- DL manuals

- AIREDALE

- Freezer

- LogiCool InRak

- Technical Manual

AIREDALE LogiCool InRak Technical Manual

Summary of LogiCool InRak

Page 1

Logicool inrak™ technical manual ems52086 fm00542 • direct expansion • chilled water • dual circuit chilled water.

Page 2

Logicool inrak™ it cooling 2 introduction inrak™ technical manual 7462807 v1.11.0_04_2016 customer services warranty, commissioning & maintenance as standard, airedale guarantees all non consumable parts only for a period of 12 months, variations tailored to suit product and application are also ava...

Page 3

En378-1 :2008 (100 year life) it cooling logicool inrak™ 3 introduction inrak™ technical manual 7462807 v1.11.0_04_2016 health and safety important the information contained in this manual is critical to the correct operation and maintenance of the unit and should be read by all persons responsible ...

Page 4

Logicool inrak™ it cooling 4 introduction inrak™ technical manual 7462807 v1.11.0_04_2016 environmental considerations freeze protection airedale recommends the following actions to help protect the unit during low temperature operation. This also includes the units subject to low ambient temperatur...

Page 5

Customer services 2 health and safety 3 manual handling 3 environmental considerations 4 freeze protection 4 environmental policy 4 specifiers guide 7 nomenclature 7 introduction 7 standard and optional features 8 unit overview 10 front door assembly 12 rear door assembly 13 optional features 13 pac...

Page 6

Installation 52 dimensions 52 unpacking and lifting 53 positioning 54 levelling 55 incoming services 56 electrical services incoming cabling 59 interconnecting wiring 60 refrigeration pipe work 62 refrigerant pipe sizing guide 62 oil charging guide 67 system refrigerant charging 68 breaking the syst...

Page 7

Specifiers guide nomenclature logicool inrak lir lir 60 42u x2 50 0 case width (mm x 10 = 600) 60 42u case height x2 c0 cc x1 single circuit, tandem compressor single circuit, single compressor single circuit, chilled water cooling dual circuit, chilled water cooling 400 v / 3ph /n/ 50hz 380v / 3ph ...

Page 8

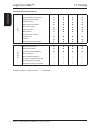

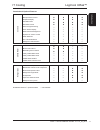

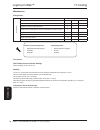

C0 cc x1 x2 door hot swappable fan assembly ● ● ● ● independent fan isolation ● ● ● ● discharge grille ● ● ● ● removable access panel ● ● ● ● secure door locks ● ● ● ● return air grille ● ● ● ● mains isolator ● ● ● ● g4 return door air filter ○ ○ ○ ○ levelling feet ● ● ● ● castors ● ● ● ● anti-recir...

Page 9

Standard and optional features c0 cc x1 x2 controls microprocessor control ● ● ● ● graphical display ● ● ● ● unit status led ● ● ● ● dew point control ● ● ● ● filter change monitoring ○ ○ ○ ○ touch screen display ○ ○ ○ ○ rack pressure management ○ ○ ○ ○ dynamic air volume control ○ ○ ○ ○ water detec...

Page 10

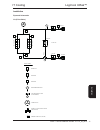

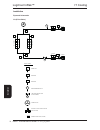

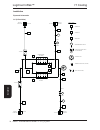

Unit overview standard front door features • hot swappable fan assembly • independant fan isolation • discharge grille • removable access panel • secure door lock standard construction features • levelling feet • castors • anti-recirculation brush seal • side access panels standard rear door feature...

Page 11

Standard front door features • hot swappable fan assembly • independant fan isolation • discharge grille • removable access panel • secure door lock standard construction features • levelling feet • castors • anti-recirculation brush seal • side access panels standard rear door features • secure doo...

Page 12

Logicool inrak™ it cooling 12 introduction inrak™ technical manual 7462807 v1.11.0_04_2016 front door assembly# standard features ec fan motor 310mm diameter backward curved centrifugal fans with ec motors mounted with inlet ring shall be provided to ensure optimum efficiency. The fan section shall ...

Page 13

It cooling logicool inrak™ 13 introduction inrak™ technical manual 7462807 v1.11.0_04_2016 packaging for specific markets units shall be shipped, mounted on wooden pallet and covered with polythene. The pallet shall be mechanically fixed to the unit for transportation only. Optional features sterlin...

