- DL manuals

- ABB

- DC Drives

- ACS320 series

- User Manual

ABB ACS320 series User Manual - Introduction to The Manual

Introduction to the manual 19

2

Introduction to the manual

Contents of this chapter

The chapter describes applicability, target audience and purpose of this manual. It

describes the contents of this manual and refers to a list of related manuals for more

information. The chapter also contains a flowchart of steps for checking the delivery,

installing and commissioning the drive. The flowchart refers to chapters/sections in

this manual.

Applicability

The manual is applicable to the ACS320 drive firmware version 4.03c or later. See

parameter

on page

.

Target audience

The reader is expected to know the fundamentals of electricity, wiring, electrical

components and electrical schematic symbols.

The manual is written for readers worldwide. Both SI and imperial units are shown.

Special US instructions for installations in the United States are given.

Purpose of the manual

This manual provides information needed for planning the installation, installing,

commissioning, using and servicing the drive.

Summary of ACS320 series

Page 1

Abb drives user’s manual acs320 drives (0.5 to 30 hp).

Page 2

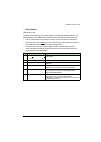

List of related manuals you can find manuals and other product documents in pdf format on the internet. See section document library on the internet on the inside of the back cover. For manuals not available in the document library, contact your local abb representative. Drive manuals code (english)...

Page 3: User’S Manual

User’s manual acs320 drives (0.5 to 30 hp) 3aua0000062599 rev e en effective: 2016-07-05 2016 abb oy. All rights reserved. 1. Safety table of contents 4. Mechanical installation 6. Electrical installation 8. Start-up index.

Page 5: Table of Contents

Table of contents 5 table of contents list of related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1. Safety contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6

6 table of contents implementing the ac power line connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 selecting the supply disconnecting device (disconnecting means) . . . . . . . . . . . . . . . . . . . . 36 european union . . . . . . . . . . . . . . . . . . . ....

Page 7

Table of contents 7 8. Start-up contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 hvac control panel features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 g...

Page 8

8 table of contents local control vs. External control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102 local control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102 external control ...

Page 9

Table of contents 9 ai panel loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117 external fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117 stall p...

Page 10

10 table of contents settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 load analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136 peak v...

Page 11

Table of contents 11 group 42: ext / trim pid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243 group 44: pump protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246 group 45: energy saving . . ...

Page 12

12 table of contents detailed point descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319 bacnet protocol technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325 binary input object instan...

Page 13

Table of contents 13 reforming the capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380 power connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380 control panel . . . ...

Page 14

14 table of contents frame sizes r0 and r1, ip20 / nema 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405 frame size r2, ip20 (cabinet installation) / ul open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 406 frame size r2, nema 1 . . . . . . . . . . ....

Page 15: Safety

Safety 15 1 safety contents of this chapter the chapter contains safety instructions which you must follow when installing, operating and servicing the drive. If ignored, physical injury or death may follow, or damage may occur to the drive, motor or driven equipment. Read the safety instructions be...

Page 16

16 safety safety in installation and maintenance these warnings are intended for all who work on the drive, motor cable or motor. Electrical safety warning! If you ignore the safety instructions, injury or death can occur. If you are not a qualified electrician, do not do electrical work. • only qua...

Page 17

Safety 17 general safety warning! If you ignore the safety instructions, injury or death can occur. If you are not a qualified electrician, do not do electrical work. • never attempt to repair a malfunctioning drive; contact your local abb representative or authorized service center for service supp...

Page 18

18 safety.

Page 19: Introduction to The Manual

Introduction to the manual 19 2 introduction to the manual contents of this chapter the chapter describes applicability, target audience and purpose of this manual. It describes the contents of this manual and refers to a list of related manuals for more information. The chapter also contains a flow...

Page 20

20 introduction to the manual contents of this manual the manual consists of the following chapters: • safety (page 15 ) gives safety instructions you must follow when installing, commissioning, operating and servicing the drive. • introduction to the manual (this chapter, page 19 ) describes applic...

Page 21

Introduction to the manual 21 related documents see list of related manuals on page 2 . Categorization by frame size the acs320 drive is manufactured in frame sizes r0…r4. Some instructions and other information which only concern certain frame sizes are marked with the symbol of the frame size (r0…...

Page 22

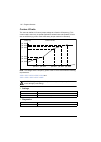

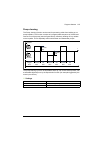

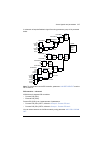

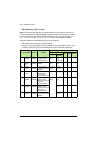

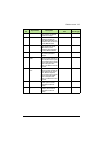

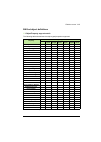

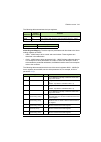

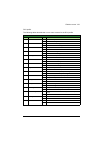

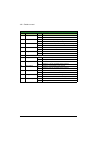

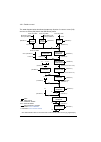

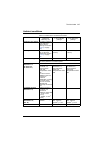

22 introduction to the manual quick installation and commissioning flowchart task see identify the frame size of your drive: r0…r4. Operation principle and hardware description : type designation key on page 27 technical data : ratings on page 384 or in section definitions on page 385 plan the insta...

Page 23: Operation Principle and

Operation principle and hardware description 23 3 operation principle and hardware description contents of this chapter the chapter briefly describes the operation principle, layout, type designation label and type designation information. It also shows a general diagram of power connections and con...

Page 24

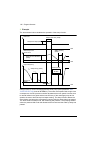

24 operation principle and hardware description product overview layout the layout of the drive is presented below. The figure shows a frame size r2 drive. The construction of the different frame sizes r0…r4 varies to some extent. 1 cooling outlet through top cover 2 mounting holes 3 panel cover (a)...

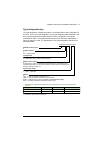

Page 25

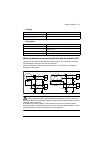

Operation principle and hardware description 25 power connections and control interfaces the diagram gives an overview of connections. I/o connections are parameterable. Rono ronc 3 9 di1 di2 di3 di4 di5 +24 v aux. Voltage output +24 v dc, max. 200 ma dosrc gnd dcom doout dognd digital/frequency out...

Page 26

26 operation principle and hardware description see application macros on page 79 for i/o connections for the different macros and chapter electrical installation on page 45 for installation in general. Type designation label the type designation label is attached to the left side of the drive. An e...

Page 27

Operation principle and hardware description 27 type designation key the type designation contains information on the specifications and configuration of the drive. You find the type designation on the type designation label attached to the drive. The first digits from the left express the basic con...

Page 28

28 operation principle and hardware description.

Page 29: Mechanical Installation

Mechanical installation 29 4 mechanical installation contents of this chapter the chapter tells how to check the installation site, unpack, check the delivery and install the drive mechanically. Checking the installation site the drive may be installed on the wall or in a cabinet. Check the enclosur...

Page 30

30 mechanical installation floor the floor/material below the installation should be non-flammable. Free space around the drive the required free space for cooling above and below the drive is 75 mm (3 in). No free space is required on the sides of the drive, so drives can be installed side by side....

Page 31

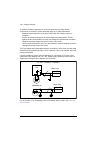

Mechanical installation 31 unpacking the drive (1) is delivered in a package that also contains the following items (frame size r2 shown in the figure): • plastic bag (2) including clamping plate (also used for i/o cables in frame sizes r3 and r4), i/o clamping plate (for frame sizes r0…r2), clamps ...

Page 32

32 mechanical installation installing the instructions in this manual cover drives with the ip20 degree of protection. To comply with nema 1, use the mul-r1, mul-r3 or mul-r4 option kit, which is delivered with multilingual installation instructions (3afe68642868, 3afe68643147 or 3aua0000025916, res...

Page 33

Mechanical installation 33 3. Position the drive onto the screws on the wall. 4. Tighten the screws in the wall securely. On din rail • click the drive to the rail. • to detach the drive, press the release lever on top of the drive (1b). 3 4 1 1b.

Page 34

34 mechanical installation fasten clamping plates 1. Fasten the clamping plate to the plate at the bottom of the drive with the provided screws. 2. For frame sizes r0…r2, fasten the i/o clamping plate to the clamping plate with the provided screws. 1 2.

