- DL manuals

- ABLE

- Measuring Instruments

- Computrac Vapor Pro Rx

- Installation & Maintenance Instructions Manual

ABLE Computrac Vapor Pro Rx Installation & Maintenance Instructions Manual

Installation & Maintenance Instructions

Computrac® Vapor Pro® Rx

Moisture Analyser

Reading Office

Cutbush Park, Danehill, Lower Earley,

Reading, Berkshire. RG6 4UT. UK.

Tel: +44 (0)118 9311188

Email: info@able.co.uk

Aberdeen Office

Unit 6 Airside Business Park, Kirkhill Industrial Estate,

Dyce, Aberdeen. AB21 0GT. UK.

Tel: +44 (0)1224 725999

Email: ab@able.co.uk

Internet: www.able.co.uk

e-procurement: www.247able.com

Registered in England No: 01851002

VAT No: GB 417 2481 61

Summary of Computrac Vapor Pro Rx

Page 1

Installation & maintenance instructions computrac® vapor pro® rx moisture analyser reading office cutbush park, danehill, lower earley, reading, berkshire. Rg6 4ut. Uk. Tel: +44 (0)118 9311188 email: info@able.Co.Uk aberdeen office unit 6 airside business park, kirkhill industrial estate, dyce, aber...

Page 2: Computrac

Page 2 computrac ® vapor pro ® rx proprietary rights notice the material in this manual contains valuable information developed by arizona instrument llc for use with the computrac ® line of moisture analyzers. No part of this manual can be reproduced or transmitted in any form or by any means, elec...

Page 3

Page 3 table of contents 1. Warnings and safety information .............................................................................................. 4 2. Introduction ..................................................................................................................................

Page 4

Page 4 1. Warnings and safety information the vp-series moisture analyzers comply with the underwriter laboratories inc. Standards and european council directives for electrical equipment for laboratory use, electromagnetic compatibility, and the stipulated safety requirements. However, improper use...

Page 5

Page 5 • substances that release caustic vapors such as acids should be analyzed in the smallest sample size possible to still achieve satisfactory results. If vapors condense on the vp-series moisture analyzers housing parts, stop the testing, wipe the surface clean with a suitable neutralizer and ...

Page 6

Page 6 2. Introduction arizona instrument is proud to continue its leadership role in developing new technology for the moisture analysis industry. The computrac ® vapor pro ® rx is a giant step forward in the measurement of very low moisture levels. A revolutionary moisture analyzer with a detectio...

Page 7

Page 7 3. Principles of operation the computrac ® vapor pro ® rx utilizes a cylinder shaped bottle heater, a dry air-carrier gas flow system and a moisture sensor. The instrument heats a sample of test material contained in a 20 ml septum bottle or sealed freeze dried container. Volatiles, driven of...

Page 8

Page 8 4. Unpacking unpack the instrument and locate the following items: azi part number computrac ® vapor pro ® rx (ct-3500 or ct-3500-l) ct 3500-l or ct-3500-l-100v ct 3500l-220v differences accessory kit y990-0151 1 power cord (varies with area) 200-0002 usa/canada 200-0003 england 200-0008 euro...

Page 9

Page 9 5. Installation place the computrac ® vapor pro ® rx on a solid level surface that is large enough to accommodate the instrument and any accessories or materials that may be required for your work (balance, printer, sample bottles, samples, etc.). Using 1/8" id clear tubing [azi p/n 345-0050]...

Page 10

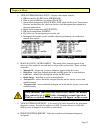

Page 10 • instructions on the drierite ® website tell how to regenerate the drierite ® for continued use. For further information, contact w.A. Hammond drierite co ltd at (937) 376-2927 or at www.Drierite.Com . The following diagrams are not to scale but illustrate the preferred connecting arrangeme...

Page 11: Caution

Page 11 if you plan to use a printer, electronic balance, and/or computer, connect them to the marked connectors at the back of the instrument. The accessory keyboard connects to a fitting on the side nearest the printer connector of the instrument. Connect all accessories while the instrument is tu...

Page 12

Page 12 after a quick view of the instrument identification and the firmware version, the main test screen will appear. Allow the instrument to warm up for 20 minutes..

Page 13

Page 13 6. Check sensor status the display shows the function of the soft-keys at the bottom of the screen. Use the soft-key buttons below the display on the front panel to move through the menu screens and system settings. The function of each soft key will change as needed to provide the selection...

Page 14

Page 14 7. Dryness test for all tests using a bottle, ensure the slick teflon ® side of the septum is to the inside of the bottle or the moisture trapped in the septum will cause false moisture indications. When the display on the main test screen indicates “ready to test”: • press [memry] • then se...

