- DL manuals

- ABB

- Servo Drives

- ACS800

- Hardware Manual

ABB ACS800 Hardware Manual

Summary of ACS800

Page 1

Acs800 hardware manual acs800-07 drives (500 to 2800 kw) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 2

Acs800 single drive manuals hardware manuals (appropriate manual is included in the delivery) acs800-01/u1 hardware manual 0.55 to 160 kw (0.75 to 200 hp) 3afe64382101 (english) acs800-01/u1/04 marine supplement 0.55 to 160 kw (0.75 to 200 hp) 3afe64291275 (english) acs800-11/u11 hardware manual 5.5...

Page 3: Hardware Manual

Acs800-07 drives 500 to 2800 kw hardware manual 3afe64731165 rev e en effective: 15.2.2008 © 2008 abb oy. All rights reserved. Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 4

Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 5: Update Notice

Update notice 1 update notice new (page 6): safety / installation and maintenance work • after maintaining or modifying a drive safety circuit or changing circuit boards inside the module, retest the functioning of the safety circuit according to the start-up instructions. • do not change the electr...

Page 6

Update notice 2 new (page 37): type code the table below contains the new option code definition for the safe torque off function. New (page 61): emergency stop note: if you add or modify the wiring in the drive safety circuits, ensure that the appropriate standards (e.G. Iec 61800-5-1, en 62061, en...

Page 7

Update notice 3 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 8

Update notice 4 warning! The safe torque off function does not disconnect the voltage of the main and auxiliary circuits from the drive. Therefore maintenance work on electrical parts of the drive or the motor can only be carried out after isolating the drive system from the main supply. Note: the s...

Page 9

Update notice 5 changed (page 115): leds new (page 126): ambient conditions cabinets with option +q968: the installation site altitude in operation is 0 to 2000 m. • close the disconnector and switch the power on. • test the operation of the sto function when the motor is stopped: - give a stop comm...

Page 10

Update notice 6 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 11: Safety Instructions

Safety instructions 5 safety instructions what this chapter contains this chapter contains safety instructions you must follow when installing, operating and servicing the drive. If ignored, physical injury or death may follow, or damage may occur to the drive, the motor or driven equipment. Read th...

Page 12

Safety instructions 6 installation andmaintenance work these warnings are intended for all who work on the drive, motor cable or motor. Ignoring the instructions can cause physical injury or death, or damage the equipment. Warning! • only qualified electricians are allowed to install and maintain th...

Page 13

Safety instructions 7 warning! • during the installation procedure, the inverter modules may have to be temporarily extracted from the cabinet. The modules have a high centre of gravity. In order to minimise the danger of toppling over, keep the support legs of the modules extended whenever manoeuvr...

Page 14

Safety instructions 8 grounding these instructions are intended for all who are responsible for the grounding of the drive. Incorrect grounding can cause physical injury, death or equipment malfunction and increase electromagnetic interference. Fibre optic cables warning! • ground the drive, the mot...

Page 15

Safety instructions 9 operation these warnings are intended for all who plan the operation of the drive or operate the drive. Ignoring the instructions can cause physical injury or death or damage the equipment. Warning! • if the drive is equipped with an optional brake unit, make sure there are inv...

Page 16

Safety instructions 10 permanent magnet motor drives these are additional warnings concerning permanent magnet motor drives. Warning! Do not work on the drive when the permanent magnet motor is rotating. Also when the supply power is switched off, a rotating permanent magnet motor feeds power to the...

Page 17: Table of Contents

Table of contents 11 table of contents acs800 single drive manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 safety instructions what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 18

Table of contents 12 reading and setting of values (page 1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28 reading and setting of values (page 2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29 terminal blocks . . . . . . . . . . . . . . . . . . . ....

Page 19

Table of contents 13 thermal overload protection of the motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 protection against short-circuit in the motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 protection against short-circuit ins...

Page 20

Table of contents 14 connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79 motor connection – units without common motor terminal cubicle . . . . . . . . . . . . . . . . . . . . . . . . .80 output busbars . . . . . . . . ...

Page 21

Table of contents 15 maintenance what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103 safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 22

Table of contents 16 ce marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128 definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 23: About This Manual

About this manual 17 about this manual what this chapter contains this chapter describes the intended audience and contents of the manual. It contains a flowchart of steps in checking the delivery, installing and commissioning the drive. The flowchart refers to chapters/sections in this manual and o...

Page 24

About this manual 18 motor control and i/o board (rmio) shows external control connections to the motor control and i/o board and its specifications. Installation checklist and start-up helps in checking the mechanical and electrical installation of the drive. Maintenance contains preventive mainten...

Page 25

About this manual 19 product and service inquiries address any inquiries about the product to your local abb representative, quoting the type code and serial number of the unit in question. A listing of abb sales, support and service contacts can be found by navigating to abb website and selecting d...

Page 26

About this manual 20 terms and abbreviations term/abbreviation explanation apbu type of optical branching unit used for connecting parallel- connected converter modules to the rdcu. Dssb diode supply system board dsu diode supply unit frame (size) relates to the construction type of the component in...

Page 27: Hardware Description

Hardware description 21 hardware description what this chapter contains this chapter describes the construction of the drive in short. The acs800-07 the acs800-07 is a cabinet-mounted drive for controlling ac motors. Cabinet line-up the drive consists of several cubicles that contain the supply and ...

