- DL manuals

- A.O. Smith

- Water Heater

- DURA-Power DRE-52

- Installation And Operation Manual

A.O. Smith DURA-Power DRE-52 Installation And Operation Manual

1

COMMERCIAL ELECTRIC WATER HEATERS

CAUTION

TEXT PRINTED OR UNDERLINED IN RED

CONTAINS INFORMATION RELATIVE TO YOUR

SAFETY. PLEASE READ THOROUGHLY BEFORE

ATTEMPTING ANY CONVERSION.

PRINTED IN U.S.A. 0906

PART NO. 196674-001

A DIVISION OF A.O. SMITH CORPORATION

MCBEE, SOUTH CAROLINA

www.hotwater.com

Models DRE & DVE - 52/80/120

• INSTALLATION • OPERATION • MAINTENANCE • LIMITED WARRANTY

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER AND

NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

Summary of DURA-Power DRE-52

Page 1

1 commercial electric water heaters caution text printed or underlined in red contains information relative to your safety. Please read thoroughly before attempting any conversion. Printed in u.S.A. 0906 part no. 196674-001 a division of a.O. Smith corporation mcbee, south carolina www.Hotwater.Com ...

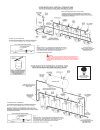

Page 2: Rough-In-Dimensions

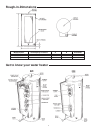

2 rough-in-dimensions model number tank capacity in gallons a b inlet/outlet dre/dve-52 50 55 1/4 21 3/4 1 1/4 dre/dve-80 80 59 1/2 25 1/4 1 1/4 dre/dve-120 119 62 1/4 29 1/2 1 1/4 get to know your water heater.

Page 3: Contents

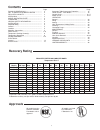

3 contents page rough-in-dimensions ....................................... 2 get to know your water heater ............... 2 recovery capacity ........................................... 3 approvals ............................................................ 3 model and rating plate .................

Page 4: Model and Rating

4 model and rating foreword detailed installation diagrams are in this manual. These diagrams will serve to provide the installer with a reference for the materials and method of piping suggested. It is necessary that all water piping and the electrical wiring be installed and connected as shown in ...

Page 5: Installation

5 installation required ability installation or service of this water heater requires ability equivalent to that of a licensed tradesman in the field involved. Plumbing and electrical work are involved. General the installation must conform to these instructions and the local code authority having j...

Page 6

6 the pressure setting of the relief valve should not exceed the pressure capacity of any component in the system. The temperature setting of the relief valve should not exceed 210°f. An unplugged 3/4" relief valve opening is provided for installing temperature and pressure relief valve. Temperature...

Page 7: Piping Diagrams

7 piping diagrams one temperature with circulating loop insert b vacuum relief valve. Install per local codes. Caution: if building cold water supply has a back- flow preventer, check valve or water meter with check valve. Provisions for thermal expansion of water in the hot water system must be pro...

Page 8

8 insert b vacuum relief valve. Install per local codes. Danger temperature setting should not exceed safe temperature at fixtures. See water temperature control warning on page 6. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti-scald valve for hot water s...

Page 9

9 insert b vacuum relief valve. Install per local codes. Danger temperature setting should not exceed safe temperature at fixtures. See water temperature control warning on page 6. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti-scald valve for hot water s...

Page 10

10 one temperature one heater vertical storage tank forced circulation without building recirculation two temperature with mixing valve and circulating loop insert b vacuum relief valve. Install per local codes. Two temperature with mixing valve caution: if building cold water supply has a back-flow...

Page 11

11 insert b vacuum relief valve. Install per local codes. Danger temperature setting should not exceed safe temperature at fixtures. See water temperature control warning on page 6. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti-scald valve for hot water ...

Page 12

12 danger temperature setting should not exceed safe temperature at fixtures. See water temperature control warning on page 6. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti-scald valve for hot water supplied to fixtures. Insert b vacuum relief valve. Ins...

