- DL manuals

- Animo

- Coffee Maker

- OptiVend 1

- Service Enclosure

Animo OptiVend 1 Service Enclosure

Summary of OptiVend 1

Page 1

Choco 1 2 3 4 1 ts /tl 2 ts 3 ts 4 ts hs s o f t w a r e v2.0 ‘easy cup volume adjustment’ service enclosure.

Page 2

Service enclosure 2 01/2007 (rev. 6) v2.0 table of contents preface................................................................................................................................................ 3 1. Operation ............................................................................

Page 3

01/2007 (rev. 6) v2.0 3 service enclosure preface purpose of this document this document serves as a service enclosure that enables qualified service personnel to safely install, program and maintain the appliance. • ' qualified service personnel' are defined as people that can program the appliance...

Page 4

Service enclosure 4 01/2007 (rev. 6) v2.0 1. Max./min. Levelprobes 2. Hot water valves 3. Temperature sensor 4. Heating element 5. Inlet valve 6. Gear moters 7. Ingredient holders 8. Outlet 9. Hot water connection 10. Evaparation extractor 11. Mixer housing 12. Hot water outlet / drink outlet 13. Mi...

Page 5

01/2007 (rev. 6) v2.0 5 service enclosure 1. Operation 1.1 the operation of the hot water system switch the machine off with the on/off switch. The display will light up. The magnetic valve (fig. 1-5) opens and the hot water reservoir is filled to the maximum electrode (fig. 1-1). The heating elemen...

Page 6

Service enclosure 6 01/2007 (rev. 6) v2.0 1.5 safety features • f1 drip tray full (option): the control panel is deactivated when the drip tray is full. Power to the dosing valves (fig. 1-2) is also cut off. • f2 heating : the control panel is deactivated when the hot water reservoir drops below the...

Page 7: Boiler

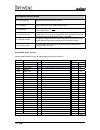

01/2007 (rev. 6) v2.0 7 service enclosure 2. Menu structure 2.1 the user menu boiler 85°c 60°c ? ? ? ? ? See software structure operator -/ service menu ca. 100 (ov choco) ca. 250ml (ov4) fig. 2.

Page 8

Service enclosure 8 01/2007 (rev. 6) v2.0 2.2 the operator/service menu the majority of the settings, including the product settings, are secured with a pin code. This pin code ensures that users cannot gain access to the service menu. We recommend that you do not leave this document with the user a...

Page 9

01/2007 (rev. 6) v2.0 9 service enclosure 2.2.1 the operator menu range: factory settings: no > yes yes 00 :00 00 :00 23 :59 the time from where the machine comes in or comes out (off) the stand-by modus 00 :00 00 :00 = not active 23 :59 00 :00 00 :00 = not active 23 :59 pin-code -> service menu pin...

Page 10

Service enclosure 10 01/2007 (rev. 6) v2.0 2.2.2 the service menu bold = added or changed from software v2.0 range: factory settings: no > yes yes nee > ja ja 0,00 – 2,00 0,10 0,00 = free product token = coin 0-255 120 ml 0 -255 0 0 -65535 depending on recipe 0 -255 depending on recipe 0 -255 depend...

Page 11

01/2007 (rev. 6) v2.0 11 service enclosure range: factory settings: 0 -255 depending on recipe 0 -255 depending on recipe 0 – 65535 depending on recipe 0 – 255 depending on recipe 0 – 255 depending on recipe 0 – 255 depending on recipe 0 – 255 depending on recipe 0 – 255 depending on recipe 0 – 255 ...

Page 12

Service enclosure 12 01/2007 (rev. 6) v2.0 range: factory settings: > no no yes 0-255 40 testing the product without leaving the menu. Service menu structure continuation of settings recipe 1.

Page 13

01/2007 (rev. 6) v2.0 13 service enclosure range: factory settings: 75-97 85 °c (ts/tl 90°c) 0-10 1 °c 70-95 78°c 60-95 60°c choco-1-2 = 5 sec. 0-15 3-4 = 0 sec. No (= stand-by) > yes yes (= in use) > no no yes english continuation of the service menu structure.

Page 14

Service enclosure 14 01/2007 (rev. 6) v2.0 range: factory settings: no > yes yes 0-255 120 sec. 00:00-23:59 the time from where the machine comes in or comes out (off) the stand-by modus 00 :00 00 :00 = not active 23 :59 00 :00 00 :00 = not active 23 :59 > yes no g13 system mdb system > yes no yes c...

Page 15

01/2007 (rev. 6) v2.0 15 service enclosure range: factory settings: 0-65535 + token 0,05 (€ 0,05) 0-65535 + token 0,10 (€ 0,10) 0-65535 + token 0,20 (€ 0,20) 0-65535 + token 0,50 (€ 0,50) 0-65535 + token 1,00 (€ 1,00) 0-65535 + token 2,00 (€ 2,00) no > yes yes 0-65535 1,00 (€ 1,00) 0-255 2 (€0,00) c...

