- DL manuals

- ABB

- DC Drives

- MicroFlex e150

- User Manual

ABB MicroFlex e150 User Manual

Summary of MicroFlex e150

Page 1

Abb motion control user’s manual microflex e150 servo drive mn1961wen.

Page 2

List of related manuals you can find manuals and other product documents in pdf format on the internet. See section document library on the internet on the inside of the back cover. For manuals not available in the document library, contact your local abb representative. Drive hardware manuals and g...

Page 3: User’S Manual

User’s manual microflex e150 lt0291a04en effective: 2013-12-01 2013 abb oy. All rights reserved. 1. Safety table of contents 4. Mechanical installation 6. Electrical installation: ac input, motor and brake 9. Start-up.

Page 5: Table of Contents

Table of contents 5 table of contents list of related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1. Safety safety in installation and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6

6 table of contents european union . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 other regions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 emergency stop de...

Page 7

Table of contents 7 digital outputs dout3 - dout6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 usb interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73 rs485 interface . . ...

Page 8

8 table of contents safe torque off (sto) acceptance test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115 10. Fault tracing what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117 problem d...

Page 9

Table of contents 9 digital inputs din4 - din9 (opt1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146 digital outputs dout0 (status), dout1, dout2 (x3) . . . . . . . . . . . . . . . . . . . . . . . . . 147 digital outputs dout3 - dout6 (opt1) . . . . . . . . . ....

Page 10

10 table of contents installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176 validating the operation of the safe torque off function . . . . . . . . . . . . . . . . . . . . . . . . 176 technical data: digital inputs sto1...

Page 11: Safety

Safety 11 1 safety safety in installation and maintenance these warnings are intended for all who work on the drive, motor cable or motor. Electrical safety warning! Ignoring the following instructions can cause physical injury or death, or damage to the equipment. Only qualified electricians are al...

Page 12

12 safety • even when the motor is stopped, dangerous voltage is present at the power circuit terminals l1, l2, l3, u, v, w, r1, r2 (connector x1). • if a motor is driven mechanically, it can generate hazardous voltages that are conducted to its power terminals. The enclosure must be earthed/grounde...

Page 13

Safety 13 • stop the motor. • ensure that there is no voltage on the drive power terminals according to step 1 or 2, or if possible, according to the both of the following steps: 1. Disconnect the motor from the drive with a safety switch or by other means. Measure that there is no voltage present o...

Page 14: Safe Start-Up and Operation

14 safety safe start-up and operation these warnings are intended for all who plan to start-up or operate the drive. General safety warning! Ignoring the following instructions can cause physical injury or death, or damage to the equipment. • before adjusting the drive and putting it into service, m...

Page 15: Introduction to The Manual

Introduction to the manual 15 2 introduction to the manual what this chapter contains the chapter describes applicability, target audience and purpose of this manual. It describes the contents of this manual and refers to a list of related manuals for more information. The chapter also contains a fl...

Page 16: Contents Of This Manual

16 introduction to the manual contents of this manual the manual consists of the following chapters: • safety (page 11 ) gives safety instructions you must follow when installing, commissioning, operating and servicing the drive. • introduction to the manual (this chapter, page 15 ) describes applic...

Page 17

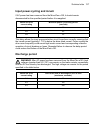

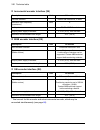

Introduction to the manual 17 quick installation and start-up flowchart task see plan the electrical installation and acquire the accessories needed (cables, fuses, etc.). Check the ratings, required cooling air flow, input power connection, compatibility of the motor, motor connection, and other te...

Page 18: Terms And Abbreviations

18 introduction to the manual terms and abbreviations the following units and abbreviations might appear in this manual. General terms unit / term / abbreviation description w watt a ampere Ω ohm μf microfarad pf picofarad mh millihenry Φ phase ms millisecond μs microsecond ns nanosecond mm millimet...

Page 19

Introduction to the manual 19 see also page 177 for safety related abbreviations. Trademarks ethercat® is a registered trademark and patented technology, licensed by beckhoff automation gmbh, germany. Windows xp, windows vista and windows 7 are registered trademarks of the microsoft corporation. (nc...

Page 20

20 introduction to the manual.

Page 21: Hardware Description

Hardware description 21 3 hardware description what this chapter contains the chapter briefly describes the operation principle, layout, type designation label and type designation information. It also shows a general diagram of power connections and control interfaces. Features the microflex e150 i...

Page 22

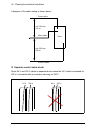

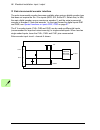

22 hardware description operating principle the figure below shows the simplified main circuit diagram of the drive. The rectifier converts three-phase ac voltage to dc voltage. The capacitor bank of the intermediate circuit stabilizes the dc voltage. The inverter converts the dc voltage back to ac ...

Page 23: Product Overview

Hardware description 23 product overview connections - front panel earth/ground earth/ground (nc) l1 ac phase 1/l l2 ac phase 2 / n l3 ac phase 3 u motor u v motor v w motor w r1 brake r2 brake the seven-segment display and the two ethercat leds are described in microflex e150 indicators on page 119...

Page 24

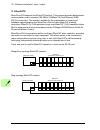

24 hardware description connections - top panel see chapter electrical installation: ac input, motor and brake on page 43 for installation in general. 14 shield 7 din4 13 cref1 6 din5 12 din8 5 din6 11 din9 4 din7 10 usrv+ 3 cref0 9 dout5 2 dout3 8 dout6 1 dout4 opt1: input / output e1 / e2 ethercat...

Page 25: Type Designation Label

Hardware description 25 type designation label a description of the product’s catalog numbering system is shown below: * note: model ..Eina.. Cannot store or run a mint program, but it does support individual mint commands entered in the mint workbench command window. Commands received from a host a...

Page 26

26 hardware description.

Page 27: Mechanical Installation

Mechanical installation 27 4 mechanical installation what this chapter contains the chapter describes the mechanical installation procedure of the drive. Requirements for the installation site the safe operation of this equipment depends upon its use in the appropriate environment. The following poi...

