- DL manuals

- Anritsu

- Measuring Instruments

- Site Master S810D

- User manual

Anritsu Site Master S810D User manual

Summary of Site Master S810D

Page 1

Cable and antenna analyzer 25 mhz to 20 ghz site master ™ s810d/s820d user’s guide ms2712 site master s331d site master site master.

Page 3: Warranty

Warranty the anritsu product(s) listed on the title page is (are) warranted against defects in materials and workmanship for one year from the date of shipment. Anritsu's obligation covers repairing or replacing products which prove to be defec- tive during the warranty period. Buyers shall prepay t...

Page 7: Table Of Contents

Table of contents chapter 1 general information introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 8: Appendix A Reference Data

Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13 using the soft carrying case. . . . . . . . . . . . . . . . . . . . . . . . . 3-14 chapter 4 cable and antenna analyzer measurements introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 9: Chapter 1

Chapter 1 general information introduction this chapter provides a description, performance specifications, optional accessories, pre- ventive maintenance, and calibration requirements for the site master™ models s810d and s820d. Throughout this manual, the term site master will refer to the s810d a...

Page 10: Standard Accessories

Standard accessories the following items are supplied with the site master: part number description 10680-00001 site master s810d/s820d user’s guide 65717 soft carrying case 633-27 rechargeable nimh battery 40-168 ac/dc adapter 806-62 automotive cigarette lighter/12 volt dc adapter 800-441 serial in...

Page 11: K Connectors

Coaxial calibration components k connectors part number description 22k50 precision k(m) short/open, 40 ghz 22kf50 precision k(f) short/open, 40 ghz 28k50 precision termination, dc to 40 ghz, 50 w, k(m) 28kf50 precision termination, dc to 40 ghz, 50 w, k(f) 15kkf50-1.5a armored test port cable, 1.5 ...

Page 12: Coaxial Adapters

Coaxial adapters part number description 34nn50a precision adapter, dc to 18 ghz, n(m)-n(m), 50 ohm 34nfnf50 precision adapter, dc to 18 ghz, n(f) - n(f), 50 ohm 34rknf50 precision ruggedized adapter, k(m)-n(f), dc to 18 ghz, 50 ohms 34rsn50 precision ruggedized adapter, wsma(m)-n(m), dc to 18 ghz, ...

Page 13: Performance Specifications

Performance specifications the specifications on the following pages describe the warranted performance of the instru- ment at 23°c ± 3°c when the unit is calibrated with the appropriate coaxial calibration kit for the built-in test port connector. A warm-up time of 15 minutes should be allowed prio...

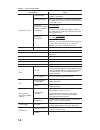

Page 14: 1-6

Description value distance to fault vertical range: return loss: 0.00 to 60 db vswr: 1.00 to 65.53 horizontal range: 0 to (# of data points –1) x horizontal resolution to a maximum of 1197m (3929 ft), # of data points = 130, 259, or 517 horizontal resolution coaxial cable (rectangular windowing): ( ...

Page 15: 1-7

Description value options value power monitor (s8x0d/5) detector range: –50 to +20 dbm, 10 nw to 100 mw offset range: 0 to +60 db display range: –80 to 80 dbm resolution: 0.1 db, 0.1 xw (x = n, m, m based on detector power) measurement accuracy: ±1db maximum for >–40 dbm and 560-7n50b ports: s8x0d: ...

Page 16: Preventive Maintenance

Preventive maintenance site master preventive maintenance consists of cleaning the unit and inspecting and clean- ing the rf connectors on the instrument and all accessories. Clean the site master with a soft, lint-free cloth dampened with water or water and a mild cleaning solution. Caution: to avo...

Page 17: Esd Precautions

The site master itself is self-calibrating, meaning that there are no field-adjustable compo- nents. However, the osl calibration components are crucial to the integrity of the calibra- tion and therefore, must be verified periodically to ensure performance conformity. This is especially important i...

