Installation, operation and maintenance manual please read and save these instructions for future reference. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instr...

Kitchen hoods • type i and type ii 2 receiving upon receiving the product, check to ensure all items are accounted for by referencing the delivery receipt or packing list. Inspect each crate or carton for shipping damage before accepting delivery. Alert the carrier of any damage detected. The custom...

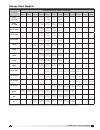

Kitchen hoods • type i and type ii 3 hood model hood depth (multiply by length) for hood weight* 2 ft .609 m 2.5 ft .762 m 3 ft .914 m 3.5 ft 1.067 m 4 ft 1.219 m 4.5 ft 1.372 m 5 ft 1.524 m 5.5 ft 1.676 m 6 ft 1.829 m 6.5 ft 1.981 m 7 ft 2.134 m 7.5 ft 2.286 m xb, xk, xx, xtew 30 lbs/ft 44.64 kg/m ...

Kitchen hoods • type i and type ii 4 supply plenum - weights and dimensions proximity hood weights hood weight is determined using a simple formula. Select the figures provided in columns a and b (see tables) from the three respective categories—hood width, filter type and hood height—based on the ho...

Kitchen hoods • type i and type ii 5 prior to installation prior to installation, check with the authorities having jurisdiction (ahj) on clearance requirements to structures surrounding the hood and other equipment. Verify there is enough space to safely lift hood up into its operating position and...

Kitchen hoods • type i and type ii 6 note all hanger brackets must be used and the hood must be properly supported while lifting to prevent damage or distortion to the hood. Note the hood must be hung evenly. If hung unevenly, this may cause grease drainage problems. Provide additional support if ne...

Kitchen hoods • type i and type ii 7 filler panel installation 1. Uncrate the hood and lay it on the floor with protective material between the hood and the floor. 2. Bolt the filler panels together with 5/16 in. Bolts provided in the hardware package. 3. Position the filler panels to the hood back, and...

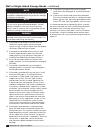

Kitchen hoods • type i and type ii 8 back and front clearance reduction options one inch (2.54 cm) layer of insulation in 3 in. (7.62 cm) back stand-off meets zero inch requirements for clearance to combustible surfaces as outlined under the clearance reduction methods. Three inches (7.62 cm) uninsu...

Kitchen hoods • type i and type ii 9 installing the back supply plenum install the supply duct collar 1. Find the center of the back supply plenum. 2. If the back supply plenum is to have one opening, cut the opening such that it is centered at l /2 from the plenum end. (fig. 1) 3. If the back suppl...

Kitchen hoods • type i and type ii 10 installing front/side external supply plenums using hanger brackets and threaded rod using the uni-strut the uni-strut (supplied by others) supporting the hood may be cantilevered over the end of the hood. Utilizing the external supply plenum’s hanger brackets, ...

Kitchen hoods • type i and type ii 11 installing backsplash panels hood front panel hood end panel backsplash panel slide flange behind back of the hood section view of backsplash panel overlap flat backsplash panel material: stainless insulated backsplash panel material: stainless insulation: 1 in....

Kitchen hoods • type i and type ii 12 installing end skirts 1. After the hood is hung in position, line up the top of the end skirt with the end panels of the hood. 2. Drill a hole in the hood end panel to line up with the hole in the end skirt. Attach the end skirt with a 1/4 in. Bolt and cap nut t...

Kitchen hoods • type i and type ii 13 double island canopy style hoods a double island hood is created by installing two wall style hoods back to back. Use the installation procedure described for single island canopy hoods; install and level both hoods. After leveling, secure the hoods together by ...

Kitchen hoods • type i and type ii 14 a proximity style hood is designed to be mounted close to the cooking appliance and typically incorporates underhang instead of overhang as utilized with canopy style hoods. The proximity design, in addition to the hanger brackets, may include a back mounting fla...

Kitchen hoods • type i and type ii 15 caution according to nfpa 96, ch. 8-3 replacement air: replacement air quantity shall be adequate to prevent negative pressures in the commercial cooking area(s) from exceeding 4.98 pa (0.02 in. Wg). Note the airflow rates were established under controlled labor...

Kitchen hoods • type i and type ii 16 airflow 2 in. (50.8 mm) rotating vane anemometer nominal filter size (h x l) imperial conversion factor metric conversion factor inches millimeters 16 x 16 400 x 400 1.63 .157 16 x 20 500 x 400 2.13 .198 20 x 16 400 x 500 1.90 .177 20 x 20 500 x 500 2.48 .230 tot...

Kitchen hoods • type i and type ii 17 14 in. (355.6 mm) 14 in. (355.6 mm) 2.75 in. (69.85 mm) 2.75 in. (69.85 mm) 10 in. (254 mm) 10 in. (254 mm) fig. 8 nominal filter size (h x l) imperial conversion factor metric conversion factor inches millimeters 16 x 16 400 x 400 1.66 .154 16 x 20 400 x 500 2....

Kitchen hoods • type i and type ii 18 high velocity cartridge filters - rotating vane method with all the filters in place, determine the total hood exhaust volume with a rotating vane anemometer as follows: 1. All cooking equipment should be on. If the hood has internal short circuit make-up air, it...