Page 28: Checking The Delivery

28 mechanical installation • the threaded holes in the top and bottom of the case are for cable clamps. The holes are threaded for m4 bolts no longer than 11 mm (0.43 in). • the d-type connectors on the front panel of the microflex e150 are secured using two hexagonal jack screws (sometimes known as...

Page 29: Mounting and Cooling

Mechanical installation 29 mounting and cooling ensure you have read and understood requirements for the installation site on page 27 . Mount the microflex e150 vertically on its rear side, the side opposite the front panel. M5 bolts or screws should be used to mount the microflex e150. Detailed dim...

Page 30

30 mechanical installation effects of mounting surface and proximity the proximity of the microflex e150 to other components could affect cooling efficiency. If the microflex e150 is mounted beside another microflex e150 (or other obstruction), there should be a minimum space of 15 mm (0.6 in) to ma...

Page 31: Installing

Mechanical installation 31 installing 1. Mark the hole locations. See dimension drawing (all models) on page 128 for complete dimensions. 2. Position the drive and check the hole positions are correct. 3. Drill the holes, mount the drive and tighten all four screws until the drive is secure. 167.7 m...

Page 32

32 mechanical installation.

Page 33: Planning The Electrical

Planning the electrical installation 33 5 planning the electrical installation what this chapter contains the chapter contains the instructions that you must follow when checking the compatibility of the motor and drive, selecting cables, protective devices, and cable routing. Note: the installation...

Page 34: Emergency Stop Devices

34 planning the electrical installation european union to meet the european union machinery directive, according to standard en 60204-1, safety of machinery, the disconnecting device must be one of the following types: • a switch-disconnector of utilization category ac-23b (en 60947-3) • a disconnec...

Page 35

Planning the electrical installation 35 thermal overload and short circuit protection thermal overload protection the drive protects itself and the input and motor cables against thermal overload when the cables are dimensioned according to the nominal current of the drive. No additional thermal pro...

Page 36: Selecting The Power Cables

36 planning the electrical installation selecting the power cables general rules dimension the input power and motor cables according to local regulations. • the input power and the motor cables must be able to carry the corresponding load currents. See electrical power network specification on page...

Page 37

Planning the electrical installation 37 alternative power cable types motor cables (also recommended for supply cabling): allowed for ac power cabling motor cable shield to function as a protective conductor, the shield must have the same cross-sectional area as the phase conductors when they are ma...

Page 38: Inductive Loads

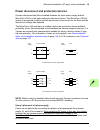

38 planning the electrical installation protecting the contacts of relay outputs and attenuating inductive loads inductive loads (relays, contactors, motors) cause voltage transients when switched off. Equip inductive loads with noise attenuating circuits (varistors, rc filters [ac] or diodes [dc]) ...

Page 39: Selecting The Control Cables

Planning the electrical installation 39 selecting the control cables it is recommended that all control cables are shielded. Double-shielded twisted pair cable is recommended for analog signals. For pulse encoder cabling, follow the instructions given by the encoder manufacturer. Use one individuall...

Page 40

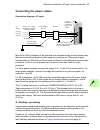

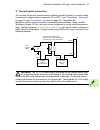

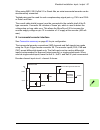

40 planning the electrical installation a diagram of the cable routing is shown below: separate control cable ducts route 24 v and 230 v cables in separate ducts unless the 24 v cable is insulated for 230 v or insulated with an insulation sleeving for 230 v. Control cables min. 300 mm motor cable po...

Page 41

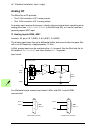

Planning the electrical installation 41 typical installation example mount ac filter and microflex e150 on the same metal panel. Ac power from fuses or reactor ac power wires should be as short as possible, typically less than 0.3 m (1 ft). Longer wires must be shielded as shown. Wire colors can var...

Page 42

42 planning the electrical installation.

Page 43: Electrical Installation:

Electrical installation: ac input, motor and brake 43 6 electrical installation: ac input, motor and brake what this chapter contains the chapter describes how to connect input power cables, motor and brake resistor. Warning! The work described in this chapter may only be carried out by a qualified ...

Page 44

44 electrical installation: ac input, motor and brake checking the insulation of the assembly drive every drive has been tested for insulation between the main circuit and the chassis at the factory. If further high potential (‘hipot’) testing is performed, use only dc voltages as ac voltage hipot t...

Page 45: Connecting The Power Cables

Electrical installation: ac input, motor and brake 45 connecting the power cables connection diagram: ac input microflex e150 is designed to be powered from standard single or three-phase lines that are electrically symmetrical with respect to earth/ground. The power supply module within the microfl...

Page 46

46 electrical installation: ac input, motor and brake when using unearthed/ungrounded distribution systems, an isolation transformer with an earthed/grounded secondary is recommended. This provides three-phase ac power that is symmetrical with respect to earth/ground and can prevent equipment damage...

Page 47: Input Power Conditioning

Electrical installation: ac input, motor and brake 47 input power conditioning certain power line conditions must be avoided; an ac line reactor, an isolation transformer or a step up/step down transformer might be required for some power conditions: • if the feeder or branch circuit that provides p...

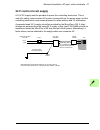

Page 48: Power Supply Filters

48 electrical installation: ac input, motor and brake power supply filters to comply with ec directive 2004/108/ec, an ac power filter of the appropriate type must be connected. This can be supplied by abb and will ensure that the microflex e150 complies with the ce specifications for which it has b...

Page 49

Electrical installation: ac input, motor and brake 49 power disconnect and protection devices a power disconnect should be installed between the input power supply and the microflex e150 for a fail-safe method to disconnect power. The microflex e150 will remain in a powered condition until all input...

Page 50

50 electrical installation: ac input, motor and brake drive overload protection the microflex e150 will immediately trip and disable if there is an overload condition. The parameters for managing drive overloads are configured automatically by the commissioning wizard (page 100 ). If they need to be...

