- DL manuals

- ABB

- Relays

- REF 610

- Technical Reference Manual

ABB REF 610 Technical Reference Manual

Summary of REF 610

Page 1

Feeder protection relay ref 610 ref 610 technical reference manual.

Page 3

3 contents copyrights ................................................................................. 7 1. Introduction ..............................................................9 1.1. This manual .............................................................. 9 1.2. Use of symbols ...............

Page 4

5.1.4.10. Settings ....................................... 55 5.1.4.11. Technical data on protection functions ...................................... 66 5.1.5. Trip-circuit supervision .................................. 70 5.1.6. Trip lockout function ..................................... 72 5.1.7. ...

Page 5

5 6.1.2. Fast tripping and initiation of shot 1 using start signals ......................................................154 6.1.3. Selecting adaptive sequence length ...............155 6.2. Arc protection.........................................................156 6.2.1. Arc protection with one re...

Page 6

6.

Page 7

7 copyrights the information in this document is subject to change without notice and should not be construed as a commitment by abb oy. Abb oy assumes no responsibility for any errors that may appear in this document. In no event shall abb oy be liable for direct, indirect, special, incidental or c...

Page 8

8.

Page 9

9 1. Introduction 1.1. This manual this manual provides thorough information on the protection relay ref 610 and its applications, focusing on giving a technical description of the relay. Refer to the operator ’ s manual for instructions on how to use the human-machine interface (hmi) of the relay, ...

Page 10

1.4. Product documentation in addition to the relay and this manual, the delivery contains the following relay- specific documentation: table 1.4.-1 ref 610 product documentation name document id installation manual 1mrs752265-mum technical reference manual 1mrs755310 operator's manual 1mrs755311 1....

Page 11

11 2. Safety information dangerous voltages can occur on the connectors, even though the auxiliary voltage has been disconnected. Non-observance can result in death, personal injury or substantial property damage. Only a competent electrician is allowed to carry out the electrical installation. Nati...

Page 12

12.

Page 13

13 3. Product overview 3.1. Use of the relay the feeder protection relay ref 610 is a versatile multifunction protection relay mainly designed to protectincoming and outgoing feeders in a wide range of feeder applications. The relay is based on a microprocessor environment. A self-supervision system...

Page 14

* two galvanically isolated digital inputs and three additional galvanically isolated digital inputs on the optional i/o module * disturbance recorder: * recording time up to 80 seconds * triggering by one or several internal or digital input signals * records four analog channels and up to eight us...

Page 15

15 4. Application ref 610 is a versatile multifunction protection relay mainly designed for protection of incoming and outgoing feeders in mv distribution substations. The relay can also be used as back-up protection for motors, transformers and generators, in industrial as well as in utility applic...

Page 16

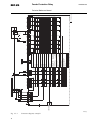

Sg b4 sg b 3 sg b2 sg b 1 sg b5 x3 .1 6 5 4 3 2 1 x4 .1 sg r 4 sg r 3 sg r2 s g r1 sg r5 so 1 p o 2 so 2 ir f 3 4 5 6 7 8 9 1 0 11 1 2 1 3 14 15 16 1 71 8 19 2 1 2 2 2 3 2 4 sg r 7 sg r 8 so 4 so 5 sg r 6 so 3 x3 .1 16 1 718 1 9 2 0 21 22 23 24 1 2 3 4 5 6 7 8 9 11 12 16 17 13 14 10 15 18 19 20 21 2...

Page 17

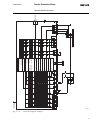

17 sg b 4 sg b 3 sg b2 sg b 1 sg b5 sg r4 sg r3 sg r2 s g r1 sg r 5 sg r7 sg r 8 sg r 6 1 2 3 4 5 6 7 8 9 11 12 16 17 13 14 10 15 18 19 20 21 22 23 2 3 4 5 6 1 10 11 12 13 14 15 9 18 19 16 17 20 8 7 ~ x5 .1 x5 .2 x3 .1 6 5 4 3 2 1 x4 .1 so 1 p o 2 so 2 ir f 3 4 5 6 7 8 9 1 0 1 1 1 2 13 14 15 1 6 17 ...

Page 18

18.

Page 19

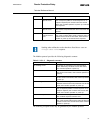

19 5. Technical description 5.1. Functional description 5.1.1. Product functions 5.1.1.1. Protection functions the protection functions of ref 610 with their iec symbols and ieee device numbers are presented in the table below: table 5.1.1.1.-1 iec symbols and ieee device numbers function descriptio...

Page 20

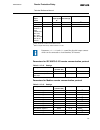

5.1.1.3. Outputs the relay is provided with: * three power output contacts po1, po2 and po3 * two signal output contacts so1 and so2 * three optional signal output contacts so3, so4 and so5 switchgroups sgr1...8 are used for routing internal signals from the protection stages, the external trip sign...

Page 21

21 5.1.1.6. Non-volatile memory the relay can be configured to store various data in a non-volatile memory, which retains its data also in case of loss of auxiliary voltage (provided that the battery has been inserted and is charged). Operation indication messages and leds, disturbance recorder data...

Page 22

Warning fault code: 33 a040280 fig. 5.1.1.7.-3 warning with numeric code for fault codes, refer to section 5.1.18. Self-supervision (irf) system. 5.1.1.8. Time synchronization time synchronization of the relay ’ s real-time clock can be realized in two different ways: via serial communication using ...

Page 23

23 the pulse length of the digital input signal does not affect time synchronization. If time synchronization messages are received from a communication protocol as well, they have to be synchronized within ±0.5 minutes at minute-pulse or ±0.5 seconds at second-pulse synchronization. Otherwise the t...

Page 24

2 3 4 5 6 1 10 11 12 13 14 15 sgb4 sgb3 sgb2 sgb1 sgb5 x3 .1 6 5 4 3 2 1 x4 .1 1 2 3 4 5 6 7 8 9 11 12 16 17 sgr4 sgr3 sgr2 sgr1 sgr5 so1 po2 so2 eid 3 4 5 6 7 8 9 10 1 1 12 13 14 15 16 17 18 1 9 21 22 23 2 4 q > i> i> > i>>> i 0 > i 0 >> d i> 13 14 sgr7 sgr8 so4 so5 sgr6 so3 x3 .1 16 17 18 19 20 21...

Page 25

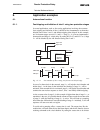

25 5.1.4. Protection 5.1.4.1. Block diagram led1 led2 led3 led4 led5 led6 led7 led8 i l1 i l2 i l3 sgb1...5 i 0 sgl1...8 sgf1...Sgf5 i l 1 i l 2 i l 3 i 0 q > cbfp il1 il2 il3 i io io i>>> d i> start trip i>> i> io>> io> arc i>, arc i0> programmable leds (4 analogue + up to 8 digital channels) the d...

