- DL manuals

- AIREDALE

- Freezer

- LogiCool InRak

- Technical Manual

AIREDALE LogiCool InRak Technical Manual

Summary of LogiCool InRak

Page 1

Technical manual logicool inrak™ 300mm chilled water.

Page 2

Logicool inrak™ it cooling 2 introduction inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 customer services warranty, commissioning & maintenance as standard, airedale guarantees all non consumable parts only for a period of 12 months, variations tailored to suit product and application are als...

Page 3

It cooling logicool inrak™ 3 introduction inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 health and safety important the information contained in this manual is critical to the correct operation and maintenance of the unit and should be read by all persons responsible for the installation, com...

Page 4

Logicool inrak™ it cooling 4 introduction inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 environmental considerations airedale ltd endeavours to ensure that the information in this document is correct and fairly stated, but none of the statements are to be relied upon as a statement or represe...

Page 5

Contents customer services 2 health and safety 3 manual handling 3 environmental considerations 4 freeze protection 4 environmental policy 4 specifiers guide 6 nomenclature 6 introduction 6 unit overview 7 general 9 airflow 11 electrical 13 controls 15 lon bms connection 17 technical data - chilled ...

Page 6

Specifiers guide nomenclature introduction the logicool inrak is an efficient in-row it cooling solution for data centre applications. The inrak delivers complete confidence, with redundancy features such as dual power supplies. It is extremely efficient, offering the latest fan technology coupled w...

Page 7

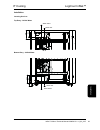

Unit overview standard front door features • discharge grille • removable access panel • secure door lock standard construction features • levelling feet • castors • anti-recirculation brush seal • side access panels standard control features • microprocessor control • graphical display • unit statu...

Page 8

Unit overview standard rear door features • secure door lock • return air grille optional rear door features • g4 return door air filters standard electrical components • electrical switch gear • controller ups backup optional electrical components • condensate pump • energy manager • phase rotation...

Page 9

General system configuration general features cw hydrophilic fin chilled water coil ● top service connections* ○ bottom service connections* ○ axial fan door ● 2 way chilled water regulating valve ● 3 way chilled water regulating valve ○ 2 way picv valve ○ condensate pump** ○ brazed pipework connect...

Page 10

2 way chilled water regulating valve the chilled water valve has an indication of flow on the stem. The actuator is securely attached to the top of the valve so that when there is a demand for cooling the valve opens allowing water to flow through the coil. No demand, the water is shut off allowing ...

Page 11

Airflow system configuration airflow features cw 48v dc axial fans ● g4 filtration ○ constant air volume ○ constant aisle pressure control ● fan capacity control ○ ● standard features ○ optional features – feature not available dc axial fan 48v dc axial fans the fan’s small size shall allow for up t...

Page 12

Fan capacity control capacity control will allow the unit to modulate air volume based on demand for unit cooling. The controller will modulate the chilled water valve alone to try and increase unit cooling performance whilst maintaining the fans at their minimum speed. However, if the cooling perfo...

Page 13

Electrical system configuration electrical features cw ultracap controller backup ● mains isolator ● mcbs ● dual power supply ○ retractable control panel ● internal iec power connection ● ● standard features ○ optional features – feature not available ultracap controller standard electrical features...

Page 14

Internal iec power connection an internal iec power connector shall be fitted. The connector shall be to specification c13 and c14. The power connector shall incorporate a retaining clip to safeguard against accidental disconnection. Retractable control panel dual power supply priority switch mains ...

Page 15

Controls system configuration controls features cw unit controller ● pgd1 display ● pgd touch display with audible alarm (door mounted) ○ supply air temperature control ● return air temperature control ○ additional control temperature sensors ○ tri colour led for easy fault detection ● fire detectio...

Page 16

Supply air temperature control modulation of unit capacity to ensure that user defined supply air set points shall be maintained and/or a high/low return air temperature alarm. During peak demand, the standby units shall temperature assist. Return air temperature control an optional temperature sens...

Page 17

Constant aisle pressure management the inrak shall be fitted with aisle pressure management, which allows the differential pressure across the it equipment to be monitored and controlled to achieve: • positive air pressure in the cold aisle. • negative air pressure in the hot aisle at the server out...