Page 18: Customer Service

Customer service for the latest service and sales contact information in your area, please visit: http://www.Anritsu.Com/contact.Asp 1-10 chapter 1 general information.

Page 19: Chapter 2

Chapter 2 functions and operations introduction this chapter provides a brief overview of the site master functions and operations, provid- ing the user with a starting point for making basic measurements. For more detailed infor- mation, refer to the specific chapters for the measurements being mad...

Page 20: Display Overview

Battery charging illuminates when the battery is being charged. The indicator automatically shuts off when the battery is fully charged. External power illuminates when the site master is being powered by the external charging unit. Serial interface rs232 db9 interface to a com port on a personal co...

Page 21: Front Panel Overview

Front panel overview the site master menu-driven user interface is easy to use and requires little training. Hard keys on the front panel are used to initiate function-specific menus. There are four function hard keys located below the status window: mode, frequency/distance, amplitude and measure/d...

Page 22: Function Hard Keys

Function hard keys mode opens the mode selection box (below). Use the up/down arrow key to select a mode. Press the enter key to implement. Note: available mode selections will vary according to model number and op- tions installed. Freq/dist displays the frequency or distance to fault soft key menu...

Page 23: Keypad Hard Keys

Keypad hard keys this section contains an alphabetical listing of the site master front panel keypad controls along with a brief description of each. More detailed descriptions of the major function keys follow. The following keypad hard key functions are printed in black on the keypad keys. 0-9 the...

Page 24: 2-6

The following keypad hard key functions are printed in blue on the keypad keys. This key is used to adust the brightness of the color display. Use the up/down arrow key and enter to adjust the display brightness. Auto scale automatically scales the status window for optimum resolution in cable and a...

Page 25: Soft Keys

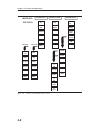

Soft keys each keypad key opens a set of soft key selections. Each of the soft keys has a correspond- ing soft key label area on the status window. The label identifies the function of the soft key for the current mode selection. The following figures show the soft key labels for each mode selection...

Page 26: 2-8

2-8 chapter 2 functions and operations mode=dtf: softkeys: bottom top freq/dist amplitude d2 dtf aid more d1 loss cable window back prop vel waveguide loss waveguide waveguide coax cable window back cutoff freq page up select trace page down back bottom of list delete trace delete all traces top of ...

Page 27: 2-9

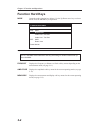

Chapter 2 functions and operations 2-9 mode=power monitor: softkeys: units rel offset db zero amplitude figure 2-7. Power monitor mode soft key labels (option 5) options hour clock status minute self test month language english day year units printer change date format back back gps reset gps on/off...

Page 28: 2-10

2-10 chapter 2 functions and operations options hour clock status minute self test month language english day year printer change date format back back gps reset gps on/off back reset quality location figure 2-9. Sys key menu in power monitor mode.

Page 29: 2-11

Freq/dist displays the frequency and distance menu depending on the measurement mode. Frequency menu the frequency and distance menu for cable and antenna analyzer measurements provides for setting sweep frequency end points when freq mode is selected. Se- lected frequency values may be changed usin...

Page 30: 2-12

Distance sub-menu (coax cable) provides for setting the cable loss and relative propagation velocity of the coax- ial cable. Selected values may be changed using the up/down arrow key or key- pad. Q loss — opens the cable loss parameter for data entry. Enter the loss per meter (or foot) for the type...

Page 31: 2-13

Q resolution — opens the status window to change the resolution. Choose 130, 259, or 517 data points. (in dtf mode, resolution can only be adjusted through the dtf aid table.) q single sweep — toggles the sweep between single sweep and continuous sweep. In single sweep mode, each sweep must be activ...

Page 32: 2-14

Q on/off — turns the selected marker on or off. Q edit — opens the selected marker parameter for data entry. Press enter when data entry is complete or escape to restore the previous value. Q delta (mx-m1) — displays delta amplitude value as well as delta fre- quency or distance for the selected mar...