Page 14

Logicool inrak™ it cooling 14 introduction inrak™ technical manual 7462807 v1.11.0_04_2016 cooling mode - chilled water cooling (c0) standard features chilled water coil 3/8” plain tube cooling coil with 1.8 mm fin pitch and hydrophilic fins. Dependant on model the coil shall be single (c0) or dual ...

Page 15

It cooling logicool inrak™ 15 introduction inrak™ technical manual 7462807 v1.11.0_04_2016 cooling mode - direct expansion cooling (dx) single ec inverter driven compressor comprising of an ec inverter driven scroll compressor which provides variable control of the system performance, by adjusting i...

Page 16

Logicool inrak™ it cooling 16 introduction inrak™ technical manual 7462807 v1.11.0_04_2016 refrigeration components standard features oil separator fitted to ensure higher than usual levels of circulatory oil of the variable speed compressor stay within the unit, and are not lost to external pipe wo...

Page 17

It cooling logicool inrak™ 17 introduction inrak™ technical manual 7462807 v1.11.0_04_2016 dual power switch dual supply for redundancy and backup in the event of mains supply failure shall be provided. The dual power supply switch ensures that the inrak always has an incoming power supply. For the ...

Page 18

Logicool inrak™ it cooling 18 introduction inrak™ technical manual 7462807 v1.11.0_04_2016 controls display/keypad the display keypad features a simple array of keys to navigate through the in built menus. With an 8 x 22 character (132 x 64 pixel) screen size, back lit in white for improved contrast...

Page 19

It cooling logicool inrak™ 19 introduction inrak™ technical manual 7462807 v1.11.0_04_2016 controls standard features temperature/ humidity sensor unit mounted temperature and humidity sensor shall be supplied as standard. This shall be mounted at the inlet side of the unit monitoring return air con...

Page 20

Logicool inrak™ it cooling 20 introduction inrak™ technical manual 7462807 v1.11.0_04_2016 controls lon bms connection the airedale controllers, using special serial cards, shall be integrated into lonworks® networks. The rs485 and the ftt10 standards shall be supported by the lonworks® serial cards...

Page 21

It cooling logicool inrak™ 21 introduction inrak™ technical manual 7462807 v1.11.0_04_2016 controls dynamic pressure control (dx units) with dx units the fans will operate with constant pressure control except the fan speed will modulate within predefined upper and lower limits, to maintain the targ...

Page 22

Technical data - direct expansion operating limits moisture content operating band m oi st ur e co nt en t k g/ kg d ry a ir hot aisle cold aisle dry bulb temperature °c) 40 % 60 % 70 % 80 % 90 % 20% 10% 10 15 20 25 5 0 15 10 5 0 20 25 30 35 40 10 0% 50 % re lat ive h um idi ty w et bu lb or sa tur ...

Page 23

Technical data - direct expansion performance data - single compressor (x1) full load (x1) ambient (°c) unit air on db / rh 25 30 35 40 46 lir6042u-x123-0 25°c / 42% gross total cooling (kw) 18.83 18.83 21.14 20.33 20.50 power input (kw) 4.43 4.43 6.19 6.84 9.53 eer 4.25 4.25 3.42 2.97 2.15 30°c / 3...

Page 24

Technical - direct expansion performance data - tandem compressor (x2) full load (x2) ambient (°c) unit air on db / rh 25 30 35 40 46 lir6042u-x240-0 25°c / 42% gross total cooling (kw) 27.62 27.62 26.66 25.51 26.53 power input (kw) 7.29 7.29 7.97 8.81 11.51 eer 3.79 3.79 3.34 2.89 2.30 30°c / 32% g...

Page 25

Technical - direct expansion performance data - single compressor (x1) max eer (x1) ambient (°c) unit air on db / rh 25 30 35 40 46 lir6042u-x123-0 25°c / 42% gross total cooling (kw) 10.85 10.85 10.97 10.52 13.66 power input (kw) 2.15 2.15 2.27 2.58 4.43 eer 5.05 5.05 4.83 4.08 3.08 30°c / 32% gros...