Page 35: Planning The Electrical

Planning the electrical installation 35 5 planning the electrical installation contents of this chapter the chapter contains the instructions that you must follow when checking the compatibility of the motor and drive, and selecting cables, protections, cable routing and way of operation for the dri...

Page 36

36 planning the electrical installation selecting the supply disconnecting device (disconnecting means) install a hand-operated supply disconnecting device (disconnecting means) between the ac power source and the drive. The disconnecting device must be of a type that can be locked to the open posit...

Page 37

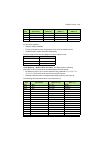

Planning the electrical installation 37 selecting the power cables general rules dimension the input power and motor cables according to local regulations . • the input power and the motor cables must be able to carry the corresponding load currents. See section ratings on page 384 or in section def...

Page 38

38 planning the electrical installation alternative power cable types power cable types that can be used with the drive are presented below. Motor cable shield to function as a protective conductor, the shield must have the same cross-sectional area as the phase conductors when they are made of the ...

Page 39

Planning the electrical installation 39 additional north american requirements type mc continuous corrugated aluminium armor cable with symmetrical grounds or shielded power cable is recommended for the motor cables if metallic conduit is not used. The power cables must be rated for 75 °c (167 °f). ...

Page 40

40 planning the electrical installation selecting the control cables general rules all analog control cables and the cable used for the frequency input must be shielded. Use a double-shielded twisted pair cable (figure a, for example jamak by draka nk cables) for analog signals. Employ one individua...

Page 41

Planning the electrical installation 41 routing the cables route the motor cable away from other cable routes. Motor cables of several drives can be run in parallel installed next to each other. It is recommended that the motor cable, input power cable and control cables are installed on separate tr...

Page 42

42 planning the electrical installation protecting the drive, input power cable, motor and motor cable in short circuit situations and against thermal overload protecting the drive and input power cable in short-circuit situations arrange the protection according to the following guidelines. Size th...

Page 43

Planning the electrical installation 43 using residual current devices (rcd) with the drive acs320-03x drives are suitable to be used with residual current devices of type b. Other measures for protection in case of direct or indirect contact, such as separation from the environment by double or rei...

Page 44

44 planning the electrical installation protecting the contacts of relay outputs inductive loads (relays, contactors, motors) cause voltage transients when switched off. Equip inductive loads with noise attenuating circuits (varistors, rc filters [ac] or diodes [dc]) in order to minimize the emc emi...

Page 45: Electrical Installation

Electrical installation 45 6 electrical installation contents of this chapter the chapter tells how to check the insulation of the assembly and the compatibility with it (ungrounded) and corner grounded tn systems as well as connect power cables, control cables and embedded fieldbus. Warning! Obey t...

Page 46

46 electrical installation motor and motor cable check the insulation of the motor and motor cable as follows: 1. Check that the motor cable is disconnected from the drive output terminals t1/u, t2/v and t3/w. 2. Measure the insulation resistance between the phase conductors and between each phase c...

Page 47

Electrical installation 47 checking the compatibility with it (ungrounded) and corner grounded tn systems warning! Disconnect the internal emc filter when installing the drive on an it system (an ungrounded power system or a high resistance-grounded [over 30 ohms] power system), otherwise the system...

Page 48

48 electrical installation connecting the power cables connection diagram notes: • do not use an asymmetrically constructed motor cable. • if there is a symmetrically constructed grounding conductor in the motor cable in addition to the conductive shield, connect the grounding conductor to the groun...

Page 49

Electrical installation 49 connection procedure 1. Fasten the grounding conductor (pe) of the input power cable under the grounding clamp. Connect the phase conductors to the u1, v1 and w1 terminals. Use a tightening torque of 0.8 n·m (7 in-lb) for frame sizes r0…r2, 1.7 n·m (15 in-lb) for r3, and 2...

Page 50

50 electrical installation connecting the control cables i/o terminals the figure below shows the i/o terminals. Tightening torque is 0.4 n·m / 3.5 in-lb. Warning! All elv (extra low voltage) circuits connected to the drive must be used within a zone of equipotential bonding, in other words, within ...

Page 51

Electrical installation 51 voltage and current connection for analog inputs bipolar voltage (-10…10 v) and current (-20…20 ma) are also possible. If a bipolar connection is used instead of a unipolar one, see section programmable analog inputs on page 107 for how to set parameters accordingly. Pnp a...

Page 52

52 electrical installation frequency input if di5 is used as a frequency input, see section frequency input on page 111 for how to set parameters accordingly. Connection example of a two-wire sensor hvac default, supply fan, return fan, cooling tower fan, condenser, booster pumps, pfa control, inter...

Page 53

Electrical installation 53 default i/o connection diagram the default connection of the control signals depends on the application macro in use, which is selected with parameter 9902 applic macro . The default macro is the hvac default. It provides a general purpose i/o configuration with three cons...

Page 54

54 electrical installation connection procedure 1. Remove the terminal cover by simultaneously pushing the recess and sliding the cover off the frame. 2. Digital signals : strip the outer insulation of the digital signal cable 360 degrees and ground the bare shield under the clamp. 3. Connect the co...

Page 55

Electrical installation 55 connecting the embedded fieldbus embedded fieldbus can be connected to the drive with eia-485 or rs-232. Connection diagram eia-485 the figure below shows the fieldbus connection. Terminate the eia-485 bus with a 120 ohm resistor at the end of the network by setting the ju...

Page 56

56 electrical installation.

Page 57: Installation Checklist

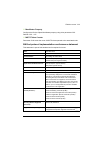

Installation checklist 57 7 installation checklist contents of this chapter this chapter contains the task list to be followed after the mechanical and electrical installation before proceeding to starting up the drive. Checking the installation check the mechanical and electrical installation of th...

Page 58

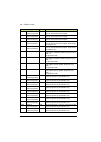

58 installation checklist the input power connections at u1, v1 and w1 are ok and tightened with the correct torque. Appropriate input power fuses and disconnector are installed. The motor connections at u2, v2 and w2 are ok and tightened with the correct torque. The motor cable, input power cable a...

Page 59: Start-Up

Start-up 59 8 start-up contents of this chapter this chapter contains a brief description of the assistant (hvac) control panel (operator keypad), start-up assistant and application selection. This chapter also includes the application macros used for defining a group of parameters. Macros change a ...

Page 60

60 start-up • language selection for the display • drive connection that can be made or detached at any time • start-up assistant to facilitate drive commissioning • copy function for moving parameters to other acs320 drives • backup function for saving parameter sets • context sensitive help • real...

Page 61

Start-up 61 fault and alarm adjustments the drive can detect a wide variety of potential system problems. For example, initial system operation may generate faults of alarms that indicate set-up problems. 1. Faults and alarms are reported on the control panel with a number. Note the number reported....

Page 62

62 start-up start-up start-up can be performed in two ways: • using the start-up assistant. See section start-up by using the start-up assistant . • changing the parameters individually. See section start-up by changing the parameters individually . Start-up by using the start-up assistant to start ...

Page 63

Start-up 63 start-up by changing the parameters individually to change the parameters, follow these steps: to complete the control connections by manually entering the parameters, see section parameters mode on page 66 . For detailed hardware description, see the chapter technical data . 1 select me...

Page 64

64 start-up notes: • the current parameter value appears below the highlighted parameter. • to view the default parameter value, press the up/down buttons simultaneously. • the most typical and necessary parameters to change belong to group 99: start- up data , group 10: start/stop/dir , group 11: r...

Page 65

Start-up 65 status information top . The top line of the lcd display shows the basic status information of the drive. • hand – indicates that the drive control is local, that is, from the control panel. • auto – indicates that the drive control is remote, such as the basic i/o (x1) or fieldbus. • of...

Page 66

66 start-up operating the drive auto/hand – the very first time the drive is powered up, it is in the auto control (auto) mode, and is controlled from the control terminal block x1. To switch to hand control (hand) and control the drive using the control panel, press and hold the or button. • pressi...

Page 67

Start-up 67 to complete the control connections by manually entering the parameters, see section parameters mode . For detailed hardware description, see chapter dimension drawings . Notes: • the current parameter value appears below the highlighted parameter. • to view the default parameter value, ...

