- DL manuals

- Aircel

- Dryer

- DHT-100

- Installation And Operation Manual

Aircel DHT-100 Installation And Operation Manual

Installation

and Operation Manual

Aircel

High Inlet Temperature Refrigerated Air Dryer

Models DHT-20, 40, 50, 75, 100, and 125

Installation,

Operation, and

Service Information

This manual is property of the owner. Leave with the unit when set-up and

start-up are complete. Aircel LLC. reserves the right to change design and

specifications without prior notice.

Throughout this manual,

signal words are present

to advise of safety

precautions and/or

standard practices. Obey these

signal words as defined below:

DANGER!

- indicates an

imminently hazardous

situation which, if not

avoided, will result in death

or serious injury.

WARNING!

- indicates a

potentially hazardous

situation which, if not

avoided, could result in

death or serious injury.

CAUTION

! - indicates a

potentially hazardous

situation which, if not

avoided, may result in

minor or moderate injury.

Notice:

- used to address

practices not related to

personal injury.

Illustrations are for reference

only, as actual product may vary.

Patent Number for DHT-50 to 125:

6,691,428

Summary of DHT-100

Page 1

Installation and operation manual aircel high inlet temperature refrigerated air dryer models dht-20, 40, 50, 75, 100, and 125 installation, operation, and service information this manual is property of the owner. Leave with the unit when set-up and start-up are complete. Aircel llc. Reserves the ri...

Page 2: Warning!

2 warning! General safety procedures • improper installation, operation, service or maintenance may contribute to conditions in the work area or facility that could result in personal injury and product or property damage. Check that all equipment is properly selected and sized for the intended use....

Page 3

High inlet temperature refrigerated air dryer 3 contents safety statements .................................................. 2 data sheet ............................................................. 3 refrigerated dryer serial plate label .................... 4 refrigerant safety precautions ........

Page 4

4 refrigerated dryer serial plate label for mfg personnel: affix label here if data sheet on pg. 3 was not completed. Aircel dht series - models 20 - 125.

Page 5: Caution!

High inlet temperature refrigerated air dryer 5 refrigerant safety precautions refrigerant first aid recommendations inhalation if high concentrations are inhaled, immediately remove individual from affected area to an area with a fresh air supply. Keep individual calm. If not breathing, give artifi...

Page 6

6 design parameters type of dryer: refrigerated power supply: 115, 230 volt / single phase / 60hz refrigerant type: r-134a chemical composition: hfc parameter description optimum maximum minimum air pressure (psig) 150-175 200 80 air inlet temperature (°f) 100-180 200 40 ambient temperature (°f) 75 ...

Page 7

High inlet temperature refrigerated air dryer 7 refrigeration circuit refrigerant is cycled through a closed loop system commonly known as high pressure and low pressure. Refrigerant is compressed by the compressor to a gas with high temperature and high pressure, which then travels to the condenser...

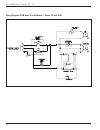

Page 8

8 air inlet air outlet separation cell air to refrigerant heat exchanger refrigerant inlet air refrigerant refrigerant outlet exiting air incoming air stainless steel mist eliminator pre-cooler / heater typical schematic flow diagram (40 - 125 scfm rated models) aircel dht series - models 20 - 125.

Page 9: Caution!

High inlet temperature refrigerated air dryer 9 purpose and intended use high inlet temperature refrigerated air dryers are designed for the purpose of removing moisture from the compressed air by using mechanical refrigeration and providing dew points as low as (48° f- 50° f). These dryers are used...

Page 10: Warning!

10 lifting information 1. Use all lifting points provided. Special care must be used when lifting the dryer to prevent tip- over. 2. Use clevis connectors, not hooks, on lifting slings. 3. Only lift unit under support frame/base by using the fork lift openings provided. Do not lift by piping. 4. Che...

Page 11

High inlet temperature refrigerated air dryer 11 installation 1. Locate unit on a level foundation. Dryer should be mounted on a suitably structured flat and level floor or base that is free from vibration. 2. Install unit to provide adequate clearance for maintenance services. Dryer and accompanyin...

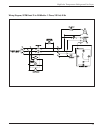

Page 12

12 typical installation aircel dht series - models 20 - 125 typical installation.

Page 13

High inlet temperature refrigerated air dryer 13 preliminary start-up checklist notice: for all models, wait at least 6 hours after transporting or moving of dryer system before starting the dryers. Turn the main power switch to the dryer on, but do not turn the dryer on/off switch to the on positio...

Page 14

14 has been completed, the compressed air outlet valve on the high inlet temperature refrigerated air dryer system can now be slowly opened to supply clean dry compressed air to the facility. 10. After start-up and approximately one month of service, check that all piping and fittings are tight and ...

Page 15: Warning!

High inlet temperature refrigerated air dryer 15 warning! • to avoid possible hazard or injury, the operator should be fully familiar with the high inlet temperature series refrigerated air dryer system and its operation. • when the system is shutdown and power removed, lock out power supply and dep...

Page 16: Warning!