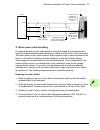

Page 51: 24 V Control Circuit Supply

Electrical installation: ac input, motor and brake 51 24 v control circuit supply a 24 v dc supply must be provided to power the controlling electronics. This is useful for safety reasons where ac power is removed from the power stage, but the controlling electronics must remain powered to retain po...

Page 52: Motor Connections

52 electrical installation: ac input, motor and brake motor connections microflex e150 will operate with a large number of brushless servo motors. For information on selecting servo motors please contact your local abb representative. The motor must be capable of being powered by an inverter pwm out...

Page 53

Electrical installation: ac input, motor and brake 53 motor power cable shielding it is essential that the motor cable shield is correctly bonded to a functional earth, typically the same earthed metal backplane on which the microflex e150 is mounted. The motor power output cable carries a high freq...

Page 54

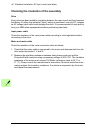

54 electrical installation: ac input, motor and brake continuation of motor power cable shielding when using a motor contactor, or extending the motor cable through a terminal box, ensure that the motor cable shielding is continued all the way to the motor. 1. Make a single circular cut in the cable...

Page 55

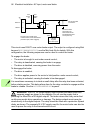

Electrical installation: ac input, motor and brake 55 motor circuit contactors if required by local codes or for safety reasons, an m-contactor (motor circuit contactor) can be installed to provide a physical disconnection of the motor windings from the microflex e150 (see motor connections on page ...

Page 56

56 electrical installation: ac input, motor and brake this circuit uses dout1 as a motor brake output. The output is configured using mint keyword motorbrakeoutput; see the mint help file for details. With this configuration, the following sequences can be used to control the brake. To engage the br...

Page 57

Electrical installation: ac input, motor and brake 57 thermal switch connection you can use the motor's thermal switch contacts (normally closed), to control a relay connected to a digital input on connector x3 or opt1 (see connections - front panel on page 23 , and connections - top panel on page 2...

Page 58

58 electrical installation: ac input, motor and brake brake resistor (regeneration resistor) an optional external brake resistor might be required to dissipate excess power from the internal dc-bus during motor deceleration. The brake resistor must have a resistance of at least 39 Ω, an inductance o...

Page 59: Electrical Installation:

Electrical installation: input / output 59 7 electrical installation: input / output what this chapter contains the chapter describes how to connect low voltage control signals. The following conventions will be used to refer to the inputs and outputs: i/o . . . . . . . . . . . Input / output ain . ...

Page 60: Analog I/o

60 electrical installation: input / output analog i/o the microflex e150 provides: • two 12-bit resolution ±10 v analog inputs. • one 12-bit resolution ±10 v analog output. An analog input receives the torque / velocity reference signal when operating as an analog drive (see controlrefsource in the ...

Page 61

Electrical installation: input / output 61 typical input circuit to provide 0-10 v (approx.) input from a 24 v source analog output aout0 location: x4, pin 1 (aout0), 5 (agnd) the analog output can be used to drive loads of 4 kΩ or greater. Shielded twisted pair cable should be used. The shield conn...

Page 62: Digital I/o

62 electrical installation: input / output digital i/o the microflex e150 provides: • 10 general purpose digital inputs. • 2 dedicated safe torque off (sto) inputs. • 7 general purpose digital outputs. Connector digital input / output common connection purpose x3 sto1 sref to enable the drive and pr...

Page 63

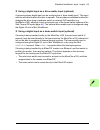

Electrical installation: input / output 63 using a digital input as a drive enable input (optional) a general purpose digital input can be configured as a ‘drive enable input’. This input must be activated to allow the drive to operate. This provides an additional method for stopping the drive using...

Page 64

64 electrical installation: input / output digital inputs - safe torque off (sto) location: x3, pin 18 (sto1), 8 (sref), 19 (sto2), 9 (sref) the two safe torque off (sto) inputs are identical. Each input directly enables part of the motor output control circuit. Both inputs must be powered to allow ...

Page 65

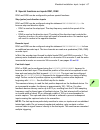

Electrical installation: input / output 65 digital inputs - general purpose din0, din3 location: x3, pins 17 & 7 (din0), 15 & 5 (din3) these general purpose digital inputs are buffered by a tlp280 opto-isolator, allowing the input signals to be connected with either polarity. The inputs do not share...

Page 66

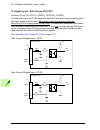

66 electrical installation: input / output digital inputs - general purpose din1, din2 location: x3, pins 16 & 6 (din1), 14 & 4 (din2) these general purpose fast digital inputs are buffered by a tlp115 opto-isolator, allowing the input signals to be connected with either polarity. The inputs do not ...

Page 67

Electrical installation: input / output 67 special functions on inputs din1, din2 din1 and din2 can be configured to perform special functions. Step (pulse) and direction inputs din1 and din2 can be configured using the statement encodermode(1)=4 to become step and direction inputs: • din1 is used a...

Page 68

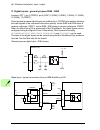

68 electrical installation: input / output digital inputs - general purpose din4 - din9 location: opt1, pin 3 (cref0), pin 4 (din7), 5 (din6), 6 (din5), 7 (din4), 11 (din9), 12 (din8), 13 (cref1) these general purpose digital inputs are buffered by a tlp280 opto-isolator, allowing the input signals ...

Page 69

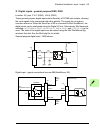

Electrical installation: input / output 69 status output (dout0) location: x3, pins 1 (status-), 11 (status+) the optically isolated status output is designed to source current from the user supply. The tlp127 has a maximum power dissipation of 200 mw at 25 °c. The output includes a self-resetting f...

Page 70

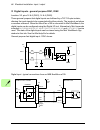

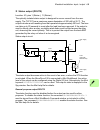

70 electrical installation: input / output status output - typical connections to an abb nextmove e100: digital outputs dout1, dout2 location: x3, pins 13 & 3 (dout1), 12 & 2 (dout2) the optically isolated general purpose outputs are designed to source current from an individual user supply connecti...

