- DL manuals

- ABB

- DC Drives

- ACS850 series

- Hardware Manual

ABB ACS850 series Hardware Manual

Summary of ACS850 series

Page 1

Acs850 hardware manual acs850-04 drive modules (400 to 560 kw, 450 to 700 hp) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 2

List of related manuals you can find manuals and other product documents in pdf format on the internet. See section document library on the internet on the inside of the back cover. For manuals not available in the document library, contact your local abb representative. Manual code (english) standa...

Page 3: Hardware Manual

Acs850-04 drive modules 400 to 560 kw (450 to 700 hp) hardware manual 3aua0000081249 rev a en effective: 2011-03-11 © 2011 abb oy. All rights reserved. Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 4

Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 5: Update Notice

Update notice 1 update notice this notice concerns the following acs850-04 hardware manuals : code: 3aua0000102679 rev a valid: from 29.6.2011 until the release of rev b of the manual contents: unpacking drawings for the additional boxes in the transport package of the drive module and installation ...

Page 6

Update notice 2 install the pe terminal (4) and assembly support (8) as shown below. 1 2 3 4 5 6 7 8 2 1 3 4 5 6 7 8 ramp package contents 1 screw package 2 fasrtening bracket 3 telescopic extraction and insertion ramp 4 pe terminal 5 cardboard box 6 pedestal guide plate 7 top guide plate 8 support ...

Page 7

Update notice 3 install the grounding busbar (2) as shown below. 5 6 7 8 9 sub - 3a - 3a 1 8 2 3 4 5 6 7 9 8 1 2 3 4 5 6 7 9 output power cabling panel (option +h381) package contents 1 paper fill 2 grounding busbar to be connected to the input power cabling panel and the drive module 3 cardboard tr...

Page 8

Update notice 4 4 5 6 7 8 sub - 3a - 3a 1 2 3 4 5 6 7 8 2 1 3 4 5 6 7 8 input power cabling panel (option +h381) package contents 1 screw package 2 paper fill 3 input power cabling panel 4 cardboard tray 5 top cardboard cover 6 support 7 bands 9 plastic bag phone: 800.894.0412 - fax: 888.723.4773 - ...

Page 9: Table of Contents

Table of contents 5 table of contents list of related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 table of contents safety instructions what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 10

Table of contents 6 arranging the grounding inside the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38 selecting the busbar material and preparation of the joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38 tightening torques . . . ...

Page 11

Table of contents 7 routing the cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 separate control cable ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 cont...

Page 12

Table of contents 8 connecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83 flowchart of the control cable installation process (external control unit) . . . . . . . . . . . . . . . .83 flowchart of the control cable i...

Page 13

Table of contents 9 fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 replacing the circuit board compartment cooling fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 replacing the m...

Page 14

Table of contents 10 example circuit diagrams what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133 example circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 15: Safety Instructions

Safety instructions 11 safety instructions what this chapter contains this chapter contains the safety instructions which you must follow when installing, operating and servicing the drive. If ignored, physical injury or death may follow, or damage may occur to the drive, motor or driven equipment. ...

Page 16

Safety instructions 12 safety in installation andmaintenance electrical safety these warnings are intended for all who work on the drive, motor cable or motor. Warning! Ignoring the following instructions can cause physical injury or death, or damage to the equipment: • only qualified electricians a...

Page 17

Safety instructions 13 grounding these instructions are intended for all who are responsible for the grounding of the drive. Warning! Ignoring the following instructions can cause physical injury, death, increased electromagnetic interference and equipment malfunction: • ground the drive, motor and ...

Page 18

Safety instructions 14 permanent magnet motor drives these are additional warnings concerning permanent magnet motor drives. Warning! Ignoring the instructions can cause physical injury or death, or damage to the equipment. • do not work on the drive when the permanent magnet motor is rotating. Also...

Page 19

Safety instructions 15 general safety these instructions are intended for all who install and service the drive. Warning! Ignoring the following instructions can cause physical injury or death, or damage to the equipment: • - lift the drive module using the lifting lugs attached to the top and base ...

Page 20

Safety instructions 16 fiber optic cables - push the drive module into the cabinet and pull it from the cabinet carefully preferably with help from another person as shown below. Keep a constant pressure with one foot on the base of the module to prevent the module from falling on its back. Use safe...

