- DL manuals

- ABB

- DC Drives

- ACS850 series

- Hardware Manual

ABB ACS850 series Hardware Manual

Summary of ACS850 series

Page 1

Acs850 hardware manual acs850-04 drive modules (1.1 to 45 kw).

Page 3: Hardware Manual

Acs850-04 drive modules 1.1 to 45 kw hardware manual 3aua0000045496 rev d en effective: 2009-07-20 © 2009 abb oy. All rights reserved..

Page 5: Safety Instructions

Safety instructions 5 safety instructions what this chapter contains this chapter contains safety instructions which you must follow when installing, operating and servicing the drive. If ignored, physical injury or death may follow, or damage may occur to the drive, the motor, or driven equipment. ...

Page 6: Installation And

Safety instructions 6 installation and maintenance work these warnings are intended for all who work on the drive, motor cable or motor. Warning! Ignoring the following instructions can cause physical injury or death, or damage to the equipment. Only qualified electricians are allowed to install and...

Page 7: •

Safety instructions 7 • depending on the external wiring, dangerous voltages (115 v, 220 v or 230 v) may be present on the terminals of the relay outputs of the drive. • the drive supports the “safe torque off” function. See page 42 . Warning! Ignoring the following instructions can cause physical i...

Page 8: Start-Up and Operation

Safety instructions 8 start-up and operation these warnings are intended for all who plan the operation of the drive, start up or operate the drive. Warning! Ignoring the following instructions can cause physical injury or death, or damage to the equipment. • before adjusting the drive and putting i...

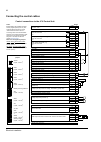

Page 9: Table Of Contents

Table of contents 9 table of contents safety instructions what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 use of warnings and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 10

Table of contents 10 mechanical installation contents of the package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33 delivery check and drive module identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 11

Table of contents 11 supply cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 motor and motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 braking ...

Page 12

Table of contents 12 dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80 cooling characteristics, noise levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80 supp...

Page 13

Table of contents 13 du/dt and common mode filtering what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99 when is du/dt or common mode filtering required? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 14

Table of contents 14.

Page 15: About This Manual

About this manual 15 about this manual what this chapter contains this chapter describes the intended audience and contents of this manual. It contains a flowchart of steps in checking the delivery, installing and commissioning the drive. The flowchart refers to chapters/sections in this manual and ...

Page 16

About this manual 16 operation principle and hardware description describes the drive module. Planning the cabinet assembly guides in planning the installation of the drive module into a user-defined cabinet. Mechanical installation instructs how to place and mount the drive. Planning the electrical...

Page 17

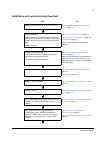

About this manual 17 installation and commissioning flowchart task see identify the frame size of your drive: a, b, c or d. Drive designation label or technical data: ratings (page 77 ) plan the installation. Check the ambient conditions, ratings, required cooling air flow, input power connection, c...

Page 18

About this manual 18 connect the power cables. Connect the control and the auxiliary control cables. Electrical installation: power cable connection : (page 52 ) and connecting the control cables : (page 62 ) for optional equipment: mains chokes (page 91 ) emc filters (page 93 ) resistor braking (pa...

Page 19: Terms And Abbreviations

About this manual 19 terms and abbreviations term/abbreviation explanation chk-xx series of optional mains chokes for the acs850. Emc electromagnetic compatibility. Fio-01 optional digital i/o extension for the acs850. Fio-11 optional analog i/o extension for the acs850. Fio-21 optional analog/digit...

Page 20

About this manual 20

Page 21: Operation Principle

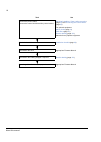

Operation principle and hardware description 21 operation principle and hardware description what this chapter contains this chapter describes the operating principle and construction of the acs850-04 drive module in short. Operation principle main circuit the main circuit of the drive module is sho...

Page 22: Product Overview

Operation principle and hardware description 22 motor control the motor control is based on direct torque control. Two phase currents and dc link voltage are measured and used for the control. The third phase current is measured for earth fault protection. Product overview the acs850-04 is an air-co...