Page 26

Technical - direct expansion performance data - tandem compressor (x2) max eer (x2) ambient (°c) unit air on db / rh 25 30 35 40 46 lir6042u-x240-0 25°c / 42% gross total cooling (kw) 14.94 14.94 14.82 14.24 13.80 power input (kw) 3.22 3.22 3.30 3.70 4.34 eer 4.64 4.64 4.49 3.85 3.18 30°c / 32% gros...

Page 27

Intentionally blank it cooling logicool inrak™ 27 inrak™ technical manual 7462807 v1.11.0_04_2016 te ch nic al dx.

Page 28

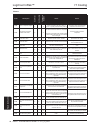

Technical - direct expansion mechanical data - single compressor (x1) logicool inrak™ it cooling 28 inrak™ technical manual 7462807 v1.11.0_04_2016 te ch ni ca l dx (1) nominal data based on 35°c/24% rh air on condition, 35°c ambient temperature, and without optional filtration. (2) minimum air volu...

Page 29

It cooling logicool inrak™ 29 inrak™ technical manual 7462807 v1.11.0_04_2016 te ch nic al dx (1) values given for cooling only unit variants at 11°c evaporating and 46°c condensing. (2) stated motor power is based on maximum electrical power absorbed. (3) values are per compressor. (4) values may c...

Page 30

Technical - direct expansion mechanical data - tandem compressor (x2) logicool inrak™ it cooling 30 inrak™ technical manual 7462807 v1.11.0_04_2016 te ch ni ca l dx (1) nominal data based on 35°c/24% rh air on condition, 35°c ambient temperature, and without optional filtration. (2) minimum air volu...

Page 31

Technical - direct expansion electrical data - tandem compressor (x2) lir6042u-x240-0 lir6042u-x250-0 standard condenser match - cr65 cr80 unit data cooling only (1) nominal run amps a 27.9 29.4 maximum start amps a 89.3 89.3 recommended mains fuse size (4) a 50 50 max mains incoming cable size (5) ...

Page 32

Logicool inrak™ it cooling 32 inrak™ technical manual 7462807 v1.11.0_04_2016 te ch ni ca l dx frequency (hz) db fan load % sound measurement overall db(a) 63 125 250 500 1000 2000 4000 8000 lir6042u-x123 n+1 100 overall lw 85 84 97 79 72 72 72 68 71 sound pressure @ 1m 77 76 89 71 64 64 64 60 63 50...

Page 33

Technical data - chilled water operating limits cooling min max room temperature °c 16 28 room rh at 24°c % 40 55 return air temperature °c 25 40 entering water temperature °c 8 16 leaving water temperature °c 13 21 moisture content operating band m oi st ur e co nt en t k g/ kg d ry a ir minimum wa...

Page 34

Technical data - chilled water performance data - (c0) full load - (c0) water temperatures (°c) air on db / rh 10/16 11/17 12/18 13/19 14/20 lir6042u-c030 25°c / 42% gross total cooling (kw) 20.28 18.67 17.20 15.54 13.34 power input (kw) 0.36 0.36 0.36 0.36 0.36 eer 56.33 51.86 47.78 43.17 37.06 30°...

Page 35

Technical data - chilled water performance data - (c0) full load - (c0) water temperatures (°c) air on db / rh 10/16 11/17 12/18 13/19 14/20 lir6042u-c045 25°c / 42% gross total cooling (kw) 24.53 22.28 20.11 18.02 16.00 power input (kw) 0.97 0.97 0.97 0.97 0.97 eer 25.29 22.97 20.73 18.58 16.49 30°...

Page 36

Technical data - chilled water performance data - (c0) part load - (c0) water temperatures (°c) air on db / rh 10/16 11/17 12/18 13/19 14/20 lir6042u-c030 25°c / 42% gross total cooling (kw) 11.39 10.60 9.95 9.22 8.17 power input (kw) 0.08 0.08 0.08 0.08 0.08 eer 142.38 132.50 124.38 115.25 102.13 3...

Page 37

Technical data - chilled water performance data - (c0) part load - (c0) water temperatures (°c) air on db / rh 10/16 11/17 12/18 13/19 14/20 lir6042u-c045 25°c / 42% gross total cooling (kw) 14.52 13.66 12.81 11.62 9.78 power input (kw) 0.15 0.15 0.15 0.15 0.15 eer 96.80 91.07 85.40 77.47 65.20 30°c...