Page 21

Safety instructions 17 printed circuit boards safe start-up and operation general safety these warnings are intended for all who plan the operation of the drive or operate the drive. Permanent magnet motor drives warning! Do not run the motor over the rated speed. Motor overspeed leads to overvoltag...

Page 22

Safety instructions 18 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 23: Introduction to The Manual

Introduction to the manual 19 introduction to the manual what this chapter contains this chapter describes the intended audience and contents of the manual. It contains a flowchart of steps in checking the delivery, installing and commissioning the drive. The flowchart refers to chapters/sections in...

Page 24

Introduction to the manual 20 start-up refers to the start-up instructions of the cabinet-installed drive. Fault tracing describes the led indications and refers to the fault tracing instructions of the drive. Maintenance contains preventive maintenance instructions. Technical data contains the tech...

Page 25

Introduction to the manual 21 route the cables. Routing the cables (page 56 ) check the insulation of the supply cable, the motor and the motor cable and the resistor cable (if present). Checking the insulation of the assembly (page 72 ) units with optional cabling panels (+h318) • install the cabli...

Page 26

Introduction to the manual 22 terms and abbreviations connect the external control cables to the drive control unit. Connecting the control cables (page 83 ) control cable connection procedure of units with internal control unit (option +p905) , page 96 check the installation. Installation checklist...

Page 27

Introduction to the manual 23 htl high-threshold logic igbt insulated gate bipolar transistor; a voltage-controlled semiconductor type widely used in inverters due to their easy controllability and high switching frequency. I/o input/output jcu the control unit of the drive module. The external i/o ...

Page 28

Introduction to the manual 24 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 29

Operation principle and hardware description 25 operation principle and hardware description what this chapter contains this chapter describes the operating principle and construction of the drive module in short. Product overview the acs850-04 is a drive module for controlling asynchronous ac induc...

Page 30

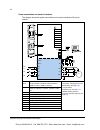

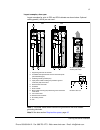

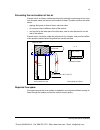

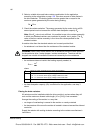

Operation principle and hardware description 26 layout the components of the standard unit are shown below. Item description a drive module 1 lifting lugs 2 fastening bracket 3 input cable connection busbars and optional dc+ and dc- busbars (+h356) 4 circuit board compartment 5 power supply and fibe...

Page 31

Operation principle and hardware description 27 12 base fastening srews 13 handle for pulling the drive module out of the cabinet 14 pedestal guide plate 15 telescopic extraction and insertion ramp 16 top guide plate 17 optional common mode filter (+e208) b control unit (jcu) 1 control unit with fro...

Page 32

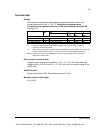

Operation principle and hardware description 28 the drive module and optional selections are shown below: control unit and control panel variations and cabling panels. Item description a drive module 1 input power cabling panel fastened to the drive module 2 output power cabling panel fastened to th...

Page 33

Operation principle and hardware description 29 the control unit layout is shown below (cover assembly and protective coverings of the slots removed). Slots 1 and 2 for optional i/o extension and encoder/resolver interface modules slot 3 for optional fieldbus adapter module relay outputs +24vd digit...

Page 34

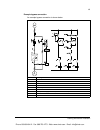

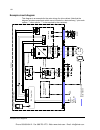

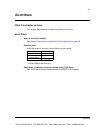

Operation principle and hardware description 30 power connections and control interfaces the diagram shows the power connections and control interfaces of the drive module. Slot 1 and slot 2 i/o extension modules (fio-01, fio-11, fio-21) and/or encoder or resolver interface modules (fen-01, fen-11, ...

Page 35

Operation principle and hardware description 31 external control unit connection cables the cables for connecting the drive module and control panel to the control unit are shown below. See sections connecting the external control unit to the drive module (page 85 ) and connecting a pc (page 97 ) fo...

Page 36

Operation principle and hardware description 32 type designation key the type designation contains information on the specifications and configuration of the drive module. The first digits from left express the basic configuration. The optional selections are given thereafter, separated by plus sign...

Page 37

Operation principle and hardware description 33 option codes (plus codes) resistor braking d150 brake chopper and brake resistor connection busbars, and r+ and r- terminals in the power cabling panel (+h381) if the panel is ordered filters e205 du/dt filter e208 common mode filter. Includes three ex...