Page 23

Operation principle and hardware description 23 layout slots 1 and 2 for optional i/o extensions and encoder/resolver interface ac supply connection dc connection drive module, frame size a jcu control unit with cover assembly removed power unit jcu control unit with optional cover assembly external...

Page 24

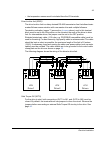

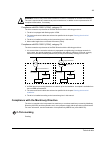

Operation principle and hardware description 24 power connections and control interfaces the diagram shows the power connections and control interfaces of the drive. Slot 1 slot 2 slot 3 control unit (jcu) fxx fxxx fxx control panel or pc memory unit (see page 75 ) braking resistor (optional) power ...

Page 25: Type Designation

Operation principle and hardware description 25 type designation the type designation contains information on the specifications and configuration of the drive. The first digits from left express the basic configuration (e.G. Acs850-04- 04a8-5). The optional selections are given thereafter, preceded...

Page 26: Ordering Information

Operation principle and hardware description 26 ordering information for a complete listing of options and accessories available for the acs850-04, refer to acs850 ordering information (available on request)..

Page 27: Cabinet Construction

Planning the cabinet assembly 27 planning the cabinet assembly what this chapter contains this chapter guides in planning the installation of a drive module into a user-defined cabinet. The issues discussed are essential for safe and trouble-free use of the drive system. Note: the installation examp...

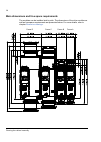

Page 28

Planning the cabinet assembly 28 main dimensions and free space requirements the modules can be installed side by side. The dimensions of the drive modules as well as free space requirements are presented below. For more details, refer to chapter dimension drawings . Frame c frame b frame a frame d.

Page 29

Planning the cabinet assembly 29 note: emc filters of type jfi-x1 mounted directly above the drive module do not increase the free space requirements. (for emc filters of type jfi-0x, see the dimension drawing of the filters on page 115 .) the temperature of the cooling air entering the unit must no...

Page 30

Planning the cabinet assembly 30 arrange the cooling of the modules so that the requirements given in chapter technical data are met: • cooling air flow note: the values in technical data apply to continuous nominal load. If the load is less than nominal, less cooling air is required. • allowed ambi...

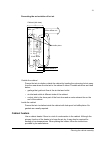

Page 31: Cabinet Heaters

Planning the cabinet assembly 31 preventing the recirculation of hot air outside the cabinet prevent hot air circulation outside the cabinet by leading the outcoming hot air away from the area where the inlet air to the cabinet is taken. Possible solutions are listed below: • gratings that guide air...

Page 32

Planning the cabinet assembly 32.

Page 33: Mechanical Installation

Mechanical installation 33 mechanical installation contents of the package the drive is delivered in a cardboard box. To open, remove any banding and lift the top off the box..

Page 34

Mechanical installation 34 the box contains: • acs850-04 drive module, with factory-installed options • three cable clamp plates (two for power cabling, one for control cabling) with screws • screw-type terminal blocks to be attached to the headers on the jcu control unit and the power unit • emc fi...

Page 35: Before Installation

Mechanical installation 35 delivery check and drive module identification check that there are no signs of damage. Before attempting installation and operation, check the information on the type designation label of the drive module to verify that the unit is of the correct type. The label is locate...

Page 36: Installation Procedure

Mechanical installation 36 installation procedure direct wall mounting 1. Mark the locations for the four holes. The mounting points are shown in dimension drawings . 2. Fix the screws or bolts to the marked locations. 3. Position the drive onto the screws on the wall. Note: only lift the drive by i...

Page 37

Mechanical installation 37 mains choke installation see the chapter mains chokes on page 91 . Emc filter installation see the chapter emc filters on page 93 . Braking resistor installation see the chapter resistor braking on page 103 ..

Page 38

Mechanical installation 38.

Page 39: Motor Selection

Planning the electrical installation 39 planning the electrical installation what this chapter contains this chapter contains the instructions that you must follow when selecting the motor, cables, protections, cable routing and way of operation for the drive. If the recommendations given by abb are...

Page 40

Planning the electrical installation 40 • a circuit breaker suitable for isolation in accordance with en 60947-2. Other regions the disconnecting means must conform to the applicable safety regulations. Thermal overload and short circuit protection thermal overload protection the drive protects itse...