Page 26

When one or several phase currents exceed the set start value of the low-set stage, i>, the stage will generate a start signal after a ~ 55 ms ’ start time. When the set operate time at definite-time characteristic or the calculated operate time at idmt characteristic elapses, the stage will generat...

Page 27

27 stage i>>> can be set out of operation in sgf3. This state will be indicated by dashes on the lcd and by “ 999 ” when the set start value is read via serial communication. Stages i>> and i>>> will be reset in 50 ms after all three phase currents have fallen below the set start value of the stage....

Page 28

Current rises from a value below 0.12 x i 0 > to a value above 1.5 x i 0 > within less than 60 ms. The start situation ends when the current falls below 1.25 x i 0 > and remain below for at least 200 ms. The selection is made in sgf4. Consider carefully when using the automatically doubled setting f...

Page 29

29 table 5.1.4.4.-1 thermal level at constant currents i/i θ thermal level (%) 1.0 90.7 0.9 73.5 0.8 58 0.7 44.4 0.5 22.7 0.3 8.2 0 0 when the thermal capacity exceeds the trip level, θ t >, the stage will generate a trip signal. The operate time, i.E. The time from when the stage starts until it tr...

Page 30

Q 1000 100000 10000 t/s 100 10 1 0 1 1 10 5 10 15 25 40 60 90 t [min] i/i 1.05 a040313 fig. 5.1.4.4.-1 trip curves when no prior load 30 ref 610 ref 610 feeder protection relay technical reference manual 1mrs755310

Page 31

31 q 1000 100000 10000 t/s 100 10 1 0 1 1 10 5 10 15 25 40 60 90 t [min] i/i 1.05 a040314 fig. 5.1.4.4.-2 trip curves at prior load 0.7 x i θ feeder protection relay technical reference manual ref 610 ref 610 1mrs755310

Page 32

Q 1000 100000 10000 t/s 100 10 1 0 1 10 5 10 15 25 40 60 90 t [min] i/i 1.05 1 a040315 fig. 5.1.4.4.-3 trip curves at prior load i x i θ 32 ref 610 ref 610 feeder protection relay technical reference manual 1mrs755310

Page 33

33 5.1.4.5. Phase discontinuity protection the phase discontinuity protection detects phase unbalance between phases i l1 , i l2 and i l3 , caused by a broken conductor, for instance. The difference between the minimum and maximum phase currents is calculated as follows: Δ = − ( ) × i i i ax max min...

Page 34

Normally, the cbfp controls the upstream circuit breaker. However, it can also be used for tripping via redundant trip circuits of the same circuit breaker. 5.1.4.7. Arc protection the arc protection detects arc situations in air insulated metal-clad switchgears, caused by human error during mainten...

Page 35

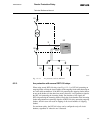

35 the warning signal generated in case of continuous light on the light sensor inputs can be routed to so2 by setting switch sgf1/8 to 1. Arc i> arc i0> sgf3/6=1 sgf3/7=1 sgf4/6=0 il 0 25 ms arc protection arc trip l> light output light sensor 1 light sensor 2 external arc and or i a040316_2 fig. 5...

Page 36

The ar function monitors the position and status of the circuit breaker. Information on the circuit-breaker position is always required whereas circuit-breaker status is optional. For safety reasons, shot initiation is not possible when the circuit breaker is open. If the circuit breaker is not read...

Page 37

37 if the network fault has still not been cleared, i.E. All selected auto-reclose shots have been unsuccessful, and the protection trips the circuit breaker before expiration of the set reclaim time, the ar function will generate a definite trip alarm. The circuit breaker will now remain open and t...

Page 38

T 100 ms t sg1/ 1...8 t and i>> trip ext ar initiation i> trip i> start *) io>> trip io> trip open cb command cb position closed shot due and shot initiation blocking of shot io> start *) *) shot initiation by a start signal applies only to shot 1 and definite tripping. Or or or io> start delay i> s...

Page 39

39 inhibition of the auto-reclose function the ar function can be inhibited ( ar inhibit ) by any of the following signals: * external ar inhibit signal * trip signal from the arc protection stage, arc * trip signal from the thermal protection stage, θ > * trip signal from the cbfp * alarm signal fr...

Page 40

Circuit-breaker closing when the set dead time elapses, the ar function will issue a reclosing command to the circuit breaker ( close cb command ). Reclosing can be inhibited via a digital input ( cb close inhibit ). External inhibition of reclosing by the digital input signal is selected in sgb. Wh...

Page 41

41 lockout of the auto-reclose function the lockout signal indicates whether the ar function is ready for shot initiation. The ar function will be locked out in any of the following situations: * the ar function generates a definite trip alarm * the ar function is inhibited * circuit-breaker closing...

Page 42

T s i i k [ ] = > − ⎛ ⎝ ⎜ ⎜ ⎜ ⎜ ⎞ ⎠ ⎟ ⎟ ⎟ ⎟ × β α 1 (4) t = operate time i = phase (or earth-fault) current value k (or k 0 ) = time multiplier i> (or i 0 >) = set start value the actual operate time of the relay (see fig. 5.1.4.9.-1...Fig. 5.1.4.9.- 4), includes an additional filter and detection t...

Page 43

43 the time/current curve groups based on the iec standard are illustrated in fig. 5.1.4.9.-1...Fig. 5.1.4.9.-4. If the ratio between the current and the set start value is higher than 20, the operate time is the same as when the ratio is 20. Feeder protection relay technical reference manual ref 61...

Page 44

K 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 2 3 4 5 6 7 8 9 10 20 30 40 70 60 50 t/s 1 3 4 5 6 7 8 9 10 2 20 i/i> 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1 0.05 0.1 0.2 0.3 0.4 0.6 0.8 1.0 0.5 0.7 0.9 a040319 fig. 5.1.4.9.-1 normal inverse-time characteristic 44 ref 610 ref 610 feeder protection relay tec...

Page 45

45 k 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 2 3 4 5 6 7 8 9 10 20 30 40 70 60 50 t/s 1 3 4 5 6 7 8 9 10 2 20 i/i> 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1 0.05 0.1 0.2 0.3 0.4 0.6 0.8 1.0 0.7 0.5 0.9 a040320 fig. 5.1.4.9.-2 very inverse-time characteristic feeder protection relay technical reference m...

Page 46

K 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 2 3 4 5 6 7 8 9 10 20 30 40 70 60 50 t/s 1 3 4 5 6 7 8 9 10 2 20 i/i> 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1 0.05 0.1 0.2 0.3 0.4 0.6 0.8 1.0 a040321 fig. 5.1.4.9.-3 extremely inverse-time characteristic 46 ref 610 ref 610 feeder protection relay technical re...