Page 38

Technical data - chilled water mechanical data - (c0) (1) nominal data based on 35°c/24% air on condition, 10/16°c water temperatures, and without optional filtration. (2) minimum air volume increases to 1m 3 /s if electric heat option is selected. Logicool inrak™ it cooling 38 inrak™ technical manu...

Page 39

Technical data - chilled water electrical data - (c0) it cooling logicool inrak™ 39 inrak™ technical manual 7462807 v1.11.0_04_2016 te ch nic al singl e c irc uit (c 0) lir6042u-c030 lir6042u-c040 lir6042u-c045 lir6042u-c060 standard outdoor unit match - chiller chiller chiller chiller unit data coo...

Page 40

Frequency (hz) db fan load % sound measurement overall db(a) 63 125 250 500 1000 2000 4000 8000 lir6042u-c030 n+1 100 overall lw 81 84 94 79 70 66 59 53 48 sound pressure @ 1m 73 76 86 71 62 58 51 45 40 50 overall lw 65 69 77 63 56 53 46 40 34 sound pressure @ 1m 57 61 69 55 48 45 38 32 26 lir6042u-...

Page 41

Unit and solenoid valve pressure drops (c0) 1 - lir6042u-c045-0, lir6042u-c060-0, lir6042u-c045-1, lir6042u-c060-1. 2 - lir6042u-c030-0, lir6042u-c040-0, lir6042u-c030-1, lir6042u-c040-1. 1 - lir6042u-c045-0, lir6042u-c060-0, lir6042u-c045-1, lir6042u-c060-1. 2 - lir6042u-c030-0, lir6042u-c040-0, li...

Page 42

Technical data - dual circuit chilled water operating limits cooling min max room temperature °c 16 28 room rh at 24°c % 40 55 return air temperature °c 25 40 entering water temperature °c 8 16 leaving water temperature °c 13 21 moisture content operating band m oi st ur e co nt en t k g/ kg d ry a ...

Page 43

Technical data - dual circuit chilled water performance data - (cc) full load - (cc) it cooling logicool inrak™ 43 inrak™ technical manual 7462807 v1.11.0_04_2016 te ch nic al du al c irc uit (c c) water temperatures (°c) air on db (°c)/rh (%) 10/16 11/17 12/18 13/19 14/20 lir6042u-cc22 25 / 42 gros...

Page 44

Technical data - dual circuit chilled water performance data - (cc) full load - (cc) logicool inrak™ it cooling 44 inrak™ technical manual 7462807 v1.11.0_04_2016 te ch ni ca l du al c irc ui t (c c) water temperatures (°c) air on db (°c)/rh (%) 10/16 11/17 12/18 13/19 14/20 lir6042u-cc30 25 / 42 gr...

Page 45

Technical data - dual circuit chilled water performance data - (cc) part load - (cc) water temperatures (°c) air on db (°c) / rh (%) 10/16 11/17 12/18 13/19 14/20 lir6042u-cc22 25 / 42 gross total cooling (kw) 8.24 7.62 6.96 6.23 5.39 power input (kw) 0.09 0.09 0.09 0.09 0.09 eer 91.56 84.67 77.33 6...

Page 46

Technical data - dual circuitl chilled water performance data - (cc) part load - (cc) water temperatures (°c) air on db (°c) / rh (%) 10/16 11/17 12/18 13/19 14/20 lir6042u-cc30 25 / 42 gross total cooling (kw) 10.07 9.18 8.29 7.38 6.40 power input (kw) 0.13 0.13 0.13 0.13 0.13 eer 77.46 70.62 63.77...

Page 47

It cooling logicool inrak™ 47 inrak™ technical manual 7462807 v1.11.0_04_2016 te ch nic al du al c irc uit (c c) intentionally blank.

Page 48

Technical data - dual circuit chilled water mechanical data - (cc) lir6042u-cc22 lir6042u-cc26 lir6042u-cc30 lir6042u-cc40 capacity nom cooling (gross) (1) kw 25.82 31.40 36.03 42.68 nom fan power input (1) kw 0.33 0.67 1.10 2.39 nom eer (1) 78.24 46.87 30.53 17.86 dimensions - w x d x h mm 600 x 13...