Page 15

Page 15 8. Rh sensor calibration check the water calibration test verifies that the instrument is working properly. This test only takes a few minutes. Arizona instrument recommends that this test be run every day to verify the system’s calibration and accuracy. For greatest accuracy, each test shou...

Page 16

Page 16 when “ready to test” is displayed on the main test screen: • press [memry] • highlight rh sensor cal • press [start] accuracy of results should be within five (5) percent of the capillary capacity, usually 1000 micrograms (950 to 1050 µg). If using a different value capillary tube, use ±5% o...

Page 17

Page 17 9. Rh sensor calibration the relative humidity sensor is calibrated using the same technique as for the calibration check. The difference is in what happens to the results. The calibration calculation may be used to calibrate the sensor, whereas the check calculation is only for information....

Page 18

Page 18 when “ready to test” is displayed on the main test screen: • press [memry], • highlight rh sensor cal • press [start] allow the test to proceed until completed. It should take five to seven (5 to 7) minutes. Note: at least five (5) tests are required for the proper analysis and correction fa...

Page 19

Page 19 10. Temperature calibration tip: the temperature calibration and verification take approximately five (5) hours. Parts required in addition to the vapor pro ® rx amt. Azi part number description 1 y990-0142 (110 vac) y990-0165 (220 vac) temperature calibration kit with 9 vdc, 100 ma, 3.5 mm ...

Page 20

Page 20 turn the vapor pro ® rx on. From the main test screen, press [menu] to bring up the main menu. Press [down] (if necessary) so that calibration menu is highlighted - press [selct]. At the calibration menu, press [down] until temperature calibration is highlighted - press [selct]. Highlight en...

Page 21

Page 21 11. Running moisture tests the computrac ® vapor pro ® rx has 102 available positions to store test parameters for different materials. Storing the parameters ensures that each test of the same material will use the same parameters to assure accurate, reliable, and repeatable testing. Select...

Page 22

Page 22 selecting programmed test temperature • determining the test temperature generally, use the highest temperature possible without causing other ‘undesirable’ conditions (such as melting or excessive release of other volatiles). The instrument is relatively insensitive to the exact temperatu...

Page 23

Page 23 predict: ends the test when the built-in programmed criteria that mathematically calculate the end point moisture content have been satisfied. Use predict if you want to more accurately determine the actual moisture content or are working independently of other standards or methods. This cal...

Page 24

Page 24 selecting bottle purge control • highlight bottle purge control. • press [selct], then [edit]. The bottle purge time is the time dry carrier gas flows through the sample bottle before a test begins. A value of 000 will disable the bottle purge. Any number other than 000 will adjust the purge...

Page 25

Page 25 12. Determining optimum parameters correlation to reference method for best accuracy and speed, the sample should evolve between 200 and 5,000 micrograms of water during the test. Larger amounts will not significantly improve accuracy and will only add to the test time. Smaller quantities wi...

Page 26

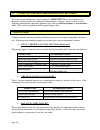

Page 26 the following table gives general guidance for the selection of sample size for various expected moisture levels. Note that the maximum sample size is also limited by the sample bottle. Do not fill the bottle over half full. Table 1 - sample size expected moisture use .001 - .015% or 50-150 ...

Page 27

Page 27 13. Running moisture tests using unsealed bottles tare a clean, empty sample bottle, including the septum and cap. Based on the expected moisture content of the sample, determine optimum sample size using the chart on page 26. However, do not fill the bottle over ½ full so that sufficient ca...

Page 28

Page 28 caution the bottle transport, holder lever, and bottle are very hot when the test is finished and the transport extends. Do not touch the bottle with your bare hands until it has had time to cool. A glove may be needed to press the lever to open the bottle holder. Use the extractor tab at th...

Page 29

Page 29 14. Computrac ® vapor pro ® rx menu system in the idle state, the main test screen displays menu access soft keys at the bottom. From left to right they are: • [memry] key - for accessing stored memory start selections, • [menu] key - for accessing the main menu, and • [graph] key - changes ...

Page 30

Page 30 the [menu] key brings up a screen showing the following options: • memory start menu • stored data menu • calibration menu • setup menu • diagnostic menu • use the [up] and [down] keys to scroll through the selections. • use the [esc] and [selct] keys to “escape” or “select” your choice. Tem...

Page 31

Page 31 memory start menu • add/edit memory start - lists of stored test parameter sets. sample id: (name) test temperatures result display type ending criteria method of entering sample weight bottle purge control. • reorder memory start - allows the stored parameter sets to be rearrang...

Page 32

Page 32 calibration menu • perform rh sensor cal - a program to be used carefully and only when required to calibrate the moisture sensor. This selection uses stored data sets and calibrated microcapillary tubes to calculate and execute the automatic adjustment of the instrument. The result is a sto...