Page 41: Ground Fault Protection

Planning the electrical installation 41 a calculated temperature value (based on a motor thermal model) or an actual temperature indication given by motor temperature sensors. The user can tune the thermal model further by feeding in additional motor and load data. Ptc sensors can be connected direc...

Page 42: Safe Torque Off

Planning the electrical installation 42 safe torque off the drive supports the safe torque off function according to standards pren 61800-5-2; en 954-1 (1997); iec/en 60204-1: 1997; en 61508: 2002 and en 1037: 1996. The safe torque off function disables the control voltage of the power semiconductor...

Page 43

Planning the electrical installation 43 selecting the power cables general rules dimension the supply (input power) and motor cables according to local regulations . • the cable must be able to carry the drive load current. See the chapter technical data for the rated currents. • the cable must be r...

Page 44: Of Inductive Loads

Planning the electrical installation 44 alternative power cable types power cable types that can be used with the drive are represented below. Motor cable shield to function as a protective conductor, the shield must have the same cross-sectional area as a phase conductor when they are made of the s...

Page 45

Planning the electrical installation 45 with noise attenuating circuits (varistors, rc filters [ac] or diodes [dc]) in order to minimize the electromagnetic emissions at switch-off. If not suppressed, the disturbances may connect capacitively or inductively to other conductors in the control cable a...

Page 46: Routing The Cables

Planning the electrical installation 46 selecting the control cables it is recommended that all control cables be shielded. Double-shielded twisted pair cable is recommended for analog signals. For pulse encoder cabling, follow the instructions given by the encoder manufacturer. Use one individually...

Page 47

Planning the electrical installation 47 where control cables must cross power cables make sure they are arranged at an angle as near to 90 degrees as possible. Do not run extra cables through the drive. The cable trays must have good electrical bonding to each other and to the grounding electrodes. ...

Page 48

Planning the electrical installation 48.

Page 49: Electrical Installation

Electrical installation 49 electrical installation what this chapter contains this chapter describes the electrical installation procedure of the drive. Warning! The work described in this chapter may only be carried out by a qualified electrician. Follow the safety instructions on the first pages o...

Page 50

Electrical installation 50 1 2 3 4 5.

Page 51

Electrical installation 51 checking the insulation of the assembly drive do not make any voltage tolerance or insulation resistance tests (e.G. Hi-pot or megger) on any part of the drive as testing can damage the drive. Every drive has been tested for insulation between the main circuit and the chas...

Page 52: Power Cable Connection

Electrical installation 52 power cable connection power cable connection diagram 1) (pe) (pe) 3) pe for alternatives, see planning the electrical installation : supply disconnecting device (page 39 ). Optional braking resistor (see the chapter resistor braking [page 103 ]) l1 l2 l3 udc+ udc– r– r+ 2...

Page 53

Electrical installation 53 procedure cabling drawings with tightening torques for each frame size are presented on pages 56 to 58 . 1. Frame sizes c and d only: remove the two plastic connector covers at the top and bottom of the drive. Each cover is fastened with two screws. 2. On it (ungrounded) s...

Page 54

Electrical installation 54 11. With frame size c or d, cut suitable slots on the edges of the connector covers to accommodate the supply and motor cables. Refit the covers. (tighten the screws to 3 n·m [25 lbf·in]). 12. Secure the cables outside the unit mechanically. 13. Ground the other end of the...

Page 55

Electrical installation 55 installation of power cable clamp plates two identical power cable clamp plates are included with the drive. The picture below depicts a frame size a drive; the installation is similar with other frame sizes. Note: pay attention to supporting the cables adequately within t...

Page 56

Electrical installation 56 power cable connection – frame size a supply cable below cable clamp, cover bare shield with insulating tape cable clamp on bare shield 1.5 n·m (13 lbf·in) above cable clamp, cover bare shield with insulating tape braking resistor cable 1.5 n·m (13 lbf·in) cable clamp on b...

Page 57

Electrical installation 57 power cable connection – frame size b supply cable below cable clamp, cover bare shield with insulating tape cable clamp on bare shield 1.5 n·m (13 lbf·in) above cable clamp, cover bare shield with insulating tape cable clamp on bare shield 1.5 n·m (13 lbf·in) braking resi...