Page 71

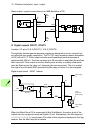

Electrical installation: input / output 71 dout1 - typical connections to an abb nextmove e100: digital outputs dout3 - dout6 location: opt1, pin 2 (dout3), 1 (dout4), 9 (dout5), 8 (dout6), 10 (usrv+) the optically isolated general purpose outputs are designed to source current from a common user su...

Page 72

72 electrical installation: input / output when the microflex e150 is connected to mint workbench, the active level of the outputs can be configured using the digital i/o tool. Alternatively, the mint keyword outputactivelevel can be used. The state of the outputs is displayed in the spy window. See...

Page 73: Usb Interface

Electrical installation: input / output 73 usb interface location: u1 the usb connector is used to connect the microflex e150 to a pc running mint workbench. The microflex e150 is a self-powered, usb 2.0 (12 mbps) compatible device. If it is connected to a slower usb 1.0 host pc or hub, communicatio...

Page 74

74 electrical installation: input / output connections to a 4-wire rs485 device - abb keypad kpd202-501 shown: note: the microflex e150 and other abb equipment use ‘big endian’ word order and byte order for modbus protocols. If this is incompatible with other modbus equipment, the word and byte orde...

Page 75: Ethernet Interface

Electrical installation: input / output 75 ethernet interface the ethernet interface supports ethercat® (coe and eoe) and standard ethernet. Standard ethernet the standard ethernet connection supports several protocols, including ethernet/ip, modbus tcp, http and icmp. See the application notes at w...

Page 76

76 electrical installation: input / output ethercat® microflex e150 supports the ethercat protocol. This protocol provides deterministic communication over a standard 100 mbit/s (100base-tx) fast ethernet (ieee 802.3u) connection. This makes it suitable for the transmission of control and feedback s...

Page 77

Electrical installation: input / output 77 multi-branch ethercat network: ethercat configuration ethercat configuration is usually performed from the ethercat manager. To assist with configuration, the microflex e150 provides an ethercat slave information (esi) file. This .Xml file describes the dri...

Page 78

78 electrical installation: input / output ethernet connectors location: e1 & e2 ethernet port e2 (in) is fixed in ethercat mode. To set port e1 (out) to ethercat mode, front panel dip switch 4 (page 79 ) must be in the off position. If only one port is used for ethercat operation, it must be the e2...

Page 79: Dip Switches

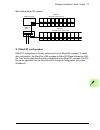

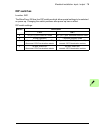

Electrical installation: input / output 79 dip switches location: sw1 the microflex e150 has four dip switches which allow special settings to be selected on power up. Changing the switch positions after power up has no effect. Dip switch settings: switch description on > 4 e1 (out) port: ethercat m...

Page 80: Motor Feedback

80 electrical installation: input / output motor feedback location: x8 microflex e150 supports incremental encoder, encoder with biss (bi-directional synchronous serial interface) or ssi (synchronous serial interface), endat or smart abs absolute encoder, or sincos encoder feedback, for use with lin...

Page 81

Electrical installation: input / output 81 when using biss, ssi, endat 2.2 or smart abs, an extra incremental encoder can be simultaneously connected. Twisted pairs must be used for each complementary signal pair e.G. Cha+ and cha- or data+ and data-. The overall cable shield (screen) must be connec...

Page 82

82 electrical installation: input / output hall input circuit - u phase shown: encoders without halls incremental encoders without hall feedback connections can be connected to the microflex e150. However, if hall connections are not present, it will be necessary for the microflex e150 to perform an...

Page 83

Electrical installation: input / output 83 halls-only feedback devices feedback devices using only hall sensors can be connected to the microflex e150. However, since there are no encoder connections, the microflex e150 will not be able to perform smooth speed control or accurate positioning control...

Page 84

84 electrical installation: input / output ssi interface the ssi (synchronous serial interface) encoder interface is specifically designed for use with baldor ssi motors, which incorporate a custom baumer ssi encoder. Contact abb technical support to confirm compatibility of other ssi devices. The s...

Page 85

Electrical installation: input / output 85 smart abs interface the smart abs encoder connections are made using the 15-pin d-type female connector x8. Smart abs interface cable connections: sincos interface the sincos connections (sin and cos incremental channels only) are made using the 15-pin d-ty...

Page 86

86 electrical installation: input / output extra incremental encoder interface the extra incremental encoder becomes available when using a digital encoder type that does not require the sin / cos inputs (biss, ssi, endat 2.2, smart abs). In mint, the main digital encoder source remains as encoder 0...

Page 87: Installation Checklist

Installation checklist 87 8 installation checklist this chapter contains a list for checking the mechanical and electrical installation of the drive. Checklist check the mechanical and electrical installation of the drive before start-up. Go through the checklist together with another person. Warnin...

Page 88

88 installation checklist safe torque off (sto) connections the sto inputs are an intrinsic part of a safe drive installation. The acceptance test of the safety function must be carried out by an authorized person with expertise and knowledge of the safety function. The test must be documented and s...

Page 89: Start-Up

Start-up 89 9 start-up what this chapter contains this chapter describes software installation and the start-up procedure of the drive. Introduction before powering the microflex e150 you will need to connect it to the pc using a usb or ethernet cable and install the mint workbench software. This in...

Page 90

90 start-up connecting the microflex e150 to the pc the microflex e150 can be connected to the pc using either usb or tcp/ip. To use usb, connect a usb cable between a pc usb port and the microflex e150 usb port. Your pc must be using windows xp, windows vista or windows 7. To use tcp/ip, connect a ...

Page 91: Starting The Microflex E150

Start-up 91 starting the microflex e150 if you have followed the instructions in the previous sections, you should have now connected the power sources, your choice of inputs and outputs, and the usb cable or ethernet cable linking the pc to the microflex e150. Preliminary checks before you apply po...

Page 92

92 start-up to confirm that the usb driver is installed, check that a motion control category is listed in windows device manager:.