Page 33

Page 33 setup menu • clock setup - set the internal clock for the correct time and date. • ext balance setup - select the type of external balance: azi zsp150/sp150 or sci sa80. For more information, see commonly asked questions. select the tare mode. (fixed weight, manual bottle weight entry, or ...

Page 34

Page 34 • access key setup - allows entry of the passwords used to prevent unauthorized alteration of stored parameter sets, or stored data sets. key enable - off to disable access protection and on to enable access protection master key - controls all functions. calibr key - controls calibrat...

Page 35

Page 35 diagnostic menu • view system sensor status - displays the current value of: rh measured by the rh sensor (rh sensor), flow in rate in milliliters per minute (flow in), sensor block temperature (block rtd), rtd stands for resistive temperature detector and describes the solid-state dev...

Page 36

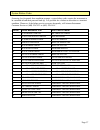

Page 36 15. Condition prompts and system failure codes to assure proper performance, your computrac ® vapor pro ® rx uses an intelligent self- diagnostic system to detect any problems in the hardware, software, sensors or flow system. Operating abnormalities and fault conditions will result in condi...

Page 37

Page 37 system failure codes occurring less frequently than condition prompts, system failure codes require the instrument to be switched off and then powered back up. It is possible for a failure to occur due to a transient condition. However, if the failure persists or occurs frequently, call ariz...

Page 38

Page 38 16. Commonly asked questions below are some commonly asked questions with answers and possible solutions. Q: “what if my calibration check results are out of range?” a: perform a sensor calibration. The computrac ® vapor pro ® rx self-adjusts the internal calibration factors to the high prec...

Page 39: Pressure Is Adequate?”

Page 39 q: “what if the instrument indicates low flow when the input pressure is adequate?” a: #1 the needle may be clogged. Use the following procedure to clean the needle assembly and sensor chamber. For assistance, call azi customer service at 800-528-7411 or 602-470-1414. • set instrument oven t...

Page 40

Page 40 q: “what about interferences?” a: the only known interferences are from ammonium hydroxide, ethanol, methanol and acetone. Samples containing these and similar chemicals should never be used. Additionally, never use these substances as cleaning agents in or on the computrac ® vapor pro ® rx....

Page 41: Vapor Pro

Page 41 q: “how do i set up the computrac ® vapor pro ® rx to use the azi zsp150/sp150 or sci sa800 digital balance?” a: follow the steps below. • beginning at the starting screen, select the prompts in order: • main • setup • ext balance setup • select balance driver • select the azi sp150 or sci s...

Page 42: Caution:

Page 42 17. Repair and maintenance routine maintenance consists of checking the hydrophobic filter for clogging or contamination, checking the needles for clogs, and cleaning the flow path between the needle and the filter. For clean samples, such as most plastic resin pellets, this is seldom necess...

Page 43: ***important ***

Page 43 instrument cover removal • remove the access cover. See access cover removal on page 42. • the sensor block is hot (68 °c); do not touch it with bare hands until it has been allowed to cool down. • remove the instrument cover by unlatching the two latches on the back chassis wall. A long scr...

Page 44: Caution

Page 44 when used, the hydrophobic filter on top of the sensor block must be replaced if it becomes contaminated. Replace it only with the hydrophobic filter available from arizona instrument (azi part no. 990-0059). Before replacing a filter, it is good practice to flush the new filter with dry car...

Page 45: Caution:

Page 45 • install a new filter by rotating it clockwise until finger tight. Reattach the clear tubing. If condensed material is visible in the tubing, replace the tubing. Note that this is a special type of hydrophobic tubing. The proper tubing is available from azi as azi part number 345-0050. • re...

Page 46

Page 46 • if flow in is not 75 ± 2 ml/min (ct-3500-l) or 100 ± 10 ml/min (ct-3500), adjust the pressure regulator. There are two configurations of the flow regulator. • on older instruments: locate the flow regulator that is mounted to the right of the display. loosen the lock nut on the adjustm...

Page 47

Page 47 18. Specifications and ratings these specifications are intended as a guide to proper use of the instrument. Specifications and features will vary with application. Azi product specifications are controlled by iso-9001 procedures and are established and verified during design. They are not t...

Page 48

Page 48 19. Warranty arizona instrument llc warrants the computrac ® vapor pro ® rx to be free from defects in materials or workmanship for two (2) years from the date of purchase for those instruments sold in the usa. All international sales normally carry a one (1) year warranty. Azi will repair o...

Page 49

Page 49 trademark and copyright protection computrac ® , vapor pro ® ,arizona instrument ® , azi ® and the stylized azi are all registered trademarks of arizona instrument llc. Instrument firmware is copyright protected. All specifications subject to change without notice. Us patents nos. 5,712,421;...