Page 49

Technical data - dual circuit chilled water electrical data - (cc) lir6042u-cc22 lir6042u-cc26 lir6042u-cc30 lir6042u-cc40 standard outdoor unit match - chiller chiller chiller chiller unit data cooling only nominal run amps (1) a 1.3 2.4 2.9 4.4 maximum start amps a 2.4 2.4 4.4 4.4 recommended main...

Page 50

Technical data - dual cool chilled water sound data - (cc) frequency (hz) db fan load % sound measurement overall db(a) 63 125 250 500 1000 2000 4000 8000 lir6042u-cc22-0 n+1 100 overall lw 81 84 94 79 70 66 59 53 48 sound pressure @ 1m 73 76 86 71 62 58 51 45 40 50 overall lw 65 69 77 63 56 53 46 4...

Page 51

Technical data - dual cool chilled water unit pressure drops (cc) unit and leak isolation pressure drop (cc) 0 20 40 60 80 100 120 0 0.5 1 1.5 2 2.5 3 pre ss ure d ro p ( kp a) flow rate (l/s) 1 2 1 lir6042u-cc30-0, lir6042u-cc40-0, lir6042u-cc30-1, lir6042u-cc40-1. 2 lir6042u-cc22-0, lir6042u-cc26-...

Page 52

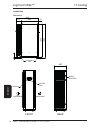

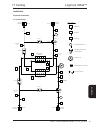

Logicool inrak™ it cooling 52 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n installation dimensions adjustable feet 274 1040 30 1344 1950 1994 44 air discharge air discharge status led display mains isolator front rear 600

Page 53

It cooling logicool inrak™ 53 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n installation unpacking and lifting 746 546 54 44 the unit is to be carefully unpacked, inspected and any damage reported to airedale immediately. All packaging is to be recycled accordingly..

Page 54

Logicool inrak™ it cooling 54 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n adjacent racks must be flush at the front 1040 1200 600 550 860 610 server server inrak installation positioning the inrak requires space at the front and rear of the unit for maintenance purposes. This is...

Page 55

It cooling logicool inrak™ 55 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n installation levelling the unit once positioned shall be levelled. This ensures that the unit has an air tight seal between the inrak and any adjacent server racks. Unit need to be level to ensure that any...

Page 56

Bottom entry - direct expansion logicool inrak™ it cooling 56 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n installation incoming services top entry - direct expansion hole 'a' Ø 50mm controls in/out holes 'b' Ø 50mm mains power supply hole 'c' Ø 50mm hole 'd' Ø 50mm condensate dr...

Page 57

Installation incoming services top entry - chilled water bottom entry - chilled water it cooling logicool inrak™ 57 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n hole 'a' Ø50mm controls in/out holes 'b' Ø50mm mains power supply hole 'c' Ø50mm hole 'd' Ø50mm condensate drain hole '...

Page 58

Bottom entry - dual cool chilled water installation incoming services top entry - dual cool chilled water logicool inrak™ it cooling 58 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n cable and pipe work passing through floors / ceilings are required to be sealed by integral grommet...

Page 59

Installation electrical services incoming cabling the electrical services enter the unit through either the base or the roof of the unit. Termination is via a terminal box at the base of the unit (bottom connections only, top connection direct to isolator). It cooling logicool inrak™ 59 inrak™ techn...

Page 60

Logicool inrak™ it cooling 60 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n installation interconnecting wiring inrak n1 mains incoming supply 1 400v/3~/50hz 380v/3~/60hz 201 l1 202 l2 203 l3 pe n2 mains incoming supply 2 400v/3~/50hz 380v/3~/60hz 204 l1 205 l2 206 l3 pe 860 suppl...

Page 61

It cooling logicool inrak™ 61 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n installation interconnecting wiring inrak rx-tx- network connections (incoming connection) rx+tx+ gnd rx-tx- network connections (outgoing connection) rx+tx+ gnd 881 wired bms connection (modbus, bacnet, l...

Page 62

Refrigerant pipe sizing guide important the pipe sizes/refrigerant charges quoted are for guidance only. It is the responsibility of the installing contractor/site engineer to check the pipe sizes/refrigerant charges are correct for each system installation and application. Split systems may require...

