- DL manuals

- ABB

- Servo Drives

- ACS880-17

- Hardware Manual

ABB ACS880-17 Hardware Manual

Summary of ACS880-17

Page 1

Abb industrial drives hardware manual acs880-17 drives (132…400 kw, 200…450 hp).

Page 2

List of related manuals you can find manuals and other product documents in pdf format on the internet. See section document library on the internet on the inside of the back cover. For manuals not available in the document library, contact your local abb representative.The code below opens an onlin...

Page 3: Hardware Manual

Hardware manual acs880-17 drives (132…400 kw, 200…450 hp) 3axd50000035158 rev b en effective: 2018-01-18 2018 abb oy. All rights reserved. 1. Safety instructions 4. Mechanical installation table of contents 6. Electrical installation 9. Start-up.

Page 5: Table Of Contents

5 table of contents 1. Safety instructions contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 use of warnings and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 general ...

Page 6

6 channeled air inlet through bottom (option +c128) . . . . . . . . . . . . . . . . . . . . . . . . . 41 channeled air outlet (option +c130) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 marine construction (option +c121) . . . . . . . . . . . . . . . . . . . . . . . ....

Page 7

7 fastening the cabinet to the floor and wall or roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 general rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 fastening methods . . . . . . . . . . . . . . . . . . . . ...

Page 8

8 implementing the safe torque off function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82 implementing the atex-certified safe motor disconnection function (option +q971) . . 82 implementing the prevention of unexpected start-up function . . . . . . . . . . . . . . . . . ....

Page 9

9 grounding the motor cable shield at the motor end . . . . . . . . . . . . . . . . . . . . . . . . . 109 connecting a pc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109 installing option modules . . . . . . . . . . . . . . . . . . . . ...

Page 10

10 recommended annual maintenance actions by the user . . . . . . . . . . . . . . . . . . . . 132 recommended maintenance intervals after start-up . . . . . . . . . . . . . . . . . . . . . . . 132 cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 11

11 iec . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171 terminal data for the drive control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172 electrical power network specification . . . ....

Page 12

12 14. The safe torque off function what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199 description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199 compliance ...

Page 13: Safety Instructions

Safety instructions 13 1 safety instructions contents of this chapter this chapter contains the safety instructions which you must obey when you install and operate the drive and do maintenance on the drive. If you ignore the safety instructions, injury, death or damage can occur. Use of warnings an...

Page 14

14 safety instructions general safety in installation, start-up and maintenance these instructions are for all personnel that install the drive and do maintenance work on it. Warning! Obey these instructions. If you ignore them, injury or death, or damage to the equipment can occur. • secure the cab...

Page 15

Safety instructions 15 all frames; • beware of hot surfaces. Some parts, such as heatsinks of power semiconductors, remain hot for a while after disconnection of the electrical supply. • beware of hot air exiting from the air outlets. • keep the drive in its package or protect it otherwise from dust...

Page 16

16 safety instructions iec/en 61800-5-1, subclause 6.5.3, for example, "this machine starts automatically". • the maximum number of drive power-ups is five in ten minutes. Too frequent power- ups can damage the charging circuit of the dc capacitors. • make sure that any safety circuits (for example,...

Page 17

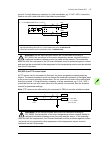

Safety instructions 17 • use a multimeter with an impedance of at least 1 mohm. • make sure that the voltage between the drive input power terminals (l1, l2, l3) and the grounding (pe) busbar is close to 0 v. Measuring holes of the standard drive in the shroud are shown below. L1, l2, l3 pe frame r1...

Page 18

18 safety instructions • frame r11: make sure that the voltage of the drive ac busbars between the drive module and the lcl filter and the grounding (pe) busbar are close to 0 v. Measuring holes of the standard drive in the shroud are shown below. Pe ac busbars.

Page 19

Safety instructions 19 • make sure that the voltage between the dc busbars is close to 0 v. You can measure the voltage through the holes in the cover. 7. Install temporary grounding as required by the local regulations. Connect the ac and dc busbars to pe with a temporary grounding tool. 8. Ask the...

Page 20

20 safety instructions • the motor cable terminals of the drive are at a dangerous voltage when the input power is on, regardless of whether the motor is running or not. • the dc bus is at a dangerous voltage. • external wiring can supply dangerous voltages to the relay outputs of the control units ...

Page 21: Drives

Safety instructions 21 additional instructions for permanent magnet motor drives safety in installation, start-up and maintenance these are additional warnings concerning permanent magnet motor drives. The other safety instructions in this chapter are also valid. Warning! Obey these instructions. If...

Page 22

22 safety instructions.

Page 23: Introduction To The Manual

Introduction to the manual 23 2 introduction to the manual contents of this chapter this chapter describes the manual. It contains a flowchart of steps in checking the delivery, installing and starting up the drive. The flowchart refers to chapters/sections in this manual and to other manuals. Targe...

Page 24: Related Documents

24 introduction to the manual electrical installation gives instructions on wiring the drive. Control unit of frame r11 contains the default i/o connection diagrams, descriptions of the terminals and technical data for the control unit of the drive. Installation checklist contains a list for checkin...

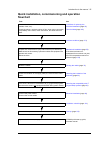

Page 25: Flowchart

Introduction to the manual 25 quick installation, commissioning and operation flowchart task see plan the electrical installation and acquire the accessories needed (cables, fuses, etc.). Check the ratings, required cooling air flow, input power connection, compatibility of the motor, motor connecti...

Page 26: Terms And Abbreviations

26 introduction to the manual terms and abbreviations term/ abbreviation explanation control unit, control board the drive contains two zcu control units. One controls the line-side converter, the other the motor-side converter. As standard, the external i/o control signals are connected to the cont...

Page 27

Introduction to the manual 27 sto safe torque off. See chapter the safe torque off function (page 199 ). Zcu control unit type. The drive contains two zcu control units. One controls the line-side converter, the other the motor-side converter. See also control unit, control board and drive control u...

Page 28

28 introduction to the manual.

Page 29: Operation Principle And

Operation principle and hardware description 29 3 operation principle and hardware description contents of this chapter this chapter briefly describes the operation principle and construction of the drive. Operation principle the acs880-17 is a four-quadrant, air-cooled, cabinet-installed drive for ...