Page 68

68 start-up start-up assistant mode to start the start-up assistant, follow these steps: the start-up assistant will guide you through the start-up. The start-up assistant guides you through the basic programming of a new drive. (familiarize yourself with basic control panel operation and follow the...

Page 69

Start-up 69 the order of tasks presented by the start-up assistant depends on your entries. The following task list is typical. Task name description spin the motor • prompts for control panel display language selection. • prompts for motor data. • guides user through rotation check. Commission driv...

Page 70

70 start-up changed parameters mode to view (and edit) a listing of all parameters that have been changed from macro default values, follow these steps: fault logger mode use the fault logger mode to see drive fault history, fault state details and help for the faults. 1. Select fault logger in the ...

Page 71

Start-up 71 • upload to panel – copies all parameters from the drive to the control panel. This includes user sets of parameters (if defined) and internal parameters. The control panel memory is non-volatile and does not depend on the panel’s battery. To upload parameters to control panel, follow th...

Page 72

72 start-up • download full set – restores the full parameter set from the control panel to the drive. Use this option to restore a drive, or to configure identical drives. This download does not include user sets of parameters. To download all parameters to drive, follow these steps: note: download...

Page 73

Start-up 73 • download application – copies a partial parameter set from the control panel to a drive. The partial set does not include internal motor parameters, parameters 9905 … 9909 , 1605 , 1607 , 5201 , nor any group 53: efb protocol parameters. Use this option to transfer parameters to system...

Page 74

74 start-up handling inexact downloads in some situations, an exact copy of the download is not appropriate for the target drive. Some examples: • a download to an old drive specifies parameters/values that are not available on the old drive. • a download (from an old drive) to a new drive does not ...

Page 75

Start-up 75 4. Highlight the desired value for the target drive. 5. Press save to save setting. 6. Press exit to step back to the differences view and continue for each remaining exception. 7. When your editing is complete, press ready in the differences list and then select “yes, save parameters.” ...

Page 76

76 start-up 3 select clock visibility with the up/down buttons and select sel to change the visibility of the clock. 4 scroll to show clock with the up/down buttons and select sel to make the clock visible. 5 scroll to set time with the up/down buttons and select sel. 6 change the hours and minutes ...

Page 77

Start-up 77 10 change the days, months and year with the up/down buttons and select ok to save the values. The active value is displayed in inverted color. 11 scroll to date format with the up/down buttons and select sel. 12 the date formats are displayed. Select a date format with the up/down butto...

Page 78

78 start-up i/o settings mode to view and edit the i/o settings, follow these steps: 1 select menu to enter the main menu. 2 scroll to i/o settings with the up/down buttons and select enter. 3 scroll to the i/o setting you want to view with the up/down buttons and select sel. 4 select the setting yo...

Page 79: Application Macros

Application macros 79 9 application macros contents of this chapter this chapter describes the application macros. For each macro, there is a wiring diagram showing the default control connections (digital and analog i/o). The chapter also explains how to save a user macro and how to recall it. Over...

Page 80

80 application macros general considerations the following considerations apply for all macros: • when using a direct speed reference in auto mode, connect the speed reference to analog input 1 (ai1), and provide the start command using digital input 1 (di1). In hand/off mode, the control panel prov...

Page 81

Application macros 81 selecting an application macro to select a macro, follow these steps: restoring defaults to restore the factory default settings, select application macro hvac default. Control wiring each macro has specific requirements for control wiring. Specific wiring requirements are incl...

Page 82

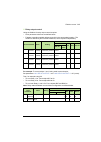

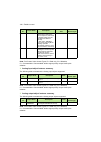

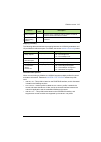

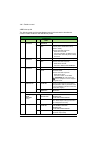

82 application macros application / macro listing this section describes the following macros: 9902 value macro 9902 value macro 1 hvac default (page 83 ) 9 int timer cs (page 91 ) 2 supply fan (page 84 ) 10 floating pnt (page 92 ) 3 return fan (page 85 ) 11 dual setppid (page 93 ) 4 clng twr fan (p...

Page 83

Application macros 83 hvac default this macro provides the factory default parameter settings for the drive. Factory defaults can be restored at any time by setting parameter 9902 applic macro to 1. The diagram below shows typical wiring using this macro. When using direct speed reference in auto mo...

Page 84

84 application macros supply fan this macro configures for supply fan applications where the supply fan brings fresh air in according to signals received from a transducer. When using direct speed reference in auto mode or process pid, see general considerations on page 80 . For more information see...

Page 85

Application macros 85 return fan this macro configures for return fan applications where the return fan removes air according to signals received from a transducer. When using direct speed reference in auto mode or process pid, see general considerations on page 80 . For more information see default...

Page 86

86 application macros cooling tower fan this macro configures for cooling tower fan applications where the fan speed is controlled according to the signals received from a transducer. When using direct speed reference in auto mode or process pid, see general considerations on page 80 . For more info...

Page 87

Application macros 87 condenser this macro configures for condenser and liquid cooler applications where fan speed is controlled according to signals received from a transducer. When using direct speed reference in auto mode or process pid, see general considerations on page 80 . For more informatio...

Page 88

88 application macros booster pump this macro configures for booster pump applications where the pump speed is controlled according to a signal received from a transducer. When using direct speed reference in auto mode or process pid, see general considerations on page 80 . For more information see ...

Page 89

Application macros 89 pfa control macro this macro provides parameter settings for pump and fan alternation (pfa) applications. To enable the macro, set the value of parameter 9902 applic macro to 7 (pump alterna). Note: parameter 2108 start inhibit must remain in the default setting 0 (off). Parame...

Page 90

90 application macros internal timer this macro configures for applications where a built-in timer starts and stops the motor. When the variable speed pump reaches a maximum speed limit, auxiliary pumps start as needed. When using direct speed reference in auto mode or process pid, see section gener...

Page 91

Application macros 91 internal timer with constant speeds / prv this macro configures for applications such as a timed powered roof ventilator (prv) which alternates between two constant speeds (constant speed 1 and 2) based on a built-in timer. Momentarily activating digital input 3 (di3) provides ...

Page 92

92 application macros floating point this application macro is for applications where speed reference needs to be controlled through digital inputs (di4 & di5). By activating digital input 4, the speed reference increases, by activating digital input 5, the speed reference decreases. If both digital...

Page 93

Application macros 93 dual setpoint with pid this macro configures for dual setpoint pid applications, where activating digital input 3 (di3) changes the process pid controller’s setpoint to another value. When using direct speed reference in auto mode or process pid, see section general considerati...

Page 94

94 application macros dual setpoint with pid and constant speeds this macro configures for applications with 2 constant speeds, active pid and pid alternating between two setpoints using digital inputs. Set pid setpoints (internal to the drive) using parameters 4011 ( set 1) and 4111 ( set 2). The d...

Page 95

Application macros 95 e-bypass this macro configures for an e-bypass device which can bypass the drive and connect the motor direct on-line. When using direct speed reference in auto mode or process pid, see section general considerations on page 80 . For more information see default values with dif...

Page 96

96 application macros hand control this macro configures for drive control using only the control panel with no automated control. Typically, this is a temporary configuration used prior to control wiring. Parameters changed relative to hvac default parameter value parameter value 9902 applic macro ...

Page 97

Application macros 97 e-clipse this macro configures an e-clipse bypass device which can bypass the drive and connect the motor direct on-line. When using direct speed reference in auto mode or process pid, see section general considerations on page 80 . Note : this macro is available only for the u...

Page 98

98 application macros modbus configuration macro this macro configures the drive communication and control parameters. The macro is available in acs320 drives with firmware version 4.03c or later. To enable the macro, set the value of parameter 9902 applic macro to 21 (ac500 modbus). The ac500 modbu...

Page 99: Program Features

Program features 99 10 program features contents of this chapter the chapter describes program features. For each feature, there is a list of related user settings, actual signals, and fault and alarm messages. Start-up assistant introduction the start-up assistant (requires the assistant control pa...