Page 38

Operation principle and hardware description 34 paper manuals. Note: the delivered manual set may include manuals in english if the translation is not available. R700 english r701 german r702 italian r703 dutch r704 danish r705 swedish r706 finnish r707 french r708 spanish r709 portuguese r711 russi...

Page 39

Planning the cabinet installation 35 planning the cabinet installation what this chapter contains this chapter guides in planning drive cabinets and installing the drive module into a user-defined cabinet so that the front of the module faces the cabinet door. The chapter gives cabinet layout exampl...

Page 40

Planning the cabinet installation 36 layout examples, door closed layout examples for ip22 and ip54 cabinets are shown below (input power cable lead-through from top and motor cable lead-through from bottom). Ip54 ip22 roof air flow viewed from top (ip54) 1a 4 3 1b 2a 2b 5 6 1a 4 3 1b 2a 2b 5 6 1a a...

Page 41

Planning the cabinet installation 37 layout examples, door open layout examples for units in ip22 and ip54 cabinets are shown below. Optional cabling panels (+h318) are not used. . Note 1: the power cable shields can also be grounded to the drive module grounding terminals. Note 2: see also section ...

Page 42

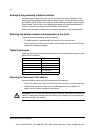

Planning the cabinet installation 38 arranging the grounding inside the cabinet arrange the grounding of the drive module by leaving the contact surfaces of the fastening points unpainted (bare metal-to-metal contact). The module frame will be grounded to the pe busbar of the cabinet via the fasteni...

Page 43

Planning the cabinet installation 39 planning the cabinet placement on a cable channel note the following when planning to place the cabinet on a cable channel: • the cabinet structure must be sturdy enough. If the whole cabinet base will not be supported from below, the cabinet weight will lie on t...

Page 44

Planning the cabinet installation 40 • 360° high frequency grounding of the cable shields at the cable lead-throughs improves the emc shielding of the cabinet. • 360° high frequency grounding of the motor cable shields at their entries is recommended. The grounding can be implemented by a knitted wi...

Page 45

Planning the cabinet installation 41 planning the grounding of the cable shields at the cabinet lead-through follow the principle shown below when planning the grounding of the cable shields at the cabinet lead-through. Planning the cooling note following guidelines when planning the cooling of the ...

Page 46

Planning the cabinet installation 42 • leave enough free space around the components to ensure sufficient cooling. Observe the minimum clearances given for each component. For the required free space around the drive module, see page 43 . • also ventilate the heat dissipated by cables and other addi...

Page 47

Planning the cabinet installation 43 preventing the recirculation of hot air prevent hot air circulation outside the cabinet by leading the outcoming hot air away from the area where the inlet air to the cabinet is taken. Possible solutions are listed below: • gratings that guide air flow at the air...

Page 48

Planning the cabinet installation 44 free space at top with air inlet gratings in the cabinet door the required free space at the top of the module is shown below when the air inlet gratings are located only in the lower part of the cabinet door. Free space around the drive module 45 mm (1.77 in.) f...

Page 49

Planning the cabinet installation 45 planning the use of the cubicle heaters use a cubicle heater if there is a risk of condensation in the cabinet. Although the primary function of the heater is to keep the air dry, it may also be required for heating at low temperatures. Phone: 800.894.0412 - fax:...

Page 50

Planning the cabinet installation 46 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 51

Planning the electrical installation 47 planning the electrical installation what this chapter contains this chapter contains the instructions that you must follow when selecting the motor, cables, protections, cable routing and way of operation for the drive system. Note: the installation must alwa...

Page 52

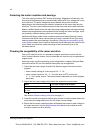

Planning the electrical installation 48 protecting the motor insulation and bearings the drive employs modern igbt inverter technology. Regardless of frequency, the drive output comprises pulses of approximately the drive dc bus voltage with a very short rise time. The pulse voltage can almost doubl...

Page 53

Planning the electrical installation 49 example 1: when the supply voltage is 440 v and the drive is operating in the motor mode only, the maximum peak voltage in the motor terminals can be approximated as follows: 440 v · 1.35 · 2 = 1190 v. Check that the motor insulation system withstands this vol...