Page 47

47 k 2 3 4 5 6 7 8 9 10 20 30 40 50 60 70 80 90 100 200 300 400 700 600 500 t/s 1 3 4 5 6 7 8 9 10 2 20 i/i> 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0.05 0.1 0.2 0.3 0.4 0.7 1.0 0.5 0.6 0.8 0.9 a040322 fig. 5.1.4.9.-4 long-time inverse-time characteristic feeder protection relay technical reference manual...

Page 48

Idmt characteristics according to the ieee c37.112 ref 610 provides three time/current curve groups which comply with the ieee c37.112 standard: extremely inverse, very inverse and inverse. The relationship between time and current is expressed as follows: t s a i i b n p [ ] = > ⎛ ⎝⎜ ⎞ ⎠⎟ − + ⎛ ⎝ ⎜...

Page 49

49 n 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 2 3 4 5 6 7 8 9 10 20 30 40 70 60 50 t/s 1 3 4 5 6 7 8 9 10 2 20 i/i> 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1 1 2 3 4 5 6 8 15 10 12 a040323 fig. 5.1.4.9.-5 extremely inverse-time characteristic feeder protection relay technical reference manual ref 610 ref...

Page 50

N 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 2 3 4 5 6 7 8 9 10 20 30 40 70 60 50 t/s 1 3 4 5 6 7 8 9 10 2 20 i/i> 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1 1 2 3 4 5 6 8 15 10 12 a040324 fig. 5.1.4.9.-6 very inverse-time characteristic 50 ref 610 ref 610 feeder protection relay technical reference manual ...

Page 51

51 n 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 2 3 4 5 6 7 8 9 10 20 30 40 70 60 50 t/s 1 3 4 5 6 7 8 9 10 2 20 i/i> 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1 1 2 3 4 5 6 8 15 10 12 a040325 fig. 5.1.4.9.-7 inverse-time characteristic feeder protection relay technical reference manual ref 610 ref 610 1mrs7...

Page 52

Ri-type characteristic the ri-type characteristic is a special characteristic which is principally used for obtaining time grading with mechanical relays. The relationship between time and current is expressed as follows: t s k i i [ ] = − × > 0 339 0 236 . . (6) t = operate time i = phase (or earth...

Page 53

53 k 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 2 3 4 5 6 7 8 9 10 20 30 40 70 60 50 t/s 1 3 4 5 6 7 8 9 10 2 20 i/i> 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1 0.05 0.2 0.3 0.4 0.5 0.6 0.7 1.0 0.8 0.9 0.1 a040326 fig. 5.1.4.9.-8 ri-type characteristic feeder protection relay technical reference manual ref ...

Page 54

Rd-type characteristic (rxidg) the rd-type characteristic is a special characteristic, which is principally used in earth-fault protection and which requires a high degree of selectivity even at high resistance faults. The protection can operate in a selective way even if it is not directional. Math...

Page 55

55 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 2 3 4 5 6 7 8 9 10 20 30 40 50 60 70 t/s 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1 1 2 3 4 5 7 8 9 10 20 i/i> 6 0.5 0.6 0.7 0.8 0.9 1.0 k 30 40 0.4 0.3 0.2 0.1 0.05 a051411 fig. 5.1.4.9.-9 rd-type inverse-time characteristic 5.1.4.10. Settings there are two alt...

Page 56

Switching between setting groups via a digital input has a higher priority than via the hmi or with the parameter v150 . The setting values can be altered via the hmi or with a pc provided with relay setting tool. Before the relay is connected to a system it must be assured that the relay has been g...

Page 57

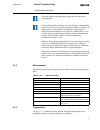

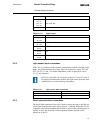

57 switchgroups and parameter masks the settings can be altered and the functions of the relay selected in the sg_ selector switchgroups. The switchgroups are software based and thus not physical switches to be found in the hardware of the relay. A checksum is used for verifying that the switches ha...

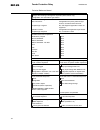

Page 58

Table 5.1.4.10.-2 sgf1 switch function default setting sgf1/1 selection of the latching feature for po1 0 sgf1/2 selection of the latching feature for po2 0 sgf1/3 selection of the latching feature for po3 * when the switch is in position 0 and the measuring signal which caused the trip falls below ...

Page 59

59 table 5.1.4.10.-4 sgf3 switch function default setting sgf3/1 inhibition of stage i>> 0 sgf3/2 inhibition of stage i>>> 0 sgf3/3 inhibition of stage i 0 >> 0 sgf3/4 inhibition of stage Δ i> 1 sgf3/5 inhibition of stage θ > 1 sgf3/6 inhibition of stage arc 1 * when the switch is in position 1, the...

Page 60

Switch function default setting sgf5/7 selection of the latching feature for programmable led7 0 sgf5/8 selection of the latching feature for programmable led8 * when the switch is in position 0 and the signal routed to the led is reset, the programmable led is cleared. * when the switch is in posit...

Page 61

61 switch function default setting sgb1...5/18 cb position open 0 sgb1...5/19 cb position closed 0 sgb1...5/20 external ar initiation by the digital input signal 0 Σ sgb1...5 0 sgr1...Sgr8 the start, trip and alarm signals from the protection stages, the signals from the auto-reclose function, and t...

Page 62

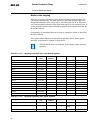

Po1 po2 po3 so1 so2 so3 so4 optional i/o card i> t> i>> t>> i>>> t>>> i0> t0> i0>> t0>> Δ i> Δ t> θ > alarm θ > trip ext. Trip arc trip open cb command close cb command definite trip alarm cb reclosing failed shot due ar lockout 1 2 4 8 16 32 64 128 256 512 1024 2048 4096 8192 16384 32768 65536 1310...

Page 63

63 switch function default setting sgr1...Sgr3 sgr4...Sgr5 sgr6...Sgr8 sgr1...8/13 alarm signal from stage θ > 0 0 0 sgr1...8/14 trip signal from stage θ > 1 0 0 sgr1...8/15 external trip signal 0 0 0 sgr1...8/16 open cb command from ar 0 0 0 sgr1...8/17 close cb command from ar 0 0 0 sgr1...8/18 de...

Page 64

Switch function default setting sgl1...8/23 disturbance recorder triggered 0 Σ sgl1...Sgl8 0 auto-reclose sg1...Sg3 switchgroup sg1 is used for blocking the initiation of one or several auto-reclose shots, sg2 for blocking of protection stages at one or several auto-reclose shots, and sg3 for inhibi...