16 service information to reach a field service technician or for technical support, please call the number listed on the manual back cover. Maintenance refrigerated air dryers require very little maintenance for satisfactory operation. Good performance can be expected if the following routine maint...

Page 17

High inlet temperature refrigerated air dryer 17 filter element replacement 1. Depressurize the air system to release the compressed air from the air dryer. Notice: shutting down the air compressor will not depressurize the air dryer unit. Close air line valves before and after dryer and then depres...

Page 18: Warning!

18 troubleshooting warning! • before any service or maintenance work is performed on the high inlet temperature series refrigerated air dryer system, disconnect power supply and lock out power supply and depressurize system before performing maintenance or service work. • follow proper lock out/tag ...

Page 19: Warning!

High inlet temperature refrigerated air dryer 19 gas by-pass valve (or constant expansion valve) to lower refrigerant pressure to required settings. 2. Low refrigerant readings generally indicate: • low ambient temperature - provide ambient temperatures above 15°f. • refrigerant control setting too ...

Page 20

20 problem probable cause remedy water downstream of dryer system or no discharge from separator/ filter. Failed or short circuited timer on drain. Replace timer drain. Failed drain solenoid. Replace timer drain. Bulk liquid entering the dryer from upstream. Check drains on after cooler or air compr...

Page 21

High inlet temperature refrigerated air dryer 21 problem probable cause remedy water downstream and dryer system not working properly or not working (cont). Refrigeration compressor short cycles and cannot maintain suction pressure, dryer undersized. Check airflow (cfm) and dryer capacity. Reduce ai...

Page 22

22 problem probable cause remedy low air pressure downstream due to continuous air flow through the moisture drain line. Failed or short circuited timer on drain. Replace timer drain. Failed drain solenoid. Replace timer drain. Solenoid valve stuck open. Reference the “timer drain stuck open” troubl...

Page 23

High inlet temperature refrigerated air dryer 23 problem probable cause remedy high refrigeration circuit head pressure (compressor is overloaded and gauge is reading out of recommended pressure range). Refrigeration condenser coil fouled or dirty or air flow blocked. Clean / blow off condensing coi...

Page 24

24 compressed air temperature to refrigeration dryer too low. The inlet compressed air temperature must be higher than 40° f. If compressed air temperature is lower than 40° f, turn refrigerated air dryer off. Air may pass through the dryer under this condition, once the compressed air temperature h...

Page 25

High inlet temperature refrigerated air dryer 25 refrigerant material safety data sheet material safety data sheet prepared to u.S. Osha, cma, ansi and canadian whmis standards 1. Product identification chemical name; class: non-flammable gas mixture containing one of the following components in a n...

Page 26

26 refrigerant material safety data sheet, continued non-flammable gas mixture msds - 50040 effective date: april 19, 2005 page 2 of 5 3. Hazard identification emergency overview : this gas mixture is a colorless, odorless gas. Releases of this gas mixture for which nitrogen is the balance gas may p...

Page 27

High inlet temperature refrigerated air dryer 27 non-flammable gas mixture msds - 50040 effective date: april 19, 2005 page 3 of 5 8. Exposure controls - personal protection ventilation and engineering controls : no special ventilation systems or engineering controls are needed under normal circumst...

Page 28

28 refrigerant material safety data sheet, continued non-flammable gas mixture msds - 50040 effective date: april 19, 2005 page 4 of 5 11. Toxicological information 1,1,2-trichloro-1,1,2- trifluoroethane (continued): lc 50 (inhalation-mouse) 260 gm/m 3 /2 hours: behavioral: somnolence (general depre...

Page 29

High inlet temperature refrigerated air dryer 29 15. Regulatory information additional u.S. Regulations: u.S. Sara reporting requirements : this gas mixture is subject to the reporting requirements of sections 302, 304, and 313 of title iii of the superfund amendments and reauthorization act, as fol...

Page 30

30 wiring diagram, scfm rated 20 to 50 models: 1 phase, 120 volt, 60 hz aircel dht series - models 20 - 125.

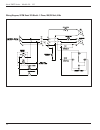

Page 31

High inlet temperature refrigerated air dryer 31 wiring diagram, scfm rated 75 to 100 models: 1 phase, 120 volt, 60 hz.

Page 32

32 wiring diagram, scfm rated 125 model: 1 phase, 208/230 volt, 60 hz aircel dht series - models 20 - 125.

Page 33

33 service notes date service performed notes high inlet temperature refrigerated air dryer.

Page 34

34 service notes, continued date service performed notes aircel dht series - models 20 - 125.

Page 35

Service notes, continued date service performed notes 35 high inlet temperature refrigerated air dryer.

Page 36

© 2013 aircel llc. Printed in usa august 2013 aircel llc. 323 crisp circle maryville, tn 37801 sales@airceldryers.Com orderentry@airceldryers.Com www.Airceldryers.Com parts and service for genuine aircel replacement parts, call: 800-767-4599 www.Airceldryers.Com for faster service, have unit’s model...