Page 54

Planning the electrical installation 50 * manufactured before 1.1.1998 ** for motors manufactured before 1.1.1998, check for additional instructions with the motor manufacturer. *** if the intermediate dc circuit voltage of the drive is increased from the nominal level by resistor braking, check wit...

Page 55

Planning the electrical installation 51 high-output motors and ip 23 motors for motors with higher rated output than what is stated for the particular frame size in en 50347 (2001) and for ip23 motors, the requirements of abb random-wound motor series (for example m3aa, m3ap, m3bp) are given below. ...

Page 56

Planning the electrical installation 52 sine filters sine filters protect the motor insulation system. Therefore, du/dt filter can be replaced with a sine filter. The peak phase-to-phase voltage with the sine filter is approximately 1.5 · u n . Common mode filters common mode filter is available as ...

Page 57

Planning the electrical installation 53 a four-conductor system is allowed for input cabling, but shielded symmetrical cable is recommended. To operate as a protective conductor, the shield conductivity requirements according to iec 60439-1 are shown below when the protective conductor is made of th...

Page 58

Planning the electrical installation 54 typical power cable sizes (us) cable sizing is based on nec table 310-16 for copper wires, 75 °c (167 °f) wire insulation at 40 °c (104 °f) ambient temperature. Not more than three current- carrying conductors in raceway or cable or earth (directly buried). Fo...

Page 59

Planning the electrical installation 55 motor cable shield to effectively suppress radiated and conducted radio-frequency emissions, the shield conductivity must be at least 1/10 of the phase conductor conductivity. The requirements are easily met with a copper or aluminium shield. The minimum requi...

Page 60

Planning the electrical installation 56 selecting the control cables shielding all control cables must be shielded. Use a double-shielded twisted pair cable for analog signals. This type of cable is recommended for the pulse encoder signals also. Employ one individually shielded pair for each signal...

Page 61

Planning the electrical installation 57 where control cables must cross power cables ensure that they are arranged at an angle as near to 90 degrees as possible. Do not run extra cables through the drive. The cable trays must have good electrical bonding to each other and to the grounding electrodes...

Page 62

Planning the electrical installation 58 separate control cable ducts continuous motor cable shield or enlosure for equipment in the motor cable to ensure safety and minimize the emission level when safety switches, contactors, connection boxes or similar equipment are installed in the motor cable be...

Page 63

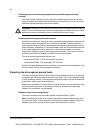

Planning the electrical installation 59 implementing thermal overload and short-circuit protection protecting the drive and input power cable in short-circuits protect the drive with fuses and the input cable with fuses or a circuit breaker as shown below: size the fuses or circuit breaker at the di...

Page 64

Planning the electrical installation 60 protecting the drive and the input power and motor cables against thermal overload the drive protects itself and the input and motor cables against thermal overload when the cables are dimensioned according to the nominal current of the drive. No additional th...

Page 65

Planning the electrical installation 61 implementing the emergency stop function for safety reasons, install the emergency stop devices at each operator control station and at other operating stations where emergency stop may be needed. Note: pressing the stop key ( ) on the control panel of the dri...

Page 66

Planning the electrical installation 62 warning! The safe torque off function does not disconnect the voltage of the main and auxiliary circuits from the drive. Therefore maintenance work on electrical parts of the drive or the motor may only be carried out after isolating the drive system from the ...

Page 67

Planning the electrical installation 63 implementing the atex-certified safe motor disconnection function (option +q971) with option +q971, the drive provides atex-certified safe motor disconnection without contactor using the drive safe torque off function. For more information, see acs850 atex-cer...

Page 68

Planning the electrical installation 64 implementing a safety switch between the drive and motor it is recommended to install a safety switch between the permanent magnet synchronous motor and the drive output. The switch is needed to isolate the motor during any maintenance work on the drive. Using...

Page 69

Planning the electrical installation 65 example bypass connection an example bypass connection is shown below. Switch description q1 drive main switch q4 bypass circuit breaker k1 drive main contactor k4 bypass contactor k5 drive output contactor s11 drive main contactor on/off control s40 motor pow...

Page 70

Planning the electrical installation 66 switching the motor power supply from drive to direct-on-line 1. Stop the drive and the motor with the drive control panel (drive in the local control mode) or the external stop signal (drive in the remote control mode). 2. Open the main contactor of the drive...

