temperature may be adjusted from 80°f/27°c to 180°f/82°c. The thermostat was adjusted to 120°f/49°c before the heater was shipped from the factory. It is recommended that lower water temperatures be used to avoid the risk of scalding. It is further recommended, in all cases, that the water tem...

5 warning this water heater is a condensing unit and requires a drain to be located in close proximity to allow the condensate to drain safely. The condensate drains from the unit at the exhaust elbow located at the bottom of the unit. Note: it is important that the condensate hose not be elevated a...

6 see maintenance section for details of tank cleanout procedure. Air requirements keep appliance area clear and free of combustible materials, gasoline and other flammable vapors and liquids. Do not obstruct the flow of combustion and ventilating air. Warning for safe operation provide adequate air...

7 bth 300 & 400 figure 5 direct vent horizontal vent figure 6 do not terminate exhaust over public area where condensate or vapor can cause nuisance or hazard. On direct vent installations, inlet vent hood must be located 1' (30.5cm) minimum from any opening in building. On direct vent installations...

8 4. The manufacturer also recommends the vent system terminations not be installed closer than 3' (91cm) from an inside corner of an l shaped structure. And not less than 1' (30.5 cm) above grade or anticipated snow level. 5. The vent termination shall not be mounted directly above or within 3' (91...

9 wall. Align the holes by drilling a hole through the center of the template from the inside through to the outside. The template can now be positioned on the outside wall using the drilled holes as a centering point for the template. 3. A) masonry side walls chisel an opening approximately 1/2" (1...

10 installation of vent system warning the optional intake venting arrangement and the exhaust venting arrangement must be installed to run directly to the outdoors and not in any way be connected to another venting system (i.E. Furnace, dryers or space heaters). It is crucial that the venting arran...

11 f. Contact the manufacturer, supplier, or competent consulting agency if you have any questions about the application or installation of pvc, pvc cellular core, abs or cpvc pipe. G. Take the time and effort to do a professional job. Shortcuts will only cause you problems and delays in start-up. T...

12 gas piping contact your local gas service company to ensure that adequate gas service is available and to review applicable installation codes for your area. Size the main gas line in accordance with table 3. The figures shown are for straight lengths of pipe at 0.5 in. W.C. (125pa) pressure drop...

13 pressures of 1/2 psig (3.45kpa) or less, the appliance need not be disconnected, but must be isolated from the supply pressure test by closing the manual gas shutoff valve. Before placing the heater in operation, check for gas leakage. Use soap and water solution or other material acceptable for ...

14 2. Toxic chemicals, such as those used for boiler treatment, shall never be introduced into this system. 3. This unit may never be connected to any existing heating system or component(s) previously used with non-potable water heating appliance. 4. When the system requires water for space heating...

15 figure 16 operation sequence of operation typical control/appliance operating sequence 1. When the control is powered, it should first display “0”, then the input line voltage (“120”), the calibration setting (12), then the actual water temperature in the tank. 2. If the control determines that t...

16 error codes the following error codes are external to the controller. 01 pressure switch fail on, should be off 11 pressure switch fail off, should be on 02 ignition fail after 3 attempts 04 eco open 05 temperature probe open 15 temperature out of bounds 25 temperature out of bounds > 220 degrees...

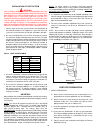

17 display flashes “05” when button is pressed: display flashes “15” when button is pressed: display flashes “25” when button is pressed: eco switch open (figure 21) eco led flashing: eco switch open, eco led flashing figure 21 control bad (figure 22) all leds flashing: possible cause remedy 1. This...

18 do not use this heater if any part has been under water. Immediately call a qualified service technician to inspect the heater and to replace any part of the control system and any gas control which has been under water. Light the unit in accordance with the operating instructions label attached ...

19 lighting and operation instructions a. This appliance does not have a pilot. It is equipped with an ignition device which automatically lights the burner. Do not try to light the burner by hand. B. Before operating smell all around the appliance area for gas. Be sure to smell next to the floor be...

20 warning under no circumstances should the input exceed the rate shown on the heater rating plate. Overfiring could result in damage or sooting of the heater. Cathodic protection caution hydrogen gas can be produced in a hot water system served by this heater that has not been used for a long peri...

21 figure 24 to dissolve and remove the more stubborn mineral deposits, a.O. Smith un•lime® professional delimer should be used. Note: un•lime is not available in canada. Please call customer service at 1-800-265-8520 for approved alternatives. A.O. Smith un•lime® professional delimer is an easy to ...

22 powered anode operation to insure a long, trouble-free operating life, the bth-300 & 400 are equipped with a powered anode system consisting of: 1. A power supply with a built-in diagnostic led. 2. Two titanium anodes. 3. Wiring harness with ground lead. Replacement parts for this system may be o...

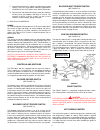

23 one temperature - one heater horizontal storage tank forced circulation with or without building recirculation danger temperature setting should not exceed safe temperature at fixtures. See water temperature control warning on page 3. If higher preheat temperatures are necessary to obtain adequat...

24 * pipe relief valve to open drain. Note: if tempered water is recirculated, return line should be connected at point “a”. Install in accordance with local codes. Two temperature - one heater high temperature with or without building recirculation danger temperature setting should not exceed safe ...

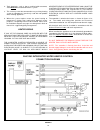

25 two temperature - two heaters high temperature with or without building recirculation two temperature - three heaters (two pre-heaters/one booster heater) with or without building recirculation must be identical heaters for multiple heater installation see manifold kit specifications, page 28. Ca...

26 * pipe relief valve to open drain ** 140°f (60°c)to 150°f (66°c) should be maximum water temperature maintained in the pre-heaters. 120°f (49°c) should be the minimum temperature of water in the pre-heaters. Connect circulating line from fixtures, if used, to cold water supply line of pre-heater....

27 note 1: toggle switch controls 180°f (82°c) water circulation. Install on or close to dishwasher. Toggle switch must be closed (on) during the rinse operation and open (off) when dishwasher is not operating or when on long standby. Note 2: install line temperature control in an uninsulated tee be...

28 manifold kits precision cut type “l” all copper a.O. Smith manifold kits assure water flow balance of all units. Without this balance, the full water heating and storage potential of the system cannot be achieved. Plus, the units with the higher water flow may have a shortened life. Unions shown ...

29 checklist and service information important the installer may be able to observe and correct certain problems which might arise when the unit is put into operation or when it is re-fired after a prolonged shutdown. However, it is recommended that only qualified servicemen, using appropriate test ...

30 motor will not run 1. Confirm 120v ac to the controller. Also, to verify correct polarity, check for 120 v ac between hot supply and ground. If there is no voltage, check for a loose connection where it connects to the controller. 2. If there is 120 volts to the controller, check for loose connec...

31 model bth limited warranty a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this water heater. 1. The tank if the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potable ...

32 a.O. Smith water products co., inc. 5621 w. 115th street • alsip, illinois 60803 phone: 1-800-433-2545 • fax: 1-800-433-2515 www.Hotwater.Com • e-mail: parts@hotwater.Com.