Page 65

65 table 5.1.4.10.-12 sg3 switch function default setting sg3/1 inhibition of the ar function by the trip signal from stage i>>> 1 sg3/2 ihibition of the ar function by the trip signal from stage i 0 >> 1 sg3/3 inhibition of the ar function by the alarm signal from stage θ > 1 sg3/4 inhibition of th...

Page 66

Setting switch function default setting 4 * 1 = recorded data and information on the number of starts of the protection stages are retained a) 1 5 * 1 = the real-time clock is running also during loss of auxiliary voltage a) 1 Σ 31 a) the prerequisite is that the battery has been inserted and is cha...

Page 67

67 feature stage i> stage i>> stage i>>> * at definite-time characteristic ±2% of the set operate time or ±25 ms ±2% of the set operate time or ±25 ms ±2% of the set operate time or ±25 ms * at idmt characteristic according to iec 60255- 3: accuracy class index e 5 * at idmt characteristic according...

Page 68

Feature stage i 0 > stage i 0 >> time dial, n 1...15 resetting time, maximum 50 ms b) 50 ms retardation time, typical 30 ms 30 ms set resetting time, t 0r> 0.05...2.50 s drop-off/pick-up ratio, typical 0.96 0.96 operate time accuracy * at definite-time characteristic ±2% of the set operate time or ±...

Page 69

69 feature value operation accuracy * 10...100% ±3% of the set start value and ±1 unit table 5.1.4.11.-5 stage arc and l> feature value stage arc set trip value arci> 0.5...35.0 x i n operate time a) arci 0 > 5.0...800% i n operate time a) resetting time 30 ms operation accuracy ±7% of the set start...

Page 70

Table 5.1.4.11.-6 auto-reclose function feature value number of shots 0...3 cb closing time 0.1...10 s start delay of stage i> 0...300 s start delay of stage i 0 > 0...300 s reset time 3...300 s cutout time 0.1...300 s dead time of shot 1 0.1...300 s dead time of shot 2 0.1...300 s dead time of shot...

Page 71

71 the external shunt resistor is used to enable trip-circuit supervision also when the circuit breaker is open. The resistance of the external shunt resistor is to be calculated so that it does not cause malfunction of the trip-circuit supervision or affect the operation of the trip coil. Too high ...

Page 72

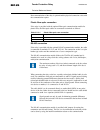

+ - rext r int tcs hw sw x4.1 rs 18 19 16 17 so2 7 8 6 hmi po1 sgf1/8 trip-circuit supervision tcs state warning a040329_2 fig. 5.1.5.-1 connecting the trip-circuit supervision using two external contacts and the external resistor in the trip circuit 5.1.6. Trip lockout function the trip lockout fun...

Page 73

73 5.1.7. Trip counters for circuit-breaker condition monitoring the trip counters for circuit-breaker condition monitoring provide history data, which can be used for circuit-breaker service scheduling. With this information, the service cycle can be estimated for the future. The monitoring functio...

Page 74

The first value shows the average current of all three phases measured during one minute. The value is updated once a minute. The second value shows the average current during an adjustable time range, ranging from 0 to 999 minutes, with an accuracy of one minute. This value is updated at the expira...

Page 75

75 as soon as the recorder has been triggered and the recording has finished, the recording can be uploaded and analyzed by means of a pc provided with a special program. 5.1.11.2. Disturbance recorder data one recording contains data from the four analog channels and up to eight digital channels. T...

Page 76

Triggering of the recorder immediately after it has been cleared or the auxiliary voltage connected may result in a shortened total recording length. Disconnection of the auxiliary voltage after the recorder has been triggered, but before the recording has finished, on the other hand, may result in ...

Page 77

77 unloading correct information from the recorder requires that m80 and m83 have been set. Unloading is done by using a pc application. The uploaded recorder data is stored in separate files defined by the comtrade® format. 5.1.11.6. Event code of the disturbance recorder the disturbance recorder g...

Page 78

Table 5.1.12.-1 recorded data register data description event1 * phase current l1, measured as a multiple of the rated current, i n , is displayed in two registers: the main register and the sub register. When a stage starts but does not trip, the maximum fault current during the start period will b...

Page 79

79 register data description number of starts the number of times each protection stage, i>, i>>, i>>>, Δ i, i 0 > and i 0 >>, has started, counting up to 999. Number of trips * the number of times each protection stage, i>, i>>, i>>>, has tripped. When the counters reach their maximum values (65535...

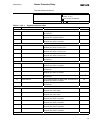

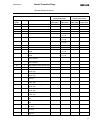

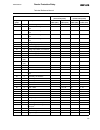

Page 80

A051551 fig. 5.1.13.-1 communication port 1) front connection for local communication the relay is connected to a pc used for local parameterization via the infrared port on the front panel. The front connection allows the use of the spa bus protocol only. The optical front connection galvanically i...

Page 81

81 the iec 60870-5-103 protocol can be used only through the rear connection of the relay on the optional communication module. Connecting the relay to a fibre-optic communication bus requires a fibre-optic communication module. The line-idle state of the fibre-optic communication module can be sele...

Page 82

Table 5.1.14.-1 information mapping of configuration set 1 and 2 event reason event code configuration set 1 configuration set 2 function type information number gi relative time t ype identification disturbance recorder triggered/cleared 0e31/ 0e32 x x 178 100 - - 1 hmi setting password opened/clos...

Page 83

83 event reason event code configuration set 1 configuration set 2 function type information numbe r gi relative time t ype identification trip lockout activated/reset 1e37/ 1e38 x x 10 223 x - 1 external trip/reset 1e39/ 1e40 x x 10 222 - - 1 cbfp activated/reset 1e41/ 1e42 x x 160 85 - - 1 po1 act...

Page 84

Event reason event code configuration set 1 configuration set 2 function type information numbe r gi relative time t ype identification open cb command/reset 3e13/ 3e14 x x 169 127 - - 1 close cb command/reset 3e15/ 3e16 x x 169 128 - - 1 cb reclosing failed/reset 3e17/ 3e18 x x 169 163 - - 1 cb rec...

Page 85

85 table 5.1.15.-1 rtu character format coding system 8-bit binary bits per character 1 start bit 8 data bits, the least significant bit is sent first 1 bit for even/odd parity; no bit if parity is not used 1 stop bit if parity is used; 2 stop bits if parity is not used table 5.1.15.-2 ascii charact...

Page 86

Table 5.1.15.1.-1 supported application functions function code function description 01 read coil status reads the status of discrete outputs. 02 read digital input status reads the status of discrete inputs. 03 read holding registers reads the contents of output registers. 04 read input registers r...

Page 87

87 code name description 15 return slave no response count the number of messages addressed to the slave for which a response (neither a normal response nor an exception response) has not been sent since its last restart, clear counters operation or power up is returned in the response. 16 return sl...