Page 33: 2-15

Limit pressing limit in cable and antenna analyzer frequency and distance mode acti- vates a menu of limit related functions. Use the corresponding soft key to select the desired limit function. Then use the up/down arrow key to change its value, which is displayed in the message area at the bottom ...

Page 34: 2-16

Sys in cable and antenna analyzer or optional power monitor mode, pressing the sys key displays the following system menu soft key selections: q options — displays a second level of functions: q units — select the unit of measurement (metric or english). Q printer — displays a menu of supported prin...

Page 35: Power Monitor Menus

Power monitor menus selecting power monitor from the mode menu causes the soft keys, described below, to be displayed and the corresponding values shown in the message area. The following soft keys are available when the amplitude key is pressed. Q units — toggles between dbm and watts. Q rel — turn...

Page 36: Symbols

Symbols table 2-1 provides a listing of the symbols used as condition indicators on the tft lcd status window. Self test at turn-on, the site master runs through a series of quick checks to ensure the system is functioning properly. Note that the voltage and temperature are displayed in the lower le...

Page 37: Error Messages

Error messages self test error messages a listing of self test error messages is provided in table 2-2. Chapter 2 functions and operations 2-19 error message description battery low battery voltage is less than 9.5 volts. Charge battery. If condition per- sists, call your anritsu service center. Ext...

Page 38: Range Error Messages

Range error messages a listing of range error messages is provided in table 2-3. 2-20 chapter 2 functions and operations error message description range error:f1 > f2 the start (f1) frequency is greater than the stop (f2) frequency. Range error:d1 > d2 the start (d1) distance is greater than the sto...

Page 39: General Error Messages

General error messages a listing of general error messages is provided below. Chapter 2 functions and operations 2-21 error message description cal incomplete a complete open, short, and load calibration must be performed before calibration can be turned on. Dist requires f1 valid distance to fault ...

Page 40: Battery Information

Battery information charging a new battery note: use only anritsu approved batteries, adapters and chargers with this in- strument. The nimh battery supplied with the site master has already completed three charge and discharge cycles at the factory and full battery performance should be realized af...

Page 41: 2-23

If the ac/dc adapter is left plugged into the system and the battery level drops below 11.9 volts, the charger will automatically begin a unique charge cycle that will quickly recharge the battery to 100% capacity. This unique charge cy- cle will safely keep the battery at a full charge as long as t...

Page 42: 2-24

Determining remaining battery life when the ac-dc adapter is unplugged from the site master, the battery indicator symbol will be continuously displayed at the top left corner of the site master display (figure 2-10). A totally black bar within the battery icon indicates a fully charged battery. Whe...

Page 43: Battery Life

Battery life the nimh battery will last longer and perform better if allowed to completely discharge before recharging. For maximum battery life, it is recommended that the nimh battery be completely discharged and recharged once every three months. It is normal for nimh batteries to self-discharge ...

Page 44: 2-26

Important battery information · with a new nimh battery, full performance is achieved after three to five complete charge and discharge cycles. The nimh battery supplied with the site master has already completed three charge and discharge cycles at the factory. · recharge the battery only in the si...

Page 45: Chapter 3

Chapter 3 getting started introduction this chapter provides a brief overview of the anritsu site master. The intent of this chapter is to provide the user with a starting point for making basic cable and antenna analyzer and power monitor measurements. Procedures that are specific to cable and ante...

Page 46: Selecting The Frequency

Cw source module setup with option 22 before making cable loss - two port measurements with option 22 enabled, the cw source module must be installed. Note: to avoid damaging the site master, always turn off its power before connecting/disconnecting the cable from the cw source module to or from the...

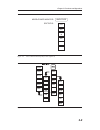

Page 47: Calibration

To manually select the frequency range for an osl calibration: step 1. Press the freq/dist key. Step 2. Press the f1 soft key. Step 3. Enter the desired start frequency using the key pad or the up/down arrow key. Step 4. Press enter to set f1 to the desired frequency. Step 5. Press the f2 soft key. ...