Page 28

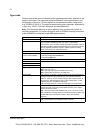

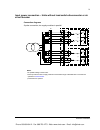

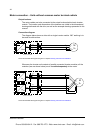

Hardware description 22 the following drawing represents a 2×d4 + 2×r8i drive with optional load switch- disconnector. No. Description no. Description 1 supply (input) cable lead-throughs. Top entry optional. 10 inverter dc fuses. 2 input busbars. 11 inverter modules. 3 load switch-disconnector. 12 ...

Page 29

Hardware description 23 swing-out frame the swing-out frame inside the control and i/o cubicle provides space for the control electronics of the drive, i/o terminal blocks, and optional electrical equipment. The lead-throughs for i/o cables, the auxiliary voltage transformer, and further space for a...

Page 30

Hardware description 24 cabling direction the drawing below shows the available power cabling directions of the drive. Note that the desired cabling direction must be specified on ordering. 3 2 a b c d description 1 main supply – bottom entry at each supply module (without load switch-disconnector o...

Page 31

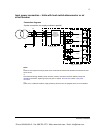

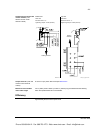

Hardware description 25 single-line circuit diagram of the drive m gro und f ault sup e rvision v olt ag e di splay of dss b mot or fa n sup ply 400 v a c m 230/ 115 v a c dc b u s m 3~ mai n sup p ly 400 v a c m 400 v a c m m m 230/ 11 5 va c +24 vdc not es: – the diagr am repr ese nt s a frame 2×d...

Page 32

Hardware description 26 controls door switches load switch-disconnector the drive has a load switch-disconnector handle. In units without an optional load switch-disconnector (+f253), the handle operates the internal switch-disconnector contained within each supply module. Warning! The load switch-d...

Page 33

Hardware description 27 supply unit control electronics the supply module(s) is controlled by the dssb (diode supply system board), located inside the control and i/o cubicle. The dssb is connected to – and powered from – the supply module(s) via the quick connectors at the back of the modules. The ...

Page 34

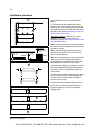

Hardware description 28 reading and setting of values (page 1 of 2) + display mode autoexit (20 s.) autoexit (20 s.) autoexit (2 s.) display mode + enter settings and diagn. Mode set time in sec. (up and down keys) setting power loss ride- through time 1) + display mode autoexit (2s.) switching faul...

Page 35

Hardware description 29 reading and setting of values (page 2 of 2) efc peak 4) vac phase balance 0-100% 6) setting overload supervision displaying diagnostics codes display mode exit + autoexit (2s.) setting number of parallel modules 3) display mode set no. Of parallel mod- ules … continued from p...

Page 36

Hardware description 30 terminal blocks x500 ribbon cable to dscb board via module quick connector x2 measurement for actual value display (factory-wired) 1 dc+ intermediate circuit voltage (+ and - busbars) 2 dc- x3 measurement for actual value display (factory-wired) 1 u phase voltage 2 v phase vo...

Page 37

Hardware description 31 digital input and relay output terminals the dsu can be controlled through two control interfaces: local and remote. The operation switches placed on the cabinet door are connected to the local control interface. The remote control interface can be used in parallel when contr...

Page 38

Hardware description 32 emergency stop input the dssb board has a built-in logic that fulfils the emergency stop requirements according to iec/en60204-1 / category 0(immediate removal of power) provided that: • the diode supply unit (dsu) is equipped with optional main contactors, and • an emergency...

Page 39

Hardware description 33 earth (ground) current function the control board (dssb) measures the input currents of the diode supply unit. The earth current function constantly monitors the sum of the phase currents. The chart below describes the operation. For information on the leds, see the chapter f...

Page 40

Hardware description 34 power loss ride-through function the power loss ride-through function keeps the supply unit operative over an unexpected input power break. The user can activate the function by setting the power loss ride-through delay with the buttons on the dssb board. Note: units with an ...

Page 41

Hardware description 35 this diagram shows the control interfaces of the inverter unit. Motor control the motor control is based on the direct torque control (dtc) method. Two phase currents and dc link voltage are measured and used for the control. The third phase current is measured for earth faul...

Page 42

Hardware description 36 type code the type code of the drive is indicated on the type designation label, attached on the supply cubicle door. The type code contains information on the specifications and configuration of the drive. The first digits from left express the basic configuration (e.G. Acs8...

Page 43

Hardware description 37 line options f250+q951 = line contactor + emergency stop (category 0) f250+q952 = line contactor + emergency stop (category 1) f253+f260 = ar ac fuses + load switch-disconnector (6-pulse) (load switch-disconnectors in dsu modules removed) a004+f253+f260 = ar ac fuses + load s...

Page 44

Hardware description 38 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 45: Mechanical Installation

Mechanical installation 39 mechanical installation what this chapter contains this chapter describes the mechanical installation procedure of the drive. General see chapter technical data for allowable operating conditions and requirements for free space around the unit. The unit should be installed...

Page 46

Mechanical installation 40 moving the unit …by crane use the steel lifting lugs attached to the top of the cabinet. Insert the lifting ropes or slings into the holes of the lifting lugs. The lifting lugs can be removed (not mandatory) once the cabinet is in its final position. If the lifting lugs ar...