Page 58

Electrical installation 58 power cable connection – frame sizes c and d (connector covers removed) supply cable u2 v2 w2 above cable clamp, cover bare shield with insulating tape screw lug detail direct lug connection instead of using the screw lugs included, the conductors of power cables can be co...

Page 59

Electrical installation 59 dc connection the udc+ and udc– terminals are intended for common dc configurations of a number of acs850 drives, allowing regenerative energy from one drive to be utilised by the other drives in motoring mode. One or more drives are connected to the ac supply depending on...

Page 60

Electrical installation 60 each drive has an independent dc capacitor pre-charging circuit. The ratings of the dc connection are given on page 82 . ~ = + – udc+ udc- v1 w1 u1 ~ = v2 w2 u2 acs 8 5 0- 0 4 pre-charging circuit.

Page 61

Electrical installation 61 installation of optional modules optional modules such as fieldbus adapters, i/o extensions and encoder interfaces ordered using option codes (see type designation on page 25 ) are pre-installed at the factory. Instructions for installing additional modules into the slots ...

Page 62

Electrical installation 62 connecting the control cables control connections to the jcu control unit notes: [default setting with acs850 standard control program (factory macro). See firmware manual for other macros.] *total maximum current: 200 ma the wiring shown is for demonstrative purposes only...

Page 63

Electrical installation 63 jumpers di/dio grounding selector (located between xd24 and xdi) – determines whether the dignd (ground for digital inputs di1…di5) floats, or if it is connected to diognd (ground for digital input di6, and digital input/outputs dio1 and dio2). If dignd floats, the common ...

Page 64

Electrical installation 64 di6 (xdi:6) as a thermistor input 1…3 ptc sensors can be connected to this input for motor temperature measurement. Notes: • do not connect both ends of the cable shields directly to ground. If a capacitor cannot be used at one end, leave that end of the shield unconnected...

Page 65

Electrical installation 65 • the temperature sensor must be isolated from the i/o terminals. Drive-to-drive link (xd2d) the drive-to-drive link is a daisy-chained rs-485 transmission line that allows basic master/follower communication with one master drive and multiple followers. Termination activa...

Page 66

Electrical installation 66 grounding and routing the control cables the shields of all control cables connected to the jcu control unit must be grounded at the control cable clamp plate. Use four m4 screws to fasten the plate as shown below left (two of the screws are also used to hold the cover mou...

Page 67

Electrical installation 67 mounting the clamp plate remove outer jacket of cable at clamp to expose cable shield. Tighten clamp to 1.5 n·m (13 lbf·in) 0.7 n·m (6.2 lbf·in) routing the control cables run cables through the cover mounting bracket use shrink tubing or tape to contain strands.

Page 68

Electrical installation 68.

Page 69: Installation Checklist

Installation checklist 69 installation checklist checklist check the mechanical and electrical installation of the drive before start-up. Go through the checklist below together with another person. Read the safety instructions on the first pages of this manual before you work on the unit. Check mec...

Page 70

Installation checklist 70 the supply (input power) voltage cannot be applied to the output of the drive through a bypass connection. Motor connection box and other covers are in place. Check.

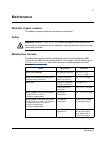

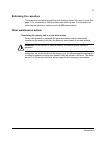

Page 71: Maintenance

Maintenance 71 maintenance what this chapter contains this chapter contains preventive maintenance instructions. Safety warning! Read the safety instructions on the first pages of this manual before performing any maintenance on the equipment. Ignoring the safety instructions can cause injury or dea...

Page 72: Heatsink

Maintenance 72 heatsink the heatsink fins pick up dust from the cooling air. The drive runs into overtemperature warnings and faults if the heatsink is not clean. In a normal environment, the heatsink should be checked annually, in a dusty environment more often. Clean the heatsink as follows (when ...

Page 73: Cooling Fan

Maintenance 73 cooling fan the actual lifespan of the cooling fan depends on the drive usage and ambient temperature. Fan failure can be predicted by the increasing noise from fan bearings and the gradual rise in the heatsink temperature in spite of heatsink cleaning. If the drive is operated in a c...