Page 48: Osl Calibration Procedure

Q when an open is connected, a trace will be displayed between 0-20 db. Q when a short is connected, a trace will be displayed between 0-20 db. Q when a load is connected, a trace will be displayed between 0-50 db. The following procedures explain standard osl calibration. Refer to figure 3-2 for a ...

Page 49: 3-5

Connector is selected. The selected connector type is marked by the symbol (*) and is also displayed at the bottom of the screen. Step 4. If the correct dut connector is selected, proceed with the calibration (go to step 5). To choose a different connector, use the up/down arrow key to high- light t...

Page 50: 3-6

Waveguide osl calibration step 1. Select the appropriate frequency range, as described on page 3-2. Step 2. Press the start cal (3) key to start the osl calibration. Step 3. Select the waveguide soft key. The waveguide flange selection menu will ap- pear, with the start calibration function highligh...

Page 51: 3-7

Note: the calibration coefficients stored in the site master and used during the osl or wg calibrations are specific to the calibration components listed as accessories for the s810d or s820d. Using calibration components that are not listed as accessories may lead to inaccurate calibration results,...

Page 52: Auto Scale

Auto scale the site master can automatically set the scale to the minimum and maximum values of the measurement on the y-axis of the graph. This function is particularly useful for mea- surements in swr mode. To automatically set the scale, press the auto scale key. The site master will automaticall...

Page 53: Save And Recall A Setup

Step 1. Press the mode key. Step 2. Select dtf return loss or dtf swr mode. The site master automatically sets d1 to zero. Step 3. Press the d2 soft key. Step 4. Enter the appropriate d2 value for the maximum length of the transmission line and press the enter key to set the d2 value. Step 5. Press ...

Page 54: Recalling A Display

Step 2. Use the soft keys to enter a label for the saved trace. For example, to save a display with the name “tx1 return loss” press the soft key group that contains the letter “t” then press the “t” soft key. Press the soft key group that contains the letter “x” then press the “x” soft key. Press t...

Page 55: Adjusting Limits

Step 3. Press the edit soft key and enter an appropriate value using the keypad or up/down arrow key to move the marker without redrawing the trace. Pressing the on/off soft key activates or deactivates the m1 marker function. Step 4. Press the back soft key to return to the markers menu. Step 5. Re...

Page 56: 3-12

The site master also does not allow vertical limit segments. A limit segment in which the start and end frequencies are the same, but the limit values are dif- ferent, cannot be specified. Enabling the limit beep both limit types can indicate a limit violation by enabling the limit beep. An audible ...

Page 57: Printing

Printing printing is accomplished by selecting an available printer and pressing the print key as de- scribed below. Refer to the particular printer operating manual for specific printer settings. Printing a screen step 1. Obtain the desired measurement display. Step 2. Press the sys key and the opt...

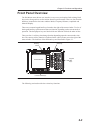

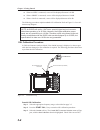

Page 58: 3-14

Using the soft carrying case the soft carrying case has been designed such that the strap can be unsnapped to allow the case to be easily oriented horizontally; thus allowing the anritsu controls to be more easily accessed (figure 3-5). 3-14 chapter 3 getting started figure 3-5. Using the site maste...

Page 59: Chapter 4

Chapter 4 cable and antenna analyzer measurements introduction this chapter provides a description of cable and antenna analyzer measurements, including line sweeping fundamentals and line sweeping measurement procedures, available when the site master is in frequency or dtf mode. Line sweep fundame...

Page 60: Fixed Cw Mode

The performance of a transmission feed line system may be affected by excessive signal re- flection and cable loss. Signal reflection occurs when the rf signal reflects back due to an impedance mismatch or change in impedance caused by excessive kinking or bending of the transmission line. Cable los...