Page 100

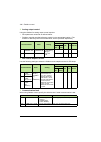

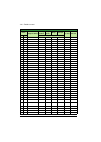

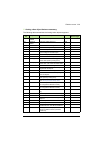

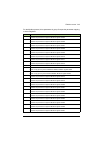

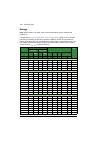

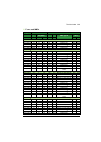

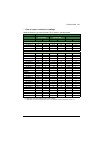

100 program features list of the tasks and the relevant drive parameters depending on the selection made in the application task (parameter 9902 applic macro ), the start-up assistant decides which consequent tasks it suggests. Name description set parameters language select selecting the language 9...

Page 101

Program features 101 contents of the assistant displays there are two types of displays in the start-up assistant: main displays and the information displays. The main displays prompt the user to feed in information. The assistant steps through the main displays. The information displays contain hel...

Page 102

102 program features local control vs. External control the drive can receive start, stop and direction commands and reference values from the control panel or through digital and analog inputs. Embedded fieldbus enables control over an open fieldbus link. A pc equipped with drivewindow light pc too...

Page 103

Program features 103 external control when the drive is in external control, the commands are given through the standard i/o terminals (digital and analog inputs) and/or the fieldbus interface. In addition, it is also possible to set the control panel as the source for the external control. External...

Page 104

104 program features block diagram: start, stop, direction source for ext1 the figure below shows the parameters that select the interface for start, stop, and direction for external control location ext1. Block diagram: reference source for ext1 the figure below shows the parameters that select the...

Page 105

Program features 105 reference types and processing the drive can accept a variety of references in addition to the conventional analog input and control panel signals. • the drive reference can be given with two digital inputs: one digital input increases the speed, the other decreases it. • the dr...

Page 106

106 program features reference trimming in reference trimming, the external reference is corrected depending on the measured value of a secondary application variable. The block diagram below illustrates the function. Settings parameter additional information 1102 ref1/2 selection 4230 … 4232 trimmi...

Page 107

Program features 107 programmable analog inputs the drive has two programmable analog voltage/current inputs. The inputs can be inverted, filtered and the maximum and minimum values can be adjusted. The update cycle for the analog input is 8 ms (12 ms cycle once per second). The cycle time is shorte...

Page 108

108 program features programmable analog output one programmable current output (0 … 20 ma) is available. Analog output signal can be inverted, filtered and the maximum and minimum values can be adjusted. The analog output signals can be proportional to motor speed, output frequency, output current,...

Page 109

Program features 109 programmable digital inputs the drive has five programmable digital inputs. The update time for the digital inputs is 2 ms. It is possible to delay the state change of digital inputs with delays defined in group group 18: freq in & tran out . This enables very simple program seq...

Page 110

110 program features diagnostics programmable relay output the drive has one programmable relay output. It is possible to add three additional relay outputs with the optional mrel-0 relay output extension module. For more information, see mrel-01 output relay module user’s manual (3aua0000035974 [en...

Page 111

Program features 111 frequency input digital input di5 can be programmed as a frequency input. Frequency input (0…16000 hz) can be used as external reference signal source. The update time for the frequency input is 50 ms. Update time is shorter when information is transferred to the application pro...

Page 112

112 program features actual signals several actual signals are available: • drive output frequency, current, voltage and power • motor speed and torque • intermediate circuit dc voltage • active control location (local, ext1 or ext2) • reference values • drive temperature • operating time counter (h...

Page 113

Program features 113 power loss ride-through if the incoming supply voltage is cut off, the drive will continue to operate by utilizing the kinetic energy of the rotating motor. The drive will be fully operational as long as the motor rotates and generates energy to the drive. The drive can continue...

Page 114

114 program features maintenance trigger a maintenance trigger can be activated to show a notice on the panel display when, for example, drive power consumption has exceeded the defined trigger point. Settings parameter group 29: maintenance trig acceleration and deceleration ramps two user-selectab...

Page 115

Program features 115 critical speeds a critical speeds function is available for applications where it is necessary to avoid certain motor speeds (drive output frequencies) or speed bands (output frequency bands) because of, for example, mechanical resonance problems. The user can define three criti...

Page 116

116 program features custom u/f ratio the user can define a u/f curve (output voltage as a function of frequency). This custom ratio is used only in special applications where linear and squared u/f ratio are not sufficient (eg, when motor break-away torque needs to be boosted). Note: the voltage an...

Page 117

Program features 117 r compensation when ir compensation is activated, the drive gives an extra voltage boost to the motor at low speeds. Ir compensation is useful in applications that require high breakaway torque. Settings parameter 2603 ir comp volt programmable protection functions ai ai set min...

Page 118

118 program features motor thermal protection the motor can be protected against overheating by activating the motor thermal protection function. The drive calculates the temperature of the motor on the basis of the following assumptions: 1. The motor is in the ambient temperature of 30 °c when powe...

Page 119

Program features 119 incorrect wiring defines the operation when incorrect input power cable connection is detected. Settings parameter 3023 wiring fault preprogrammed faults overcurrent the overcurrent trip limit for the drive is 325% of the drive nominal current. Dc overvoltage the dc overvoltage ...

Page 120

120 program features power limit power limitation is used to protect the input bridge and the dc intermediate circuit. If the maximum allowed power is exceeded, the drive torque is automatically limited. Maximum overload and continuous power limits depend on the drive hardware. For specific values, ...

Page 121

Program features 121 parameter lock the user can prevent parameter adjustment by activating the parameter lock. Settings parameters 1602 parameter lock and 1603 pass code pid control there are two built-in pid controllers in the drive: • process pid (pid1) and • external/trim pid (pid2). The pid con...

Page 122

122 program features block diagrams the figure below shows an application example: the controller adjusts the speed of a pressure boost pump according to the measured pressure and the set pressure reference. Ref k ti td i dfiltt errvinv oh1 ol1 frequency reference %ref = 4010 ... . .. A c t p a r f ...

Page 123

Program features 123 the following figure presents the speed/scalar control block diagram for process controller pid1. Pi d ac t pi d 1 o u t 11 06 n 11 0 2 sw itch ex t 1 /e x t 2 c ont ro l pa ne l sw itch l o c/ re m 11 0 1 sw itch loc al r ef pa n el r ef 1 pa ne l r e f2 n va lu e n 1104 li m i...

Page 124

124 program features settings diagnostics parameter additional information 1101 local control mode reference type selection 1102 ext1/2 selection 1106 pid1 activation 1107 ref2 minimum limit 1501 pid2 output (external controller) connection to ao 9902 pid control macro selection group 40: process pi...

Page 125

Program features 125 sleep function for the process pid (pid1) control the sleep function operates on a 2 ms time level. The block diagram below illustrates the sleep function enable/disable logic. The sleep function can be put into use only when the pid control is active. 1) 1 = activate sleeping 0...

Page 126

126 program features example the time scheme below visualizes the operation of the sleep function. Sleep function for a pid controlled pressure boost pump (when parameter 4022 sleep selection is set to internal): the water consumption falls at night. As a consequence, the pid process controller decr...

Page 127

Program features 127 settings diagnostics motor temperature measurement through the standard i/o this section describes the temperature measurement of one motor when the drive i/o terminals are used as the connection interface. Motor temperature can be measured using pt100 or ptc sensors connected t...

Page 128

128 program features to fulfill the insulation requirement, connect a thermistor (and other similar components) to the drive’s control terminals using any of these alternatives: • separate the thermistor from live parts of the motor with double reinforced insulation. • protect all circuits connected...

Page 129

Program features 129 settings diagnostics parameter additional information group 13: analogue inputs analog input settings group 15: analogue outputs analog output settings group 35: motor temp meas motor temperature measurement settings other at the motor end the cable shield should be grounded thr...

Page 130

130 program features timed functions a variety of drive functions can be time controlled, eg start/stop and ext1/ext2 control. The drive offers • four start and stop times (start time 1…4, stop time 1…4) • four start and stop days (start day 1…4, stop day 1…4) • four timed functions for collecting t...

Page 131

Program features 131 a parameter which is triggered by a timed function can be connected to only one timed function at a time. Examples air conditioning is active on weekdays from 8:00 to 15:30 (8 a.M to 3:30 p.M) and on sundays from 12:00 to 15:00 (12 to 3 p.M). By pressing the extension time switc...