Page 74

Maintenance 74 fan replacement (frames c and d) to remove the fan, release the retaining clip (arrowed) carefully using a screwdriver. Pull the fan holder out. Disconnect the fan cable. Carefully bend the clips on the fan holder to free the fan. Install new fan in reverse order. Note : the airflow d...

Page 75: Reforming The Capacitors

Maintenance 75 reforming the capacitors the capacitors must be reformed if the drive has been stored for a year or more. See page 35 for information on finding out the manufacturing date. For information on reforming the capacitors, contact your local abb representative. Other maintenance actions tr...

Page 76

Maintenance 76.

Page 77: Technical Data

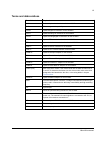

Technical data 77 technical data what this chapter contains this chapter contains the technical specifications of the drive, e.G. The ratings, sizes and technical requirements, and provisions for fulfilling the requirements for ce and other markings. Ratings nominal ratings with 400 v ac supply driv...

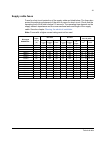

Page 78

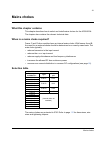

Technical data 78 nominal ratings with 500 v ac supply drive type acs850-04… frame size input ratings output ratings nominal no-overload use light-overload use heavy-duty use i 1n *i 1n i 2n i max p n i ld p ld p ld i hd p hd p hd a a a a kw hp a kw hp a kw hp -03a0-5 a 2.3 4.0 3.0 4.4 1.5 1.5 2.8 1...

Page 79

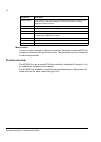

Technical data 79 derating the continuous output currents stated above must be derated if any of the following conditions apply: • the ambient temperature exceeds +40 °c (+104°f) • the drive is installed higher than 1000 m above sea level. Note: the final derating factor is a multiplication of all a...

Page 80: Dimensions And Weights

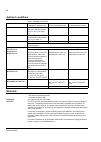

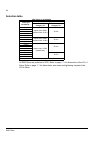

Technical data 80 dimensions and weights see also chapter dimension drawings on page 107 . Cooling characteristics, noise levels frame size height (without cable clamp plates) height (with cable clamp plates) width depth (without control panel ) depth (with control panel) weight mm (in.) mm (in.) mm...

Page 81: Supply Cable Fuses

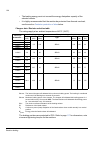

Technical data 81 supply cable fuses fuses for short circuit protection of the supply cable are listed below. The fuses also protect the adjoining equipment of the drive in case of a short circuit. Check that the operating time of the fuse is below 0.5 seconds. The operating time depends on the supp...

Page 82: Dc Connection

Technical data 82 ac input (supply) connection voltage ( u 1 ) 380 … 480 v ac +10%/-15%, 3-phase frequency 50 … 60 hz ±5% network type grounded (tn, tt) or ungrounded (it). Note: connection to an ungrounded (it) or corner-grounded delta network is not allowed at altitudes of 2000 m (6600 ft) or high...

Page 83: Jcu Control Unit

Technical data 83 current see section ratings. Switching frequency 3 khz (default). Maximum motor cable length frames a and b: 150 m (492 ft) * frames c and d: 300 m (984 ft) * *100 m with en 61800-3 category c3 filter terminals frame a: detachable screw terminal block for 0.25 … 4 mm 2 wire. Frame ...

Page 84

Technical data 84 digital inputs/outputs dio1 and dio2 (xdio:1 and xdio:2) input/output mode selection by parameters. Dio1 can be configured as a frequency input (0…16 khz) for 24 v level square wave signal (sinusoidal or other wave form cannot be used). Dio2 can be configured as a 24 v level square...

Page 85: Efficiency

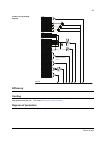

Technical data 85 isolation and grounding diagram efficiency approximately 98% at nominal power level cooling method internal fan, flow from bottom to top. Air-cooled heatsink. Free space around the unit see chapter planning the cabinet assembly . Degrees of protection ip20 (ul open type). See chapt...