Page 18

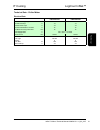

Logicool inrak™ it cooling 18 inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 te ch ni ca l cooling min max room temperature °c 16 28 room %rh at 24°c % 40 55 return air temperature °c 25 40 entering water temperature °c 8 16 leaving water temperature °c 13 24 technical data - chilled water ope...

Page 19

Technical data - chilled water performance data full load all the performance data is based on a shr of 1.0. Maximum duty data is based on achievable duty at maximum air volume. Performance data is based upon a unit with no filtration. Water temperatures (°c) air on db / rh 10/15 11/16 12/18 13/20 1...

Page 20

Technical data - chilled water mechanical data lir3042u-c025 lir3042u-c040 capacity nom cooling (gross) (1) kw 22.1 36.4 nom fan power input (1) kw 0.30 1.55 nom eer (1) 73.67 23.51 dimensions - w x d x h mm 300 x 1120 x 1995 300 x 1120 x 1995 weight - machine / operating kg 223 / 236 223 / 236 cons...

Page 21

Technical data - chilled water electrical data lir3042u-c025 lir3042u-c040 unit data cooling only nominal run amps a 7.5 7.5 maximum start amps a 7.5 7.5 recommended mains fuse size a 16 16 max mains incoming cable size mm² 16 16 mains supply 50hz v 230 / 1ph / + n / 50hz mains supply 60hz v 220 / 1...

Page 22

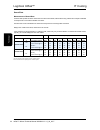

Frequency (hz) db fan load % sound measurement overall db(a) 63 125 250 500 1000 2000 4000 8000 lir3042u-c025 100 overall l w 100 81 82 81 100 92 91 90 87 sound pressure @ 1m 92 73 74 73 92 84 83 82 79 50 overall l w 90 75 78 94 86 86 81 79 74 sound pressure @ 1m 82 67 70 86 78 78 73 71 66 lir3042u-...

Page 23

0 10 20 30 40 50 60 0 0.5 1 1.5 2 2 1 0 10 20 30 40 50 60 0 0.5 1 1.5 2 2 1 technical data - chilled water unit pressure drop 1 - lir3042u-c040 2 - lir3042u-c025 water flowrate (l/s) water flowrate (l/s) pressure drop (kpa) pressure drop (kpa) coil pressure drop curves it cooling logicool inrak™ 23 ...

Page 24

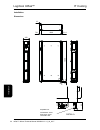

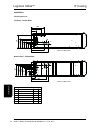

A 12 76.1 1000 31.4 300 1950 60 adjustable foot foot diameter - 25mm stud length - 45mm thread size - m10 detail a 60 44.6 logicool inrak™ it cooling 24 inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 ins ta lla tio n installation dimensions.

Page 25

Notes, 1. All external corners to be protected. 2. Underside of unit to be protected (see above). 3. Unit to be wrapped in bubble wrap. 4. Unit to be strapped to pallet. 1 2 3 4 5 unit to be strapped and wrapped to pallet before fitting exterior case under edge of unit (both sides) to be protected 7...

Page 26

All 18mm parts - sterling board nine off pressed wood corner blocks (97 x 97 x 100mm) 700 25 650 164 160 100 487 1490 100 equal 100 equal 100 100 100 100 595 100 595 100 154 18 100 72 18 18 70 100 310 100 70 logicool inrak™ it cooling 26 inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 ins ta ll...

Page 27

Front rear 90° 90° 210mm 310mm 310mm 360mm 1000mm server server the inrak requires space at the front and rear of the unit for maintenance purposes. This is highlighted above. The fan door can be removed for ease of fan maintenance. Important it cooling logicool inrak™ 27 inrak™ 300mm technical manu...

Page 28

Installation levelling the unit once positioned shall be levelled. This ensures that the unit has an air tight seal between the inrak and any adjacent server racks. Unit need to be level to ensure that any condensate collected is disposed of correctly. Note: the brush seal compresses when the feet a...

Page 29

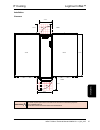

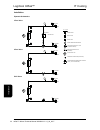

Installation incoming services top entry - chilled water bottom entry - chilled water 169 204 204 60 169 water outlet water inlet water outlet water inlet it cooling logicool inrak™ 29 inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 ins ta lla tio n.