Page 61: 4-3

Use this feature with caution, as the later introduction of an interfering signal might be mis- taken for a problem with the antenna or cable run. If fixed cw is on during a normal rl or swr measurement, the site master may be more susceptible to interfering signals. Interfering signals can make the...

Page 62: 4-4

Step 3. Set the start and stop frequencies, automatically by selecting a signal standard or manually using the f1 and f2 soft keys, as described on page 3-3. Step 4. Calibrate the site master as described on page 3-3. Step 5. Connect the device under test to the site master. A trace will be displaye...

Page 63: One Port Testing

Cable/waveguide loss measurement the transmission feed line insertion loss test verifies the signal attenuation level of the ca- ble system in reference to the specification. This test can be conducted with the site master in one of two ways: one port testing, using either cable loss - one port mode...

Page 64: 4-6

Device under test q transmission feed line procedure - cable loss - one port mode step 1. Press the mode key. Step 2. Select freq-cable loss - one port using the up/down arrow key and press enter . Step 3. Set the start and stop frequencies, f1 and f2, as described on page 3-3. Step 4. Connect the t...

Page 65: 4-7

Step 6. Connect the device under test to the site master phase stable test port exten - sion cable. A trace will be displayed on the screen as long as the site master is in sweep mode. Connect a short to the other end of the device under test ca- ble. Step 7. Press the amplitude key and set top and ...

Page 66: 4-8

4-8 chapter 4 cable & antenna measurements figure 4-5. Typical transmission line cable loss trace with smoothing applied.

Page 67: Two Port Testing

Two port testing for cable system loss values of less than 10db, the standard cable loss – one port mea- surement described in the previous section produces accurate results. However, for systems with cables losses greater than 10db, a two port measurement is required. With options 22sf or 22nf, the...

Page 68: 4-10

Distance-to-fault (dtf) transmission line test the distance-to-fault transmission line test verifies the performance of the transmission line assembly and its components and identifies the fault locations in the transmission line system. This test determines the return loss value of each connector p...

Page 69: 4-11

Note: selecting the right propagation velocity, attenuation factor and distance is very important for accurate measurements, otherwise the faults can not be identified accurately. Step 9. Press save display (page 3-9) name the trace, and press enter. Step 10. Record the connector transitions. Figure...

Page 70: Resolution

Procedure - dtf-swr mode the following steps explain how to measure dtf in swr mode. Step 1. Press the mode key. Step 2. Select the dtf-swr using the up/down arrow key and press enter. Step 3. Follow the same procedure as dtf-return loss mode, above. Resolution there are three sets of data points (1...

Page 71: 4-13

Antenna subsystem return loss test antenna subsystem return loss measurement verifies the performance of the transmit and receive antennas. This measurement can be used to analyze the performance of the antenna before installation. The antenna can be tested for the entire frequency band, or tested t...

Page 72: 4-14

The following trace is an example of an antenna return loss measurement trace. Calculate the threshold value and compare the recorded lowest return loss to the calcu- lated threshold value. Maximum return loss = - - + æ èç ö ø÷ 20 1 1 log vswr vswr notes: vswr is the antenna manufacturer’s specified...

Page 73: Chapter 5

Chapter 5 power measurement introduction the site master can be used for making power measurements with broadband rf detectors, such as the 10 mhz to 20 ghz anritsu 560-7n50b or 560-7s50b. The power monitor dis- plays the measured power results in dbm or watts. Power measurement required equipment q...

Page 74: 5-2

Displaying relative power note: with option 22, the site master can make this relative power measure- ment over a swept frequency range (page 4-8). Step 9. With the desired base power level input to the site master, press the rel soft key. The message area will show relative: on and the power readin...

Page 75: 5-3/5-4

Note: with option 5, the site master is equipped with an interface connector that mates directly with the rf detector. With option 22, the site master is equipped with a different interface connector that mates to the cw source module. With the cw source module installed on the site master, power mo...