Page 30

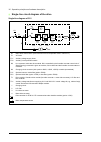

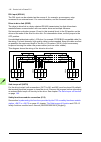

30 operation principle and hardware description single-line circuit diagram of the drive single-line diagram of r11 q1 main switch-disconnector (switch-disconnector and separate fuses in frame r11) f1 ac fuses f21 auxiliary voltage supply fuses f22 auxiliary circuit protection switch q2 line contact...

Page 31

Operation principle and hardware description 31 line-side converter the line-side converter rectifies three-phase ac current to direct current for the intermediate dc link of the drive. The line-side converter is also capable of regenerating, ie. Feeding braking energy back into the electrical power...

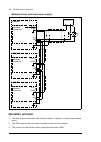

Page 32: Cabinet Layout

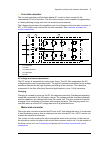

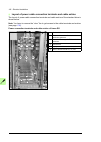

32 operation principle and hardware description cabinet layout the layout drawings give an example of the r11 cabinets. The contents of the cabinet depend on the ordered options. For example: • in the lower power r11 cabinets with only a few options the “door” fan is replaced with a shroud (basic ca...

Page 33

Operation principle and hardware description 33 a main breaker and power cabling cubicle b drive module cubicle c swing-out frame on the drive module side open 1 main switch-disconnector (q1) handle 2 drive control panel (see page 40 ) 3 operating buttons and door lights (see page 39 ) 4 indicators,...

Page 34

34 operation principle and hardware description d swing-out frame 13 main fuses for control devices, ip54 fan with option +b055, transformer with option +b055, v- meter (option +g334), starter for auxiliary motor fan (option +m600) 14 buffering module and power supply unit 15 terminal blocks x18 and...

Page 35

Operation principle and hardware description 35 e swing-out frame 30 auxiliary voltage transformer (t102 with option +b055) and distribution components (see page 91 ) 31 auxiliary voltage transformer (t21) and distribution components (see page 91 ) 32 line-side control unit 33 extraction ramp 34 aux...

Page 36

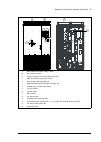

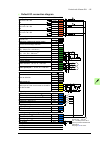

36 operation principle and hardware description overview of power and control connections the diagram shows the power connections and control interfaces of the drive. Connection overview of r11 a motor-side converter control unit (drive control unit) b line-side converter control unit for the contro...

Page 37

Operation principle and hardware description 37 9 terminal blocks for customer connections installed in the drive cabinet. For the locations, see overview of power and control connections (page 36 ). Wiring details are given starting on page 99 . 10 socket for external isu control 11 line-side conve...

Page 38

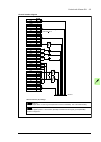

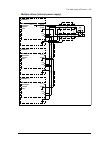

38 operation principle and hardware description external control cable connection terminals connection terminals of r11 the layout of external control cable connection terminals at the left-hand side of the drive cabinet is shown below. The composition depends on the options selected. 4 8 3 7 2 6 1 ...

Page 39: Door Switches And Lights

Operation principle and hardware description 39 door switches and lights main disconnecting device (q1) the main disconnecting device switches the main supply to the drive on and off. To disconnect the main supply, turn the switch-disconnector (frame r11) to the 0 (off) position. Label in english la...

Page 40

40 operation principle and hardware description warning! The main disconnecting device does not isolate the input power terminal or v-meter (option +g334) from the power line. To isolate the input power terminals and v-meter, open the main breaker of the supply transformer. Note: the drive is not fi...

Page 41

Operation principle and hardware description 41 descriptions of cabinet options note: all options are not available for all drive types, do not coexist with certain other options, or may require additional engineering. Check actual availability with abb. Degree of protection definitions according to...

Page 42

42 operation principle and hardware description marine construction (option +c121) the option includes the following accessories and features: • reinforced mechanics • grab railings • door flush bolt which allows the door to open 90 degrees and prevents it from slamming close • self-extinctive mater...

Page 43

Operation principle and hardware description 43 the option includes the following accessories and features: • reinforced plinth • flat bars at base of the cabinet for fastening. Empty cubicles (options +c196, +c197, +c198, +c199, +c200, +c201) the option adds an empty 400, 600 or 800 mm wide cubicle...

Page 44

44 operation principle and hardware description environmental temperature. The customer must switch the heating off when it is not needed by cutting the supply voltage off. The customer must supply the heater from an external 110…240 v ac power source. See also • powering the heating and lighting eq...

Page 45

Operation principle and hardware description 45 v-meter with selector switch (option +g334) the option contains a voltmeter and a selector switch on the cabinet door. The switch selects the two input phases across which the voltage is measured. A-meter in one phase (option +g335) the option contains...

Page 46

46 operation principle and hardware description bottom cable entry/exit (options +h350 and +h352) for ul listed (+c129) units, the default input and output cabling direction is through the roof of the cabinet. The bottom entry (+h350) and bottom exit (+h352) options provide power and control cable e...

Page 47

Operation principle and hardware description 47 the output indication of the relay can be wired by the customer for example to • the main contactor or breaker control circuit of the drive, to open it in case of motor overtemperature, • the appropriate digital input of the drive, to trip the drive an...

Page 48

48 operation principle and hardware description pt100 relays (options +2l506, +3l506, +5l506, +8l506) pt100 temperature monitoring relays are used for overtemperature supervision of motors equipped with pt100 sensors. For example, there can be three sensors to measure the temperature of the motor wi...

Page 49: Type Designation Label

Operation principle and hardware description 49 description the output for the auxiliary fan is wired from the 3-phase supply voltage to terminal block x601 through a motor starter switch and a contactor. The contactor is operated by the drive. The 230 v ac control circuit is wired through a jumper ...

Page 50: Type Designation Key

50 operation principle and hardware description type designation key the type designation contains information on the specifications and configuration of the drive. The first digits from left express the basic configuration (eg, acs880-17-0650a-3). The optional selections are given thereafter, separ...

Page 51

Operation principle and hardware description 51 cabinet equipment g300 cabinet and module heating elements (external supply) g301 cabinet lighting g307 terminals for connecting external control voltage (230 v ac or 115 v ac, eg. Ups) g313 output for motor heater (external supply) g327 ready light, w...

Page 52

52 operation principle and hardware description l525 faio-01 analog i/o extension module l526 fdio-01 digital i/o extension module l536 fptc-01 thermistor protection module l537 fptc-02 atex-certified thermistor protection module starter for auxiliary motor fan m600 trip limit setting range: 1 … 1.6...