Page 30

Installation incoming services top entry - chilled water incoming services item description size qty a water inlet/outlet Ø 67mm 2 b condensate drain Ø 38mm 1 c primary mains supply (a) - 1 d controls Ø 20mm 3 e bms (ethernet) - 1 f secondary supply (b) - 1 bottom entry - chilled water a a b c d e f...

Page 31

Installation incoming services top entry - chilled water bottom entry - chilled water controls sensor cable connections controls sensor cable connections customer control connections customer control connections retractable control panel electrical services incoming cabling the electrical services e...

Page 32

By-pass leg inlet leg outlet leg cw coil m port c po rt b port a bl wts bi optional optional optional bi bi dr bi inlet leg outlet leg cw coil m port c port a bl wts optional optional bi bi dr bi inlet leg outlet leg cw coil m bl wts optional optional bi bi dr bi 2 port valve picv valve key: all ite...

Page 33

Interconnecting wiring mains power connections l1 n1 pe l2 n2 pe controls connections 502 522 860 861 862 500 864 500 885 886 887 886 888 889 890 889 560 non-critical alarm - n/o 561 non-critical alarm - common 562 non-critical alarm - n/c 563 critical alarm - n/o 564 critical alarm - common 565 cri...

Page 34

Logicool inrak™ it cooling 34 inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 ins ta lla tio n commissioning please ensure all documents have been completed correctly and returned to airedale technical support to validate warranty. General to be read in conjunction with the commissioning sheets...

Page 35

M ain te nanc e it cooling logicool inrak™ 35 inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 inputs or outputs not required will not be connected, nor will they appear on the display keypad. Operational maintenance checks owner’s responsibilities to ensure that the unit can be maintained corre...

Page 36

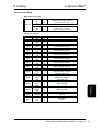

M ain te nanc e logicool inrak™ it cooling 36 inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 maintenance general inspections service tools/test equipment • touch up paint • stiff brush safety equipment • safety glasses / goggles frequency task 3 months 12 months 60 months general inspections c...

Page 37

M ain te nanc e it cooling logicool inrak™ 37 inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 maintenance controls procedures the following controller settings are to be recorded on the maintenance sheet. Service tools/test equipment • small terminal screwdriver safety equipment • electrostatic...

Page 38

M ain te nanc e logicool inrak™ it cooling 38 inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 maintenance electrical inspection procedures electrical connections ensure all electrical connections are tight and correctly terminated. Electrical earthing check that the unit is correctly earthed. V...

Page 39

M ain te nanc e it cooling logicool inrak™ 39 inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 maintenance waterside procedures binder points binder points should be fitted to both the flow and return pipe work adjacent to the unit. Water strainer a water strainer must be fitted to the inlet sid...

Page 40

M ain te nanc e logicool inrak™ it cooling 40 inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 unit operation checks record the following operating conditions of the unit at stable conditions. • waterside pressure drop (kpa) • water flowrate (l/s) • water return temperature (°c) • water supply t...

Page 41

Fault possible cause remedy/action unit will not start no power check power supply to the controller. Wired incorrectly check wire connections in accordance with wiring diagram on control panel. Loose wires check all wires, connections, terminals etc. Fan not operating - power on power supply failur...

Page 42

Tr ou ble sh oo tin g logicool inrak™ it cooling 42 inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 alarms alarm menu display alarm log the alarm page offers a log of the last 100 alarm messages in a scrolling log, pressing the alarm button will enter the alarm page. Consequently the most recen...

Page 43

43 inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 it cooling logicool inrak™ after sales warranty all airedale products or parts (non consumable) supplied for installation within the uk mainland and commissioned by an airedale engineer, carry a full parts & labour warranty for a period of 12 m...

Page 44

44 inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 logicool inrak™ it cooling.

Page 45

45 inrak™ 300mm technical manual 9439563 v1.1.0_02_2017 it cooling logicool inrak™.

Page 46

Tm_inrak_300_9439563_v1.1.0_02_2017 head offi ce airedale international air conditioning ltd leeds road rawdon leeds ls19 6jy tel: +44 (0) 113 2391000 fax:+44 (0) 113 2507219 e-mail enquiries@airedale.Com web www.Airedale.Com.