Page 132

132 program features user load curve the user can specify a load curve (motor torque as a function of frequency) for supervision. The curve is defined by five points. Supervision can be set for the torque dropping below the underload curve, exceeding the overload curve, or both. A fault is generated...

Page 133

Program features 133 diagnostics energy optimizer energy optimizer optimizes the flux so that the total energy consumption and motor noise level are reduced when the drive operates below the nominal load. The total efficiency (motor and drive) can be improved by 1 … 10% depending on the load torque ...

Page 134

134 program features energy saving energy saving tools calculate energy saved in kwh and mwh, energy saved in local currency as well as reduction in co 2 emission, all compared to the situation when the pump is connected directly to the supply. Two actual signals, 0176 saved amount 1 and 0177 saved ...

Page 135

Program features 135 pump cleaning the pump cleaning function can be used for preventing solids from building up on pump impellers. The function consists of a programmable sequence of forward and reverse runs of the pump (see the figure below), effectively shaking off any residue on the impeller. Th...

Page 136

136 program features load analyzer the load analyzer can be used for analyzing the customer’s process and sizing the drive and the motor. Peak value logger the user can select a signal ( group 01: operating data ) to be monitored by the peak value logger (pvl). The signal is sampled at 2 ms interval...

Page 137

Program features 137 settings diagnostics pfa control (requires use of mrel-01 option purchased separately) pfa control the pump and fan alternation (pfa) control switches auxiliary pumps on and off as required by capacity changes. The autochange function alternates between pumps to keep the duty ti...

Page 138

138 program features an autochange function (when enabled and with the appropriate switchgear) equalizes duty time between the pump motors. Autochange periodically increments the position of each motor in the rotation – the speed regulated motor becomes the last auxiliary motor, the first auxiliary ...

Page 139

Program features 139 spfc powering routine the diagram below illustrates the spfc powering routine. 1. At start, relay ro 1 is closed and motor 1 is connected to the drive output. 2. The drive waits for the time specified by parameter 8122 pfa start delay to ensure that the contactor (ro 1) has stab...

Page 140

140 program features how to parameterize spfc control 1. Set pfa reference steps (parameters 8103 … 8105 ) if needed. 2. Set pfa start and stop frequencies (parameters 8109 … 8114 ). 3. Set pfa auxiliary motor start and stop delays (parameters 8115 … 8116 ). 4. Set the number of auxiliary motors (pa...

Page 141

Program features 141 diagnostics group 81: pfa control ; 8123 pfa enable pfa control settings; enables pfa/spfc function. Actual signal additional information 0116 application block output signal 0162 ro 1 status 0163 to status 0173 ro 2…4 status. With option mrel-01 only. Alarm autochange pfa autoc...

Page 142

142 program features connection diagram example a c s 320- xx -x xx x- x.

Page 143: Actual Signals And

Actual signals and parameters 143 11 actual signals and parameters contents of this chapter the chapter describes the actual signals and parameters and gives the fieldbus equivalent values for each signal/parameter. It also contains a table of the default values for the different macros. Note: when ...

Page 144

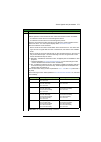

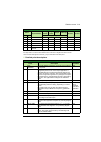

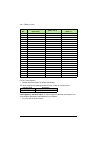

144 actual signals and parameters terms and abbreviations fieldbus equivalent example: if parameter 2008 maximum freq (see page 191 ) is set from an external control system, an integer value of 1 corresponds to 0.1 hz. All the read and sent values are limited to 16 bits (-32768…32767). Actual signal...

Page 145

Actual signals and parameters 145 parameters in the short parameter view parameters in the short parameter view no. Name/value description default 11 reference select panel reference type, external control location selection and external reference sources and limits. See group 11: reference select i...

Page 146

146 actual signals and parameters 53 efb protocol embedded fieldbus link settings. See chapter fieldbus control on page 283 . 5301 efb protocol id contains the identification and program version of the protocol. Note: you can reset this parameter only with parameter 9802 comm prot sel . - 5302 efb s...

Page 147

Actual signals and parameters 147 5320 efb par 20 abb drives profile (abb drv lim or abb drv full) status word. Read only copy of the fieldbus status word. 0000 hex 98 options external serial communication activation. 9802 comm prot sel activates the external serial communication and selects the int...

Page 148

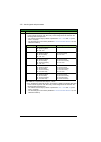

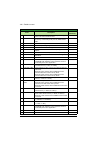

148 actual signals and parameters parameter listing parameter data is specific to acs320 firmware version 4.01c. Group 99: start-up data this group defines special start-up data required to: • set up the drive • enter motor information. Note: parameters checked under the heading “s” can be modified ...

Page 149

Actual signals and parameters 149 9907 motor nom freq 10.0 … 500 hz 0.1 hz 60 hz (us) defines the nominal motor frequency. • range: 10 … 500 hz (typically 50 or 60 hz) • sets the frequency at which output voltage equals parameter 9905 motor nom volt • field weakening point = norm freq * supply volt ...

Page 150

150 actual signals and parameters group 01: operating data this group contains drive operating data, including actual signals. The drive sets the values for actual signals, based on measurements or calculations. You cannot set these values. Group 01: operating data code description range resolution ...

Page 151

Actual signals and parameters 151 0115 kwh counter (r) 0 … 10000 h 1 h - the drive’s accumulated power consumption in kilowatt hours. • can be reset by pressing up and down buttons simultaneously when in parameter set mode. 0116 appl blk output 0 … 100% (torque: 0 … 600%) 0.1% - application block ou...

Page 152

152 actual signals and parameters 0134 comm ro word 0...65535 1 0 free data location that can be written from serial link. • used for relay output control. • see parameter 1401. 0135 comm value 1 -32768 … +32767 1 0 free data location that can be written from serial link. 0136 comm value 2 -32768 … ...

Page 153

Actual signals and parameters 153 0159 pid comm value 2 data received from fieldbus for pid control (pid1 and pid2). 0160 di 1-5 status status of digital inputs. Example: 10000 = di1 is on, di2...Di5 are off. 0161 pulse input freq 1 = 1 hz value of frequency input in hz. 0162 ro status 1 = 1 status ...

Page 154

154 actual signals and parameters 0176 saved amount 1 0.0 … 999.9 energy saved in local currency (remainder when the total saved energy is divided by 1000). See the note on page 251 . • to find out the total saved energy in currency units, add the value of parameter 0177 saved amount 2 multiplied by...

Page 155

Actual signals and parameters 155 group 03: fb actual signals this group monitors fieldbus communications. Group 03: fb actual signals code description range resolution default s 0301 fb cmd word 1 - - - read-only copy of the fieldbus command word 1. • the fieldbus command is the principal means for...

Page 156

156 actual signals and parameters 0303 fb sts word 1 - 1 - hex read-only copy of the status word 1. • the drive sends status information to the fieldbus controller. The status consists of two status words. 0304 fb sts word 2 - 1 - hex read-only copy of the status word 2. • see parameter 0303 fb sts ...

Page 157

Actual signals and parameters 157 0305 fault word 1 - 1 0000 hex read-only copy of the fault word 1. • when a fault is active, the corresponding bit for the active fault is set in the fault words. • each fault has a dedicated bit allocated within fault words. • see chapter fault tracing on page 359 ...

Page 158

158 actual signals and parameters 0308 alarm word 1 - 1 0000 hex read-only copy of the alarm word 1. • when a fault is active, the corresponding bit for the active fault is set in the fault words. • each fault has a dedicated bit allocated within fault words. • bits remain set until the whole alarm ...

Page 159

Actual signals and parameters 159 group 04: fault history this group stores a recent history of the faults reported by the drive. Group 04: fault history code description range resolution default s 0401 last fault fault code text 1 0 0 = clear the fault history (on panel = no record). N = fault code...

Page 160

160 actual signals and parameters group 10: start/stop/dir this group: • defines external sources (ext1, and ext2) for commands that enable start, stop and direction changes. • locks direction or enables direction control. To select between the two external locations use the next group, parameter 11...

Page 161

Actual signals and parameters 161 5 = di1p, 2p, 3p – start forward, start reverse, and stop. • start and direction commands are given simultaneously with two separate momentary push-buttons (the p stands for “pulse”). • start forward command is through a normally open push-button connected to digita...