Page 53

Operation principle and hardware description 53 r700 english r701 german r702 italian r703 dutch r704 danish r705 swedish r706 finnish r707 french r708 spanish r709 portuguese r711 russian r713 polish code description.

Page 54

54 operation principle and hardware description.

Page 55: Mechanical Installation

Mechanical installation 55 4 mechanical installation contents of this chapter this chapter describes the mechanical installation procedure of the drive. Examining the installation site examine the installation site: • the installation site is sufficiently ventilated or cooled to transfer away the dr...

Page 56: Necessary Tools

56 mechanical installation note: try to avoid installing the drive on an elevated platform or a recess. The module extraction/installation ramp supplied with the drive can only be used on a level floor. Necessary tools the tools required for moving the unit to its final position, fastening it to the...

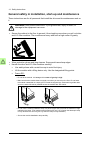

Page 57

Mechanical installation 57 moving and unpacking the drive move the drive in its original packaging to the installation site as shown below to avoid damaging the cabinet surfaces and door devices. When you are using a pallet truck, check its load capacity before you move the drive. The drive cabinet ...

Page 58

58 mechanical installation moving the crate with a forklift free width for fork tines: 750 mm (29.5”).

Page 59

Mechanical installation 59 removing the transport package remove the transport package as follows: 1. Undo the screws that attach the wooden parts of the transport crate together. 2. Remove the wooden parts. 3. Remove the clamps with which the drive cabinet is mounted onto the transport pallet by un...

Page 60

60 mechanical installation moving the cabinet on rollers warning: do not move marine versions (option +c121) on rollers. Lay the cabinet on the rollers and move it carefully until close to its final location. Remove the rollers by lifting the unit with a crane, forklift, pallet truck or jack. Moving...

Page 61

Mechanical installation 61 final placement of the cabinet move the cabinet into its final position with a slate bar (spud bar). Place a piece of wood between the edge of the cabinet and the bar to protect the cabinet frame..

Page 62

62 mechanical installation installing the ip54 roof (option +b055) frame r11 1. Undo the lifting eye screws and remove the lifting eyes. 2. To remove the top front profile of the cabinet, undo the mounting screws. Undo the back mounting screws. 3. Install the roof. 4. Connect the power supply wires ...

Page 63

Mechanical installation 63 fastening the cabinet to the floor and wall or roof general rules • the drive must be installed in an upright vertical position. • the cabinet can be installed with its back against a wall (a), or back-to-back with another unit (b). • leave 400 mm (15.75”) of free space ab...

Page 64

64 mechanical installation fastening methods fasten the cabinet to the floor by using clamps along the edge of the cabinet bottom, or by bolting the cabinet to the floor through the holes inside (if they are accessible). Alternative 1 – clamping alternative 2 – using the holes inside the cabinet 1. ...

Page 65: Units)

Mechanical installation 65 fastening the cabinet to the floor and wall or roof (marine units) obey the general rules given in section general rules on page 63 . See the dimension drawing delivered with the drive for the locations of the fastening holes in the flat bars below the cabinet and for fast...

Page 66: Miscellaneous

66 mechanical installation miscellaneous cable duct in the floor below the cabinet a cable duct can be constructed below the 500 mm wide middle part of the cabinet. The cabinet weight lies on the two 50 mm wide transverse sections which the floor must carry. Prevent the cooling air flow from the cab...

Page 67

Mechanical installation 67 warning! Make sure that the incoming air is sufficiently clean. If not, dust goes into the cabinet. The outlet filter on the cabinet roof prevents dust from going out. The collected dust can cause drive malfunction and danger of fire. Air outlet duct on the cabinet roof (o...

Page 68

68 mechanical installation warning! Make sure that the return wire is connected correctly. Welding current must not return via any component or cabling of the drive. If the welding return wire is connected improperly, the welding circuit can damage electronic circuits in the cabinet. Warning! Do not...

Page 69: Electrical Installation

Guidelines for planning the electrical installation 69 5 guidelines for planning the electrical installation contents of this chapter this chapter contains instructions for planning the electrical installation of the drive. Some instructions are mandatory to follow in every installation, others prov...

Page 70

70 guidelines for planning the electrical installation select the motor size and drive type from to the rating tables in chapter technical data on basis of the ac line voltage and motor load. Use the drivesize pc tool if you need to tune the selection more in detail. Make sure that the motor withsta...

Page 71

Guidelines for planning the electrical installation 71 requirements table the following table shows how to select the motor insulation system and when an optional drive du/dt and common mode filters and insulated n-end (non-drive end) motor bearings are required. Ignoring the requirements or imprope...

Page 72

72 guidelines for planning the electrical installation the abbreviations used in the table are defined below. Additional requirements for explosion-safe (ex) motors if you will use an explosion-safe (ex) motor, follow the rules in the requirements table above. In addition, consult the motor manufact...

Page 73

Guidelines for planning the electrical installation 73 additional requirements for abb motors of types other than m2_, m3_, m4_, hx_ and am_ use the selection criteria given for non-abb motors. Additional requirements for abb high-output and ip23 motors the rated output power of high output motors i...

Page 74

74 guidelines for planning the electrical installation additional data for calculating the rise time and the peak line-to-line voltage if you need to calculate the actual peak voltage and voltage rise time considering the actual cable length, proceed as follows: • peak line-to line voltage: read the...

Page 75: Selecting The Power Cables

Guidelines for planning the electrical installation 75 selecting the power cables general rules select the input power and motor cables according to local regulations: • select a cable capable of carrying the drive nominal current. See section ratings (page 163 ) for the rated currents, and section ...

Page 76

76 guidelines for planning the electrical installation this table shows the minimum cross-sectional area related to the phase conductor size according to iec 61800-5-1 when the phase conductor and the protective conductor are made of the same metal. If this is not so, the cross-sectional area of the...

Page 77

Guidelines for planning the electrical installation 77 alternative power cable types the recommended and not allowed power cable types to be used with the drive are presented below. Recommended power cable types power cable types for limited use not allowed power cable types motor cable shield if th...

Page 78

78 guidelines for planning the electrical installation selecting the control cables shielding all control cables must be shielded. Use a double-shielded twisted pair cable for analog signals. This type of cable is recommended for the pulse encoder signals also. Employ one individually shielded pair ...