Page 16

Service enclosure 16 01/2007 (rev. 6) v2.0 range: factory settings: 0-25000 12500 cups show the number of drawn cups cup counter wil be cleared continuation of the service menu structure:.

Page 17

01/2007 (rev. 6) v2.0 17 service enclosure range: factory settings: shows the actual boiler temperature shows the actual water level boiler shows actual level drip tray last 16 error reports continuation of the service menu structure:.

Page 18

Service enclosure 18 01/2007 (rev. 6) v2.0 range: factory settings: after loading defaults the pin-code will be again : 2-2-2-2-2 0 – 9 model 4 optivend model choco 0 1 1 2 2 3 3 4 4 1ts/tl 5 2 ts 6 3ts 7 4ts 8 hs 9 use only key 1 - 4. (key 5 - 10 are not availible) enter new pin-code repeat new pin...

Page 19

01/2007 (rev. 6) v2.0 19 service enclosure 2.2.3 additional information operator-/ service menu items operator menu 1.0 free vend select paid dosing or free dosing. 1.1 time set the actual time here. 1.2 switching times set the times when the machine is to be activated here. 1.3 pin-code a pin code ...

Page 20

Service enclosure 20 01/2007 (rev. 6) v2.0 continuation service menu 2.2 settings 2.2.1 machine on is similar to the function of the stand-by button on the service panel. 2.2.2 show clock clock in the upper left corner of the display activated. 2.2.3 language language setting. The language will be e...

Page 21

01/2007 (rev. 6) v2.0 21 service enclosure continuation service menu 2.6 clear counter here, the electronic counter for each separate recipe can be reset to zero. The number of activated rinsing cycles can also be reset to zero. 2.7 clear all cntrs after confirming this menu item, all electronic cou...

Page 22

Service enclosure 22 01/2007 (rev. 6) v2.0 continuation service menu 2.10 read log shows last 16 error messages. 2.11 clear log log is deleted. 2.12 load defaults optivend model choco 0 1 1 2 2 3 3 4 4 1ts/tl 5 2 ts 6 3ts 7 4ts 8 hs 9 attention: when you confirm this setting, all the factory setting...

Page 23

01/2007 (rev. 6) v2.0 23 service enclosure start stop 100 30 70 water dosing waiting time wt cacao dosing 80 60 cacao dosing cacao dosing ☺ fig.3 0 t 3. Recipe settings 3.1 introduction the recipe settings can be changed in this menu. The term recipe settings refers to: waiting times, instant dosing...

Page 24

Service enclosure 24 01/2007 (rev. 6) v2.0 3.2 time scale recipe adjustment wt wt wt wt wt water 1 ingredient 1 ingredient 2 ingredient 3 ingredient 4 mixer1 mixer 2 water 2 water 3 cycle 2 wt wt cycle 1 wt cycle 3 wt choco 1 2 3 / 3ts 4 / 4ts 1ts/tl 15ml/sec. (choco 20ml/sec.) 15ml/sec. 20ml/sec. 0...

Page 25

01/2007 (rev. 6) v2.0 25 service enclosure 3.3 additional information recipe adjustment continuation service menu 2.1 recipe adjust. 2.1.0 recipe 1 2.1.0.0 recipe active temporarily deactivates the relevant product button. 2.1.0.1 price a price per product button can be set with this item. Set to 0....

Page 26

Service enclosure 26 01/2007 (rev. 6) v2.0 3.4 standard recipe settings mathematical example from the following tables (see recepy enclosure) menu no parameter calculation execution 2.1.X.0 recipe active x unit v = ml 2.1.X.1 price 0,10 2.1.X.2 cup volume 120 2.1.X.3 multicup 0 2.1.X.4 cycle 1 wt 0 ...

Page 27

01/2007 (rev. 6) v2.0 27 service enclosure warning • the appliance must be opened to descale the water reservoir. This exposes live parts that can easily be touched. This can lead to life-threatening situations! Warning • the machine must not be submerged or sprayed. • stay with the machine while ma...

Page 28

Service enclosure 28 01/2007 (rev. 6) v2.0 warning • do not leave the unit during maintenance. • always follow the prescriptions, that are delivered with the used descaling solvent. • it is advisable to wear protecting glasses and gloves during descaling. • after descaling, run the appliance through...

Page 29

01/2007 (rev. 6) v2.0 29 service enclosure 9. Put the plug back in the socket and switch the machine back on. The reservoir will now heat up. Place the measuring cup under the outlet (fig. 8-2) and activate the cleaning program at least 3x (fig.8-1) so that the acid solution is discharged from the w...