Page 71

Planning the electrical installation 67 connecting a motor temperature sensor to the drive i/o warning! Iec 60664 requires double or reinforced insulation between live parts and the surface of accessible parts of electrical equipment which are either non- conductive or conductive but not connected t...

Page 72

Planning the electrical installation 68 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 73: Installation

Installation 69 installation what this chapter contains in this chapter, the drive module is installed in a 400 mm wide rittal ts 8 cabinet in a bookshelf way of mounting: the module is placed in an upright position on the cabinet bottom with its front facing the cabinet door. The following rittal p...

Page 74

Installation 70 note 2 : with input and motor cables of size 4 × 240 mm 2 per phase, dc cables cannot be lead to the terminals of the input cabling panel through the input cabling panel lead-throughs. Lead the dc cables then through the cabinet roof directly to the terminals. If resistor cables are ...

Page 75

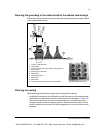

Installation 71 moving and unpacking the unit warning! Follow the safety instructions, page 12 . Ignoring the instructions can cause physical injury or death, or damage to the equipment move the transport package by pallet truck to the installation site. Unpack the package as follows: • cut the band...

Page 76

Installation 72 checking the delivery check that all items listed under section moving and unpacking the unit are present. Check that there are no signs of damage. Before attempting installation and operation, check the information on the type designation label of the drive to verify that the unit i...

Page 77

Installation 73 brake resistor and resistor cable check the insulation of the brake resistor assembly (if present) as follows: 1. Check that the resistor cable is connected to the resistor, and disconnected from the drive output terminals r+ and r-. 2. At the drive end, connect the r+ and r- conduct...

Page 78

Installation 74 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 79

Installation 75 connecting the power cables warning! Follow the safety instructions, page 12 . Ignoring the instructions can cause physical injury or death, or damage to the equipment connection diagram input output u1 v1 w1 u2 v2 w2 r - acs850-04 u1 v1 w1 3 ~ motor r+ udc+ udc - pe u2 v2 w2 r - r+ ...

Page 80

Installation 76 1 for alternatives, see section selecting the supply disconnecting device (disconnecting means) on page 47. In the mounting example of this chapter, the disconnecting device is not in the same cubicle with the drive module. 2 if a shielded cable is used (not required but recommended)...

Page 81

Installation 77 input cable connection procedure warning! Follow the instructions in chapter safety instructions . Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Lead the cables into the inside of the cabinet. It is recommended to apply 360° grounding of...

Page 82

Installation 78 motor cable connection procedure warning! Follow the instructions in chapter safety instructions . Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Lead the cables into the inside of the cabinet. Ground the cable shield 360° at the lead-thr...

Page 83

Installation 79 • or by twisting the shield as follows: flattened width > 1/5 · length. Dc connection the udc+ and udc– terminals are intended for common dc configurations of a number of drives, allowing regenerative energy from one drive to be utilised by the other drives in the motoring mode. Cont...

Page 84

Installation 80 mounting the drive module into the cabinet warning! Follow the safety instructions, page 12 . Ignoring the instructions can cause physical injury or death, or damage to the equipment. Handle the drive module carefully. Make sure that the module does not fall down when moving it on th...

Page 85

Installation 81 1 4a 4b 3 2 6 2 6 4a 4b 5a 5b 5b phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 86

Installation 82 assembly drawing of fastening the drive module to the cabinet phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 87

Installation 83 removing the protective covering from the module air outlet warning! Remove the protective covering from the top of the drive module after the installation. If the covering is not removed, the cooling air cannot flow freely through the module and the drive will run to overtemperature...

Page 88

Installation 84 removing the cover assembly of the external control unit the cover assembly needs to be removed before the installation of optional modules and the connection of control cabling. Follow this procedure to remove the cover assembly. The numbers refer to the illustrations below. 1. Pres...

Page 89

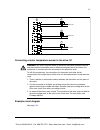

Installation 85 fastening the control cable clamp plate fasten the control cable clamp plate either to the top or base of the control unit with four screws as shown below. Connecting the external control unit to the drive module warning! Handle the fiber optic cables with care. When unplugging optic...