Page 88

Table 5.1.15.1.-4 possible exception codes code name description 01 illegal function the slave does not support the requested function. 02 illegal data address the slave does not support the data address or the number of items in the query is incorrect. 03 illegal data value a value contained in the...

Page 89

89 to read a fault record: 1. Write a preset single register command (function 06) to hr601 using a selection code as data value. 2. Read the selected fault record (function 04) from hr601, register count 28. Alternatively, a fault record can be read using one command (function 23) only. Selection c...

Page 90

Modbus di/co data point address and the value to which the point has changed (0 or 1). Spa events lacking a corresponding di/co data point are shown as spa channel and event code (informative event) in the event record. The maximum capacity of the modbus event buffer is 99 events. The time stamp of ...

Page 91

91 selection code -1...-99 with selection code -1...-99, the master can move backwards from the newest event as many events as defined by the selection code and read that specific event record. After this, the master can continue reading the following records using selection code 1, irrespective of ...

Page 92

Modbus data mapping there are two types of monitoring data: digital indications and measurands. For convenience and efficiency, the same data can be read from different data areas. Measurands and other 16-bit values can be read either from the ir or hr (read- only) area and digital indication values...

Page 93

93 table 5.1.15.1.-7 mapping of modbus data: analog data description hr/ir address (.Bit) di/coil bit address writeable value range comment phase current i l1 x i n 404 0...5000 0...50 x phase current i l2 x i n 405 0...5000 phase current i l3 x i n 406 0...5000 0...50 x earth-fault current x i n 40...

Page 94

Description hr/ir address (.Bit) di/coil bit address writeable value range comment trip signal from stage arc (light and di) 411.00 33 0/1 1 = activated trip signal from stage arc (light and di) cd 411.01 34 light signal output 411.02 35 0/1 1 = activated light signal output cd 411.03 36 trip lockou...

Page 95

95 description hr/ir address (.Bit) di/coil bit address writeable value range comment so2 cd 413.09 74 so3 413.10 75 0/1 1 = activated so3 cd 413.11 76 so4 413.12 77 0/1 1 = activated so4 cd 413.13 78 so5 413.14 79 0/1 1 = activated o5 cd 413.15 80 di1 414.00 81 0/1 1 = activated di1 cd 414.01 82 di...

Page 96

Table 5.1.15.1.-10 mapping of modbus data: relay identification description hr/ir address (.Bit) di/coil bit address writeable value range comment type designation of the relay 701...708 ascii chars, 2 chars/register table 5.1.15.1.-11 mapping of modbus data: real-time clock description hr/ir addres...

Page 97

97 description hr/ir address (.Bit) di/coil bit address writeable value range comment number of ar shots (shot 2) initiated by the start or trip signal from stage i 0 > 825 0...255 counter number of ar shots (shot 3) initiated by the trip signal from stage i>> 826 0...255 counter number of ar shots ...

Page 98

Table 5.1.15.1.-14 fault record address signal name range comment 601 latest selection code a) 1...2 1 = read oldest unread record 2 = read oldest stored record 602 sequence number 1...255 603 unread records left 0...6 604 time stamp of the recorded data, date 2 bytes: yy.Mm 605 time stamp of the re...

Page 99

99 address signal name range comment 673 unread records left 0...99 674 time stamp of the event, date 2 bytes: yy.Mm 675 time stamp of the event, date and time 2 bytes: dd.Hh 676 time stamp of the event, time 2 bytes: mm.Ss 677 time stamp of the event, time 0...999 0...999 ms 678 modbus di point or ...

Page 100

5.1.16.1. Protocol parameters the dnp parameters can all be adjusted using relay setting tool. For the dnp parameters, refer to table 5.1.17.-14. Storing dnp 3.0 parameters all dnp parameters are stored on the external dnp 3.0 module. After parameterization with relay setting tool, ref 610 must be s...

Page 101

101 table 5.1.16.2.-1 binary data description dnp point address event class ur enable value range comment start signal from stage i> 0 1 1 0/1 1 = activated trip signal from stage i> 1 1 1 0/1 1 = activated start signal from stage i>> 2 1 1 0/1 1 = activated trip signal from stage i>> 3 1 1 0/1 1 = ...

Page 102

Description dnp point address event class ur enable value range comment di2 41 1 1 0/1 1 = activated di3 42 1 1 0/1 1 = activated di4 43 1 1 0/1 1 = activated di5 44 1 1 0/1 1 = activated disturbance recorder 45 1 1 0/1 1 = triggered 0 = cleared hmi setting password 46 1 1 0/1 1 = opened 0 = closed ...

Page 103

103 description dnp point address event class ur enable deadband value range number of ar shots (shot 1) initiated by the digital input signal 11 3 1 1 0...255 number of ar shots (shot 1) initiated by the start or trip signal from stage i> 12 3 1 1 0...255 number of ar shots (shot 1) initiated by th...

Page 104

Always when sending multi-fragment responses (slave devices only) configurable, with confirmation type selector timeouts while waiting for: data link confirm configurable with primary data link layer timeout, not relevant when no ack complete appl. Fragment no, multi-fragment application frames not ...

Page 105

105 other value: 999 (counters 0...5) and 255 (counters 10...21) point-by-point list attached sends multi-fragment responses yes no table 5.1.16.3.-1 supported function codes code function description supported transfer function codes 0 confirm message fragment confirmation no response yes 1 read re...

Page 106

Code function description supported 19 save configuration save configuration respond with status of operation no 20 enable unsolicited messages enable unsolicited messages respond with status of operation yes 21 disable unsolicited messages disable unsolicited messages respond with status of operati...

Page 107

107 object request (slave must parse) response (master must parse) object group variation description function codes (dec) qualifier codes (hex) function codes (dec) qualifier codes (hex) 20 5 32-bit binary counter without flag 20 6 16-bit binary counter without flag 20 7 32-bit delta counter withou...

Page 108

Object request (slave must parse) response (master must parse) object group variation description function codes (dec) qualifier codes (hex) function codes (dec) qualifier codes (hex) 23 1 32-bit frozen counter event without time 23 2 16-bit frozen counter event without time 23 3 32-bit frozen delta...

Page 109

109 object request (slave must parse) response (master must parse) object group variation description function codes (dec) qualifier codes (hex) function codes (dec) qualifier codes (hex) 33 0 frozen analog event, all variations 33 1 32-bit frozen analog event without time 33 2 16-bit frozen analog ...

Page 110

Object request (slave must parse) response (master must parse) object group variation description function codes (dec) qualifier codes (hex) function codes (dec) qualifier codes (hex) 100 3 extended floating point 101 1 small packed binary-coded decimal 101 2 medium packed binary-coded decimal 101 3...