Page 93

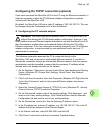

Start-up 93 configuring the tcp/ip connection (optional) if you have connected the microflex e150 to the pc using the ethernet connection, it might be necessary to alter the pc's ethernet adapter configuration to operate correctly with the microflex e150. By default, the microflex e150 has a static ...

Page 94: Mint Machine Center

94 start-up mint machine center the mint machine center (mmc) is installed as part of the mint workbench software. It is used to view the network of connected controllers in a system. Individual controllers and drives are configured using mint workbench. If you have only a single microflex e150 conn...

Page 95

Start-up 95 starting mmc 1. On the windows start menu, select programs, mint workbench, mint machine center. 2. In the controller pane, ensure that host is selected. In the information pane, click scan. 3. When the search is complete, click once on ‘microflex e150' in the controller pane to select i...

Page 96: Mint Workbench

96 start-up mint workbench mint workbench is a fully featured application for programming and controlling the microflex e150. The main mint workbench window contains a menu system, the toolbox and other toolbars. Many functions can be accessed from the menu or by clicking a button - use whichever yo...

Page 97: Help File

Start-up 97 help file mint workbench includes a comprehensive help file that contains information about every mint keyword, how to use mint workbench and background information on motion control topics. The help file can be displayed at any time by pressing f1. On the left of the help window, the co...

Page 98

98 start-up starting mint workbench note: if you have already used mmc to install firmware and start an instance of mint workbench, go straight to section 6.4.3 to continue configuration. 1. On the windows start menu, select programs, mint workbench, mint workbench. 2. In the opening dialog box, cli...

Page 99

Start-up 99 3. Click scan to search for the microflex e150. When the search is complete, click microflex e150 in the list, then click select. Note: if the microflex e150 is not listed, check the usb or serial cable between the microflex e150 and the pc. Check that the microflex e150 is powered corre...

Page 100

100 start-up commissioning wizard each type of motor and drive combination has different performance characteristics. Before the microflex e150 can be used to control the motor accurately, the microflex e150 must be ‘tuned'. Tuning is the process where the microflex e150 powers the motor in a series...

Page 101

Start-up 101 select your motor type: select the type of motor that you are using; rotary or linear, brushless or induction. Select your motor: carefully enter the details of your motor. If you are using a baldor motor, the catalog number or spec. Number can be found stamped on the motor's nameplate....

Page 102

102 start-up and enter a suitable value in the position scale factor box. Separate velocity and acceleration units can also be defined. See the mint help file for more information about scale factors. Profile parameters: it is not necessary to change anything on this screen. However, if you wish to ...

Page 103

Start-up 103 further tuning - no load attached the autotune wizard calculates many parameters that allow the microflex e150 to provide good control of the motor. In some applications, these parameters might need to be fine-tuned to provide the exact response that you require. 1. Click the fine-tunin...

Page 104

104 start-up typical autotuned response (no load): note: the graph that you see will not look exactly the same as this one! Each motor has a different response. The graph shows that the response reaches the demand quickly and only overshoots the demand by a small amount. This can be considered an id...

Page 105

Start-up 105 further tuning - with load attached to allow mint workbench to adjust the basic tuning to compensate for the intended load, it is necessary to attach the load to the motor and then perform the autotune procedure again. 1. Attach the load to the motor. 2. Click the autotune icon in the t...

Page 106

106 start-up optimizing the velocity response it might be desirable to optimize the default autotuned response to better suit your application. The following sections describe the two main tuning factors and how to correct them. Correcting overshoot the following graph shows a response where the mea...

Page 107

Start-up 107 correcting zero-speed noise in the velocity response the following graph shows a response where there is very little overshoot but a significant amount of zero-speed noise. This can cause undesirable humming or ringing in the motor. 1. Go to the fine-tuning window's velocity tab. To red...

Page 108

108 start-up ideal velocity response repeat the tests described in correcting overshoot and correcting zero-speed noise in the velocity response until the optimal response is achieved. The following graph shows an ideal velocity response. There is only a small amount of overshoot and very little zer...

Page 109

Start-up 109 performing test moves - continuous jog this section tests the basic operation of the drive and motor by performing a continuous jog. To stop a move in progress, click the red stop button or the drive enable button on the toolbar. Alternatively, use the mint workbench ‘red stop button’ f...

Page 110

110 start-up performing test moves - relative positional move this section tests the basic operation of the drive and motor by performing a positional move. To stop a move in progress, click the red stop button or the drive enable button on the toolbar. Alternatively, use the mint workbench ‘red sto...

Page 111: Further Configuration

Start-up 111 further configuration mint workbench provides a number of other tools for testing and configuring the microflex e150. Every tool is explained fully in the help file. Press f1 to display the help file, then navigate to the mint workbench book. Inside this is the toolbox book. Configurati...

Page 112

112 start-up parameters tool the parameters tool can be used to view or change most of the drive's parameters. 1. Click the parameters icon in the toolbox on the left of the screen. The main area of the mint workbench window displays the parameters editor screen. Items listed with a grey icon are re...

Page 113

Start-up 113 spy window the spy window can be used to monitor and capture parameters in real-time. If you tried the test moves in performing test moves - continuous jog on page 109 or performing test moves - relative positional move on page 110 then you have already seen the spy window, as it is dis...

Page 114

114 start-up other tools and windows remember, for help on each tool press f1 to display the help file, then navigate to the mint workbench book. Inside this is the toolbox book. • edit & debug tool this tool provides a work area including the command window and output window. The command window can...

Page 115

Start-up 115 safe torque off (sto) acceptance test drive commissioning is not complete until the sto function has been tested. The acceptance test of the safety function must be carried out by an authorized person with expertise and knowledge of the safety function. The test must be documented and s...

Page 116

116 start-up.

Page 117: Fault Tracing

Fault tracing 117 10 fault tracing what this chapter contains this section explains common problems and their solutions. The led indicators are described in microflex e150 indicators on page 119 . Problem diagnosis if you have followed all the instructions in this manual in sequence, you should have...