Page 47

Mechanical installation 41 …by fork-lift or pallet truck …on rollers (not allowed with marine versions) laying the unit on its back the centre of gravity may be quite high. Be therefore careful when transporting the unit. Tilting the cabinets must be avoided. The units are to be moved only in the up...

Page 48

Mechanical installation 42 final placement of the unit the cabinet can be moved into its final position with an iron bar and a wooden piece at the bottom edge of the cabinet. Care is to be taken to properly place the wooden piece so as not to damage the cabinet frame. Phone: 800.894.0412 - fax: 888....

Page 49

Mechanical installation 43 before installation delivery check the drive delivery contains: • drive cabinet line-up • optional modules (if ordered) installed into the control rack at the factory • ramp for extracting supply and inverter modules from the cabinet • hardware manual • appropriate firmwar...

Page 50

Mechanical installation 44 installation procedure see detailed instructions in the following few pages. (1) the cabinet can be installed with its back against a wall, or back-to-back with another unit. Fasten the unit (or first shipping split) to the floor with fastening clamps or through the holes ...

Page 51

Mechanical installation 45 fastening the cabinet to the floor (non-marine units) the cabinet is to be fastened to the floor by using clamps along the edge of the cabinet bottom, or by bolting the cabinet to the floor through the holes inside. Clamping insert the clamps into the twin slots along the ...

Page 52

Mechanical installation 46 holes inside the cabinet the cabinet can be fastened to the floor using the fastening holes inside the cabinet, if they are accessible. The recommended maximum distance between the fastening points is 800 mm (31.5”). If there is not enough working space behind the cabinet ...

Page 53

Mechanical installation 47 fastening the unit to the floor and wall (marine units) the unit must be fastened to the floor and roof (wall) as follows: use m10 or m12 screws; welding is not recommended (see section electric welding below). 1 2 3 1 2 3 bolt the unit to the floor through the holes in ea...

Page 54

Mechanical installation 48 joining the shipping splits the busbar systems and wiring harnesses of two shipping splits are joined in the common motor terminal cubicle (if present) or a busbar joining cubicle. Special m6 screws for fastening the shipping splits together are enclosed in a plastic bag i...

Page 55

Mechanical installation 49 • remove any intermediate or partitioning plates covering the rear posts of the joining cubicle. • fasten the rear post of the joining section with seven screws (below the busbar joining part) to the rear post of the next cubicle. • replace all partitioning plates in the u...

Page 56

Mechanical installation 50 dc busbars the dc busbar connection is shown below. Pe busbar the pe busbar runs continuously through the line-up near the floor at the back. The connection is shown below. No separate nuts are needed. Tighten the bolts to 55–70 nm (40–50 ft.-lbs.) side view of single busb...

Page 57

Mechanical installation 51 miscellaneous cable duct in the floor below the cabinet a cable duct can be constructed below the 400 mm wide middle part of the cabinet. The cabinet weight lies on the two 100 mm wide transverse sections which the floor must carry. Viewed from above side view this area ca...

Page 58

Mechanical installation 52 cooling air intake through bottom of cabinet units with air intake through the bottom of the cabinet (optional feature) are intended for installation on an air duct in the floor. The required air inlets in the floor are as listed below. Refer also to the dimensional drawin...

Page 59

Mechanical installation 53 electric welding it is not recommended to fasten the cabinet by welding. Cabinets without flat bars at the base • connect the return conductor of the welding equipment to the cabinet frame at the bottom within 0.5 metres of the welding point. Cabinets with flat bars at the...

Page 60

Mechanical installation 54 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 61

Planning the electrical installation 55 planning the electrical installation what this chapter contains this chapter contains the instructions that you must follow when selecting the motor, cables, protections, cable routing and way of operation for the drive system. Note: the installation must alwa...

Page 62

Planning the electrical installation 56 4. Consult the motor manufacturer before using a motor in a drive system where the motor nominal voltage differs from the ac power source voltage. 5. Ensure that the motor insulation system withstands the maximum peak voltage in the motor terminals. See the re...

Page 63

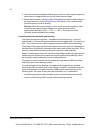

Planning the electrical installation 57 requirements table the following table shows how to select the motor insulation system and when an optional abb du/dt filter, insulated n-end (non-driven end) motor bearings and abb common mode filters are required. The motor manufacturer should be consulted r...

Page 64

Planning the electrical installation 58 * manufactured before 1.1.1998 ** for motors manufactured before 1.1.1998, check for additional instructions with the motor manufacturer. *** if the intermediate dc circuit voltage of the drive will be increased from the nominal level by resistor braking or by...

Page 65

Planning the electrical installation 59 if voltage is raised by the drive (this is a parameter selectable function for special applications only), select the motor insulation system according to the increased intermediate circuit dc voltage level, especially in the 500 v supply voltage range. Note 8...

Page 66

Planning the electrical installation 60 switch or a circuit breaker must be used for protecting each cable and motor. These devices may require a separate fuse to cut off the short-circuit current. Thermal overload protection of the motor according to regulations, the motor must be protected against...

Page 67

Planning the electrical installation 61 emergency stop devices for safety reasons, install the emergency stop devices at each operator control station and at other operating stations where emergency stop may be needed. Pressing the stop key ( ) on the control panel of the drive, or turning the opera...