Page 63

It cooling logicool inrak™ 63 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n installation refrigeration pipework oil traps for long vertical rises in both liquid and discharge lines, it is essential that oil traps are located every 4m to ensure proper oil movement/entrapment. In ad...

Page 64

Logicool inrak™ it cooling 64 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n installation liquid line if the system is configured with the inrak higher than the condenser unit it may be required to increase the degree of sub cooling to prevent flashing gas occurring in the liquid l...

Page 65

It cooling logicool inrak™ 65 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n installation calculation of system refrigerant charge (kg) the system refrigerant charge can be calculated using the following equation: sr = lr + ir + or where: sr = total system refrigerant charge (kg) l...

Page 66

Logicool inrak™ it cooling 66 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n installation liquid sub cooling the degree of liquid sub cooling required to prevent flashing of liquid refrigerant can be calculated by the following method. Given the following as an example: • refrigera...

Page 67

It cooling logicool inrak™ 67 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n oil charging guide in order to determine if a system requires additional oil to accommodate for long interconnecting pipe lines and oil traps, a simple calculation can be used to approximate the volume of ...

Page 68

System refrigerant charging system evacuation perform a deep evacuation of the system. Ensure all valves are open and that there are no parts of the system are isolated. Replace any schrader caps to ensure no leaks through the core. A schrader core may open due to the evacuation. Once the evacuation...

Page 69

It cooling logicool inrak™ 69 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n tce pt pt ts ts 5 16 " 5 16 " 5 16 " 5 16 " pt m m psh psh psl psl 5 16 " 5 16 " 5 16 " 5 16 " ts 5 16 " located externally condenser coil common discharge line liquid line liquid expansion line evaporator...

Page 70

Logicool inrak™ it cooling 70 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n ts tc e pt ts 5 16 " 5 16 " 5 16 " pt m psl ts pt psh 5 16 " 5 16 " 5 16 " 5 16 " discharge line condenser coil located externally liquid line liquid expansion line evaporator assembly variable speed scrol...

Page 71

It cooling logicool inrak™ 71 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n key: all items bi bl dr wts m binder point bleed valve drain valve water temperature sensor 2-way regulating ball valve (actuator driven) centrifugal fan normally closed isolating solenoid valve (optional)...

Page 72

Logicool inrak™ it cooling 72 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n key: all items bi bl dr wts m binder point bleed valve drain valve water temperature sensor 2-way regulating ball valve (actuator driven) centrifugal fan normally closed isolating solenoid valve (optional)...

Page 73

It cooling logicool inrak™ 73 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n installation pipework schematics cc (3 port valve) interlaced cw coil right interlaced cw coil left m port c port a wts bi bi dr optional optional circuit 1 inlet leg wts bi optional m port c port a bi opt...

Page 74

Logicool inrak™ it cooling 74 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n installation pipework schematics cc (2 port valve) interlaced cw coil right interlaced cw coil left m port b port a wts bi bi dr optional optional circuit 1 inlet leg wts bi optional m port b port a bi opt...

Page 75

It cooling logicool inrak™ 75 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n commissioning caution please ensure all documents have been completed correctly and returned to airedale technical support to validate warranty. General to be read in conjunction with the commissioning she...

Page 76

Logicool inrak™ it cooling 76 inrak™ technical manual 7462807 v1.11.0_04_2016 ins ta lla tio n commissioning fan removal alarm check alarm state when a fan goes offline. Differential pressure the differential pressure switch should cause the onrak fans to increase / decrease when the server fans are...

Page 77

M ain te nanc e it cooling logicool inrak™ 77 inrak™ technical manual 7462807 v1.11.0_04_2016 caution inputs or outputs not required will not be connected, nor will they appear on the display keypad. Operational maintenance checks owner’s responsibility to ensure that the unit can be maintained corr...

Page 78

M ain te nanc e logicool inrak™ it cooling 78 inrak™ technical manual 7462807 v1.11.0_04_2016 service tools/test equipment • touch up paint • stiff brush safety equipment • safety glasses / goggles maintenance general inspections general inspections task frequency 3 months 12 months 60 months check ...