Page 162

162 actual signals and parameters group 11: reference select this group defines: • how the drive selects between command sources. • characteristics and sources for ref1 and ref2. 1002 ext2 commands 0...34 1 1 defines external control location 2 (ext2) – the configuration of start, stop and direction...

Page 163

Actual signals and parameters 163 group 11: reference select code description range resolution default s 1101 keypad ref sel 1,2 1 1 selects the reference controlled in local control mode. 1 = ref1 (hz/rpm) – frequency reference in hz. 2 = ref2 (%) – %-reference. 1102 ext1/ext2 sel -5...12 1 0 defin...

Page 164

164 actual signals and parameters 1103 ref1 select 0...32 1 1 selects the signal source for external reference ref1. 0 = keypad – defines the control panel as the reference source. 1 = ai1 – defines analog input 1 (ai1) as the reference source. 2 = ai2 – defines analog input 2 (ai2) as the reference...

Page 165

Actual signals and parameters 165 4 = ai2/joyst – defines analog input 2 (ai2), configured for joystick operation, as the reference source. • see above (ai1/joyst) description. 5 = di3u,4d(r) – defines digital inputs as the speed reference source (motor potentiometer control). • digital input di3 in...

Page 166

166 actual signals and parameters analog input reference correction parameter values 9, 10, and 14…17 use the formula in the following table. Where: • c = main reference value (= comm for values 9, 10 and = 1 for values 14…17). • b = correcting reference (= ai1 for values 9, 10 and = ai2 for values ...

Page 167

Actual signals and parameters 167 1104 ref1 min 0.0 … 500.0 hz 0.1 hz 0.0 hz sets the minimum for external reference 1. • the minimum analog input signal (as a percent of the full signal in volts or amps) corresponds to ref1 min in hz/rpm. • parameter 1301 minimum ai1 or 1304 minimum ai2 sets the mi...

Page 168

168 actual signals and parameters group 12: constant speeds this group defines a set of constant speeds. In general: • you can program up to 7 constant speeds, ranging from 0 … 500 hz. • values must be positive (no negative speed values for constant speeds). • constant speed selections are ignored i...

Page 169

Actual signals and parameters 169 group 12: constant speeds code description range resolution default s 1201 const speed sel -13…19 1 3 defines the digital inputs used to select constant speeds. See general comments in the introduction. 0 = not sel – disables the constant speed function. 1 = di1 – s...

Page 170

170 actual signals and parameters 15…18 = timer – selects constant speed 1, constant speed 2 or the external reference depending on the state of, eg, timer 1 (if the parameter value is 15 = timer 1), timer 3 (if the parameter value is 17 = timer 3) etc, and the constant speed mode. See parameter 120...

Page 171

Actual signals and parameters 171 -12 = di1,2,3(inv) – selects one of seven constant speeds (1...7) using di1, di2 and di3. • inverse operation uses three digital inputs, as defined below (0 = di de-activated, 1 = di activated): -13 = di3,4,5(inv) – selects one of seven constant speeds (1…3) using d...

Page 172

172 actual signals and parameters 1209 timed mode sel 1…2 1 2 defines timer activated, constant speed mode. Timer can be used to change between external reference and a maximum of three constant speeds, or to change between a maximum of 4 selectable speeds, in other words, constant speeds 1,2,3 and ...

Page 173

Actual signals and parameters 173 group 13: analogue inputs this group defines the limits and the filtering for analog inputs. Group 13: analogue inputs code description range resolution default s 1301 minimum ai1 -100.0 … 100.0% 0.1% 20.0% defines the minimum value of the analog input. • define val...

Page 174

174 actual signals and parameters group 14: relay outputs this group defines the condition that activates each of the relay outputs. Group 14: relay outputs code description range resolution default s 1401 relay output 1 0…69 1 1 defines the event or condition that activates relay 1 – what relay out...

Page 175

Actual signals and parameters 175 20 = ref loss – energize relay when reference or active control place is lost. 21 = overcurrent – energize relay when an overcurrent alarm or fault occurs. 22 = overvoltage – energize relay when an overvoltage alarm or fault occurs. 23 = drive temp – energize relay ...

Page 176

176 actual signals and parameters 36 = comm(-1) – energize relay based on input from fieldbus communication. • fieldbus writes binary code in parameter 0134 that can energizes relay 1…relay 4 according to the following: • 0 = de-energize relay, 1 = energize relay. 37 = timer 1 – energize relay when ...

Page 177

Actual signals and parameters 177 1404 ro 1 on delay 0.0 … 3600.0 s 0.1 s 0.0 s defines the switch-on delay for relay 1. • on / off delays are ignored when relay output of parameter 1401 relay output 1 is set to pfa. 1405 ro 1 off delay 0.0 … 3600.0 s 0.1 s 0.0 s defines the switch-off delay for rel...

Page 178

178 actual signals and parameters group 15: analogue outputs this group defines the drive’s analog (current signal) outputs. The drive’s analog outputs can be: • any parameter of group 01: operating data . • limited to programmable minimum and maximum values of output current. • scaled (and/or inver...

Page 179

Actual signals and parameters 179 group 16: system controls this group defines a variety of system level locks, resets and enables. 1503 ao1 content max depends on selection - 60.0 sets the maximum content value • content is the parameter selected by parameter 1501 ao1 content sel . • maximum value ...

Page 180

180 actual signals and parameters 1602 parameter lock 0…2 1 1 determines if the control panel can change parameter values. • this lock does not limit parameter changes made by macros. • this lock does not limit parameter changes written by fieldbus inputs. • this parameter value can be changed only ...

Page 181

Actual signals and parameters 181 1605 user par set chg -5…5 1 0 defines control for changing the user parameter set. • see parameter 9902 applic macro . • the drive must be stopped to change user parameter sets. • during a change, the drive will not start. Note: always save the user parameter set a...

Page 182

182 actual signals and parameters 1606 local lock -5…8 1 0 defines control for the use of the hand mode. The hand mode allows drive control from the control panel. • when local lock is active, the control panel cannot change to hand mode. 0 = not sel – disables the lock. The control panel can select...

Page 183

Actual signals and parameters 183 1608 start enable 1 -5…7 1 4 selects the source of the start enable 1 signal. Note: start enable functionality differs from the run enable functionality. 0 = not sel – allows the drive to start without an external start enable signal. 1 = di1 – defines digital input...

Page 184

184 actual signals and parameters 1609 start enable 2 -5…7 1 0 selects the source of the start enable 2 signal. Note: start enable functionality differs from the run enable functionality. 0 = not sel – allows the drive to start without an external start enable signal. 1 = di1 – defines digital input...

Page 185

Actual signals and parameters 185 group 17: override this group defines the source for the override activation signal, the override speed/ frequency and pass code and how the override is enabled and disabled. When override di is activated, the drive stops and then accelerates to the preset speed or ...

Page 186

186 actual signals and parameters commissioning the override mode 1. Enter the parameters in all groups as needed, except group 17: override . 2. Select the digital input that will activate the override mode (parameter 1701 override sel ). 3. Enter the frequency reference for the override mode with ...

Page 187

Actual signals and parameters 187 group 17: override code description range resolution default s 1701 override sel -5…5 1 0 selects the source of the override activation signal. 0 = not sel – override activation signal not selected. 1 = di1 – defines digital input di1 as the override activation sign...

Page 188

188 actual signals and parameters group 18: freq in & tran out this group defines the frequency input and transistor output signal processing. 1707 override ref selects the source of the override reference. 1 = constant – selects a preset frequency or speed for the override. The frequency value is d...

Page 189

Actual signals and parameters 189 1809 fo content min - - - defines the minimum frequency output fo signal value. Signal is selected with parameter 1808 fo content sel . Fo minimum and maximum correspond to 1811 minimum fo and 1812 maximum fo settings as follows: setting range depends on parameter 1...

Page 190

190 actual signals and parameters 1820 di 4 on delay 0.0 s see parameter 1814 di 1 on delay . 1821 di 4 off delay 0.0 s see parameter 1815 di 1 off delay . 1822 di 5 on delay 0.0 s see parameter 1814 di 1 on delay . 1823 di 5 off delay 0.0 s see parameter 1815 di 1 off delay . Group 18: freq in & tr...