Kitchen hoods • type i and type ii 19 high velocity cartridge filters - shortridge meter with all the filters in place, determine the total hood exhaust volume with a shortridge meter as follows: 1. All cooking equipment should be on. If the hood has internal short circuit make-up air, it should be t...

Kitchen hoods • type i and type ii 20 grease-x-tractor™ high efficiency filters or grease grabber™ multi-filtration system rotating vane method with all the filters in place, determine the total hood exhaust volume with a rotating vane anemometer as follows: 1. All cooking equipment should be off. If ...

Kitchen hoods • type i and type ii 21 14.25 in. (361.95 mm) 14.25 in. (361.95 mm) 2.75 in. (69.85 mm) 2.75 in. (69.85 mm) 2.75 in. (69.85 mm) 2.75 in. (69.85 mm) fig. 16 14.25 in. (361.95 mm) 14.25 in. (361.95 mm) 2.75 in. (69.85 mm) 2.75 in. (69.85 mm) 2.75 in. (69.85 mm) 2.75 in. (69.85 mm) fig. 1...

Kitchen hoods • type i and type ii 22 perforated face supply - rotating vane method 1. Hood set up. If the make-up air unit has a temperature control, it should be used to keep the supply air at the desired room discharge air temperature. 2. Measure velocities. Divide the perforated face panel into ...

Kitchen hoods • type i and type ii 23 short circuit hood supply - rotating vane method all cooking equipment should be off. The hood exhaust should also be off. 1. Measure velocities velocity measurements should be made with a digital 2.75 in. (69.85 mm) rotating vane anemometer or its equivalent. O...

Kitchen hoods • type i and type ii 24 maximum increase in static pressure for exhaust air balancing baffle (fully closed) 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 500 1000 1500 2000 2500 3000 3500 duct velocity fpm in cr ease i n co ll a r st ai tc pr essur e this is a guide to assist in determining if multipl...

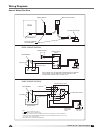

Kitchen hoods • type i and type ii 25 power source manual reset relay microswitch microswitch electric gas valve installer provided junction boxes prm basic wiring diagram red (common) power source manual reset relay yellow (n.O) black (n.C.) gas valve microswitch basic wiring diagram red (common) m...

Kitchen hoods • type i and type ii 26 manual reset relay part no. 426151 ansul snap-action switch part no. 423878 switch contacts shown with ansul automan in the cocked position black red brown l2 neutral l1 hot 110 vac/60hz 5 4 3 2 1 gnd screw power indicator reset a b relay coil electrical rating ...

Kitchen hoods • type i and type ii 27 disconnect switch in control center optional disconnect (field or factory installed) typical exhaust fan typical mua fan with control center typical hood 120 vac for lights (1400w max) h n light switch temp interlock (stand alone) fire suppression system control...

Kitchen hoods • type i and type ii 28 overall wiring plan view for switch panels the diagrams below show typical wiring for combined exhaust and supply switching when the switches are shipped loose for remote mounting, and for hood mounted switches. The diagram shows how to wire the exhaust and supp...

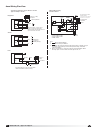

Kitchen hoods • type i and type ii 29 upper hanger upper hanger condensate gutter fig. 19 - correct upper hanger upper hanger upper hanger condensate gutter fig. 20 - incorrect note never install the second stage filter in the front filter channel. The second stage filter must be installed behind a ...

Kitchen hoods • type i and type ii 30 step 3 frequent maintenance periodic inspection - inspect filter fasteners. Verify they are not loose or missing. - each filter may be soaked in hot soapy water for two hours once a month prior to washing if grease build- up is found. - test for grease build-up by...

Kitchen hoods • type i and type ii 31 preference washing equipment cooking equipment chemical grease grabber™ filter baffle filter or grease-x-tractor™ wash frequency frequency required time or cycles type temp. 1 best commercial grade dish washer 180º f minimum griddle dish washer detergent every 3 ...

Kitchen hoods • type i and type ii 32 problem: exhaust fan is not operating or is not operating at design levels. Is the fan receiving power? Replace fuses, reset circuit breakers, check disconnect. Is the belt loose or broken? Replace or tighten belt. Is the fan rotating in correct direction? Have ...

Kitchen hoods • type i and type ii 33 problem: pilot lights are being blown out or cooking equipment is being cooled by make-up air. Are there drafts from make-up air? Try turning off or reducing the amount of make-up air; block off portions of the supply to direct air away from the problem area (te...

Kitchen hoods • type i and type ii 34 replacement parts filters part number filter description (height x width) 457626 16 x 16 aluminum baffle filter 457628 16 x 20 aluminum baffle filter 457632 20 x 16 aluminum baffle filter 457634 20 x 20 aluminum baffle filter 457627 16 x 16 stainless steel baffle fil...

Kitchen hoods • type i and type ii 35 maintenance log date ___________________time _____________ am/pm notes: ___________________________________________ _________________________________________________ _________________________________________________ ______________________________________________...

476370 • grease trap, rev. 2, february 2013 copyright 2014 © greenheck fan corporation 36 as a result of our commitment to continuous improvement, accurex reserves the right to change specifications without notice. Specific greenheck product warranties are located on greenheck.Com within the product a...