- DL manuals

- B&D

- Garage Door Opener

- Panelift B&D Storm-Shield PFI

- Installation Instructions Manual

B&D Panelift B&D Storm-Shield PFI Installation Instructions Manual

Part No. OT2515. Revision 9 - March 2016

DISCLAIMER

THESE INSTRUCTIONS ARE INTENDED FOR

PROFESSIONAL GARAGE DOOR INSTALLERS

Note: All references are taken from inside looking out.

Substrate fasteners are not included, the recommended

fasteners and high wind compliant Storm-Shield fasteners can

be downloaded from the installation section on the B&D website

Panelift

®

PFT, Panelift

®

Icon

™

PFI,

B&D Storm-Shield

™

PFI and Insul-Shield

™

INSTALLATION INSTRUCTIONS

Summary of Panelift B&D Storm-Shield PFI

Page 1

Part no. Ot2515. Revision 9 - march 2016 disclaimer these instructions are intended for professional garage door installers note: all references are taken from inside looking out. Substrate fasteners are not included, the recommended fasteners and high wind compliant storm-shield fasteners can be do...

Page 2

Contents 1.0 before you start 3 1.1 safety checklist 3 1.2 checking measurements 4 1.3 fastener recommendations for fitting panelift ® pft & pfi doors only 5 1.4 tools 6 1.5 parts checklist 7 1.6 check & mark out the opening 10 2.0 installation 11 2.1 assembling pft & pfi vertical tracks 11 2.2 asse...

Page 3

1.0 before you start the following hazards and hazard controls have been identified for installers during the installation of this door. 1.1 safety checklist hazard control • housekeeping - risk of slip trip or fall • housekeeping - risk of injury to other people or animals in the installers work ar...

Page 4

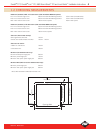

1.2 checking measurements headroom (standard) 4-8 & 4-13 cable drums (with and without b&d auto opener) ftl = front torsion large curve 290mm with std end bearing brackets 310mm with combo brackets fts = front torsion small curve 250mm with std end bearing brackets 270mm with combo brackets rts = re...

Page 5: For Pa

5 panelift ® pft, panelift ® icon ™ pfi, b&d storm-shield ™ pfi and insul-shield ™ installation instructions revision 9 - march 2016 1.3 fastener recommendations for fitting panelift ® pft & pfi doors only unlined garage substrate type fastener required washer required plug required drilled hole Ø (...

Page 6

It is recommended that this door is installed by a professorial door installer using a professional and specialized tool kit. 1.4 tools available b&d standard fastener packs fastener standard fastener pack part no. Standard fastener pack description screw, coach 5/16-9tpix50 fk0011 kit, screw, coach...

Page 7

When taking delivery of your pft or pfi sectional overhead door you will be supplied with the following:- • 1 package with door panels • 2 pairs of tracks short for vertical use, and long for horizontal use • 1 torsion bar (tube or solid) • for parts boxes refer to pft or pfi charts as there may be ...

Page 8

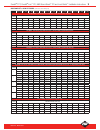

B&d panelift ® pft doors and b&d storm-shield ™ (pft boxes have green print) 1750 3050 3055 3500 3505 4500 4505 4705 4710 5000 5005 5400 5405 5600 5605 5740 5745 5800 5805 6000 6005 6200 6205 6400 6405 6600 all pft and storm-shield™ doors - main hardware single box kits, front torsion, large radius ...

Page 9

B&d panelift ® icon pfi doors (pfi boxes have red print) 1750 3050 3055 3500 3505 4500 4505 4705 4710 5000 5005 5400 5405 5600 5605 5740 5745 5800 5805 6000 6005 6200 6205 6400 6405 6600 all pfi doors - main hardware box (independent of curve size and front or rear torsion) number of panels door wid...

Page 10

1.6 check & mark out the opening 1. Using a water or lazer level, mark both sides approx. 1.5m from the floor. 2. Mark equal overlap at each side based on panel width. Approx. 1.5m mark level datum marks each side mark equal overlap based on panel width 3. Mark the track position as specified in fig...

Page 11

2.0 installation 2.1 assembling pft & pfi vertical tracks parts needed figure 2.1.1 track assembly figure 2.1.2 clearance from wall approx measurement from jamb: no seals e = 10mm, f = 5mm with seals e&f = 20mm e f •1l/h&1r/hverticalstraighttracks •1l/h&1r/hshorttoptrackangle •2polypropylenecurves •...

Page 12

2.2 assembling b&d storm-shield ™ pfi vertical tracks first assemble parts a,e and f, loosely attach the polypropylene curve (f) to the short top track bracket (e) using 2 long and 3 short 5/16 flat head bolts and nuts for each assembly as shown. The small curves will align with the upper slots at t...

Page 13

If installing taper please consult page 30. Open up the pack of door panels making sure the bottom panel (weather strip seal on the bottom of the panel and bottom hinge hole see figure 2.3.1) is on top of the pack. Bottom panel: locate both bottom hangers and cables. Insert cable through the holes o...