Page 68

Planning the electrical installation 62 • the cable must be able to carry the drive load current. See chapter technical data for the rated currents. • the cable must be rated for at least 70 ° c maximum permissible temperature of conductor in continuous use. For us, see additional us requirements . ...

Page 69

Planning the electrical installation 63 alternative power cable types power cable types that can be used with the drive are represented below. Motor cable shield to effectively suppress radiated and conducted radio-frequency emissions, the shield conductivity must be at least 1/10 of the phase condu...

Page 70

Planning the electrical installation 64 conduit where conduits must be coupled together, bridge the joint with a ground conductor bonded to the conduit on each side of the joint. Bond the conduits also to the drive enclosure. Use separate conduits for input power, motor, brake resistors, and control...

Page 71

Planning the electrical installation 65 power factor compensation capacitors power factor compensation is not needed with ac drives. However, if a drive is to be connected to a system with compensation capacitors already installed, note the following restrictions. Warning! Do not connect power facto...

Page 72

Planning the electrical installation 66 firmware manual of the drive for the required parameter settings.) otherwise, the contactor will be damaged. In scalar control, the contactor can be opened with the drive running. Relay output contacts and inductive loads inductive loads (such as relays, conta...

Page 73

Planning the electrical installation 67 selecting the control cables all control cables must be shielded. Use a double-shielded twisted pair cable (see figure a) for analogue signals. This type of cable is recommended for the pulse encoder signals also. Employ one individually shielded pair for each...

Page 74

Planning the electrical installation 68 connection of a motor temperature sensor to the drive i/o warning! Iec 60664 requires double or reinforced insulation between live parts and the surface of accessible parts of electrical equipment which are either non- conductive or conductive but not connecte...

Page 75

Planning the electrical installation 69 a diagram of the cable routing is below. Control cable ducts 90 ° min 500 mm (20 in.) motor cable input power cable control cables min 200 mm (8 in.) min 300 mm (12 in.) motor cable power cable drive 230/120 v 24 v 24 v 230/120 v lead 24 v and 230/120 v contro...

Page 76

Planning the electrical installation 70 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 77: Electrical Installation

Electrical installation 71 electrical installation what this chapter contains this chapter describes the electrical installation procedure of the drive. Warning! Only qualified electricians are allowed to carry out the work described in this chapter. Follow the safety instructions on the first pages...

Page 78

Electrical installation 72 • note: moisture inside the motor casing will reduce the insulation resistance. If this is suspected, dry the motor and repeat the measuring. It (ungrounded) systems emc filter +e202 is not suitable for use in an it (ungrounded) system. If the drive is equipped with emc fi...

Page 79

Electrical installation 73 input power connection – units without load switch-disconnector or air circuit breaker connection diagrams 6-pulse connection, two supply modules in parallel l11 l21 l31 l12 l22 l32 pe *) notes: • no parallel cabling is shown here. • each input terminal of the supply modul...

Page 80

Electrical installation 74 12-pulse connection, two supply modules in parallel l11 l21 l31 l12 l22 l32 pe *) notes: • no parallel cabling (for each module) is shown here. It is also possible to connect all input power terminals of module 1 to the transformer y-output and module 2 to the transformer ...

Page 81

Electrical installation 75 connection procedure warning! The supply modules are heavy and have a high centre of gravity. Be careful when manoeuvring the modules. Removal of module: (1) turn the supply (rectifier) module switch-disconnector handle to open position. (2) release the door handle and ope...

Page 82

Electrical installation 76 use of the dual-cable screw lug connector removal of the dual-cable screw lug connector 1 2 3 4 1 2 3 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 83

Electrical installation 77 input power connection – units with load switch-disconnector or air circuit breaker connection diagrams 6-pulse connection, two supply modules in parallel pe ***) *) notes: *) fuses are not required if the input power line is constructed of busbars that withstand the trans...

Page 84

Electrical installation 78 12-pulse connection, two supply modules in parallel pe ***) *) notes: *) fuses are not required if the input power line is constructed of busbars that withstand the transformer short circuit current. **) no bridging (connecting 1l1 to 2l1, 1l2 to 2l2, and 1l3 to 2l3) is al...

Page 85

Electrical installation 79 connection procedure open the door of the incoming (load switch-disconnector or air circuit breaker) cubicle. Remove any shrouds covering the input terminals and cable entries. Lead the cables into the cubicle. Make the 360° earthing arrangement at the cable entries as sho...

Page 86

Electrical installation 80 motor connection – units without common motor terminal cubicle output busbars the motor cables are to be connected to the output busbars behind each inverter module. The location and dimensions of the busbars are visible in the dimensional drawings delivered with the drive...

Page 87

Electrical installation 81 warning! The cabling from all inverter modules to the motor must be physically identical considering cable type, cross-sectional area, and length. Pe inverter unit cubicle u2 v2 w2 u2 v2 w2 m 3~ u1 w1 v1 pe phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - em...

Page 88

Electrical installation 82 connection procedure warning! The inverter modules are heavy and have a high centre of gravity. Be careful when manoeuvring the modules. In order to minimise the danger of toppling over, keep the support legs of the modules extended whenever manoeuvring the modules outside...