Page 79: Routing The Cables

Guidelines for planning the electrical installation 79 routing the cables route the motor cable away from other cable routes. Motor cables of several drives can be run in parallel installed next to each other. The motor cable, input power cable and control cables should be installed on separate tray...

Page 80: Protection

80 guidelines for planning the electrical installation continuous motor cable shield or enclosure for equipment on the motor cable to minimize the emission level when safety switches, contactors, connection boxes or similar equipment are installed on the motor cable between the drive and the motor: ...

Page 81

Guidelines for planning the electrical installation 81 protecting the motor against thermal overload according to regulations, the motor must be protected against thermal overload and the current must be switched off when overload is detected. The drive includes a motor thermal protection function t...

Page 82: Function

82 guidelines for planning the electrical installation implementing the safe torque off function see chapter the safe torque off function (page 199 ). Implementing the atex-certified safe motor disconnection function (option +q971) with option +q971, the drive provides atex-certified safe motor disc...

Page 83: Drive

Guidelines for planning the electrical installation 83 implementing the power-loss ride-through function implement the power-loss ride-through function as follows: check that the power-loss ride-through function of the inverter unit is enabled with parameter 30.31 undervoltage control in the acs880 ...

Page 84: Motor

84 guidelines for planning the electrical installation if there are power factor compensation capacitors in parallel with the three phase input of the drive: 1. Do not connect a high-power capacitor to the power line while the drive is connected. The connection will cause voltage transients that may...

Page 85

Guidelines for planning the electrical installation 85 implementing a bypass connection an application-engineered bypass connection is available from abb. For more information, see bypass connection for acs880-07, -17, -37 (40...1200 a) option description (3axd50000048959 [english]). Warning! Never ...

Page 86

86 guidelines for planning the electrical installation implementing a motor temperature sensor connection warning! Iec 60664 requires double or reinforced insulation between live parts and the surface of accessible parts of electrical equipment which are either non-conductive or conductive but not c...

Page 87

Guidelines for planning the electrical installation 87 drive i/o, i/o extension and encoder interface modules see • section ai1 and ai2 as pt100, pt1000, ptc and kty84 sensor inputs (xai, xao) on page 116 • section di6 (xdi:6) as ptc sensor input on page 117 • fptc-01 thermistor protection module (o...

Page 88

88 guidelines for planning the electrical installation.

Page 89: Electrical Installation

Electrical installation 89 6 electrical installation contents of this chapter this chapter gives instructions on the wiring the drive. Warnings warning! Only qualified electricians are allowed to carry out the work described in this chapter. Follow the safety instructions on the first pages of this ...

Page 90

90 electrical installation motor and motor cable warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. Warning! Use a vacuum cleaner with antistatic hose and nozzle. Using a normal vacuum cleaner creates static disc...

Page 91

Electrical installation 91 warning! Do not install the drive with the ground-to-phase varistor connected to an it system (an ungrounded power system or a high-resistance grounded [over 30 ohms] power system), otherwise the varistor circuit can be damaged. Corner-grounded and midpoint-grounded 690 v ...

Page 92

92 electrical installation connecting the control cables see chapter control unit of frame r11 (page 113 ) for the default i/o connections of the inverter unit (with the acs880 primary control program). The default i/o connections can be different with some hardware options, see the circuit diagrams...

Page 93

Electrical installation 93 grounding the outer shields of the control cables at the cabinet entry applicability this section applies to drives without solid cable conduit plate (no options +c129, +c134, +h358). Procedure ground the outer shields of all control cables 360 degrees at the emi conductiv...

Page 94

94 electrical installation • cover the turned shield and the stripped cable with copper foil to keep the shielding continuous. Note for top entry of cables: when each cable has its own rubber grommet, sufficient ip and emc protection can be achieved. However, if very many control cables come to one ...

Page 95

Electrical installation 95 routing the control cables inside the cabinet use the existing trunking in the cabinet wherever possible. Use sleeving if cables are laid against sharp edges. When running cables to or from the swing-out frame, leave enough slack at the hinge to allow the frame to open ful...

Page 96

96 electrical installation routing the control cables inside r11 cabinet 1. Stop the drive and do the steps in section electrical safety precautions (page 16 ) before you start the work. 1. Open the cabinet door. 2. If there is a mounting plate/two plates above the fan, loosen the four screws of the...

Page 97

Electrical installation 97 control cable routing to the control unit and additional terminal block x504 (option +l504) for bottom entry of cables is shown below. X504 (option +l504).

Page 98

98 electrical installation control cable routing to the control unit and additional terminal block x504 (option +l504) for top entry of cables is shown below. Connecting to the drive control unit connect the conductors to the appropriate terminals of the drive control unit (see section default i/o c...

Page 99

Electrical installation 99 notes: • do not ground the outer shield of the cable here since it is grounded at the entry. • keep any signal wire pairs twisted as close to the terminals as possible. Twisting the wire with its return wire reduces disturbances caused by inductive coupling. At the other e...

Page 100

100 electrical installation wiring the ptc thermistor relay(s) (options +l505, +2l505, +l513, +2l513) the external wiring of option +2l505 and +2l513 (two thermistor relays) is shown below. For example, one relay can be used to monitor the motor windings, the other to monitor the bearings. The maxim...

Page 101

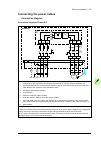

Electrical installation 101 wiring the pt100 relays (option +nl506) external wiring of eight pt100 sensor modules is shown below. Contact load capacity 250 v ac 10 a. For the actual wiring, see the circuit diagram delivered with the drive. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 ...

Page 102

102 electrical installation wiring the pt100 relays (option +nl514) external wiring of three pt100 sensors is shown below. The maximum contact load capacity is 250 v ac 10 a. For the actual wiring, see the circuit diagram delivered with the drive. For instructions on commissioning option +nl514, see...

Page 103

Electrical installation 103 powering the heating and lighting equipment (options +g300, +g301 and +g313) see the circuit diagrams delivered with drive. Connect the external power supply wires for the cabinet heater and lighting to terminal block x300 at the back of the mounting plate. For the actual...

Page 104

104 electrical installation wiring ground fault monitoring for it ungrounded systems (option +q954) we recommend to connect alarm 1 for drive tripping and alarm 2 for alarm signals in order to avoid unnecessary trippings due to the ground fault monitor self testing with alarm 2. For the actual wirin...