Page 30

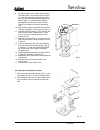

Service enclosure 30 01/2007 (rev. 6) v2.0 5. Accessibility of the various components service hatch dosing valves evaporation box right sidepanel power supply mixer(s) on/off switch ventilator inside door interface display service panel left sidepanel / rearpanel boiler / water reservoir level / ntc...

Page 31

01/2007 (rev. 6) v2.0 31 service enclosure 5.1 electronics overview warning avoid electrostatic discharges onto the (esd) controls during repairs or maintenance work. • main controls pp34a 5.1.1 • power supply 230 vac: 24v 65w 5.1.2 • interface pp42 5.1.3 display 5.1.1 main controls the pp34a (fig. ...

Page 32

Service enclosure 32 01/2007 (rev. 6) v2.0 5.1.2 power supply the 24 vdc power supply (fig. 13) consists of a 24 vdc – 65 w linked power supply unit and can be accessed by removing the rear wall. The power supply is located against the back of the main controls. Fig. 13 input 85-265vac output 24vdc ...

Page 33

01/2007 (rev. 6) v2.0 33 service enclosure 5.1.3 interface / display the pp42 interface connects all components in and on the door and is linked to the main control pp34a with a flat cable. The contrast of the display can be measured with the potentiometer. Fig. 14 5 – coin mechanism (optional) 3 – ...

Page 34

Service enclosure 34 01/2007 (rev. 6) v2.0 5.2 adjusting the hot water dosing valves the hot water dosing valves can be accessed by removing the service hatch behind the ingredient holders. Water can be supplied to the mixer beakers with the aid of the ‘water 1’and ‘water 2’ dosing valves. The ‘wate...

Page 35

01/2007 (rev. 6) v2.0 35 service enclosure 1 2 3 4 5 6 fig.17 fig. 18 fig. 19 5.3 coin mechanism (optional) the optivend is optionally available with a coin mechanism suitable for euros (€ 0.05 to 2.00) it is also easy to program the coin mechanism for tokens. It is also possible to subsequently fit...

Page 36

Service enclosure 36 01/2007 (rev. 6) v2.0 5.3.3 how to activate a existing token the following tokens pictured on the right (fig 20) are already programmed in the coin mechanism. Set the service menu as written in chapter below, starting from point 4. 5.3.4 how to programming a new token • required...

Page 37

01/2007 (rev. 6) v2.0 37 service enclosure 5.3.5 how to accept euros & tokens set a the price (fig. 24) at menu item 2.1.0.1 until 2.1.9.1 the recipe keys are unlocked after inserting enough money or a token is inserted. 5.3.6 how to accept tokens only (no euros) set price (fig. 25) for token in men...

Page 38

Service enclosure 38 01/2007 (rev. 6) v2.0 6. Troubleshooting warning • the plug must be taken out of the socket if the appliance has to be opened for cleaning or repairs. Introduction before attempting to locate the defect, check that all parts are still in place. For this purpose, remove the rear ...

Page 39

01/2007 (rev. 6) v2.0 39 service enclosure 6.3 troubleshooting table display text possible cause action f1 drip tray full drip tray is full. Empty the drip tray, message disappears. Boiler is warming up or has reached the min. Boiler temperature. The message disappears when the boiler has reached th...

Page 40

Service enclosure 40 01/2007 (rev. 6) v2.0 e7 minimum electrode error. Call the dealer or service engineer. Engineer minimum electrode error. Min. Electrode does not see water but the max. Electrode does. Check the electrode. Tip: check the functioning of the level sensors with service menu 2.9.1. P...

Page 41

01/2007 (rev. 6) v2.0 41 service enclosure the electrodes are dirty. Check the electrodes. Clean the electrodes. The magnetic valve does not close. Switch the machine off. Replace the magnetic valve if it does not close. The main controls are faulty. Test the controls. Replace the i/o control (#). 6...

Page 42

Service enclosure 42 01/2007 (rev. 6) v2.0 6.4 circuit diagram (optivend 4) s1 main switch s2 dry boil protection s3 service panel s4 key panel e1 heating element e2 main control board pp34 e3 interface pp42 e4 power supply e5 display k1 power relay kw1 inlet valve 1 hw1 hot water dosing valve 1 hw2...

Page 43

01/2007 (rev. 6) v2.0 43 service enclosure rev. 6 01/2007 art.Nr 09897 animo b.V. Headoffice dr. A.F. Philipsweg 47 p.O. Box 71 9400 ab assen the netherlands tel. No. +31 (0)592 376376 fax no. +31 (0)592 341751 e-mail: info@animo.Nl internet: http://www.Animo.Eu.