Page 191

Actual signals and parameters 191 group 20: limits this group defines minimum and maximum limits to follow in driving the motor – speed, frequency, current, torque, etc. Group 20: limits code description range resolution default s 2003 max current 0.0 … 1.1 * i 2n 0.1 a 1.1 * i 2n defines the maximu...

Page 192

192 actual signals and parameters group 21: start/stop this group defines how the motor starts and stops. The drive supports several start and stop modes. Group 21: start/stop code description range resolution default s 2101 start function 1…7 1 6 selects the motor start method. 1 = auto – the drive...

Page 193

Actual signals and parameters 193 2103 dc magn time 0.00 … 10.00 s 0.01 s 0.30 s defines the pre-magnetizing time for the dc magnetizing start mode. • use parameter 2101 start function to select the start mode. • after the start command, the drive pre-magnetizes the motor for the time defined here, ...

Page 194

194 actual signals and parameters 2109 emerg stop sel -5…5 1 0 defines control of the emergency stop command. When activated: • emergency stop decelerates the motor using the emergency stop ramp (parameter 2208 emerg dec time ). • requires an external stop command and removal of the emergency stop c...

Page 195

Actual signals and parameters 195 group 22: accel/decel this group defines ramps that control the rate of acceleration and deceleration. You define these ramps as a pair, one for acceleration and one for deceleration. You can define two pairs of ramps and use a digital input to select one or the oth...

Page 196

196 actual signals and parameters 2203 deceler time 1 0.0 … 1800.0 s 0.1 s 30.0 s sets the deceleration time for maximum frequency to zero for ramp pair 1. • actual deceleration time also depends on parameter 2204 ramp shape 1 . • see parameter 2008 maximum freq . 2204 ramp shape 1 0 … 1000.0 s 0.1 ...

Page 197

Actual signals and parameters 197 2209 ramp input 0 -5…5 1 0 defines control for forcing the ramp input to 0. 0 = not sel – not selected. 1 = di1 – defines digital input 1 as the control for forcing the ramp input to 0. • activating the digital input forces ramp input to 0. Ramp output will ramp to ...

Page 198

198 actual signals and parameters group 25: critical speeds this group defines up to three critical speeds or ranges of speeds that are to be avoided due, for example, to mechanical resonance problems at certain speeds. Group 25: critical speeds code description range resolution default s 2501 crit ...

Page 199

Actual signals and parameters 199 group 26: motor control this group provides controls for fine-tuning the motor control. 2507 crit speed 3 hi 0.0 … 500.0 hz 0.1 hz 0.0 hz sets the maximum limit for critical speed range 3. • see parameter 2503 crit speed 1 hi . Group 26: motor control code descripti...

Page 200

200 actual signals and parameters 2606 switching freq 1, 4, 8, 12, 16 khz - 4 khz defines the switching frequency of the drive. Higher switching frequency results in lower acoustic noise in the motor. See also parameter 2207 switch freq ctrl and section switching frequency derating , i2n and ild (= ...

Page 201

Actual signals and parameters 201 2609 noise smoothing 0, 1 1 0 enables the noise smoothing function. Noise smoothing distributes the acoustic motor noise over a range of frequencies instead of a single tonal frequency resulting in lower peak noise intensity. A random component with an average of 0 ...

Page 202

202 actual signals and parameters group 29: maintenance trig this group contains usage levels and trigger points. When usage reaches the set trigger point, a notice is displayed on the control panel signals that maintenance is due. Group 29: maintenance trig code description range resolution default...

Page 203

Actual signals and parameters 203 group 30: fault functions this group defines situations that the drive should recognize as potential faults and defines how the drive should respond if the fault is detected. 2907 user mwh trig 0.0 … 6553.5 mwh 0.1 mwh 0.0 defines the trigger point for the drive pow...

Page 204

204 actual signals and parameters 3002 panel comm err 1…3 1 1 defines the drive response to a control panel communication error. Note: when either of the two external control locations are active, and start, stop and/or direction are through the control panel – 1001 ext1 commands / 1002 ext2 command...

Page 205

Actual signals and parameters 205 3006 mot therm time 256 … 9999 s 1 1050 s sets the motor thermal time constant for the motor temperature model. • this is the time required for the motor to reach 63% of the final temperature with steady load. • for thermal protection according to ul requirements fo...

Page 206

206 actual signals and parameters 3009 break point freq 1 … 250 hz 1 35 hz defines the load curve together with parameters 3007 mot load curve and 3009 break point freq . Example: thermal protection trip times when parameters 3006 mot therm time , 3007 mot load curve and 3008 zero speed load have de...

Page 207

Actual signals and parameters 207 3016 supply phase selects how the drive reacts to a supply phase loss, in other words, when the dc voltage ripple is excessive. 0 = fault – drive trips on fault supply phase and the motor coasts to stop when the dc voltage ripple exceeds 14% of the nominal dc voltag...

Page 208

208 actual signals and parameters group 31: automatic reset this group defines conditions for automatic resets. An automatic reset occurs after a particular fault is detected. The drive holds for a set delay time, then automatically restarts. You can limit the number of resets in a specified time pe...

Page 209

Actual signals and parameters 209 3104 ar overcurrent 0, 1 1 0 sets the automatic reset for the overcurrent function on or off. 0 = disable – disables automatic reset. 1 = enable – enables automatic reset. • automatically resets fault 0001 overcurrent after the delay set by parameter 3103 delay time...

Page 210

210 actual signals and parameters group 32: supervision this group defines supervision for up to three signals from group 01: operating data . Supervision monitors a specified parameter and energizes a relay output if the parameter passes a defined limit. Use group 14: relay outputs , to define the ...

Page 211

Actual signals and parameters 211 lo > hi operating data supervision using relay outputs, when lo > hi. The lowest limit (hi 3203 ) is active initially, and remains active until the supervised parameter goes above the highest limit (lo 3202 ), making that limit the active limit. That limit remains a...

Page 212

212 actual signals and parameters group 33: information this group provides access to information about the drive’s current programs: versions and test date. 3208 superv 3 lim lo depends on selection 100.0 sets the low limit for the third supervised parameter. See parameter 3207 superv 3 param above...

Page 213

Actual signals and parameters 213 group 34: panel display this group defines the content for control panel display (middle area), when the control panel is in the output mode. Group 34: panel display code description range resolution default s 3401 signal1 param 101…178 1 103 selects the first param...

Page 214

214 actual signals and parameters 3404 output1 dsp form 0…9 1 5 defines the decimal point location for the first display parameter. 1…7 – defines the decimal point location. • enter the number of digits desired to the right of the decimal point. • see table for example using pi (3.14159). 8 = bar me...

Page 215

Actual signals and parameters 215 3407 output1 max depends on selection 1 - sets the maximum value displayed for the first display parameter. Note: parameter is not effective if parameter 3404 output1 dsp form = 9 (direct). 3408 signal2 param 100…178 1 104 selects the second parameter (by number) di...

Page 216

216 actual signals and parameters 3419 output3 unit 0…127 1 11 selects the units used with the third display parameter. See parameter 3405 output1 unit . 3420 output3 min depends on selection 1 - sets the minimum value displayed for the third display parameter. See parameter 3406 output1 min . 3421 ...

Page 217

Actual signals and parameters 217 group 35: motor temp meas group 35: motor temp meas code description range resolution default s 3501 sensor type 0…6 1 0 activates the motor temperature measurement function and selects the sensor type. See also parameter group 15: analogue outputs . 0 = none – func...

Page 218

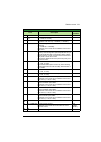

218 actual signals and parameters group 36: timed functions this group defines the timed functions. The timed functions include: • four daily start and stop times • four weekly start, stop and boost times • four timers for collecting selected periods together. A timer can be connected to multiple ti...

Page 219

Actual signals and parameters 219 a parameter can be connected to only one timer. Time period 1 3602 start time 1 3603 stop time 1 3604 start day 1 3605 stop day 1 time period 4 3614 start time 4 3615 stop time 4 3616 start day 4 3617 stop day 4 time period 3 3610 start time 3 3611 stop time 3 3612 ...