Page 89

Electrical installation 83 lead the cables into the cabinet below each inverter module. Make the 360° earthing arrangement at the cable entry as shown. Cut the cables to suitable length. Strip the cables and conductors. Twist the cable screens into bundles and connect to cabinet pe (ground) busbar. ...

Page 90

Electrical installation 84 motor connection – units with common motor terminal cubicle connection diagram connection procedure see the connection procedure on page 83. U2 v2 w2 pe the recommended cable types are given in chapter planning the electrical installation . M 3~ u1 w1 v1 pe inverter unit c...

Page 91

Electrical installation 85 control connections drive control connections the control connections are made on the terminal blocks provided in the swing-out frame of the drive. Refer to the circuit diagrams delivered with the drive, and to the chapter motor control and i/o board (rmio) . Supply unit c...

Page 92

Electrical installation 86 connection procedure turn the supply (rectifier) unit switch-disconnector into open position. Release the door handle and open the door of the control and i/o cubicle. Remove the two locking screws at the edge of the swing-out frame and open the frame. Run the cables into ...

Page 93

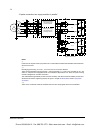

Electrical installation 87 run the cables to the swing-out frame as shown below. Wherever possible, use the existing cable trunking (1) in the cabinet. Use sleeving wherever the cables are laid against sharp edges. Leave some slack in the cable at the hinge (2) to allow the frame to open fully. Tie ...

Page 94

Electrical installation 88 installation of optional modules and pc the optional module (such as fieldbus adapter, i/o extension module and the pulse encoder interface) is inserted into the optional module slot of the rdcu drive control unit) and fixed with two screws . See the appropriate optional m...

Page 95

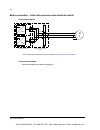

Electrical installation 89 connections and tap settings of the auxiliary voltage transformer installation of brake resistors see the chapter resistor braking . 3~ input pr im a ry secon dary 3~ input 1~ output 3~ output supply voltage terminals tap settings supply voltage 230 v 115 v 400 v (50 hz) 3...

Page 96

Electrical installation 90 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 97

Motor control and i/o board (rmio) 91 motor control and i/o board (rmio) what this chapter contains this chapter shows • external control connections to the rmio board for the the acs800 standard application program (factory macro) • specifications of the inputs and outputs of the board. To which pr...

Page 98

Motor control and i/o board (rmio) 92 note on external power supply external +24 v power supply for the rmio board is recommended if • the application requires a fast start after the connection of the input power • fieldbus communication is required when input power is disconnected. The rmio board c...

Page 99

Motor control and i/o board (rmio) 93 external control connections (non-us) external control cable connections to the rmio board for the acs800 standard application program (factory macro) are shown below. For external control connections of other application macros and programs, see the appropriate...

Page 100

Motor control and i/o board (rmio) 94 external control connections (us) external control cable connections to the rmio board for the acs800 standard application program (factory macro us version) are shown below. For external control connections of other application macros and programs, see the appr...

Page 101

Motor control and i/o board (rmio) 95 rmio board specifications analogue inputs with standard application program two programmable differential current inputs (0 ma / 4 ma ... 20 ma, r in = 100 ohm) and one programmable differential voltage input (-10 v / 0 v / 2 v ... +10 v, r in > 200 kohm). The a...

Page 102

Motor control and i/o board (rmio) 96 relay outputs three programmable relay outputs switching capacity 8 a at 24 vdc or 250 vac, 0.4 a at 120 vdc minimum continuous current 5 ma rms at 24 vdc maximum continuous current 2 a rms isolation test voltage 4 kvac, 1 minute ddcs fibre optic link with optio...

Page 103

Motor control and i/o board (rmio) 97 isolation and grounding diagram x20 1 vref- 2 agnd x21 1 vref+ 2 agnd 3 ai1+ 4 ai1- 5 ai2+ 6 ai2- 7 ai3+ 8 ai3- 9 ao1+ 10 ao1- 11 ao2+ 12 ao2- x22 1 di1 2 di2 3 di3 4 di4 9 dgnd1 5 di5 6 di6 7 +24vd 8 +24vd 11 diil 10 dgnd2 x23 1 +24 v 2 gnd x25 1 ro1 2 ro1 3 ro...

Page 104

Motor control and i/o board (rmio) 98 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 105

Installation checklist and start-up 99 installation checklist and start-up installation checklist check the mechanical and electrical installation of the drive before start-up. Go through the checklist below together with another person. Read the safety instructions on the first pages of this manual...

Page 106

Installation checklist and start-up 100 start-up procedure action additional information warning! Ensure that the disconnector of the supply transformer is locked to open position, i.E. No voltage is, or cannot be connected to drive inadvertently. Check also by measuring that there is no voltage con...

Page 107

Installation checklist and start-up 101 starting the supply unit warning! If the drive is equipped with a brake unit, make sure there are inverters connected to the intermediate circuit before start. As a rule of thumb, the sum capacitance of the inverters connected must be at least 30% of the sum c...

Page 108

Installation checklist and start-up 102 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 109: Maintenance

Maintenance 103 maintenance what this chapter contains this chapter contains preventive maintenance instructions. Safety instructions only a qualified electrician is allowed to perform the maintenance. Before starting work inside the cabinet, • isolate the drive from the supply (note that the switch...

