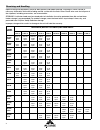

Please record the serial, model #, and mark for the hood and other equipment for future reference. Serial #: _______________________ model #: ______________________ mark: _________________ serial #: _______________________ model #: ______________________ mark: _________________ serial #: ___________...

Receiving and handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

3 maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 grease grabber™ cleaning and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 - 34 filter cleaning frequ...

4 upon receiving the equipment, check for both obvious and hidden damage. If damage is found, record all necessary information on the bill of lading and file a claim with the final carrier. Check to be sure that all parts of the shipment, including accessories, are accounted for. Storage: if a kitch...

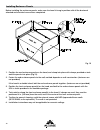

5 note: if you have a back supply plenum (bsp), this must be installed before the hood. Please see page 10. For wall/single island style hoods, prior to installation, check with local authorities having jurisdiction on clearances to combustible surfaces, etc. With the hood still inside its packing c...

6 before hanging the hoods, please verify the hood marks to make sure the correct hood is hung on the correct side. A double island hood is created by installing two wall style hoods back to back. Use the installation procedure described on page 5 for single island hoods; install and level both hood...

7 note: the installation of the canopy hoods shall be in accordance with nfpa 96 (latest edition), standard for ventilation control & fire protection of commercial cooking operations. After the hood is installed, remove all protective plastic. Note: accurex does not recommend walking or standing on ...

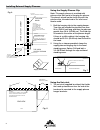

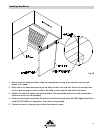

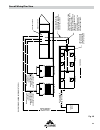

8 hood standing seam hanging clip bolted to plenum shell hanging clip hood front "c" clamp supply plenum shell hanger bracket end view threaded rod hood attach hanging clip to hood standing seam with the supplied "c" clamps (optional: drill and bolt a 1/4-20 ss bolt through the clip and hood standin...

9 attached air curtain canopy style hood attached air curtain canopy style hood backsupply backshelf hood backsupply canopy style hood backsupply canopy style hood variable supply plenum canopy style hood attached air curtain canopy style hood attached air curtain canopy style hood backsupply backsh...

10 • these fasteners are to help maintain the location of the back supply, and are not intended to hold the weight of the back supply unit. • the fasteners should not interfere with the removable air diffusers. • the 31.5 in. (79.375 cm) height is based upon the canopy hood hanging height of 78 in. ...

11 before hanging the hood according to the hood installation instructions, please check the following: 1. Make sure the back supply plenum is properly secured, as described in steps 5 and 6, page 10. . If the ductwork for the back supply will not interfere with the hood installation, it should be c...

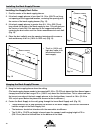

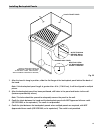

1 before installing the enclosure panels, make sure the hood is hung in position with all the ductwork attached and electrical connections completed. 1. Position the end enclosure panels on the hood, and clamp into place with clamps provided or tack- weld the panels into place (fig 19). . Fasten the...

13 fig. 0 1. After the hood is hung in position, slide the hemmed form on top of the end skirt onto the end panels of the hood. . Drill a hole in the hood end panel to line up with the hole in the end skirt. Attach the end skirt with a 1/4 in. Bolt and cap nut to the inside of the hood, or tack-weld...

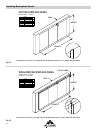

14 fig. 1 installing backsplash panels material gauge — stainless material gauge — stainless insulation — 1 in. (25.4 mm) flat backsplash panel insulated backsplash panel wall wall note: panels up to 46 in. (1168.4 mm) wide ship in one piece; over 46 in. (1168.4 mm) in multiple pieces. Note: panels ...

15 1. After the hood is hung in position, slide the flat flange of the backsplash panel behind the back of the hood. Note: if the backsplash panel length is greater than 46 in. (116.84 cm), it will be shipped in multiple pieces. . After the backsplash panel has been positioned, drill holes in the pa...