Page 220

220 actual signals and parameters group 36: timed functions code description range resolution default s 3601 timers enable -15…17 1 0 selects the source for the timer enable signal. 0 = not sel – timed functions are disabled. 1 = di1 – defines digital input di1 as the timed function enable signal. •...

Page 221

Actual signals and parameters 221 3604 start day 1 1…7 1 1 defines the weekly start day. 1 = monday…7 = sunday. • if parameter value is 1, then period 1 weekly is active from monday midnight (00:00:00). 3605 stop day 1 1…7 1 1 defines weekly stop day. 1 = monday…7 = sunday. • if parameter value is 5...

Page 222

222 actual signals and parameters 3616 start day 4 1…7 1 1 defines timer 4 weekly start day. • see parameter 3604 start day 1 . 3617 stop day 4 1…7 1 1 defines timer 4 weekly stop day. • see parameter 3605 stop day 1 . 3622 boost sel -5…5 1 0 selects the source for the booster signal. 0 = not sel – ...

Page 223

Actual signals and parameters 223 3626 timer 1 src 0…48 1 0 defines the time periods used by the timer. 0 = not sel- no timers have been selected. 1 = p1 – time period 1 selected in the timer. 2 = p2 – time period 2 selected in the timer. 3 = p1+p2 – time periods 1 and 2 selected in the timer. 4 = p...

Page 224

224 actual signals and parameters group 37: user load curve this new group defines supervision of user adjustable load curves (motor torque as a function of frequency). The curve is defined by five points. - the function replaces deleted underload parameters 3013…3015 3630 alternating timer 0.0…1000...

Page 225

Actual signals and parameters 225 3702 user load c func 1, 2 1 1 action wanted during load supervision. 1 = fault – a fault is generated when the condition defined by 3701 user load c mode has been valid longer than the time set by 3703 user load c time . 2 = alarm – an alarm is generated when the c...

Page 226

226 actual signals and parameters group 40: process pid set 1 this group defines a set of parameters used with the process pid (pid1) controller. Typically only parameters in this group are needed. Pid controller – basic set-up in pid control mode, the drive compares a reference signal (setpoint) to...

Page 227

Actual signals and parameters 227 a schematic of setpoint/feedback signal flow using parameter group 40 is presented below. Note: to activate and use the pid controller, parameter 1106 ref2 select must be set to value 19. Pid controller – advanced acs320 has 2 separate pid controllers: • process pid...

Page 228

228 actual signals and parameters typically two different pid controller sets are used when the load of the motor changes considerably from one situation to another. You can use external pid (pid2), defined in group 42: ext / trim pid , in 2 different ways: • instead of using additional pid controll...

Page 229

Actual signals and parameters 229 group 40: process pid set 1 code description range resolution default s 4001 gain 0.1 … 100.0 0.1 2.5 defines the pid controller’s gain. • at 0.1, the pid controller output changes one-tenth as much as the error value. • at 100, the pid controller output changes one...

Page 230

230 actual signals and parameters 4002 integration time 0.0 … 3600.0 s 0.1 s 3.0 s defines the pid controller’s integration time. Integration time is, by definition, is the time required to increase the output by the error value: • error value is constant and 100%. • gain = 1. • integration time of ...

Page 231

Actual signals and parameters 231 4005 error value inv 0, 1 - 0 selects either a normal or inverted relationship between the feedback signal and the drive speed. 0 = no – normal, a decrease in feedback signal increases drive speed. Error = ref - fbk 1 = yes – inverted, a decrease in feedback signal ...

Page 232

232 actual signals and parameters 4010 set point sel 0...32 1 0 defines the reference signal source for the pid controller. • parameter has no significance when the pid regulator is by-passed (see parameter 8121 reg bypass ctrl ). 0 = keypad – control panel provides reference. 1 = ai1 – analog input...

Page 233

Actual signals and parameters 233 analog input reference correction parameter values 9, 10, and 14…17 use the formula in the following table. Where: • c = main reference value (= comm for values 9, 10 and = ai1 for values 14…17). • b = correcting reference (= ai1 for values 9, 10 and = ai2 for value...

Page 234

234 actual signals and parameters 4012 setpoint min -500.0 … 500.0% 0.1% 0.0% defines the minimum value for the selected pid reference signal source. See parameter 4010 set point sel . Value in percent. Example: analog input ai1 is selected as the pid reference source (value of parameter 4010 is ai1...

Page 235

Actual signals and parameters 235 4015 fbk multiplier -32.768…32.767 0.001 0 defines an extra multiplier for the pid fbk value defined by parameter 4014 fbk sel . • used mainly in applications where the flow is calculated from the pressure difference. 0 = not selected. -32.768…32.767 = multiplier ap...

Page 236

236 actual signals and parameters 4018 act1 minimum -1000 … 1000% 1% 0% • sets the minimum value for act1. • scales the source signal used as the actual value act1 (defined by parameter 4016 act1 input act1 input). For parameter 4016 values 6 (comm act 1) and 7 (comm act 2) scaling is not done. • se...

Page 237

Actual signals and parameters 237 4022 sleep selection -11…11 - 0 defines the control for the pid sleep function. 0 = not sel – disables the pid sleep control function. 1 = di1 – defines digital input 1 as the control for the pid sleep function. • activating the digital input activates the sleep fun...

Page 238

238 actual signals and parameters 4023 pid sleep level 0.0 … 120.0 hz 0.1 hz 0.0 hz sets the motor speed / frequency that enables the pid sleep function – a motor speed / frequency below this level, for at least the time period 4024 pid sleep delay enables the pid sleep function (stopping the drive)...

Page 239

Actual signals and parameters 239 4025 wake-up dev 0.0 … 3276.7 0.1 0.0 defines the wake-up deviation – a deviation from the setpoint greater than this value, for at least the time period 4026 wake-up delay , re-starts the pid controller. • parameters 4006 units and 4007 unit scale define the units ...

Page 240

240 actual signals and parameters 4027 pid 1 param set -5…11 1 0 defines how selections are made between pid set 1 and pid set 2. Pid parameter set selection. When set 1 is selected, parameters 4001 … 4026 are used. When set 2 is selected, parameters 4001 … 4026 are used. 0 = set 1 – pid set 1 (para...

Page 241

Actual signals and parameters 241 4033 pid ref dec time 0.0 … 1800.0 s 1 = 0.1 s 0.0 s defines the time for the reference (pid setpoint) decrease from 100 to 0%. 4034 pid ref freeze not sel freezes the input (reference, pid setpoint) of the process pid controller. 0 = not sel – not selected 1 = di1 ...

Page 242

242 actual signals and parameters 4039 int setpnt sel not sel selects the source for the selection of the internal setpoint used as the process pid controller reference when parameter 4010 set point sel value is set to internal. Example: 4010 set point sel = internal 4039 int setpnt sel = di2 digita...

Page 243

Actual signals and parameters 243 group 41: process pid set 2 this group defines second set of parameters used with the process pid (pid1) controller. The operation of parameters 4101 ... 4139 is analogous with process pid set 1 (pid1) parameters 4001 … 4039 . Pid parameter set 2 can be selected by ...

Page 244

244 actual signals and parameters 4228 activate -5…12 - 1 defines the source for enabling the external pid function. • requires parameter 4230 trim mode = 0 not sel. 0 = not sel – disables external pid control. 1 = di1 – defines digital input 1 as the control for enabling external pid control. • act...

Page 245

Actual signals and parameters 245 4232 correction src 1…2 1 1 defines the trimming reference for the correction source. 1 = pid2 ref – uses appropriate ref max (switch a or b) • 1105 ref1 max when ref1 is active (a). • 1108 ref2 max when ref2 is active (b). 2 = pid2 output – uses the absolute maximu...

Page 246

246 actual signals and parameters group 44: pump protection this group defines the parameters used for the set-up of pump protection. Group 44: pump protection code description range resolution default s 4401 inlet prot ctrl not sel enables, and selects the mode of, the primary supervision of pump/f...

Page 247

Actual signals and parameters 247 4405 ai in very low 0.00 … 100.00% 1 = 0.01% 0.00% supervision level for the secondary inlet pressure monitoring function. See parameter 4401 inlet prot ctrl . Supervision level. 4406 di status inlet not sel selects the digital input for connection of a pressure swi...

Page 248