Page 79

M ain te nanc e it cooling logicool inrak™ 79 inrak™ technical manual 7462807 v1.11.0_04_2016 service tools/test equipment • voltmeter • screwdrivers / allen keys • ammeter safety equipment • safety glasses / goggles maintenance electrical inspection procedures electrical connections ensure all elec...

Page 80

M ain te nanc e logicool inrak™ it cooling 80 inrak™ technical manual 7462807 v1.11.0_04_2016 maintenance refrigeration service tools/test equipment • refrigerant manifold gauges • spanners • voltmeter safety equipment • safety glasses / goggles • gloves • overalls procedures hp/lp safety pressure s...

Page 81

M ain te nanc e it cooling logicool inrak™ 81 inrak™ technical manual 7462807 v1.11.0_04_2016 service tools/test equipment • spanners • manometer • thermometer • refractometer safety equipment • safety glasses / goggles • gloves • overalls maintenance waterside procedures binder points binder points...

Page 82

M ain te nanc e logicool inrak™ it cooling 82 inrak™ technical manual 7462807 v1.11.0_04_2016 service tools/test equipment • small terminal screwdriver safety equipment • electrostatic wristband maintenance controls procedures the following controller settings are to be recorded on the maintenance s...

Page 83

M ain te nanc e it cooling logicool inrak™ 83 inrak™ technical manual 7462807 v1.11.0_04_2016 unit operation checks record the following operating conditions of the unit at stable conditions. • suction pressure (bar) • liquid pressure (bar) • discharge pressure (bar) • suction temperature (°c) • liq...

Page 84

Tr ou ble sh oo tin g logicool inrak™ it cooling 84 inrak™ technical manual 7462807 v1.11.0_04_2016 troubleshooting fault possible cause remedy / action compressor not operating. No power to compressor. Check isolator, fuses, mcbs, contactor and control circuit wiring. Seized compressor, possibly du...

Page 85

Trou ble sh oo tin g it cooling logicool inrak™ 85 inrak™ technical manual 7462807 v1.11.0_04_2016 troubleshooting fault possible cause remedy / action suction pressure too low. Low evaporator airflow. Depending on model: check fan motor speed set point or check fan motors, belts and drives flash ga...

Page 86

Tr ou ble sh oo tin g logicool inrak™ it cooling 86 inrak™ technical manual 7462807 v1.11.0_04_2016 alarms alarm menu display alarm log the alarm page offers a log of the last 100 alarm messages in a scrolling log, pressing the alarm button will enter the alarm page. Consequently the most recent ala...

Page 87

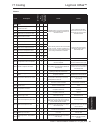

Trou ble sh oo tin g it cooling logicool inrak™ 87 inrak™ technical manual 7462807 v1.11.0_04_2016 alarms code description auto reset unit disabled component disabled cause action al02 clock board fault or not connected ● ● indicates an error with the real time clock on- board the controller. During...

Page 88

Tr ou ble sh oo tin g logicool inrak™ it cooling 88 inrak™ technical manual 7462807 v1.11.0_04_2016 alarms code description auto reset unit disabled component disabled cause action al25 inverter compressor tripped • • inverter compressor trip due to fault on power+ or system pressures during start-u...

Page 89

Trou ble sh oo tin g it cooling logicool inrak™ 89 inrak™ technical manual 7462807 v1.11.0_04_2016 alarms code description auto reset unit disabled component disabled cause action al44 inverter compressor maintenance alarm • indicates that the run hours for the particular component has exceeded the ...

Page 90

Tr ou ble sh oo tin g logicool inrak™ it cooling 90 inrak™ technical manual 7462807 v1.11.0_04_2016 alarms code description auto reset unit disabled component disabled cause action al78 power plus check failed – incompatible drive • power+ inverter is not a compatible model correct power+ model must...

Page 91

91 inrak™ technical manual 7462807 v1.11.0_04_2016 it cooling logicool inrak™ after sales warranty all airedale products or parts (non consumable) supplied for installation within the uk mainland and commissioned by an airedale engineer, carry a full parts & labour warranty for a period of 12 months...

Page 92

Tm_inrak_7462807_v1.11.0_04_2016 head offi ce airedale international air conditioning ltd leeds road rawdon leeds ls19 6jy tel: +44 (0) 113 2391000 fax:+44 (0) 113 2507219 e-mail enquiries@airedale.Com web www.Airedale.Com.