16 hood section view deflector to be placed centered under the supply duct collar supply fire damper internal supply chamber hood insulated supply plenum exhaust capture supply location detail for air curtain and combination hanger bracket exhaust plenum duct cut out area duct cut out area supply pl...

17 this is a guide to assist in determining if multiple hoods on one fan can be balanced to have equal static pressure. For multiple hoods on one fan to achieve their designed exhaust flow, all of the hoods must have equal static pressure at their designed exhaust flow. The laws of physics force the...

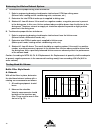

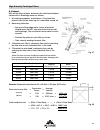

18 baffle filter style hoods a. Exhaust: with all the filters in place, determine the total hood exhaust volume with a rotating vane anemometer as follows: 1. All cooking equipment should be on. . Measure the velocities velocity measurements should be taken at five locations per filter. These must b...

19 255 (4663.44 m/h) 248 (4535.42 m/h) 256 (4681.73 m/h) 240 (4389.12 m/h) 250 (4572 m/h) measure the velocity of each location. A digital .75 in. (70 mm) rotating vane anemometer or equivalent is suggested. The center of the anemometer should be held in. (50 mm) from the face of the filters as show...

0 b. Supply (if applicable): example for perforated face supply 1. Hood set up if the make-up air unit has a temperature control, it should be used to keep the supply air at the desired room discharge air temperature. . Measure velocities divide the perforated face panel into a grid of equal areas, ...

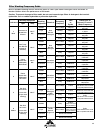

1 14 in. 10 in. .75 in. Fig. 3 fig. 33 fig. 34 nominal filter size (h x l) imperial conversion factor metric conversion factor inches millimeters 16 x 16 400 x 400 1.66 .154 16 x 0 400 x 500 .10 .195 0 x 16 500 x 400 1.96 .18 0 x 0 500 x 500 .40 .3 testing hood air volume 17.5 in. 6 in. 10 in. .75 i...

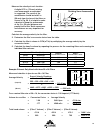

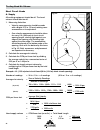

Rotation vane anemometer 2 in. Fig. 35 fig. 36 cartridge filter size imperial conversion factor metric conversion factor 16 in. (400 mm) high with 4 in. (100 mm) high inlet 1.63 1/ ft 3 5.35 1/ m 3 0 in. (500 mm) high with 4 in. (100 mm) high inlet .15 1/ ft 3 7.05 1/ m 3 16 in. (400 mm) high with 7...

3 1/2 width 1/2 height fig. 38 nominal filter size (h x l) imperial conversion factor metric conversion factor inches millimeters 16 x 16 400 x 400 1. Ft .113 m 16 x 0 400 x 500 1.67 ft .155 m 0 x 16 500 x 400 1.1 ft .11 m 0 x 0 500 x 500 1.50 ft .139 m high velocity cartridge filters a. Exhaust wit...

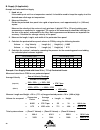

4 a. Exhaust with all the filters in place, determine the total hood exhaust volume with a rotating vane anemometer as follows: 1. All cooking equipment should be off. If the hood has internal short circuit make-up air, it should be turned off. . Measuring velocities • measurement should be taken at...

5 14.5 in. .75 in. .75 in. .5 in. 3.5 in. 14.75 in. 14.5 in. .75 in. .75 in. Fig. 4 fig. 44 fig. 43 nominal filter size (h x l) imperial conversion factor metric conversion factor inches millimeters 16 x 16 400 x 400 1.53 ft .14 m 16 x 0 400 x 500 .00 ft .185 m 0 x 16 500 x 400 .5 ft .09 m 0 x 0 500...

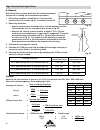

6 short circuit hoods a. Supply all cooking equipment should be off. The hood exhaust should also be off. 1. Measuring velocities • velocity measurements should be made with a digital .75 in. (70 mm) rotating vane anemometer or its equivalent. • one velocity measurement should be taken for every 8 i...