Page 90

Installation 86 3aua0000038989 txd = transmitter rxd = receiver jrib v6 v7 v1 v2 1 2 apow 2 jint 3 jrib 1 4 4 jgdr phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 91

Installation 87 mounting the external control unit the drive control unit can be fastened on a mounting plate through the fastening holes in its back or by using a din rail. Mounting the external control unit to wall 1. Fasten the fastening screws in the wall. 2. Lift the unit onto the screws and ti...

Page 92

Installation 88 mounting the external control unit vertically on a din rail 1. Fasten the latch (a) to the back of the control unit with four screws. 2. Click the control unit to the rail as shown below (b). Mounting the control unit horizontally on a din rail 1. Fasten the latches (a) to the back o...

Page 93

Installation 89 installing optional modules mechanical installation optional modules such as a fieldbus adapters, an i/o extensions and the pulse encoder interfaces are inserted in the optional module slot on the control unit. See page 30 for the available slots. 1. Remove the control unit cover. 2....

Page 94

Installation 90 connecting the control cables to the terminals of the control unit 1. Route the cables to the control unit as shown below. 2. Ground the shields of the control cables at the clamp plate. The shields should be continuous as close to the terminals of the control unit as possible. Only ...

Page 95

Installation 91 directly at both ends if they are in the same ground line with no significant voltage drop between the end points.Tighten the screws to secure the connection. 3. Connect the conductors to the appropriate detachable terminals of the control unit. See section default i/o connection dia...

Page 96

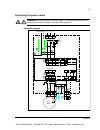

Installation 92 default i/o connection diagram notes: […] denotes default setting with acs850 standard control program (factory macro). See firmware manual for other macros. *total maximum current: 200 ma the wiring shown is for demonstrative purposes only. Further information of the usage of the co...

Page 97

Installation 93 jumpers di/dio grounding selector (located between xd24 and xdi) – determines whether the dignd (ground for digital inputs di1…di5) floats, or if it is connected to diognd (ground for di6, dio1 and dio2). See the jcu isolation and grounding diagram on page 121 . If dignd floats, the ...

Page 98

Installation 94 external power supply for the jcu control unit (xpow) external +24 v (minimum 1.6 a) power supply for the control unit can be connected to terminal block xpow. Using an external supply is recommended if • the application requires fast start after connecting the drive to the main supp...

Page 99

Installation 95 warning! As the inputs pictured above are not insulated according to iec 60664, the connection of the motor temperature sensor requires double or reinforced insulation between motor live parts and the sensor. If the assembly does not fulfil the requirement, • the i/o board terminals ...

Page 100

Installation 96 safe torque off (xsto) for the drive to start, both connections (out1 to in1, and out2 to in2) must be closed. By default, the terminal block has jumpers to close the circuit. Remove the jumpers before connecting an external safe torque off circuitry to the drive. See page 61 . Contr...

Page 101

Installation 97 connecting a pc connect the pc to the drive control unit as follows:. X7 : txd rxd ndpa-0x pc rxd txd ndpc-12 jcu phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 102

Installation 98 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 103: Installation Checklist

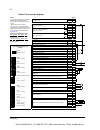

Installation checklist 99 installation checklist what this chapter contains this chapter contains a list for checking the mechanical and electrical installation of the drive. Installation checklist go through the checklist below together with another person. Warning! Follow the safety instructions, ...

Page 104

Installation checklist 100 connection of cables to devices, terminal blocks and drive module circuit boards: • cables are connected to terminals tight enough by pulling the cable. • cable termination on terminals chaining is done correctly. • bare conductors are not too far outside the terminal caus...

Page 105

Installation checklist 101 the supply voltage matches the nominal input voltage of the drive. Check the type designation label. The input power cable has been connected to the appropriate terminals, the phase order is right, and the terminals have been tightened. (pull the conductors to check.) appr...

Page 106

Installation checklist 102 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 107: Start-Up

Start-up 103 start-up what this chapter contains this chapter refers to the start-up instructions of the cabinet-installed drive. Start-up procedure 1. Ensure that the installation of the drive has been checked according to the checklist in chapter installation checklist, and that the motor and driv...

Page 108

Start-up 104 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 109: Fault Tracing

Fault tracing 105 fault tracing what this chapter contains this chapter describes the fault tracing possibilities of the drive. Leds this table describes leds of the drive module. Warning and fault messages see the firmware manual for the descriptions, causes and remedies of the control program warn...