Page 111

111 503v18 class 1 event delay 503v19 class 1 event count 503v20 class 2 event delay 503v21 class 2 event count 503v22 class 3 event delay 503v23 class 3 event count example: (class 1) the events are reported when the event delay (spa parameter 503v18 ) has elapsed or the defined amount of events (s...

Page 112

The silent interval is set with spa parameter 503v232 and the maximum random delay with spa parameters 503v233 (the width of a single time slot in milliseconds) and 503v234 (the maximum number of time slots). By setting the time-slot width to 10 milliseconds and the maximum number of time slots to 1...

Page 113

113 dnp analog values deadband the deadband is always defined in units of the original value when scaled using the internal (fixed) scaling factor, irrespective of whether the internal scaling factor is used for value presentation or not. Example: for a deadband of 2% i n when the internal scaling f...

Page 114

Variable actual settings (r), channel 0 group/channel 1 (r, w, p) group/channel 2 (r, w, p) setting range time multiplier k 0 s14 1s14 2s14 0.05...1.00 s time multiplier n 0 s15 1s15 2s15 1.0 … 15.0 resetting time of stage i 0 > s16 1s16 2s16 0.05...2.50 start value of stage i 0 >> s17 a) 1s17 2s17 ...

Page 115

115 variable actual settings (r), channel 0 group/channel 1 (r, w, p) group/channel 2 (r, w, p) setting range checksum, sgl 6 s96 1s96 2s96 0...8388607 checksum, sgl 7 s97 1s97 2s97 0...8388607 checksum, sgl 8 s98 1s98 2s98 0...8388607 a) if the protection stage is out of operation, the number indic...

Page 116

Recorded data parameter (r) value 64=i l1 >> 128=i 0 >> 256=i l3 >>> 512=i l2 >>> 1024=i l1 >>> 2048= Δ i> 4096= θ > 8192=external trip 16384=ar 32768=trip of stage arc (local) 65536=trip of stage arc (remote) trip indication code v2 0 = — 1=start of stage i> 2=trip of stage i> 3=start of stage i>> ...

Page 117

117 recorded data parameter (r) value number of starts of stage Δ i> v8 0...999 number of trips of stage i> v9 0...65535 number of trips of stage i>> v10 0...65535 number of trips of stage i>>> v11 0...65535 number of trips of other stages v12 0...65535 number of ar shots (shot 1) initiated by the t...

Page 118

Recorded data parameter (r) value number of ar shots (shot 3) initiated by the digital input signal v22 0...255 number of ar shots (shot 3) initiated by the start or trip signal from stage i> v23 0...255 number of ar shots (shot 3) initiated by the start or trip signal from stage i 0 > v24 0...255 t...

Page 119

119 recorded data event (r) value n channel 1 n-1 channel 2 n-2 channel 3 n-3 channel 4 n-4 channel 5 trip number of ar sequence 1v19 2v19 3v19 4v19 5v19 0...255 start duration of stage arc (local) 1v20 2v20 3v20 4v20 5v20 0/100% start duration of stage arc (remote) 1v21 2v21 3v21 4v21 5v21 0/100% t...

Page 120

Description parameter (channel 0) r, w value external trigger signal's edge v242 r, w 0...31 checksum of external signal storing mask v243 b) r, w 0...31 triggering state, clearing and restart v246 r, w r: 0 = recorder not triggered 1 = recorder triggered and recording stored in the memory w: 0 = cl...

Page 121

121 table 5.1.17.-7 disturbance recorder external triggering and storing event weighting factor default value of triggering mask, v241 default value of triggering edge, v242 a) default value of storing mask, v243 di1 1 0 0 0 di2 2 0 0 0 di3 4 0 0 0 di4 8 0 0 0 di5 16 0 0 0 Σ 0 0 0 a) 0 = rising edge...

Page 122

Description parameter r, w, p value store counter a) v114 r 0...65535 remote control of setting group v150 r, w 0 = setting group 1 1 = setting group 2 entering the spa password for settings v160 w 1...999 changing the spa password or taking the password protection into use v161 w (p) 1...999 changi...

Page 123

123 table footnotes from previous page c) if the optional dnp 3.0 module has been installed, the dnp 3.0 communication protocol is automatically selected. D) if the optional communication module is not installed, a warning of a faulty communication module appears on the lcd together with the fault c...

Page 124

Status of the protection stages channel state of stage (r) recorded functions (r) value trip of stage i 0 > 0,1 o8 o68 0/1 start of stage i 0 >> 0,1 o9 o69 0/1 trip of stage i 0 >> 0,1 o10 o70 0/1 start of stage Δ i> 0,1 o11 o71 0/1 trip of stage Δ i> 0,1 o12 o72 0/1 start of stage θ > 0,1 o13 o73 0...

Page 125

125 operation of output contact channel state of output (r, w, p) recorded functions (r) value output so4 0,2 o48 o108 0/1 d) output so5 0,2 o49 o109 0/1 d) enabling activation of output contacts po1, po2, po3, so1, so2, so3, so4 and so5 via the spa bus 0,2 o51 - 0/1 a) state of output when the trip...

Page 126

Description parameter (channel 504) r, w, p value user-defined register 12 504v12 r, w 0...65535 a) user-defined register 13 504v13 r, w 0...65535 a) user-defined register 14 504v14 r, w 0...65535 a) user-defined register 15 504v15 r, w 0...65535 a) user-defined register 16 504v16 r, w 0...65535 a) ...

Page 127

127 description spa parameter (channel 503) r, w value range default explanation default variation of counter objects 503v13 r, w 1...2 2 default variation of counter change event objects 503v14 r, w 1, 2, 5, 6 2 default variation of frozen counter objects 503v30 r, w 1, 2, 5, 6 2 class 1 event dela...

Page 128

Measurements table 5.1.17.-15 measured values description parameter (channel 0) r, w, p value thermal level v60 r, w (p) 0...106% a)b) one-minute average current value v61 r 0...50 x i n c) average current value during the specified time range v62 r 0...50 x i n c) maximum one-minute average current...

Page 129

129 table 5.1.17.1.-2 event codes e1...E4 and e7 channel event description 0 e1 irf 0 e2 irf disappeared 0 e3 warning 0 e4 warning disappeared 0 e7 the thermal level has been changed via serial communication table 5.1.17.1.-3 event codes e50...E51 channel event description 0 e50 relay restart 0 e51 ...

Page 130

Table 5.1.17.1.-6 event codes e13...E24 channel event description weighting factor default value 1 e13 start signal from stage i 0 > activated 1 1 1 e14 start signal from stage i 0 > reset 2 0 1 e15 trip signal from stage i 0 > activated 4 1 1 e16 trip signal from stage i 0 > reset 8 0 1 e17 start s...