Page 110

Maintenance 104 maintenance intervals if installed in an appropriate environment, the drive requires very little maintenance. This table lists the routine maintenance intervals recommended by abb. Interval maintenance action instructions every year of storage capacitor reforming see document acs 600...

Page 111

Maintenance 105 replacing the ppcs branching unit (apbu-xx) memory backup battery 1. Switch off the power to the unit. 2. Open the screws on the cover (3 pcs). 3. Slide off the cover. 4. Remove the battery. 5. Insert the new cr 2032 battery and reattach the cover. 2 3 4 phone: 800.894.0412 - fax: 88...

Page 112

Maintenance 106 checking and replacing the air filters 1. Read and repeat the steps in safety instructions above. 2. Open the cabinet doors. 3. Check the air filters and replace if necessary (see technical data for the correct filter types). The inlet (door) filters can be accessed by removing the f...

Page 113

Maintenance 107 cooling fans power module cooling fans the lifespan of the cooling fans of the supply and inverter modules is about 50 000 hours. The actual lifespan depends on the running time of the fan, ambient temperature and dust concentration. Each supply and inverter module has its own coolin...

Page 114

Maintenance 108 inverter module fan replacement 1. Read and repeat the steps in section safety instructions above. 2. Open the inverter cubicle doors. 3. Disconnect the fan wiring plug (1). 4. Remove the locking screws (2). 5. Pull the fan out along its sliding rails (3). 6. Install a new fan in rev...

Page 115

Maintenance 109 control and i/o cubicle cooling fans the cooling fans inside the control and i/o cubicle can be replaced as follows: 1. Read and repeat the steps in section safety instructions above. 2. Open the door of the control and i/o cubicle (or combined control, i/o and supply cubicle). 3. De...

Page 116

Maintenance 110 air circuit breaker cubicle fans some ip2x/ip4x units with an air circuit breaker are also fitted with two fans at the air outlet on the roof. The fans are fastened to the grating (1) which can be removed by undoing the four screws (2). If necessary, undo the screws labelled (3) to r...

Page 117

Maintenance 111 1 2 3 2 2 2 3 4 5 5 7 6 8 8 9 8 8 9 11 10 11 12 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 118

Maintenance 112 heatsinks the heatsink fins of the power modules pick up dust from the cooling air. The module runs into overtemperature warnings and faults if the heatsinks are not clean. In a “normal” environment (not especially dusty nor clean) the heatsinks should be checked annually, in a dusty...

Page 119: Fault Tracing

Fault tracing 113 fault tracing what this chapter contains this chapter instructs in interpreting the led indications of the acs800-07. Note: information on warnings and faults reported by the application program (and displayed on the cdp-312r drive control panel on the cabinet door) are contained w...

Page 120

Fault tracing 114 over temp fault supply unit has exceeded temperature fault limit. Check ambient temperature. Check cooling air flows freely. Check fan operation. Check inlet and outlet air filters. Check heatsink for dust pick-up. Dc fuse dc fuse blown. Change dc fuse. External fault digital input...

Page 121

Fault tracing 115 note: a fault indication led normally stays lit after the fault is detected. However, the led will blink during an input power break to minimise back-up battery current consumption. The battery discharge time is 30 … 60 minutes. Other leds of the drive fan failure see fan failure a...

Page 122

Fault tracing 116 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 123: Technical Data

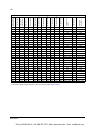

Technical data 117 technical data what this chapter contains this chapter contains the technical specifications of the drive, e.G. Ratings, frame sizes and technical requirements, provisions for fulfilling the requirements for ce and other markings, and warranty information. Ratings the ratings for ...

Page 124

Technical data 118 symbols derating the load capacity (current and power) decreases if the installation site altitude exceeds 1000 metres (3281 ft), or if the ambient temperature exceeds 40 °c (104 °f). Temperature derating in the temperature range +40 °c (+104 °f) to +50 °c (+122 °f), the rated out...

Page 125

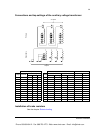

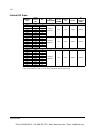

Technical data 119 acs800-07 frame sizes and power module types acs800-07 type frame size (supply+inverter modules) supply module(s) used inverter modules used qty type qty type three-phase supply voltage 380 v, 400 v or 415 v acs800-07-0610-3 1×d4 + 2×r8i 1 acs800-704-0910-7 2 acs800-104-0390-3 acs...

Page 126

Technical data 120 internal ac fuses acs800-07… type input current (a) qty. Type (iec/ul/csa) rated current (a rms) voltage (v) i 2 t pre-arc i 2 t clearing at 660v u n = 400 v (range 380-415 v) -0610-3 790 6 170m4417 bussmann 700 690 69500 465000 -0770-3 999 12 -0870-3 1128 12 -1030-3 1305 12 -1230...

Page 127

Technical data 121 dc fuses at inverter module input fuses for main circuit voltage measurement fuses f7 (2 pcs) and f8 (3 pcs) are used for dc voltage and ac supply voltage measurement respectively. The recommended type for replacement is ferraz shawmut a070grb01t13 (1 a, 700 v, ul recognized). Dc ...