Page 118

118 fault tracing supportme feature the supportme feature is available from the help menu, or by clicking the button on the motion toolbar. Supportme can be used to gather information which can then be e-mailed, saved as a text file, or copied to another application. The pc must have e-mail faciliti...

Page 119: Microflex E150 Indicators

Fault tracing 119 microflex e150 indicators ethernet leds the ethernet leds display the overall condition of the ethernet interface once the startup sequence has completed. The led codes conform to the ethercat technology group (etg) standard at the time of production. Net err (red) off: no errors o...

Page 120

120 fault tracing led flash periods the following diagram shows the definitions of the terms ‘blinking’, ‘flashing’ and ‘flickering’ used in the previous sections, as defined by the ethercat technology group. Led flash timing definitions: net run (green) off: initialisation state (or not powered). B...

Page 121

Fault tracing 121 drive status display the drive status display indicates errors and general microflex e150 status information. When an error occurs, the drive displays a sequence starting with the symbol e, followed by the five digit error code. For example, error code 10015 is displayed: the decim...

Page 122

122 fault tracing in ds402 mode (under the control of an ethercat master), the outer segments will rotate clockwise or counter-clockwise. User defined symbols can be displayed using mint keywords led and leddisplay. Homing. The drive is currently homing. See the mint keyword home . Incremental move....

Page 123

Fault tracing 123 power drive does not start when applying ac power: • check that the motor output phases are not short circuited. The drive trips on a motor phase short circuit and will not restart unless ac power is removed. Remove all power from the drive, correct the short circuit and restart th...

Page 124

124 fault tracing cannot communicate with the controller after downloading firmware: • after firmware download, always power cycle the microflex e150. Mint workbench loses contact with microflex e150 while connected using usb: • check that the microflex e150 is powered. • check that a ‘abb usb motio...

Page 125

Fault tracing 125 i can’t control the microflex e150 from my ethercat manager the drive’s reference source must be set to allow the ethercat manager to take control of the microflex e150. There are several ways to do this: • set the controlrefsourcestartup parameter to '1' using the mint workbench p...

Page 126

126 fault tracing.

Page 127: Technical Data

Technical data 127 11 technical data what this chapter contains the chapter contains the technical specifications of the drive, for example, the ratings, sizes and technical requirements as well as provisions for fulfilling the requirements for ce and other marks..

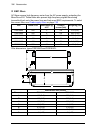

Page 128

128 technical data dimension drawing (all models) 6 63.4 (2.5) 79.5 (3.13) 82 (3.23) 11 (0.4) 5 (0.2) 6 (0.24) 167.3 (6.59) 6 (0.24) 180 (7.1) dimensions shown as: mm (inches) depth: 157 mm (6.2 in) weight: 3 a: 1.45 (3.2 lb) 6 a: 1.50 kg (3.3 lb) 9 a: 1.55 kg (3.4 lb).

Page 129

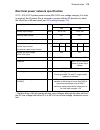

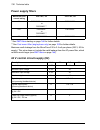

Technical data 129 electrical power network specification a 115 - 230 v ac 3-phase power source (en 61010 over-voltage category iii or less) is required. An ac power filter is required to comply with the ce directive for which the microflex e150 was tested (see ce marking on page 153 ). * the microf...

Page 130

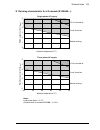

130 technical data effect of ac power supply voltage on dc-bus voltage effect of ac power supply voltage on dc-bus ripple voltage 100 100 150 200 250 300 350 125 150 175 200 225 250 ac supply voltage (rms) dc- bus voltage ( v d c ) three-phase ac supply single-phase ac supply 100 0 10 20 30 40 50 12...

Page 131

Technical data 131 effect of output current on dc-bus ripple voltage 20 0 10 20 30 40 50 60 30 40 50 60 70 80 90 100 110 120 130 140 150 single-phase ac supply three-phase ac supply % of drive rated current d c -bus ripple voltag e (v pk- pk ).

Page 132: Temperature Derating

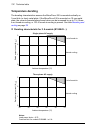

132 technical data temperature derating the derating characteristics assume the microflex e150 is mounted vertically on 3 mm thick (or less) metal plate. If the microflex e150 is mounted on 10 mm metal plate, the current characteristics shown below can be increased by up to 7% if there is no forced ...

Page 133

Technical data 133 derating characteristic for 6 a models (e152a06...): 30 0 2 4 6 1 3 5 2 4 6 1 3 5 35 40 45 50 55 30 0 35 40 45 50 55 ambient temperature (°c) three-phase ac supply single-phase ac supply natural cooling 1 m/s forced air 1 m/s forced air natural cooling rated outp ut cu rrent (a rm...

Page 134

134 technical data derating characteristic for 9 a models (e152a09...): overtemperature trips the microflex e150 contains internal temperature sensors that will cause it to trip and disable if the temperature exceeds 80 °c (3 a model), or 75 °c (6 a and 9 a models). This limit can be read using the ...

Page 135

Technical data 135 heat dissipation these figures assume drive efficiency = 95%, power factor = 0.8: microflex e150 model heat dissipation (w) 3 a 50 6 a 101 9 a 151.

Page 136

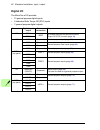

136 technical data recommended fuses, circuit breakers and wire sizes the following table describes the recommended fuses and circuit breakers for ac power connections, and suitable wires sizes for ac and motor power connections. Note: all wire sizes are based on 75 °c (167 °f) copper wire. Higher t...

Page 137: Discharge Period

Technical data 137 input power-cycling and inrush if ac power has been removed from the microflex e150, it should remain disconnected for the specified period before it is reapplied: this delay allows the input surge protection circuit to perform correctly, ensuring that the inrush current (typicall...

Page 138: Power Supply Filters

138 technical data power supply filters * see emc filters starting on page 166 for further details. ** see foot-mount filter (single phase only) on page 165 for further details. Maximum earth leakage from the microflex e150 is 3.4 ma per phase (230 v, 50 hz supply). This value does not include the e...