Page 105

Electrical installation 105 connecting the power cables connection diagram connection diagram of frame r11 1 use a separate grounding pe cable (1a) or a cable with a separate pe conductor (1b) if the conductivity of the shield does not meet the requirements for the pe conductor (see page 75 ). 2 360...

Page 106

106 electrical installation layout of power cable connection terminals and cable entries the layout of power cable connection terminals and cable entries of the standard drive is shown below. Note: you have to remove the “door” fan to get access to the cable terminals and entries (see page 136 ). Po...

Page 107

Electrical installation 107 connection procedure (iec) 1. Do the steps in section electrical safety precautions on page 16 before you start the work. 2. Open the cabinet door. For r11 bottom entry of cables: • if there is a mounting plate/two plates above the fan, loosen the four screws of the plate...

Page 108

108 electrical installation 11. Connect the twisted shields of the input cables and separate ground cable (if present) to the pe terminal of the cabinet and the phase conductors to the l1, l2 and l3 terminals. 12. Tighten the power cable screws to the torque given in terminal and exit data for the p...

Page 109: Connecting A Pc

Electrical installation 109 grounding the motor cable shield at the motor end always ground the motor cable shield at the motor end. For minimum radio frequency interference, ground the motor cable shield 360 degrees at the entry of the motor terminal box. See also continuous motor cable shield or e...

Page 110: Installing Option Modules

110 electrical installation installing option modules mechanical installation of i/o extension, fieldbus adapter and pulse encoder interface modules see page 36 for the available slots for each module. Install the option modules as follows: warning! Obey the instructions in chapter safety instructio...

Page 111

Electrical installation 111 installation of safety functions modules (frame r11) install the safety functions module next to the zcu-14 control unit as described below. Change the mounting plate of the module as shown in fso-12 safety functions module user’s manual (3axd50000015612 [english]). Warni...

Page 112

112 electrical installation case 2: fso-xx safety functions module next to the control unit install the safety functions module next to the control unit as described below. Change the original mounting plate of the module to the alternative plate included in the module package. Warning! Obey the ins...

Page 113: Control Unit Of Frame R11

Control unit of frame r11 113 7 control unit of frame r11 contents of this chapter this chapter contains the default i/o connection diagram, descriptions of the terminals and technical data for the control unit (zcu-14). The drive with frame r11 contains two zcu control units. One controls the line-...

Page 114: Zcu-14 Control Unit

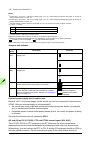

114 control unit of frame r11 zcu-14 control unit layout the layout of the external control connection terminals of the control unit is shown below. Description xpow external power input xai analog inputs xao analog outputs xd2d drive to drive link xro1 relay output ro1 xro2 relay output ro2 xro3 re...

Page 115

Control unit of frame r11 115 default i/o connection diagram relay outputs xro1…xro3 ready 250 v ac / 30 v dc 2 a no 13 com 12 nc 11 running 250 v ac / 30 v dc 2 a no 23 com 22 nc 21 faulted(-1) 250 v ac / 30 v dc 2 a no 33 com 32 nc 31 external power input xpow 24 v dc, 2 a gnd 2 +24vi 1 reference ...

Page 116

116 control unit of frame r11 notes: 1) current [0(4)…20 ma, r in = 100 ohm] or voltage [ 0(2)…10 v, r in > 200 kohm] input selected with jumper j1. Change of setting requires reboot of control unit. 2) current [0(4)…20 ma, r in = 100 ohm] or voltage [ 0(2)…10 v, r in > 200 kohm] input selected with...

Page 117

Control unit of frame r11 117 ground. If a high-frequency capacitor of a few nanofarads, eg. 3.3.Nf / 630 v, cannot be used at one end, leave that end of the shield unconnected. Warning! As the inputs pictured above are not insulated according to iec 60664, the connection of the motor temperature se...

Page 118

118 control unit of frame r11 diil input (xd24:1) the diil input can be selected as the source of, for example, an emergency stop command or an external event. For more information, see the firmware manual. Drive-to-drive link (xd2d) the drive-to-drive link is a daisy-chained rs-485 transmission lin...

Page 119

Control unit of frame r11 119 technical data power supply (xpow) 24 v (±10%) dc, 2 a supplied from the power unit of the drive, or from an external power supply through connector xpow. Connector pitch 5 mm (0.2 in), wire size 2.5 mm 2 (14 awg). Relay outputs ro1…ro3 (xro1 … xro3) connector pitch 5 m...

Page 120

120 control unit of frame r11 analog outputs ao1 and ao2 (xao) connector pitch 5 mm (0.2 in), wire size 2.5 mm 2 (14 awg) 0…20 ma, r load frequency range: 0…300 hz resolution: 11 bit + sign bit inaccuracy: 2% of full scale range drive to drive link (xd2d) connector pitch 5 mm (0.2 in), wire size 2.5...

Page 121

Control unit of frame r11 121 ground isolation diagram xpow +24vi 1 gnd 2 xai +vref 1 -vref 2 agnd 3 ai1+ 4 ai1- 5 ai2+ 6 ai2- 7 xao ao1 1 agnd 2 ao2 3 agnd 4 xd2d b 1 a 2 bgnd 3 xro1, xro2, xro3 nc 11 com 12 no 13 nc 21 com 22 no 23 nc 31 com 32 no 33 xd24 diil 1 +24vd 2 dicom 3 +24vd 4 diognd 5 xd...

Page 122

122 control unit of frame r11.

Page 123: Installation Checklist

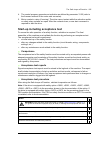

Installation checklist 123 8 installation checklist contents of this chapter this chapter contains an installation checklist which you must complete before you start up the drive. Warnings warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage ...

Page 124

124 installation checklist there is an adequately sized protective ground conductor between the drive and the switchboard, and the conductor has been connected to appropriate terminal. Proper grounding has also been measured according to the regulations. There is an adequately sized protective groun...

Page 125: Start-Up

Start-up 125 9 start-up contents of this chapter this chapter contains the start-up procedure of the drive. Start-up procedure the tasks which are needed in certain cases only are marked with underlining, and option codes are given in brackets. Default device designations (if any) are given in brack...

Page 126

126 start-up action safety warning! Obey the safety instructions during the start-up procedure. See chapter safety instructions on page 13. Checks/settings with no voltage connected ensure that the disconnector of the supply transformer is locked to the off (0) position, ie. No voltage is, and canno...