Page 128

Technical data 122 input power connection voltage (u 1 ) 380/400/415 vac 3-phase± 10 % for 400 vac units 380/400/415/440/460/480/500 vac 3-phase± 10 % for 500 vac units 525/550/575/600/660/690 vac 3-phase± 10 % for 690 vac units prospective short-circuit current (iec 60439-1, ul508c) units without e...

Page 129

Technical data 123 input terminals at each supply module (units without load switch-disconnector or air circuit breaker) input terminals (units with load switch-disconnector or air circuit breaker) conductor size max. No. And size of cable lugs per phase lug hole bolt tightening torque iec cabling 2...

Page 130

Technical data 124 motor connection voltage (u 2 ) 0 to u 1 ,3-phase symmetrical, u max at the field weakening point frequency dtc mode: 0 to 3.2 × f fwp . Maximum frequency 300 hz. F fwp = where f fwp = frequency at field weakening point; u nmains = mains (input power) voltage; u nmotor = rated mot...

Page 131

Technical data 125 output terminals at each r8i inverter module (units without common motor terminal cubicle) output terminals (units with common motor terminal cubicle) 8 × Ø13 mm per phase. See the chapter dimensions . Maximum recommended motor cable length 100 m (328 ft). Motor cables up to 500 m...

Page 132

Technical data 126 cooling method internal fans, flow direction from bottom to top filter material inlet (door) outlet (roof) ip22/ip42 units luftfilter airtex g150 – ip54 units luftfilter aircomp 300-50 luftfilter airtex g150 free space around the unit see chapter mechanical installation . Cooling ...

Page 133

Technical data 127 materials cabinet hot-dip zinc-coated (thickness approx. 20 µm) steel sheet (thickness 1.5 mm) with polyester thermosetting powder coating (thickness approx. 80 µm) on visible surfaces except back panel. Colour: ral 7035 (light beige, semigloss). Busbars tin- or silver-plated copp...

Page 134

Technical data 128 ce marking a ce mark is attached to the drive to verify that the unit follows the provisions of the european low voltage and emc directives (directive 73/23/eec, as amended by 93/68/eec and directive 89/336/eec, as amended by 93/68/eec). Definitions emc stands for electromagnetic ...

Page 135

Technical data 129 second environment the requirements of the emc directive can be met as follows: 1. The drive is equipped with emc filter +e210. The filter is suitable for tn (earthed) and it (unearthed) networks. 2. The motor and control cables are selected as specified in the drive manuals. 3. T...

Page 136

Technical data 130 “c-tick” marking a “c-tick” mark is attached to each drive in order to verify compliance with the relevant standard (iec 61800-3 (1996) – adjustable speed electrical power drive systems – part 3: emc product standard including specific test methods), mandated by the trans-tasman e...

Page 137

Technical data 131 second environment the drive complies with the limits of iec 61800-3 with the following provisions: 1. It is ensured that no excessive emission is propagated to neighbouring low-voltage networks. In some cases, the natural suppression in transformers and cables is sufficient. If i...

Page 138

Technical data 132 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 139: Dimensions

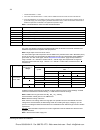

Dimensions 133 dimensions cabinet line-ups the drive consists of cubicles built into a cabinet line-up. The tables below show the composition of cabinet line-ups for each frame size and the standard combinations of options. The dimensions are in millimetres. Notes: • the side panels increase the tot...

Page 140

Dimensions 134 1×d4 + 2×r8i co ntrol, i/o & supply cubicle emc/r f i filte r loa d sw itch- disconne ctor inver ter unit joining cubicle co mmon motor termina l cubicle *brake chopper 1 *br ake res istor 1 *brake chopper 2 *br ake res istor 2 *brake chopper 3 *br ake res istor 3 shipping sp lit wid ...

Page 141

Dimensions 135 2×d4 + 2×r8i co ntrol & i/o cubicle loa d sw itch- disconne ctor air cir cuit br eake r supply unit inver ter unit joining cubicle co mmon motor termina l cubicle *brake chopper 1 *br ake res istor 1 *brake chopper 2 *br ake res istor 2 *brake chopper 3 *br ake res istor 3 shipping sp...

Page 142

Dimensions 136 2×d4 + 3×r8i control & i/o cubicle load switch- disconnector air circuit breaker supply unit inverter unit common motor terminal cubicle shipping split widths line-up width net weight (kg approx.) 400 600 800 1800 1800 1350 400 500 600 800 2300 2300 1730 400 600 600 800 2400 2400 2050...

Page 143

Dimensions 137 3×d4 + 6×r8i control & i/o cubicle load switch- disconnector air circuit breaker supply unit inverter unit (1) common motor terminal cubicle inverter unit (2) shipping split widths line-up width net weight (kg approx.) 400 800 800 800 2800 2800 2170 400 600 800 800 800 3400 3400 2570 ...