Page 131

131 channel 2 table 5.1.17.1.-8 event codes e1...E16 channel event description weighting factor default value 2 e1 po1 activated 1 1 2 e2 po1 reset 2 1 2 e3 po2 activated 4 0 2 e4 po2 reset 8 0 2 e5 po3 activated 16 0 2 e6 po3 reset 32 0 2 e7 so1 activated 64 0 2 e8 so1 reset 128 0 2 e9 so2 activate...

Page 132

Channel 3 table 5.1.17.1.-10 event codes e1...E12 channel event description weighting factor default value 3 e1 shot 1 initiated 1 1 3 e2 shot 1 ended 2 1 3 e3 shot 2 initiated 4 1 3 e4 shot 2 ended 8 1 3 e5 shot 3 initiated 16 1 3 e6 shot 3 ended 32 1 3 e7 cb position open 64 1 3 e8 cb position clo...

Page 133

133 internal relay fault when an internal relay fault preventing relay operation is detected, the relay first tries to eliminate the fault by restarting. Only after the fault is found to be permanent, the green indicator led (ready) begins to blink and the self-supervision output contact is activate...

Page 134

Fault code type of fault 104 faulty configuration set (for iec 60870-5-103) 131, 139, 195, 203, 222, 223 internal reference voltage error 240 faulty input, light sensor 2 241 faulty input, light sensor 1 253 error in the measuring unit a) can be corrected by restoring factory settings for cpu. B) al...

Page 135

135 local parameterization when the parameters are set locally, the setting parameters can be chosen via the hierarchical menu structure. The wanted language can be selected for parameter descriptions. Refer to the operator ’ s manual for further information. External parameterization relay setting ...

Page 136

Requested functions are selected separately for each input in switchgroups sgb1...5. The digital inputs can also be used to trigger the disturbance recorder; this function is selected with spa parameter v243 . The auxiliary voltage of the relay is connected to terminals x4.1/1-2, see table 5.2.1.-2....

Page 137

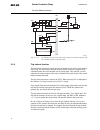

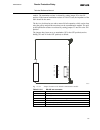

137 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 1 2 3 4 5 6 7 8 9 10 11 12 x3.1 x4.1 x2.1 danger - ris k of elect ric shoc k near inst r u ment terminals ! X5.1 tx rx x5.2 x5.3 x5.4 tx rx a040188 fig. 5.2.1.-1 rear vie...

Page 138

Danger - ris k of elect ric shoc k near inst r u ment terminals ! 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 1 2 3 4 5 6 7 8 9 10 11 12 x3.1 x4.1 x2.1 x5.5 6 5 4 3 2 1 a040187 fig. 5.2.1.-2 rear view of the relay with...

Page 139

139 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 1 2 3 4 5 6 7 8 9 10 11 12 x3.1 x4.1 x2.1 danger - ris k of elect ric shoc k near inst r u ment terminals ! X5.8 8 7 6 5 4 3 2 1 a040189 fig. 5.2.1.-3 rear view of the re...

Page 140

Terminal function ref610a1 1xxxx ref610a12xxxx ref610a15xxxx ref610a51xxxx ref610a52xxxx ref610a55xxxx x2.1-7 x2.1-8 i 0 1 a i 0 0.2 a i 0 5 a i 0 1 a i 0 0.2 a i 0 5 a x2.1-9 - - - - x2.1-10 - - - - x2.1-11 - - - - x2.1-12 - - - - a) the value denotes the rated current for each input. Table 5.2.1.-...

Page 141

141 terminal function x4.1-16 po1, no x4.1-17 x4.1-18 po1 (tcs), no x4.1-19 x4.1-20 - a) optional. Table 5.2.1.-5 digital inputs terminal function x4.1-23 di1 x4.1-24 x4.1-21 di2 x4.1-22 x3.1-1 di3 a) x3.1-2 x3.1-3 di4 a) x3.1-4 x3.1-5 di5 a) x3.1-6 a) optional. 5.2.2. Light sensor input connections...

Page 142

Rear communication of the relay is optional and the physical connection varies with the communication option. Plastic fibre-optic connection if the relay is provided with the optional fibre-optic communication module for plastic fibre, the fibre-optic cables are connected to terminals as follows: ta...

Page 143

143 module. The termination resistor is selected by setting jumper x5 to the on position. If the internal termination resistor of 120 Ω is used, the impedance of the cable should be the same. The bus is to be biased at one end to ensure fail-safe operation, which can be done using the pull-up and pu...

Page 144

Combined fibre-optic connection (plastic and glass) if the relay is provided with the optional fibre-optic communication module for plastic and glass fibre, the plastic fibre-optic cables are connected to terminals x5.3- rx (receiver) and x5.3-tx (transmitter) and the glass fibre-optic cables to ter...

Page 145

145 table 5.2.3.-5 fibre-optic rear connectors (plastic and glass) terminal function x5.3-tx transmitter for plastic fibre x5.3-rx receiver for plastic fibre x5.4-tx transmitter for glass fibre x5.4-rx receiver for plastic fibre rs-485 connection for the dnp 3.0 communication module if the relay is ...

Page 146

Module. The termination resistor is selected by setting jumper x6 or/and x12 to the on position. If the internal termination resistor of 120 Ω is used, the impedance of the cable should be the same. The bus is to be biased at one end to ensure fail-safe operation, which can be done using the pull-up...

Page 147

147 x12 x13 x11 x14 x6 x7 x8 on on on on on on 4-wire 2-wire a040357_2 fig. 5.2.3.-3 jumper location on the dnp 3.0 communication module 5.2.4. Technical data table 5.2.4.-1 dimensions (for dimension drawings, refer to the installa- tion manual) width, frame 177 mm, case 164 mm height, frame 177 mm ...

Page 148

Ripple in the dc auxiliary voltage max 12% of the dc value (at frequency of 100 hz) interruption time in the auxiliary dc voltage without resetting the relay aux rated time to trip from switching on the auxiliary voltage internal over temperature limit +100°c fuse type t2a/250 v table 5.2.4.-3 energ...

Page 149

149 table 5.2.4.-6 signal output so1 and optional so4 and so5 rated voltage 250 v ac/dc continuous carry 5 a make and carry for 3.0 s 15 a make and carry for 0.5 s 30 a breaking capacity when the control-circuit time constant l/r 1 a/0.25 a/0.15 a (5 a/3 a/1 a for series connection of so4 and so5) m...

Page 150

Table 5.2.4.-11 environmental tests and conditions recommended service temperature range (continuous) -10...+55 ° c humidity limit temperature range (short-term) -40...+70 ° c transport and storage temperature range -40...+85 ° c according to iec 60068-2-48 dry heat test (humidity according to iec 6...