Page 110

Fault tracing 106 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

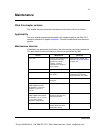

Page 111: Maintenance

Maintenance 107 maintenance what this chapter contains this chapter contains preventive maintenance instructions of the drive module. Applicability the drive module replacement described in this chapter applies to the rittal ts 8 example installation of chapter installation . The other maintenance i...

Page 112

Maintenance 108 consult your local abb service representative for more details on the maintenance. On the internet, go to abb website. Cabinet cleaning the interior of the cabinet warning! Follow the safety instructions, page 12 . Ignoring the instructions can cause physical injury or death, or dama...

Page 113

Maintenance 109 heatsink the module heatsink fins pick up dust from the cooling air. The drive runs into overtemperature warnings and faults if the heatsink is not clean. Cleaning the interior of the heatsink warning! Follow the safety instructions, page 12 . Ignoring the instructions can cause phys...

Page 114

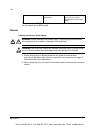

Maintenance 110 fans the actual lifespan depends on the running time of the fan, ambient temperature and dust concentration. See the firmware manual for the actual signal which indicates the running time of the cooling fan. For resetting the running time signal after a fan replacement, please contac...

Page 115

Maintenance 111 replacing the main cooling fans warning! Follow the safety instructions, page 12 . Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Remove the drive module out of the cabinet as described in section replacing the drive module on page 112 . ...

Page 116

Maintenance 112 replacing the drive module warning! Follow the safety instructions, page 12 . Ignoring the instructions can cause physical injury or death, or damage to the equipment. Handle the drive module carefully. Make sure that the module does not fall down when moving it on the floor and duri...

Page 117

Maintenance 113 8. Pull the drive module carefully out of the cabinet preferably with help from another person. 9. Install the new module in reverse order to the above. 6 3 4 8 5 5 2 2 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 118

Maintenance 114 capacitors the drive intermediate circuit employs several electrolytic capacitors. Their lifespan depends on the operating time of the drive, loading and ambient temperature. The lifespan of the capacitor can be prolonged by lowering the ambient temperature. It is not possible to pre...

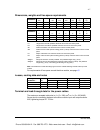

Page 119: Technical Data

Technical data 115 technical data what this chapter contains this chapter contains the technical specifications of the drive, for example, the ratings, sizes and technical requirements, provisions for fulfilling the requirements for ce and other markings. Ratings the ratings of the drive modules wit...

Page 120

Technical data 116 ambient temperature derating in the temperature range +40…55 °c (+104…131 °f), the rated output current is derated by 1% for every added 1 °c (1.8 °f) as follows: altitude derating at altitudes from 1000 to 4000 m (3300 to 13123 ft) above sea level, the derating is 1% for every 10...

Page 121

Technical data 117 dimensions, weights and free space requirements note : the dimensions include the lifting lugs but not the cabinet fastening bracket at the top of the module. For requirements of free space around the drive module, see page 43 . Losses, cooling data and noise terminal and lead-thr...

Page 122

Technical data 118 units with optional common mode filter(+e208) the additonal busbars are included in the delivery of units with optional common mode filter (+e208). The output busbars of the drive module can be enhanced with the additonal busbars in units without optional cabling panels (no +h381)...

Page 123

Technical data 119 electrical power network specification voltage (u 1 ) 380...500 vac 3-phase± 10% rated conditional short- circuit current (iec 60439-1) 65 ka when protected by fuses given in the fuse tables frequency 48 to 63 hz, maximum rate of change 17%/s imbalance max.± 3% of nominal phase to...

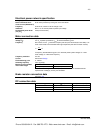

Page 124

Technical data 120 control unit (jcu-11) connection data power supply 24 v (±10%) dc, 1.6 a supplied from the power unit of the drive, or from an external power supply through connector xpow (pitch 5 mm, wire size 2.5 mm 2 ). Relay outputs ro1…ro3 (xro1 … xro3) connector pitch 5 mm, wire size 2.5 mm...

Page 125

Technical data 121 analog inputs ai1 and ai2 (xai:4 … xai:7). Current/voltage input mode selection by jumpers. See page 93 . Connector pitch 3.5 mm, wire size 1.5 mm 2 current input: –20…20 ma, r in: 100 ohm voltage input: –10…10 v, r in : 200 kohm differential inputs, common mode ±20 v sampling int...