Page 13

13 insert b vacuum relief valve. Install per local codes. Danger temperature setting should not exceed safe temperature at fixtures. See water temperature control warning on page 6. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti-scald valve for hot water ...

Page 14: Electrical

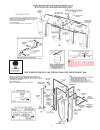

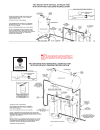

14 manifold kits all dimensions in inches. Two heaters part model number h w d a dre/dve-52 9003429 66 1/4 56 3/4 27 1/4 13 1/4 dre/dve-80 9003429 70 1/2 60 1/4 31 1/4 9 3/4 dre/dve-120 9003429 73 1/4 64 1/2 35 3/4 5 1/2 inlet and outlet size — 1 1/2 three heaters part model number h w d a dre/dve-5...

Page 15

15 branch circuit the branch circuit wire and fuse size should be established through reference to the current version of the national electrical code or any other locally approved source in conjunction with the heater amperage rating. Branch circuit wires should have a temperature rating no less th...

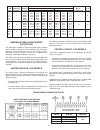

Page 16

16 full load current in amperes kw number of element single phase three phase no. Of no. Of input elements wattage 208v 240v 277v 480v 208v 240v 480v thermostats fuses 6 2000 28.8 25.0 21.7 12.5 16.7 14.4 7.2 9 3000 43.3 37.5 32.5 18.8 25.0 21.7 10.8 12 3 4000 57.7 50.0 43.3 25.0 33.3 28.9 14.4 3 6 ...

Page 17

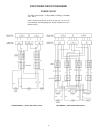

17 dve control circuit diagrams.

Page 18

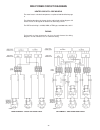

18 power circuit the power circuit wiring is 12 awg. Awm or tew type, rated 600 volts, 105°c. Power circuit fusing consists of three 30 amp class g fuses for each contactor. See wiring diagrams. Do not substitute fuses of a different rating. Dve power circuit diagrams three elements - single and thr...

Page 19

19 conversion to single phase when the heater is shipped for connection to a three-phase electrical service, it may be connected to a single-phase electrical service of the same voltage by: 1. Disconnect blue wires and yellow wires from terminal l3. 2. Reconnect all blue wires to terminal l1 (with b...

Page 20

20 heater circuits—dre models the water heater's electrical components are pictured and identified on page 2. The following describes the heater circuits and includes wiring diagrams. All heater circuits are designed for 60/50 hertz alternating current. The dre circuit wiring is 12 awg, awm, or tew ...

Page 21

21 conversion to single phase when the heater is shipped for connection to a three-phase electrical service, it may be connected to a single-phase electrical service of the same voltage by: 1. Disconnect blue wires and yellow wires from terminal l3. 2. Reconnect all blue wires to terminal l1 (with b...

Page 22: Operation

22 operation general never turn on power to the water heater without being certain the water heater is filled with water, and a temperature and pressure relief valve is installed in the relief valve opening. Do not test electrical system before heater is filled with water. Follow filling and start-u...

Page 23

23 maintenance schedule component operation interval required tank flushing periodically un•lime ® elements lime scale as needed delimer & removal element gaskets, part anode inspect as needed tank flushing should be performed in accordance with the above schedule. Tank sediment removal and element ...

Page 24

24 12. Attach element wires to connection points from which they were removed. 13. Follow filling instructions to restore hot water service. • check for water leaks around elements and proper operation when heater is filled. • close the front panel. Checklist before calling for service, check the fo...

Page 25: Leakage Checkpoints

25 leakage checkpoints instructions: use this illustration as a guide when checking for sources of water leakage. You or your dealer may be able to correct what appears to be a problem. Where possible, remove or lift top cover to examine threads of fittings installed into tank for evidence of leakag...

Page 26: Limited Warranty

26 a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this water heater: 1. The tank if the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potable watertherein, during the fi...

Page 27

27.

Page 28

28 mcbee, south carolina 29101 phone: 1-800-527-1953 fax: 800-433-2515 www.Hotwater.Com e-mail: parts@hotwater.Com.