Page 151

151 * conducted, rf-emission (mains terminal) en 55011, class a, iec 60255-25 * radiated rf-emission en 55011, class a, iec 60255-25 ce approval complies with the emc directive 89/336/eec and the lv directive 73/23/eec table 5.2.4.-13 standard tests insulation tests: dielectric tests according to ie...

Page 152

Auxiliary voltage the relay requires a secured auxiliary voltage supply to operate. The internal power supply of the relay forms the voltages required by the relay electronics. The power supply is a galvanically isolated (flyback-type) dc/dc converter. When the auxiliary voltage is connected, the gr...

Page 153

153 6. Application examples 6.1. Auto-reclose function 6.1.1. Fast tripping and initiation of shot 1 using two protection stages in several applications, such as fuse-saving applications involving down-stream fuses, tripping and initiation of shot 1 should be fast (instantaneous or short-time delaye...

Page 154

Than the reclaim time (e.G. Half of the reclaim time), the blocking of stage i>> (in this case) will be reset before the ar function. Stage i>> will now be able to continue the ar sequence and the pumping effect will thus be avoided. 6.1.2. Fast tripping and initiation of shot 1 using start signals ...

Page 155

155 at the factory default delay of 300 s for ar i> start delay and ar i 0 > start delay , the start signals will, in practise, not be used for shot initiation. However, if stages i> or i 0 > have been given an idmt characteristic, the factory default delay of 300 s will function as a trip time limi...

Page 156

Example: start by checking that the switches have been properly set: settings function sg1/5=1 blocking of initiation of shot 2 and 3 by the trip signal from stage i>> sg3/1=1 inhibition of the ar function by the trip signal from stage i>>> number of shots = 3 if one or several phase currents * exce...

Page 157

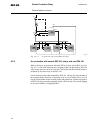

157 q3 q4 po3 po1 q2 3l q1 m1 q5 q6 a040362 fig. 6.2.1.-1 arc protection with one ref 610 6.2.2. Arc protection with several ref 610 relays when using several ref 610 relays (see fig. 6.2.2.-1), a ref 610 protecting an outgoing feeder will trip the circuit breaker of the outgoing feeder when detecti...

Page 158

Po3 po1 q2 3l q1 so1 m1 di1 q4 di1 di1 q6 q5 3i+io di1 3i+io 3i+io q3 3i+io di1 so1 so1 so1 so1 a040363 fig. 6.2.2.-1 arc protection with several ref 610 relays 6.2.3. Arc protection with several ref 610 relays and one rea 101 when realizing an arc protection with both ref 610 relays and an rea 101 ...

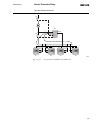

Page 159

159 hso 2 hso 1 q2 3l q1 q4 di1 s2 di1 q6 q5 3i+io di1 s3 3i+io 3i+io trip 3 m1 s4 q3 3i+io s1 di1 a040364 fig. 6.2.3.-1 arc protection with ref 610 and rea 101 feeder protection relay technical reference manual ref 610 ref 610 1mrs755310

Page 160

160

Page 161

161 7. Ordering information when ordering protection relays and/or accessories, specify the following: * order number * hmi language set number * quantity the order number identifies the protection relay type and hardware as described in the figures below and is labelled on the marking strip under t...

Page 162

Ref610c55hsns 01 i/o extension module: h = 3xso and 3xdi (110/125/220/250 v dc) l = 3xso and 3xdi (24/48/60/110/125/220/250 v dc) n = none power supply: h = 100-240 v ac/110-250 v dc, 2xdi (110/125/220/250 v dc), 3xpo 2xso l = 24-60 v dc, 2xdi (24/48/60/110/125/220/250 v dc), 3xpo, 2xso earth-fault ...

Page 163

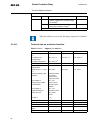

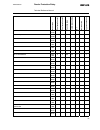

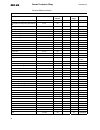

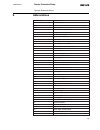

163 8. Check lists table 8.-1 setting group 1 variable group/ channel 1 (r, w, p) setting range default setting custo- mer ’ s setting start value of stage i> 1s1 0.30...5.0 x i n 0.30 x i n operate time of stage i> 1s2 0.05...300 s 0.05 s time/current characteristic for stage i> 1s3 0...9 0 time mu...

Page 164

Variable group/ channel 1 (r, w, p) setting range default setting custo- mer ’ s setting checksum, sgf 5 1s65 0...255 0 checksum, sgb 1 1s71 0...1048575 0 checksum, sgb 2 1s72 0...1048575 0 checksum, sgb 3 1s73 0...1048575 0 checksum, sgb 4 1s74 0...1048575 0 checksum, sgb 5 1s75 0...1048575 0 check...

Page 165

165 variable group/ channel 2 (r, w, p) setting range default setting custo- mer ’ s setting time multiplier n 0 2s15 1.0 … 15.0 1.0 resetting time of stage i 0 > 2s16 0.05...2.50 s 0.05 s start value of stage i 0 >> 2s17 5.0...800% i n 5.0% i n operate time of stage i 0 >> 2s18 0.05...300 s 0.05 s ...

Page 166

Variable group/ channel 2 (r, w, p) setting range default setting custo- mer ’ s setting checksum, sgl 6 2s96 0...8388607 0 checksum, sgl 7 2s97 0...8388607 0 checksum, sgl 8 2s98 0...8388607 0 table 8.-3 control parameters description parameter (channel 0) setting range default setting customer ’ s...

Page 167

167 description parameter (channel 0) setting range default setting customer ’ s setting analogue channel conversion factor and unit for i l1 , i l2 and i l3 m80, m81, m82 factor 0...65535, unit (a, ka), e.G. 10, ka 00001, ct analogue channel conversion factor and unit for the earth-fault current m8...

Page 168

168.

Page 169

169 9. Abbreviations abbreviation description ar auto reclosure ascii american standard code for information interchange cb circuit-breaker cbfp circuit-breaker failure protection cd change detect; compact disk cpu central processing unit crc cyclical redundancy check di digital input eeprom electri...

Page 170

Sgb switchgroup for digital inputs sgf switchgroup for functions sgl switchgroup for leds sgr switchgroup for output contacts so signal output sp second-pulse spa data communication protocol developed by abb tcs trip-circuit supervision udr user-defined register ur unsolicited reporting 170 ref 610 ...

Page 172

Abb oy distribution automation p.O. Box 699 fi-65101 vaasa finland +358 10 2211 +358 10 224 1080 www.Abb.Com/substationautomation 1mrs75531 0 e n 12/2007.