Page 144

Dimensions 138 frame size 1×d4 + 2×r8i phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 145

Dimensions 139 frame size 1×d4 + 2×r8i (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 146

Dimensions 140 frame size 1×d4 + 2×r8i (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 147

Dimensions 141 frame size 1×d4 + 2×r8i (with load switch-disconnector) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 148

Dimensions 142 frame size 1×d4 + 2×r8i (with load switch-disconnector) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 149

Dimensions 143 frame size 1×d4 + 2×r8i (with load switch-disconnector) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 150

Dimensions 144 frame size 1×d4 + 2×r8i (with load switch-disconnector) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 151

Dimensions 145 frame size 1×d4 + 2×r8i (with load switch-disconnector) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 152

Dimensions 146 frame size 1×d4 + 2×r8i (with load switch-disconnector) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 153

Dimensions 147 frame size 1×d4 + 2×r8i (with top entry/exit) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 154

Dimensions 148 frame size 1×d4 + 2×r8i (with top entry/exit) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 155

Dimensions 149 frame size 1×d4 + 2×r8i (with top entry/exit) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 156

Dimensions 150 frame size 2×d4 + 2×r8i phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 157

Dimensions 151 frame size 2×d4 + 2×r8i (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 158

Dimensions 152 frame size 2×d4 + 2×r8i (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 159

Dimensions 153 frame size 2×d4 + 2×r8i (with load switch-disconnector) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 160

Dimensions 154 frame size 2×d4 + 2×r8i (with load switch-disconnector) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 161

Dimensions 155 frame size 2×d4 + 2×r8i (with load switch-disconnector) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 162

Dimensions 156 frame size 2×d4 + 3×r8i phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 163

Dimensions 157 frame size 2×d4 + 3×r8i (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 164

Dimensions 158 frame size 2×d4 + 3×r8i (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 165

Dimensions 159 frame size 2×d4 + 3×r8i (with load switch-disconnector) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 166

Dimensions 160 frame size 2×d4 + 3×r8i (with load switch-disconnector) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 167

Dimensions 161 frame size 2×d4 + 3×r8i (with load switch-disconnector) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 168

Dimensions 162 frame size 2×d4 + 3×r8i (with load switch-disconnector) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 169

Dimensions 163 frame size 2×d4 + 3×r8i (with air circuit breaker) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 170

Dimensions 164 frame size 2×d4 + 3×r8i (with air circuit breaker) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 171

Dimensions 165 frame size 2×d4 + 3×r8i (with air circuit breaker) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 172

Dimensions 166 frame size 2×d4 + 3×r8i (with air circuit breaker) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 173

Dimensions 167 frame size 3×d4 + 4×r8i phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 174

Dimensions 168 frame size 3×d4 + 4×r8i (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 175

Dimensions 169 frame size 3×d4 + 4×r8i (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 176

Dimensions 170 frame size 3×d4 + 4×r8i (with load switch-disconnector) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 177

Dimensions 171 frame size 3×d4 + 4×r8i (with load switch-disconnector) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 178

Dimensions 172 frame size 3×d4 + 4×r8i (with load switch-disconnector) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 179

Dimensions 173 frame size 3×d4 + 4×r8i (with load switch-disconnector) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 180

Dimensions 174 frame size 3×d4 + 4×r8i (with air circuit breaker) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 181

Dimensions 175 frame size 3×d4 + 4×r8i (with air circuit breaker) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 182

Dimensions 176 frame size 3×d4 + 4×r8i (with air circuit breaker) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 183

Dimensions 177 frame size 3×d4 + 4×r8i (with air circuit breaker) (continued) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 184

Dimensions 178 common motor terminal cubicle depending on the drive size, the common motor terminal cubicle is either 300, 400 or 600 mm wide. Refer to the cabinet line-up tables at the beginning of this chapter. 300 mm phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrw...

Page 185

Dimensions 179 400 mm phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 186

Dimensions 180 600 mm phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 187: Resistor Braking

Resistor braking 181 resistor braking what this chapter contains this chapter describes the resistor braking options of the acs800-07. Resistor braking options the following acs800-07 (>500 kw) drives are available with brake choppers and resistors. For information on braking equipment for other acs...

Page 188

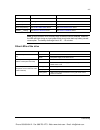

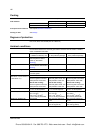

Resistor braking 182 chopper/resistor combinations – technical data the following table contains the technical data of some chopper/resistor combinations. Brake resistors – technical data the following table contains the technical data for the resistors supplied by abb. U n chopper(s) resistors r (o...

Page 189

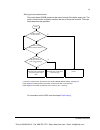

Resistor braking 183 verifying the capacity of the braking equipment 1. Calculate the maximum power (p max ) generated by the motor during braking. 2. Ensure the following condition is met: the p brmax values specified in the technical data table above are for the reference braking cycle (1 minute o...

Page 190

Resistor braking 184 calculating the maximum braking power (p br ) • braking energy transferred during any ten minute period must be less than or equal to the energy transferred during the reference braking cycle. • the braking power must not exceed the rated maximum value p brmax . Example 1 durati...

Page 191

Resistor braking 185 example 3 duration of a braking cycle is three minutes. The braking time is 10 seconds. Result: the maximum allowed braking power for the cycle is equal to the maximum braking power (p brmax ) given for the reference cycle. T = duration of the braking cycle t br p brmax t p br 6...

Page 192

Resistor braking 186 custom resistor installation and wiring effective cooling of the resistors must be ensured. Warning! All materials near the brake resistors must be non-flammable. The surface temperature of the resistors is high. The temperature of the air rising from the resistors is hundreds o...

Page 193

Resistor braking 187 the following is a wiring diagram example of the resistor connection. Brake circuit commissioning in the drive application program, overvoltage control of the drive must be disabled for correct operation of the brake chopper. This has been done at the factory for units with brak...