Page 126

Technical data 122 efficiency approximately 98% at nominal power level degree of protection without optional cabling panels ip00 ( (ul type open). Ip20 (ul type open) with optional cabling panels (+h381). Ambient conditions environmental limits for the drive are given below. The drive is to be used ...

Page 127

Technical data 123 materials drive enclosure • pc/abs 2.5 mm, colour ncs 1502-y (ral 9002 / pms 420 c) • hot-dip zinc coated steel sheet 1.5 to 2.5 mm, thickness of coating 100 micrometers, colour ncs 1502-y package plywood and cardboard, bands pp. Disposal the drive contains raw materials that shou...

Page 128

Technical data 124 ce marking a ce mark is attached to the drive to verify that the unit follows the provisions of the european low voltage and emc directives. Compliance with the european low voltage directive the compliance with the european low voltage directive has been verified according to sta...

Page 129

Technical data 125 category c4 if the provisions under category c3 cannot be met, the requirements of the standard can be met as follows: 1. It is ensured that no excessive emission is propagated to neighbouring low-voltage networks. In some cases, the inherent suppression in transformers and cables...

Page 130

Technical data 126 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 131: Dimension Drawings

Dimension drawings 127 dimension drawings what this chapter contains this chapter contains dimension drawings of the drive modules with optional parts for rittal ts 8 cabinet assembly. Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 132

Dimension drawings 128 drive module dimensions phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 133

Dimension drawings 129 drive module dimensions with optional cabling panels (+h381) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 134

Dimension drawings 130 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 135

Dimension drawings 131 cabling panels (option +h381) installed into a rittal ts 8 cabinet phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 136

Dimension drawings 132 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 137: Example Circuit Diagrams

Example circuit diagrams 133 example circuit diagrams what this chapter contains this chapter shows an example circuit diagram for a cabinet-installed drive module. Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 138

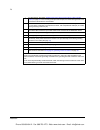

Example circuit diagrams 134 example circuit diagram this diagram is an example for the main wiring of a drive cabinet. Note that the diagram includes components which are not included in a basic delivery (* plus code options, ** other options, *** to be acquired by the customer). **motor temperatur...

Page 139: Resistor Braking

Resistor braking 135 resistor braking what this chapter contains this chapter describes how to select, protect and wire brake resistors. Availability of brake choppers and resistors brake choppers are optionally available as built-in units, indicated in the type description by +d150. Resistors are a...

Page 140

Resistor braking 136 2. Select a suitable drive and brake resistor combination for the application according to the rating table on page 139 . Take also account of other factors in the drive selection. The braking power must be greater than or equal to the maximum power generated by the motor during...

Page 141

Resistor braking 137 warning! The materials near the brake resistor must be non-flammable. The surface temperature of the resistor is high. Air flowing from the resistor is of hundreds of degrees celsius. If the exhaust vents are connected to a ventilation system, ensure that the material withstands...

Page 142

Resistor braking 138 • avoid long parallel runs with other cables. The minimum parallel cabling separation distance should be 0.3 meters. • cross the other cables at right angles. • keep the cable as short as possible in order to minimise the emc emissions and stress on chopper igbts. The longer the...

Page 143

Resistor braking 139 technical data ratings the ratings for selecting the brake system components are given below at an ambient temperature of 40 °c (104 °f). Check that the braking energy transmitted to the specified resistor(s) in 400 seconds does not exceed e r . See page 135 . Brake resistor con...

Page 144

Resistor braking 140 dimensions and weights 234 300 132 0 Ø 7 345 1270 ght: fur180f460: 32 kg fur125f500: 25 kg fur200f500: 30 kg fur210f575: 27 kg brake resistor type weight (kg) safur125f500 25 safur200f500 30 safur210f575 27 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: i...

Page 145: Du/dt Filters

Du/dt filters 141 du/dt filters what this chapter contains this chapter describes how to select du/dt filters for the drive. Du/dt filters when is du/dt filter needed? See section checking the compatibility of the motor and drive , page 48 . Selection table du/dt filter types for the drive module ty...

Page 146

Du/dt filters 142 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 147: Further Information

Further information product and service inquiries address any inquiries about the product to your local abb representative, quoting the type designation and serial number of the unit in question. A listing of abb sales, support and service contacts can be found by navigating to abb website and selec...