Page 77: And Line Sweep Tools

Chapter 6 anritsu tool box and line sweep tools introduction this chapter provides a brief overview of the anritsu tool box and the line sweep tools program. For detailed information about line sweep tools, refer to the program help. Anritsu tool box with line sweep tools the anritsu tool box is a c...

Page 78: Installing The Software

Installing the software place the installation dvd in your computer and follow the on-screen instructions (figure 6-2). If the installer does not autostart, navigate to the dvd and run setup.Exe (figure 6-3). The installation will start. Follow the on-screen instructions. The software is also availa...

Page 79: 6-3

Why use line sweep tools? Like its predecessor, hand held software tools (hhst), line sweep tools is intuitive for most users. However, unlike hhst, line sweep tools has the capability to work rapidly with a large number of traces. Line sweep tools is a program designed to increase productivity for ...

Page 80: Line Sweep Tools Features

Line sweep tools features the line sweep tools user interface is familiar to users of hand held software tools, the current industry standard line sweep post-capture trace processing software. This leads to a short learning curve and easy trace collection, validation, and reporting. Anritsu’s line s...

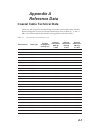

Page 81: Appendix A

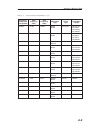

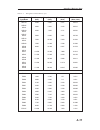

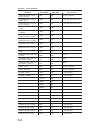

Appendix a reference data coaxial cable technical data tables a-1 and a-2 provide standard listings of common coaxial cables along with their relative propagation velocity and nominal attenuation values in db/m @ 1, 2, and 2.5 ghz. (n/a indicates that the specification is not applicable to the liste...

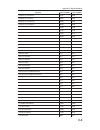

Page 82: A-2

A-2 appendix a reference data manufacturer cable type relative propagation velocity (vf) nominal attenuation db/m @ 1 ghz nominal attenuation db/m @ 2 ghz nominal attenuation db/m @ 2.5 ghz belden rg8, 8a 0.659 0.262 n/a n/a belden rg9, 9a 0.659 0.289 n/a n/a belden rg17, 17a 0.659 0.18 n/a n/a beld...

Page 83: A-3

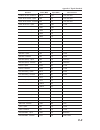

A-3 appendix a reference data manufacturer cable type relative propagation velocity (vf) nominal attenuation db/m @ 1 ghz nominal attenuation db/m @ 2 ghz nominal attenuation db/m @ 2.5 ghz eupen ec7-50 1-5/8 0.88 0.025 0.038 0.043 eupen ec12-50 2-1/4 0.88 0.022 0.034 0.039 nk cables rf ½” -50 0.88 ...

Page 84: A-4

A-4 appendix a reference data cable type maximum frequency (ghz) relative propagation velocity (v f ) nominal attenuation db/m @ 6 ghz fsj1-50a 20.4 0.84 0.53 fsj2-50 13.4 0.83 0.37 fsj4-50b 10.2 0.81 0.35 efx2-50 13.5 0.85 0.34 ldf1-50 15.8 0.86 0.31 ldf2-50 13.5 0.88 0.32 ldf4-50a 8.8 0.88 0.22 hj...

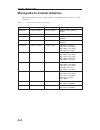

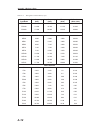

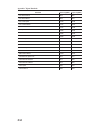

Page 85: Calibration Components

Calibration components the calibration components part numbers in the following table are broken down as fol- lows: xx: 23 = 1/8 offset short 24 = 3/8 offset short 26 = precision load a-5 appendix a reference data part number freq. Range waveguide type compatible flanges xxum70 5.85 to 8.20 ghz wr13...

Page 86: A-6

Waveguide-to-coaxial adapters part numbers that end with n = n type connector, part numbers that end with k = k type connectors. A-6 appendix a reference data part number freq. Range waveguide type compatible flanges 35um70n 5.85 to 8.20 ghz wr137, wg14 car70, par70, uar 70, pdr70 35um84n 7.05 to 10...