Page 127

Start-up 127 close the main switch-disconnector (frame r11) (q1). This will power up the main circuit of the drive as well as the auxiliary voltage circuit. Note: do not use excessive force. The main switch-disconnector (frame r11) can only be closed when the main input terminals (l1, l2, l3) are po...

Page 128

128 start-up.

Page 129: Fault Tracing

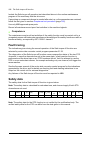

Fault tracing 129 10 fault tracing contents of this chapter this chapter describes the fault tracing possibilities of the drive. Leds warning and fault messages see the firmware manual for the descriptions, causes and remedies of the drive control program warning and fault messages. Where led color ...

Page 130

130 fault tracing.

Page 131: Maintenance

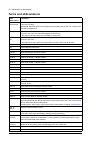

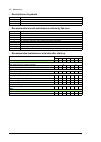

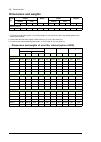

Maintenance 131 11 maintenance contents of this chapter this chapter contains preventive maintenance instructions. Maintenance intervals the table below shows the maintenance tasks which can be done by the end user. The complete maintenance schedule is available on the internet ( www.Abb.Com/drivess...

Page 132

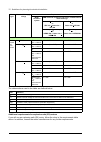

132 maintenance descriptions of symbols recommended annual maintenance actions by the user recommended maintenance intervals after start-up action description i visual inspection and maintenance action if needed p performance of on/off-site work (commissioning, tests, measurements or other work) r r...

Page 133: Cabinet

Maintenance 133 cabinet cleaning the interior of the cabinet warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. Warning! Use a vacuum cleaner with an antistatic hose and nozzle, and wear a grounding wristband. Ot...

Page 134

134 maintenance cleaning the door air inlets (ip54) 1. Stop the drive and do the steps in section electrical safety precautions (page 16 ) before you start the work. 2. Remove the fasteners at the top of the grating. 3. Lift the grating and pull it away from the door. 4. Remove the air filter mat. 5...

Page 135: Heatsink

Maintenance 135 heatsink the drive module heatsink fins pick up dust from the cooling air. The drive runs into overtemperature warnings and faults if the heatsink is not clean. When necessary, clean the heatsink as follows. Warning! Obey the instructions in chapter safety instructions . If you ignor...

Page 136: Fans

136 maintenance fans the lifespan of the cooling fans of the drive depends on the running time, ambient temperature and dust concentration. See the firmware manual for the actual signal which indicates the running time of the cooling fan. Reset the running time signal after a fan replacement. Replac...

Page 137

Maintenance 137 replacing the drive module main fans (frame r11) warning! Obey the safety instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section electrical safety precautions on page 16 be...

Page 138

138 maintenance 4 5 6 7 6.

Page 139

Maintenance 139 replacing the lcl filter module fan warning! Obey the safety instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section electrical safety precautions on page 16 before you star...

Page 140

140 maintenance replacing the auxiliary cooling fans of the drive module (frame r11) warning! Obey the safety instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. Fan in the front panel: 1. Stop the drive and do the steps in section...

Page 141

Maintenance 141 fan at the bottom of the circuit board compartment: 1. Stop the drive and do the steps in section electrical safety precautions on page 16 before you start the work. 2. Open the cabinet door. 3. To remove the marine supports in drives with option +c121, see replacing the drive and lc...

Page 142

142 maintenance replacing the ip54 (ul type12) roof fan (options +b055 and +c128, frame r11) warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section electrical safety prec...

Page 143

Maintenance 143 replacing the ip54 (ul type 12) roof fan (option +b055, frame r11) warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section electrical safety precautions on...

Page 144

144 maintenance replacing the drive and lcl filter modules (frame r11) necessary equipment and tools to replace the drive and lcl filter modules, you need: • an installation ramp • a set of screw drivers • a torque wrench with an extension bar • lifting chains • two persons. Safety warning! Obey the...

Page 145

Maintenance 145 3a 3a 3b 3b 3b 3b 3b 3b 3a: combi screw m10 3b: m6 3c: m6 3c 3c 3c 3c 3c 3c.

Page 146

146 maintenance 4. To open the module section swing-out frame, undo the m10 bolts from top and bottom (4 pcs). 4 4 4 4.

Page 147

Maintenance 147 5. Loosen the two m6 screws of the air baffle and push it to the left. (not for drives with option +c128.) 6. Remove the air baffle. 7. Remove the air baffle. (not for drives with option +c121.) 8. Remove the air baffle: (8a) in ip22/ip42 drives, (8b) in ip54 drives. 9. Disconnect al...

Page 148

148 maintenance the connections between the line-side converter control unit and drive control unit are shown below. The drive control unit remains in its place when you remove the drive module. Bpow zbib zcu drive module bgdr sto1 sto2 inu sto x3 qoia bint v8 v13 24vdc v2 v7 v20 v21 v1 v2.

Page 149

Maintenance 149 10. Loosen the m 4 screws, lift the plastic cover of the dc busbars up and remove it. 11. Disconnect the input power cabling busbars from the drive module busbar terminals. For drives with option +d150, disconnect the dc busbars also. 12. Disconnect the output power cabling and pe bu...

Page 150

150 maintenance 13. To disconnect the drive module from the lcl filter module: • (13a) remove the cover. • (13b) remove the bolts that connect the power busbars. • (13c) remove the attaching bolt. • (13d) remove the cover. • (13e) remove the bolts. • (13f) disconnect the power wire of the lcl filter...

Page 151

Maintenance 151 14. To open the support legs 90 degrees, press each leg a little down and turn it aside. 15. To remove the lower support bracket of the drive module, undo the two screws. 16. Adjust the extraction ramp to the correct height and attach it to the cabinet base with the two mounting scre...

Page 152

152 maintenance 18. To remove the cover on the charging circuit switch/contactor, undo the two mounting screws. 19. Unplug the connector and auxiliary contact wires of the charging circuit switch/contactor. 20. Undo the two bolts that attach drive module to the lcl filter module. 21. Undo the bolts ...

Page 153

Maintenance 153 22. Attach the lifting lugs of the module to be removed to the cabinet lifting lug with chains. 23. Pull the module carefully out of the cabinet preferably with help from another person. 24. Before the module back wheels reach the fastening hook on the floor, open also the back suppo...