Page 86: Ambient Conditions

Technical data 86 ambient conditions environmental limits for the drive are given below. The drive is to be used in a heated, indoor, controlled environment. Operation installed for stationary use storage in the protective package transportation in the protective package installation site altitude 0...

Page 87: Applicable Standards

Technical data 87 applicable standards the drive complies with the following standards. The compliance with the european low voltage directive is verified according to standards en 50178 and en 60204-1. • en 50178 (1997) electronic equipment for use in power installations • iec 60204-1 (2005), modif...

Page 88: Ce Marking

Technical data 88 ce marking a ce mark is attached to the drive to verify that the drive follows the provisions of the european low voltage and emc directives. Compliance with the european low voltage directive the compliance with the european low voltage directive has been verified according to sta...

Page 89: C-Tick Marking

Technical data 89 warning! The drive may cause radio interference if used in a residential or domestic environment. The user is required to take measures to prevent interference, in addition to the requirements for ce compliance listed above, if necessary. Compliance with en 61800-3 (2004), category...

Page 90: Ul Marking

Technical data 90 ul marking see the type designation label for the valid markings of your drive. Ul checklist input power connection – see section ac input (supply) connection on page 82 . Disconnecting device (disconnecting means) – see section supply disconnecting device on page 39 . Ambient cond...

Page 91: Mains Chokes

Mains chokes 91 mains chokes what this chapter contains this chapter describes how to select and install mains chokes for the acs850-04. The chapter also contains the relevant technical data. When is a mains choke required? Frame c and d drive modules have an internal mains choke. With frames a and ...

Page 92: Installation Guidelines

Mains chokes 92 installation guidelines • if an emc filter is also installed, the mains choke is connected between the supply and the emc filter. See the diagram below. • for optimal operation of the choke, the drive and the choke must be mounted on the same conductive surface. • ensure the choke do...

Page 93: Emc Filters

Emc filters 93 emc filters what this chapter contains this chapter describes how to select and install emc filters for the acs850-04. The chapter also contains the relevant technical data. When is an emc filter required? The emc product standard (en 61800-3 + amendment a11 (2000)) covers the specifi...

Page 94: Selection Table

Emc filters 94 selection table all emc filters are protected to ip20. Refer to page 113 for dimensions of the jfi-x1 filters. Refer to page 115 for dimensions, wire sizes and tightening torques of the jfi-0x filters. Emc filters for acs850-04 drive type acs850-04… filter type en 61800-3 (2004): cate...

Page 95

Emc filters 95 jfi-a1/jfi-b1 (frame a/b, category c3) installation installation guidelines • the filter is connected directly to the drive input connectors. • for optimal operation of the filter, the drive and the filter must be mounted on the same conductive surface. Connection diagram ~ ac supply ...

Page 96

Emc filters 96 mounting procedures jfi-a1 • remove the udc+/- and u1/v1/w1 terminal blocks (1), and the upper power cable clamp plate (2) from the drive. • fasten the mounting bracket (3) to the drive module base with two screws (4). Tighten to 1.5 n·m (13 lbf·in). • push the filter into place throu...

Page 97

Emc filters 97 jfi-b1 • remove the udc+/- and u1/v1/w1 terminal blocks (1), and the upper power cable clamp plate (2) from the drive. • push the filter into the connectors. • fasten the filter to the drive module base with two screws (3). Tighten to 1.5 n·m (13 lbf·in). • fasten the top edge of the ...

Page 98

Emc filters 98 jfi-0x (frames a…d, category c2) installation installation guidelines • if a mains choke is also installed, the emc filter is connected between the mains choke and the drive module. See the connection diagram below. • for optimal operation of the filter, the drive and the filter must ...

Page 99

Du/dt and common mode filtering 99 du/dt and common mode filtering what this chapter contains this chapter describes how to select du/dt and common mode filtering for the acs850-04. The chapter also contains the relevant technical data. When is du/dt or common mode filtering required? The output of ...

Page 100: Filter Types

Du/dt and common mode filtering 100 du/dt filters are optional accessories and to be ordered separately. For more information on common mode filtering, contact your local abb representative. Contact the motor manufacturer for information on the motor construction. Filter types du/dt filters motor ty...