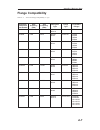

Page 87: Flange Compatibility

Flange compatibility a-7 appendix a reference data calibration component part number start frequency (ghz) stop frequency (ghz) waveguide type flange type compatible flanges xxum40 3.300 4.900 wr229 wg11a univm-229 pdr40 xxum48 3.950 5.850 wr187 wg12 univm-187 car48 par48 uar48 pdr48 xxum58 4.900 7....

Page 88: A-8

A-8 appendix a reference data calibration component part number start frequency (ghz) stop frequency (ghz) waveguide type flange type compatible flanges xxua187 3.950 5.850 wr187 wg12 univus-187 cpr187f cpr187g ug-1352/u ug-1353/u ug-1728/u ug-1729/u ug-148/u ug-149a/u xxua159 4.900 7.050 wr159 wg13...

Page 89: A-9

A-9 appendix a reference data calibration component part number start frequency (ghz) stop frequency (ghz) waveguide type flange type compatible flanges xxua62 12.400 18.000 wr62 wg18 univus-62 ug-541a/u ug-419/u ug-1665/u ug-1666/u xxua42 17.000 26.500 wr42 wg20 univus-42 ug-596a/u ug-595/u ug-597/...

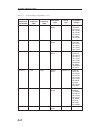

Page 90: Waveguide Technical Data

Waveguide technical data a-10 appendix a reference data offset short p/n frequency (ghz) length (mm) 24um70 6.926 20,710 ± 0.08 24um84 8.396 17,040 ± 0.05 24um100 10.084 14,675 ± 0.05 24um120 12.247 11,978 ± 0.04 24ua187 4.807 30,979 ± 0.11 24ua137 6.926 20,710 ± 0.08 24ua112 8.396 17,040 ± 0.05 24u...

Page 91: A-11

A-11 appendix a reference data waveguide type/model start frequency (ghz) stop frequency (ghz) cutoff frequency (ghz) mid-band loss (db/m, ghz) wr229 wg11a 3.300 4.900 2.577 0.0374 wr187 wg12 3.950 5.850 3.152 0.0515 wr159 wg13 4.900 7.050 3.711 0.0591 wr137 wg14 5.850 8.200 4.301 0.0738 wr112 wg15 ...

Page 92: A-12

A-12 appendix a reference data waveguide type/model start frequency (ghz) stop frequency (ghz) cutoff frequency (ghz) mid-band loss (db/m, ghz) ew132 11.000 15.350 9.220 0.17 ew180 14.000 19.700 11.150 0.1939 ew220 17.000 23.600 13.340 0.2822 cablewave we37 3.600 4.200 2.830 0.0269 we46 4.400 5.000 ...

Page 93: Appendix B

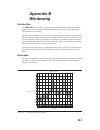

Appendix b windowing introduction the freq/dist menu (page 2-11) provides for setting the cable loss and relative propa- gation velocity of the coaxial cable. The window key opens a menu of fft windowing types for the dtf calculation. The theoretical requirement for inverse fft is for the data to ex...

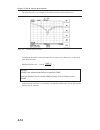

Page 94: B-2

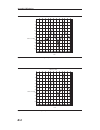

B-2 appendix b windowing d i s t a n c e t o f a u l t 5 1 0 1 5 2 0 2 5 3 0 f e e t 3 5 4 0 4 5 5 0 5 5 6 0 - 5 - 1 0 - 1 5 - 2 0 - 2 5 - 3 0 - 3 5 - 4 0 - 4 5 - 5 0 r e t u r n l o s s ( d b ) figure b-2. Nominal side lobe windowing example d i s t a n c e t o f a u l t 5 1 0 1 5 2 0 2 5 3 0 f e e...

Page 95: B-3/b-4

Appendix b windowing b-3/b-4 d i s t a n c e t o f a u l t 5 1 0 1 5 2 0 2 5 3 0 3 5 4 0 4 5 5 0 5 5 6 0 f e e t - 5 - 1 0 - 1 5 - 2 0 - 2 5 - 3 0 - 3 5 - 4 0 - 4 5 - 5 0 r e t u r n l o s s ( d b ) figure b-4. Minimum side lobe windowing example.