Page 139: Motor Output Power (X1)

Technical data 139 motor output power (x1) motor output rating adjustment description unit 3 a 6 a 9 a nominal phase current a rms 3 6 9 peak phase current for 3 s a rms 6 12 18 nominal output @ 230 v, 3Φ va 1195 2390 3585 output voltage (line-line) @ v dc-bus = 320 v v rms 0 - 230 output frequency ...

Page 140: Brake (X1)

140 technical data brake (x1) braking capacity the braking capacity of the microflex e150 can be calculated from the following formula: where the brake switching threshold is 388 v. This gives the following typical values: brake resistor selection the following calculations can be used to estimate t...

Page 141

Technical data 141 requirement enter value here a) initial motor speed, before deceleration begins, in radians per second. Multiply rpm by 0.1047 to give radians per second. Initial motor speed: u = _____________ rad/s b) final motor speed after deceleration is complete, in radians per second. Multi...

Page 142

142 technical data braking energy the braking energy to be dissipated, e, is the difference between the initial energy in the system (before deceleration begins) and the final energy in the system (after deceleration has finished). If the system is brought to rest then the final energy is zero. The ...

Page 143

Technical data 143 resistor choice p av is the value to use when assessing which brake resistor to use. However, a safety margin of 1.25 times is recommended to ensure the resistor operates well within its limits*, so: required resistor power rating = 1.25 × p av ________________ w (watts) the range...

Page 144

144 technical data resistor derating the brake resistors shown in the previous table can achieve their stated power rating only when mounted on a heat sink. In free air a derating must be applied. Furthermore, in ambient temperatures greater than 25 °c (77 °f), a temperature derating must be applied...

Page 145: Input / Output

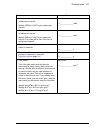

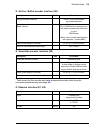

Technical data 145 input / output analog inputs ain0, ain1 (x4) analog output aout0 (x4) digital inputs sto1, sto2 (x3) see technical data: digital inputs sto1, sto2 (x3) on page 177 . Description unit all models type differential common mode voltage range v dc ±10 common mode rejection db 40 input ...

Page 146

146 technical data digital inputs din0, din3 (x3) digital inputs din1, din2 - high speed (x3) description unit all models type opto-isolated inputs input voltage nominal minimum maximum active inactive v dc 24 12 30 > 12 input current (maximum, per input) ma 50 sampling interval ms 1 minimum pulse w...

Page 147

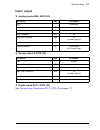

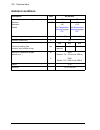

Technical data 147 digital inputs din4 - din9 (opt1) digital outputs dout0 (status), dout1, dout2 (x3) digital outputs dout3 - dout6 (opt1) description unit all models type opto-isolated inputs input voltage nominal minimum maximum active inactive v dc 24 12 30 > 12 input current (maximum, per input...

Page 148

148 technical data incremental encoder interface (x8) biss encoder interface (x8) ssi encoder interface (x8) * total current for this encoder and extra incremental encoder, which may be connected simultaneously (see page 86 ). Description unit all models encoder interface rs422 a/b differential, z i...

Page 149

Technical data 149 sincos / endat encoder interface (x8) smart abs encoder interface (x8) * total current for this encoder and extra incremental encoder, which may be connected simultaneously (see page 86 ). Ethernet interface (e1, e2) description unit all models absolute encoder interface endat / s...

Page 150: Ambient Conditions

150 technical data ambient conditions description unit all models operating temperature range °c °f minimum maximum derate v dc +0 +45 see temperature derating on page 132 . +32 +113 see temperature derating on page 132 . Storage temperature range -40 to +85 -40 to +185 humidity (maximum) % 93 3 a 6...

Page 151: Applicable Standards

Technical data 151 applicable standards microflex e150 complies with the following standards. Design and test standards ul508c: power conversion equipment. Ul840: insulation coordination including clearance and creepage distances for electrical equipment. En 61800-5-1:2007 adjustable speed electrica...

Page 152

152 technical data ethercat conformance test certificate.

Page 153: Degree of Protection

Technical data 153 degree of protection microflex e150 complies with en 60529, ip20 provided connector x1 is shrouded. For ul purposes the microflex e150 is defined as an open-type, single or three phase, single axis servo amplifier. The drive must be installed in a cabinet to fulfil the requirement...

Page 154

154 technical data compliance with the en 61800-3 definitions emc stands for electromagnetic compatibility. It is the ability of electrical/electronic equipment to operate without problems within an electromagnetic environment. Likewise, the equipment must not disturb or interfere with any other pro...

Page 155

Technical data 155 warning! A drive of category c3 is not intended to be used on a low-voltage public network which supplies domestic premises. Radio frequency interference is expected if the drive is used on such a network. Compliance with the european machinery directive this safety related drive ...

Page 156: Ec Declaration of Conformity

156 technical data ce declaration of conformity ec declaration of conformity (in accordance with en iso/iec 17050-1: 2010 and ec directives 2004/108/ec & 2006/42/ec) manufacturer: abb ltd address: 6 bristol distribution park, hawkley drive, bristol, bs32 0bf, u.K. In accordance with the following di...

Page 157: Ul Marking

Technical data 157 ul marking the microflex e150 is c-ul us listed only when used in conjunction with optional fan tray (part fan001-024, see page 164 ). The approval is valid with rated voltages. When used without optional fan tray fan001-024, the microflex e150 is ul recognized. Ul checklist • the...

Page 158: Control System

158 technical data control system the microflex e150 can use two main control configurations: • servo (position). • torque servo (current). The configuration is selected using the mint config keyword (object 5000h), or by using the mint workbench system configuration wizard. Each configuration suppo...

Page 159

Technical data 159 pid pi + tf pi + tf pwm kvtime currentmeas + + + + + + + - - - - currentlimit velerror kvelff folerror posdemand u v t p, v p v kvel kaccel 6062h 60f4h 60fbh si5 si1 si1 si2 si2 si3 si3 si4 si1 si2 si8 kderiv si7 si3 60fb kintlimit kintmode kint kprop 6060h 5007h 5023h effor t 503...