Page 154

154 maintenance replacing the lcl filter module if lcl filter module is also to be replaced: 1. To open the support legs 90 degrees, press each leg a little down and turning it aside. 2. To remove the lower support bracket of the lcl filter module, undo the two screws. 3. Adjust the extraction ramp ...

Page 155: Capacitors

Maintenance 155 7. Attach the lifting lugs of the module to be removed to the cabinet lifting lug with chains. 8. Pull the lcl filter module carefully out of the cabinet preferably with help from another person. 9. Install new module in reverse order. Capacitors the dc circuit of the drive modules o...

Page 156: Fuses

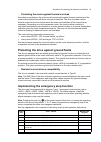

156 maintenance fuses replacing fuses (frame r11) warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive (if running) and do the steps in section electrical safety precautions (page 16 ) before you ...

Page 157

Maintenance 157 3 4 5 6.

Page 158: Control Panel

158 maintenance control panel replacing the battery 1. Turn the lid on the back of the panel counter-clockwise until the lid opens. 2. Replace the battery with a new cr2032 battery. 3. Put the lid back and tighten it by turning it clockwise. 4. Dispose of the old battery according to local disposal ...

Page 159

Maintenance 159 replacing the control unit battery warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section electrical safety precautions on page 16 before you start the wo...

Page 160: Memory Unit

160 maintenance memory unit when a drive is replaced, the parameter settings can be retained by transferring the memory unit from the defective drive to the new drive. One memory unit is located on the drive control unit (motor-side converter control unit), see page 114 , another on the line- side c...

Page 161

Maintenance 161 3. Remove the fastening screw. 4. Pull the memory unit out. 5. Install the new memory unit in reverse order. Note : there is a spare screw next to the memory unit slot. Replacing the memory unit of the line-side converter control unit (r11) warning! Obey the instructions in chapter s...

Page 162

162 maintenance.

Page 163: Technical Data

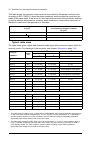

Technical data 163 12 technical data contents of this chapter this chapter contains the technical specifications of the drive, for example, the ratings, fuse data, sizes and technical requirements, provisions for fulfilling the requirements for ce and other markings. Ratings the nominal ratings for ...

Page 164

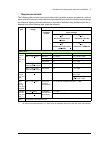

164 technical data definitions u n = 500 v 0260a-5 r11 212 260 480 160 225 247 160 240 132 0361a-5 r11 321 361 520 200 313 343 200 260 160 0414a-5 r11 355 414 722 250 359 393 250 361 200 0460a-5 r11 421 460 828 315 398 450 315 414 250 0503a-5 r11 455 503 920 355 436 492 355 460 315 u n = 690 v 0174a...

Page 165

Technical data 165 derating ambient temperature derating in the temperature range +40…50 °c (+104…122 °f), the rated output current is derated by 1% for every added 1 °c (1.8 °f). The output current can be calculated by multiplying the current given in the rating table by the derating factor (k) : f...

Page 166

166 technical data altitude derating at altitudes from 1000 to 4000 m (3281 to 13123 ft) above sea level, the derating is 1% for every 100 m (328 ft). If ambient temperature is below +40 °c (+104 .°f), the derating can be reduced by 1.5% for every 1 °c reduction in temperature. For a more accurate d...

Page 167: Fuses (Iec)

Technical data 167 high speed mode selection high speed mode of parameter 95.15 special hw settings improves control performance at high output frequencies. Abb recommends it to be selected with output frequency of 120 hz and above. Contact abb for the derating. Fuses (iec) the drive is equipped wit...

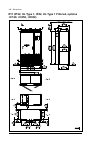

Page 168: Dimensions And Weights

168 technical data dimensions and weights 1. For marine construction (option +c121) extra height is 10 mm (0.39 in.) due to the fastening bars at the bottom of the cabinet. 2. Extra width with emc filter (option +e202): 400 mm (15.75 in.) with frame r11. 3. For drives with marine fastening bars (opt...

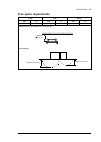

Page 169: Free Space Requirements

Technical data 169 free space requirements front side above * mm in. Mm in. Mm in. 150 5.91 - - 400 15.75 * measured from the base plate of the cabinet top. Door opening: > 400 mm (15.75 in.) 800 mm (31.50 in.) 400 mm (15.75 in.).

Page 170: Cooling Data, Noise

170 technical data cooling data, noise air flow, heat dissipation and noise for the basic drive cabinet (-) and for the sine filter cubicle (option +e206) are shown below. 1) additional heat dissipation of sine filter (option +e206) 2) noise of the drive + sine filter (option +e206) * natural convec...

Page 171: Sine Output Filter Data

Technical data 171 sine output filter data sine output filters are available as option +e206. The table below shows the types and technical data of the filters and filter cubicles used in the drive. * natural convection terminal and exit data for the power cables the locations and sizes of exits are...

Page 172: Motor Connection Data

172 technical data terminal data for the drive control unit see chapter control unit of frame r11 (page 113 ). Electrical power network specification voltage ( u 1 ) acs880-17-xxxxx-3 drives: 380…415 vac 3-phase +10%…-15%. This is indicated in the type designation label as typical input voltage leve...

Page 173: Efficiency

Technical data 173 frequency ( f 2 ) 0…+500 hz. Operation above 150 hz can require type-specific derating. For more information, contact your local abb representative. For drives with sine filter (option +e206): 120 hz. For drives with du/dt filter (option +e205): 120 hz. Current see section ratings...

Page 174: Materials

174 technical data contamination iec/en 60721-3-3:2002: classification of environmental conditions - part 3-3: classification of groups of environmental parameters and their severities - stationary use of weather protected locations iec 60721-3-1 iec 60721-3-2 chemical gases class 3c2 class 1c2 clas...

Page 175: Applicable Standards

Technical data 175 package standard package: • timber, polyethylene sheet (thickness 0.15 mm), stretch film (thickness 0.023 mm), pp tape, pet strap, sheet metal (steel) • for land and air transport when planned storage time is less than 2 months or when storage can be arranged in clean and dry cond...

Page 176: Ce Marking

176 technical data ce marking a ce mark is attached to the drive to verify that the drive complies with the provisions of the european low voltage and emc directives. The ce marking also verifies that the drive, in regard to its safety functions (such as safe torque off), conforms with the machinery...

Page 177

Technical data 177.

Page 178

178 technical data.