Page 101: Technical Data

Du/dt and common mode filtering 101 common mode filters contact your local abb representative. Technical data du/dt filters dimensions and weights degree of protection ip00 common mode filters contact your local abb representative. Installation follow the instructions included with the filters. Filt...

Page 102

Du/dt and common mode filtering 102.

Page 103: Resistor Braking

Resistor braking 103 resistor braking what this chapter contains this chapter describes how to select, protect and wire braking choppers and resistors. The chapter also contains the technical data. Braking choppers and resistors with the acs850-04 braking choppers acs850-04 (frame a…d) drives have a...

Page 104

Resistor braking 104 • the braking energy must not exceed the energy dissipation capacity of the selected resistor • it is highly recommended that the resistor be protected from thermal overload; see the section contactor protection of drive below. Chopper data / resistor selection table the ratings...

Page 105

Resistor braking 105 resistor installation and wiring all resistors must be installed outside the drive module in a place where they are cooled sufficiently, do not block the airflow to other equipment, or dissipate hot air into the air inlets of other equipment. Warning! The materials near the brak...

Page 106

Resistor braking 106 braking circuit commissioning for more information, see the appropriate firmware manual . • enable the braking chopper function. Please note that a braking resistor must be connected when the chopper is enabled • switch off the overvoltage control of the drive • adjust any other...

Page 107: Dimension Drawings

Dimension drawings 107 dimension drawings what this chapter contains dimension drawings of the acs850-04 and related accessories are shown below. The dimensions are given in millimetres and [inches]..

Page 108: Frame Size A

Dimension drawings 108 frame size a.

Page 109: Frame Size B

Dimension drawings 109 frame size b.

Page 110: Frame Size C

Dimension drawings 110 frame size c.

Page 111: Frame Size D

Dimension drawings 111 frame size d.

Page 112

Dimension drawings 112 mains chokes (type chk-0x) chk-xx dimensions parameter choke type chk-01 chk-02 chk-03 chk-04 dim a mm (in.) 120 (4.72) 150 (5.91) 150 (5.91) 150 (5.91) dim b mm (in.) 146 (5.75) 175 (6.89) 175 (6.89) 175 (6.89) dim c mm (in.) 79 (3.11) 86 (3.39) 100 (3.94) 100 (3.94) dim d mm...

Page 113: Emc Filters (Type Jfi-X1)

Dimension drawings 113 emc filters (type jfi-x1) jfi-a1.

Page 114

Dimension drawings 114 jfi-b1.

Page 115: Emc Filters (Type Jfi-0X)

Dimension drawings 115 emc filters (type jfi-0x).

Page 116

Dimension drawings 116 jfi- xx dimensions parameter filter type jfi-02 jfi-03 jfi-05 jfi-07 dim. A mm (in.) 250 (9.84) 250 (9.84) 250 (9.84) 270 (10.63) dim. B mm (in.) 45 (1.77) 50 (1.97) 85 (3.35) 90 (3.54) dim. C mm (in.) 70 (2.76) 85 (3.35) 90 (3.54) 150 (5.91) dim. D mm (in.) 220 (8.66) 240 (9....

Page 117

Dimension drawings 117 braking resistors (type jbr-xx).

Page 118

Dimension drawings 118 jbr-xx dimensions parameter resistor type jbr-01 jbr-03 jbr-04 jbr-05 jbr-06 dim. A mm (in.) 295 (1 1.61) 340 (13.39) – – – dim. B mm (in.) 155 (6.10) 200 (7.87) – – – dim. C mm (in.) 125 (4.92) 170 (6.69) – – – dim. D mm (in.) – – 345 (13.58) 465 (18.31) 595 (23.43) dim. E mm...

Page 119: Further Information

Further information product and service inquiries address any inquiries about the product to your local abb representative, quoting the type designation and serial number of the unit in question. A listing of abb sales, support and service contacts can be found by navigating to www.Abb.Com/ drives a...

Page 120

3a u a 000004 5496 r e v d e n e ffe c t iv e : 2009- 07- 20 abb oy ac drives p.O. Box 184 fi-00381 helsinki finland telephone +358 10 22 11 fax +358 10 22 22681 internet http://www.Abb.Com.