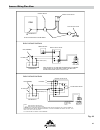

7 power source manual reset relay microswitch microswitch electric gas valve installer provided junction boxes prm basic wiring diagram red (common) power source manual reset relay yellow (n.O) black (n.C.) gas valve microswitch basic wiring diagram red (common) manual reset relay yellow (n.O) black...

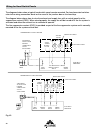

8 field wiring for the ansul snap-action switch option a relay part no. 14702 * k1a and k1b are n.O. When k1 is de-energized manual reset relay part no. 14702 k1* n.O. K1a k1b n.O. Push button switch gas valve see note 3 1 2 3 5 6 7 8 l1 110v/60hz black red brown l2 snap-action switch part no. 42387...

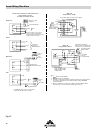

9 hood-1 b hood-1a basic wiring diagram (wiring by others) from make-up air st ar ter #3 to xrub fa n disconnect switc h wired through brea ther tube onl y from make-up air st ar ter #2 to xrub fa n disconnect switc h wired through brea ther tube onl y exhaust f an-1a exhaust f an-1b power p a ne l ...

30 exhaust fan contact supply fan contact exhaust fan contact supply fan contact separate exhaust & supply switching combined exhaust & supply switching the supply fan will be turned off if the fire system is activated, and allow the exhaust fan to continue to operate. Control panel to a fire suppre...

31 on on (no) on on (no) on on on (no) on on (no) on on on (no) on (no) on on on on (nc) on (nc) on on (nc) on (nc) on on (nc) on (nc) off off off off off off off off off on if both are not activated off if both are activated off if either are not activated off if both are not activated on if both a...

3 daily maintenance 1. Wipe grease from exposed metal surfaces on the hood interior using a clean, dry cloth. . Visually inspect the filters or cartridges for grease accumulation. 3. Remove grease cup, empty contents, and replace cup. Weekly maintenance 1. Remove the grease filters or cartridges and...

33 note: never install the second stage filter in the front filter channel. The second stage filter must be installed behind a ul classified grease-x-tractor™ primary filter model he or xx. 1. Slide the top edge of the second stage filter into the top rear filter channel; fig. 53. . Lifting the lowe...

34 1a 1b a b 3a 3b step 1 remove the front xx filters: (1a) remove middle filters first, (1b) slide ends toward middle and remove. 1c c 3c step release the hooks that hold the filters together. Slide the top hook upward and the bottom hook downward until the hook releases. Do this to all filters. St...

35 note: standard cooking will turn the beads yellow in color. Open flame cooking will cause the beads to blacken. Neither affects the performance of the beads. Caution: to prevent damage to filter media, do not wash second stage filters in detergents that contain hydroxides such as sodium hydroxide...

36 troubleshooting problem: exhaust fan is not operating or is not operating at design levels. Is the fan receiving power? Replace fuses, reset circuit breakers, check disconnect. Is the belt loose or broken? Replace or tighten belt. Is the fan rotating in correct direction? Have the electrician cor...

37 troubleshooting problem: smoke blows away before reaching the bottom of the hood. Are there pass-thru windows near the hood? Adjust amount and locations of make-up air to eliminate drafts through the pass-thru windows. Is this an air curtain hood? Turn off or reduce the amount of make-up air. Is ...

38 before calling your manufacturers representative to report a problem have the following information available: 1. Review / summary of troubleshooting section in installation operation manual. . Hood model and serial number. 3. Current cooking equipment line-up. 4. Size of hood (length, width and ...

39 accurex part number registers 45700 4 x 8 aluminum single deflection h-ob 45701 36 x 8 aluminum single deflection h-ob 4570 36 x 8 aluminum single deflection h-ob 45703 44 x 8 aluminum single deflection h-ob 453796 4 x 1 aluminum single deflection h-ob 453797 36 x 1 aluminum single deflection h-o...

Iom canopy hood, rev. 1 march 2008 copyright © 2008 accurex, llc warranty accurex warrants this equipment to be free from defects in material and workmanship for a period of one year from the date of purchase. Any units or parts which prove to be defective during the warranty period will be replaced...