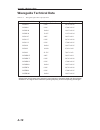

Page 97: Appendix C

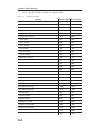

Appendix c signal standards introduction table c-1 provides a listing of common spectrum analyzer signal standards. C-1 standard center (mhz) span (mhz) valid channels amps / eia 553 - uplink 859 70 1-799, 990-1023 amps / eia 553 - downlink 859 70 1-799, 990-1023 c-450 (p) - uplink 463.5 21 1-800 c-...

Page 98: C-2

C-2 appendix c signal standards standard center (mhz) span (mhz) valid channels cdma2000 class 2, (tacs band) - downlink 916 88 0-1100, 1329-2047 cdma2000 class 3, (jtacs band) - uplink 878.5 93 1-799, 801-1039, 1041-1199 cdma2000 class 3, (jtacs band) - downlink 878.5 93 1-799, 801-1039, 1041-1199 ...

Page 99: C-3

C-3 appendix c signal standards standard center (mhz) span (mhz) valid channels n-amps / is-88u - downlink 897.5 147 1-799, 990-1023 nadc is136 cellular - uplink 859 70 1-799, 990-1023 nadc is136 cellular - downlink 859 70 1-799, 990-1023 nadc is136 pcs - uplink 1920 140 1-1199 nadc is136 pcs - down...

Page 100: C-4

Table c-2 provides a listing of common vna signal standards. C-4 appendix c signal standards standard start freq (mhz) stop freq (mhz) bluetooth us & europe uplink 2400 2484 bluetooth us & europe downlink 2400 2484 bluetooth us & europe fullband 2400 2484 bluetooth japan uplink 2472 2497 bluetooth j...

Page 101: C-5

C-5 appendix c signal standards standard start freq (mhz) stop freq (mhz) ieee 802 11 ds fullband 2412 2484 ieee 802 11 b g uplink 2400 2484 ieee 802 11 b g downlink 2400 2484 ieee 802 11 b g fullband 2400 2484 imt 2000 umts wcdma uplink 1920 1980 imt 2000 umts wcdma downlink 2110 2170 imt 2000 umts...

Page 102: C-6

C-6 appendix c signal standards standard start freq (mhz) stop freq (mhz) pdc 800 downlink 843 885 pdc 800 fullband 843 940 pdc 1500 uplink 1525 1549 pdc 1500 downlink 1477 1501 pdc 1500 fullband 1477 1549 phs uplink 1895 1918 phs downlink 1895 1918 phs fullband 1895 1918 smr 800 uplink 806 821 smr ...

Page 103: Index

Index a accessories . . . . . . . . . . . . . . . . . 1-2 optional . . . . . . . . . . . . . . . 1-2 power monitor . . . . . . . . . . . . 1-2 adapters coaxial . . . . . . . . . . . . . . . . 1-4 amplitude . . . . . . . . . . . . . . . . 2-12 attenuation nominal . . . . . . . . . . . . . . . A-1 att...

Page 104: Index-2

Integrator . . . . . . . . . . . . . . . . 2-19 integrator failure . . . . . . . . . . . . . 2-18 interfering signals . . . . . . . . . . . . . 1-5 k keypad . . . . . . . . . . . . . . . . . . 2-5 keys hard . . . . . . . . . . . . . . . . . 2-4 soft . . . . . . . . . . . . . . . . . . 2-7 l language...

Page 105: Index-3

V valley . . . . . . . . . . . . . . . . . . 2-14 verification. . . . . . . . . . . . . . . . . 1-8 vswr . . . . . . . . . . . . . . . . 1-5, 4-14 w waveguide components . . . . . . . . . . . . . A-5 specifications . . . . . . . . . . . A-10 technical data . . . . . . . A-11 - a-12 windowing . . . ....