Page 160

160 technical data torque servo configuration the diagram on page 161 shows the torque-servo control configuration. Here, the velocity loop has been removed and the output of the position controller is fed into the current loop via the torque filters. The torque servo configuration is useful when th...

Page 161

Technical data 161 + + + - pid pi + tf pwm kvtime currentmeas + + + + - - currentlimit kvelff folerror posdemand veldemand 606bh t orquedemand 6074h acceldemand 5025h u v t p kvel kaccel 6062h 60f4h 60fbh si5 si1 si1 si2 si2 si3 si3 si4 si1 si2 si8 kderiv si7 si3 60fb kintlimit kintmode kint kprop 5...

Page 162

162 technical data.

Page 163: Accessories

Accessories 163 12 accessories what this chapter contains this section describes accessories and options that you might need to use with your microflex e150. Shielded (screened) cables provide emi / rfi shielding and are required for compliance with ce regulations. All connectors and other component...

Page 164

164 accessories fan tray the fan tray (part fan001-024) provides sufficient cooling for the 6 a and 9 a microflex e150. The fan tray might be required for the 3 a model when operating in high ambient temperatures (see temperature derating on page 132 ). The fan tray requires 23 - 27.5 v dc at 325 ma...

Page 165

Accessories 165 foot-mount filter (single phase only) the single-phase foot-mount ac power filter (part fi0029a00) provides mounting holes for the microflex e150 and fan tray. This allows the filter, fan tray and microflex e150 to use minimal panel mounting space. See pages 166 and 168 for details o...

Page 166

166 accessories emc filters ac filters remove high frequency noise from the ac power supply, protecting the microflex e150. These filters also prevent high frequency signals from being transmitted back onto the power lines and help meet emc requirements. To select the correct filter, see power suppl...

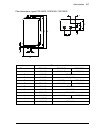

Page 167

Accessories 167 filter dimensions, types fi0014a00, fi0015a00, fi0015a02: dimensions: mm (inches) dimension fi0014a00 fi0015a00 fi0015a02 a 85 (3.35) 113.5 (4.47) 156 (6.14) b 54 (2.13) 57.5 (2.26) c 40 (1.57) 46.6 (1.83) d 65 (2.56) 94 (3.70) 130.5 (5.14) e 75 (2.95) 103 (4.06) 143 (5.63) f 27 (1.0...

Page 168

168 accessories filter dimensions, type fi0029a00: dimensions mm (inches) dimension fi0029a00 a 255 (10.04) b 100 (3.94) c 244.5 (9.63) d 70 (2.76) e 40 (1.57) f 20 (0.79) b a c d g g k j h g 5.5 mm h 11 mm k 5 mm j 10 mm f e mounting keyhole and slot detail.

Page 169

Accessories 169 brake resistors depending on the application, microflex e150 might require an external brake resistor to be connected to pins r1 and r2 of connector x1. The brake resistor dissipates energy during braking to prevent an over-voltage error occurring. See section brake (x1) on page 140 ...

Page 170: Encoder Breakout

170 accessories encoder breakout the encoder breakout (part opt-mf-200) can be used to connect motor feedback and an extra incremental encoder (see page 80 ). Alternatively, the connectors can be used together to connect a single motor that has separate cables for encoder and halls (e.G. A linear mo...

Page 171: Cables

Accessories 171 cables a wide range of motor and feedback cables are available. Motor power cables for easier installation, it is recommended that a color-coded motor power cable is used. The part number for a bsm rotary motor power cable is derived as follows: cbl 025 sp -12 s m ft 1.5 5* 2.5 8.2 3...

Page 172

172 accessories feedback cables the part number for a feedback cable is derived as follows: these feedback cables have the outer shield tied to the connector housing(s). If you are using an alternative cable with your chosen feedback device, be sure to obtain a cable that is a shielded twisted pair ...

Page 173: Appendix: Safe Torque Off

Appendix: safe torque off (sto) 173 13 appendix: safe torque off (sto) what this chapter contains the appendix describes the basics of the safe torque off function (sto) for the microflex e150. In addition, application features and technical data for the safety system calculation are presented. Basi...

Page 174

174 appendix: safe torque off (sto) warning! The sto function does not disconnect the voltage of the main and auxiliary circuits from the drive. Therefore maintenance work on electrical parts of the drive or the motor can only be carried out after isolating the drive system from the main supply. If ...

Page 175

Appendix: safe torque off (sto) 175 operation of the sto function and diagnostics if both sto inputs are powered, the sto function is in the standby state and the drive operates normally. If power is removed from one or both of the sto inputs the sto function is activated, the drive’s motor output p...

Page 176

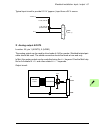

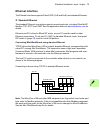

176 appendix: safe torque off (sto) installation typical input connections: note: if the contacts of the safety circuit do not open/close within 1 ms of each other, then a fault in the sto circuit or wiring is assumed and the drive will become disabled. The maximum allowed cable length between the d...

Page 177

Appendix: safe torque off (sto) 177 technical data: digital inputs sto1, sto2 (x3) sto function: data related to safety standards * according to the categorization defined in en iso 13849-1:2008. Description unit all models type opto-isolated inputs input voltage nominal minimum maximum active inact...

Page 178

178 appendix: safe torque off (sto) sto function: tüv certificate.

Page 179

Further information product and service inquiries address any inquiries about the product to your local abb representative, quoting the type designation and serial number of the unit in question. A listing of abb sales, support and service contacts can be found by navigating to www.Abb.Com/drives an...

Page 180

/7$(1 lt0 291a04 (en) eff e ctive: 2013- 12-0 1 contact us abb oy drives p.O. Box 184 fi-00381 helsinki finland telephone +358 10 22 11 fax +358 10 22 22681 www.Abb.Com/drives abb inc. Automation technologies drives & motors 16250 west glendale drive new berlin, wi 53151 usa telephone 262 785-3200 1...