Page 14

2.4 fitting pft & pfi reinforcing doors wider than 3545mm require panel reinforcing, the number and positioning of the reinforcing is shown on page 7. Some pft & pfi doors and all b&d storm-shield ™ pfi doors are supplied with double end stiles and extended wheels, figure 2.4.1. Figure 2.4.1 double ...

Page 15

View f: fasten screws in diagonal location figure 2.5.3 mid-panel 1. Line up the fold to the 2nd endstile 2. Fasten 3 locating screws 3. Line up reo evenly across panel and fasten all screws 2.6 assembling top panel pft, pfi & pfi seal figure 2.6.4 figure 2.6.6 the top panel can be easily identified...

Page 16

Assembly of the top panel is the same as panelift pft and pfi. The reinforcing must be fitted after the panel is in the tracks in a vertical position with the wheels and hangars fitted and adjusted. Special care must be taken when fitting the lower reinforcing as the hook plates must align correctly...

Page 17

Note: if jamb seals are being fitted they should be cut 100mm taller than the door height and fitted prior to fitting the vertical tracks. Refer to figure 2.8.2 for correct position. The fixing points should be spaced at 300-400mm centres. Set the vertical tracks parallel on both sides of the door. ...

Page 18

This procedure is the same for pft, pfi & b&d storm-shield ™ pfi doors. Carefully lower the wheels of the bottom panel into the tracks. The bottom door panel is to sit level in the door opening. The wheels are to sit in the “v” groove of the vertical tracks and there should be clearance between pane...

Page 19

Assemble the track as shown in figure 2.10.1, ensure that the plastic curve is aligned and butts up against the vertical track and horizontal track snugly. The horizontal tracks are identified by being the longer pair of tracks supplied and should be at least: door height + 350mm 2.10 installing hor...

Page 20: Attention Installers!

Before bracing the horizontal tracks, ensure that they are square to the opening and level. To check whether your diagonals are equal, measure from the top of the vertical track to the end of the horizontal track on both sides. Check both sides. Adjust if necessary and fix diagonal brace. Figure 2.1...

Page 21

Place the torsion bar on the floor and position the lifting parts in order. Place the spring anchor bracket onto the torsion bar, positioning it approximately half way along.The cut off comer should face the floor if mounted on the lintel, or if mounted on the ceiling should face rearward, away from...

Page 22

With two springs no shaft collar is necessary. Place the cable drum onto the torsion bar with the red cable drum on the left side and the black cable drum on the right side as in figure 41. The set screws on the cable drums should face inwards see figure 40. Place the two 3 mm cable drum spaces on e...

Page 23

2.12 fitting b&d storm-shield ™ pfi tracklocks whilst fitting tracklocks is shown here it is preferable to leave until the door is fully functioning and you are satisfied with the operation. For small curve • the top of the tracklock must be cut back 60mm as indicated at figure 2.12.3.Only after rem...

Page 24

A = 170 (fts), 190 (ftl) length vert-track = door height - a left side view projection d rear view projection install reo last e figure 2.12.5 figure 2.12.6 figure 2.12.7 figure 2.12.4 top-panel hook plate top-panel tracklock 8-11 8-11 proj-view a 10 e dash-line inside indicates approximately to cut...

Page 25

For very large doors whose springs simply become too large and heavy to handle in a complete single axle assembly, two solid torsion axles are supplied with a coupling to allow easier installation. Assemble both axle assemblies on the floor, only one spring anchor bracket is used, the other spring a...

Page 26

Bottom hangers: find the low lift bottom hangers, the cables, clevis pins, humpback spring pins, and washers. Assemble low lift bottom hangers as shown in figure 55 a. Then assemble onto the bottom panel as shown in figure 55 b. Curve assembly: insert plastic curve onto the inside of the top bracket...

Page 27

Torsion bar installation: ensure that the ceiling fixing points are suitable to accept the weight of the torsion and spring assembly. Fix the flat spring anchor brackets to the free ends of the horizontal tracks, figure 61. Rest the assemble torsion bar on top of the tracks, then slide one axle end ...

Page 28

Secure the torsion bar to prevent any rotation, as shown in figure 2.15.1. Warning: torsion springs can cause serious injury! If you are not sure, stop now! Ask trained personnel. The number of turns required for each spring is shown on a paper tag attached to the springs figure 2.15.2. If the sprin...

Page 29

Note: in coffin garages (those with no access other than the garage door), the lock handle should be installed immediately after fitting the lock panel. The lock handle is to be fixed to the middle of the second panel. Using lock plate as a guide, centre on central end stile and drill through the en...

Page 30

Tapers are accomplished using a small customised panel, which results in a slight variation in the installation process, please familiarise yourself with the standard installation before proceeding. The lifting gear is now attached to a standard central panel, which can be identified by a) having no...

Page 31

Lifting cables loose when door is opened • cable drums have slipped • diagonals out of square • check length of lifting cables torsion bar moving • cable drums not adjusted correctly • springs not adjusted correctly • shaft collar not fitted (single spring) • check end bearing brackets are square an...

Page 32

General care of your panelift cleaning colorbond ® & coloured steel finish your b&d panelift has been pre-painted with a silicone modified polyester formulation, which is one of the best paint films commercially available today. However, all exposed surfaces require some attention to guard against t...