Page 179

Technical data 179 compliance with en 61800-3:2004 definitions emc stands for e lectro m agnetic c ompatibility. It is the ability of electrical/electronic equipment to operate without problems within an electromagnetic environment. Likewise, the equipment must not disturb or interfere with any othe...

Page 180

180 technical data category c4 if the provisions under category c3 cannot be met, the requirements of the standard can be met as follows: 1. It is ensured that no excessive emission is propagated to neighbouring low-voltage networks. In some cases, the natural suppression in transformers and cables ...

Page 181: Tightening Torques

Technical data 181 tightening torques unless a tightening torque is specified in the text, the following torques can be used. Electrical connections mechanical connections insulation supports cable lugs size torque n·m note m3 0.5 strength class 4.6...8.8 m4 1 strength class 4.6...8.8 m5 4 strength ...

Page 182: Disclaimers

182 technical data disclaimers generic disclaimer the manufacturer shall have no obligation with respect to any product which (i) has been improperly repaired or altered; (ii) has been subjected to misuse, negligence or accident; (iii) has been used in a manner contrary to the manufacturer’s instruc...

Page 183: Dimensions

Dimensions 183 13 dimensions what this chapter contains this chapter contains example dimension drawings..

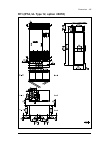

Page 184: +B054)

184 dimensions r11 (ip22, ul type 1, ip42, ul type 1 filtered, option +b054).

Page 185

Dimensions 185 r11 (ip54, ul type 12, option +b055).

Page 186: +C129, +H350, +H352)

186 dimensions r11 (ip22, ul type 1, ip42, ul type 1 filtered, options +c129, +h350, +h352).

Page 187

Dimensions 187 r11 (ip54, ul type 12, options +b055, +c128).

Page 188

188 dimensions r11 (ip54, ul type 12, options +b055, +c129).

Page 189: +H352)

Dimensions 189 r11 (ip54, ul type 12, options +b055, +c129, +h350, +h352).

Page 190: +D150)

190 dimensions r11 (ip22, ul type 1, ip42, ul type 1 filtered, option +d150).

Page 191: +D150 +D151)

Dimensions 191 r11 (ip22, ul type 1, ip42, ul type 1 filtered, options +d150 +d151).

Page 192: +E206)

192 dimensions r11 (ip22, ul type 1, ip42, ul type 1 filtered, option +e206).

Page 193

Dimensions 193 location and size of power cable connection terminals r11 input and motor cable terminal dimensions – bottom entry and exit.

Page 194

194 dimensions r11 input and motor cable terminal dimensions – top entry and exit.

Page 195

Dimensions 195 input cable terminals (r11) motor cable terminals (r11) terminals for connecting external resistors.

Page 196

196 dimensions sine filter (+e206) cubicle, 400 mm sine filter (+e206) cubicle, 600 mm.

Page 197

Dimensions 197 sine filter (+e206) cubicle, 1000 mm.

Page 198

198 dimensions.

Page 199: What This Chapter Contains

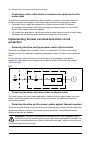

The safe torque off function 199 14 the safe torque off function what this chapter contains this chapter describes the safe torque off (sto) function of the drive and gives instructions for its use. Description the safe torque off function can be used, for example, to construct safety or supervision...

Page 200: Wiring

200 the safe torque off function the function also corresponds to prevention of unexpected start-up as specified by en 1037:1995 + a1:2008 and uncontrolled stop (stop category 0) as specified in en 60204-1. Compliance with the european machinery directive see section compliance with the european mac...

Page 201

The safe torque off function 201 cable types and lengths • double-shielded twisted-pair cable is recommended. • maximum cable lengths: • 300 m (984 ft) between activation switch [k] and drive control unit • 60 m (200 ft) between multiple drives • 60 m (200 ft) between external power supply and first...

Page 202

202 the safe torque off function single drive (internal power supply) dual-channel connection single-channel connection +24 v out1 sgnd in2 t1/u, t2/v, t3/w control logic udc+ udc– a k in1 acs880-17 motor-side converter control unit +24 v out1 sgnd in2 k in1 notes : • both sto inputs (in1, in2) must...

Page 203

The safe torque off function 203 multiple drives (internal power supply) +24 v out1 sgnd in1 in2 out1 sgnd in1 in2 out1 sgnd in1 in2 k motor-side converter control unit motor-side converter control unit motor-side converter control unit acs880-17 acs880-17 acs880-17.

Page 204: Operation Principle

204 the safe torque off function multiple drives (external power supply) operation principle 1. The safe torque off activates (the activation switch is opened, or safety relay contacts open). 2. The sto inputs on the motor-side converter control unit de-energize. 3. The control unit cuts off the con...

Page 205

The safe torque off function 205 4. The control program generates an indication as defined by parameter 31.22 (refer to the firmware manual of the motor-side converter). 5. Motor coasts to a stop (if running). The drive cannot restart while the activation switch or safety relay contacts are open. Af...

Page 206: Use

206 the safe torque off function use 1. Open the activation switch, or activate the safety functionality that is wired to the sto connection. 2. Sto inputs on the motor-side converter control unit de-energize, and the drive control unit cuts off the control voltage from the drive igbts. 3. The contr...

Page 207: Maintenance

The safe torque off function 207 warning! The safe torque off function does not disconnect the voltage of the main and auxiliary circuits from the drive. Therefore maintenance work on electrical parts of the drive or the motor can only be carried out after isolating the drive from the main supply. W...

Page 208: Fault Tracing

208 the safe torque off function include the safe torque off operation test described above in the routine maintenance program of the machinery that the drive runs. If any wiring or component change is needed after start up, or the parameters are restored, follow the test given in section acceptance...

Page 209

The safe torque off function 209 the following temperature profile is used in safety value calculations: • 670 on/off cycles per year with t = 71.66 °c • 1340 on/off cycles per year with t = 61.66 °c • 30 on/off cycles per year with t = 10.0 °c • 32 °c board temperature at 2.0% of time • 60 °c board...

Page 210

210 the safe torque off function declaration of conformity see section compliance with the european machinery directive (page 176 )..

Page 211

Further information product and service inquiries address any inquiries about the product to your local abb representative, quoting the type designation and serial number of the unit in question. A listing of abb sales, support and service contacts can be found by navigating to www.Abb.Com/searchcha...

Page 212

Www.Abb.Com/drives www.Abb.Com/drivespartners 3axd50000035158 rev b (en) 2018-01-18 contact us.