- DL manuals

- Bacharach

- Test Equipment

- Fyrite INSIGHT

- Operating & Maintenance Instructions

Bacharach Fyrite INSIGHT Operating & Maintenance Instructions

Summary of Fyrite INSIGHT

Page 1

Fyrite ® insight combustion gas analyzer instruction 0024-9460 operation & maintenance rev. 5 – october 2011 product leadership • training • service • reliability ®.

Page 2: Warranty

Warranty bacharach, inc. Warrants to buyer that at the time of delivery this product will be free from defects in mater ial and manufac ture and will conform substan tially to bacharach inc.’s ap plicable specifications. Bacharach’s liability and buyer’s remedy under this warranty are limited to the...

Page 3: Table Of Contents

Fyrite ® insight instruction 0024-9460 i table of contents 1.0 introduction ................................................................................. 1 1.1 the fyrite ® insight ...............................................................1 1.2 fyrite ® insight features & benefits ............

Page 4

Fyrite ® insight instruction 0024-9460 ii 4.9 ending a combustion test ..................................................... 30 4.10 emptying the water trap ...................................................... 30 4.11 powering off the analyzer & purging ................................31 4.12 low ...

Page 5: 1.0 Introduction

Instruction 0024-9460 1 fyrite ® insight 1.0 introduction 1.1 the fyrite ® insight the fyrite ® insight is a hand-held residential- and commercial-grade portable combustion analyzer designed for on-demand sampling of light industrial combustion equipment, residential furnaces, and appliances. The fy...

Page 6: 1.2 Fyrite

Instruction 0024-9460 2 fyrite ® insight cautions! • whentheinstrumentisusedinaninefficientfurnaceorboiler application where there is a high emission of soot, the probe samplefiltermaybecomeclogged.Checkthefilterbeforeevery usetoconfirmthatitiscleanforuseorreplacewithanewfilter. Topreventthisfromocc...

Page 7

Instruction 0024-9460 3 fyrite ® insight user information - the instrument will accept up to three lines of 20 characters of user information. This information will appear with the test records when they are printed or downloaded. Calibration and reminders - calibration can be performed by applying ...

Page 8

Instruction 0024-9460 4 fyrite ® insight sensor access-sensorreplacementcanbeaccomplishedinthefield. Easy access to the o2 and co sensors is provided through the back of the instrument. Power - the fyrite ® insight is powered by 4 aa alkaline batteries. A new set of alkaline batteries will provide a...

Page 9: 1.3 Operational Overview

Instruction 0024-9460 5 fyrite ® insight 1.3 operational overview pressing the pwr button turns the analyzer on. Note that there is a warm-up period of 60 seconds that must elapse before the analyzer can be used. To perform a combustion test, choose a fuel code that corresponds to the fuel being bur...

Page 10

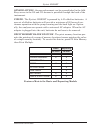

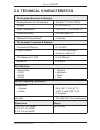

Instruction 0024-9460 6 fyrite ® insight 2.0 technical characteristics the analyzer measures & displays: primary/ambient air temperature -4 to 600 °f (-20 to 316°c) oxygen 0.1 to 20.9% o 2 stack temperature -4 to 1202 °f (–20 to 650 °c) carbon monoxide 0 to 2000 ppm co differential pressure/draft ± ...

Page 11

Instruction 0024-9460 7 fyrite ® insight general characteristics: power requirements four disposable ‘aa’ alkaline batteries (op- tional ac adapter is available) operating time minimum of 20 hours continuous operation (pump running and backlight on) warm up time 60 seconds memory up to 100 complete ...

Page 12: 3.1 Preliminary Steps

Instruction 0024-9460 8 fyrite ® insight 3.0 setting up the analyzer 3.1 preliminary steps before using the analyzer . . . •checkbatteries (section3.2) •connectprobetoanalyzer (section3.3) •checksetup (section3.5) 3.2 power 3.2.1 installing or replacing batteries install fresh batteries as described...

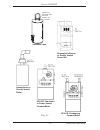

Page 13: Thermocouple

Instruction 0024-9460 9 fyrite ® insight 3.3 connecting the probe hose & thermocouple a rigid stainless steel probe with handle is connected to a flexible hose with integral water-trap / filter used to draw a gas sample into the ana- lyzer from the room, grilles, diffusers, and furnace flues. Inspec...

Page 14

Instruction 0024-9460 10 fyrite ® insight probe tube water trap/ filter assembly usb cable primary ambient air thermocouple (t-air) (optional) sample gas hose sample gas thermocouple connector (t-stack) draft hose probe stop probe handle ac power adapter jack (power) differential pressure hose (opti...

Page 15

Instruction 0024-9460 11 fyrite ® insight 3.4 front panel push buttons note that a push button may perform several functions, depending on the analyzer’s model number and what screen is being displayed at the time. • powers the analyzer on and off. Hold this button down for at least 2 seconds to tur...

Page 16: 3.5 Setup Mode

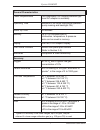

Instruction 0024-9460 12 fyrite ® insight 3.5 setup mode the analyzer is preset at the factory for the parameters shown below, but can be changed as described in their corresponding sections. Function parameter to change fuel natural gas section 4.3 temperature unit °f section 3.5.2 pressure unit in...

Page 17

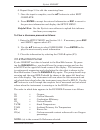

Instruction 0024-9460 13 fyrite ® insight 3.5.3 pressure units select to display pressure in inches of water column (inwc), millibar (mb), pascals (pa), hectopascals (hpa), or millimeter of water column (mmwc) as follows: 1. Enter the setup menu per section 3.5.1. If necessary, press esc until menu ...

Page 18

Instruction 0024-9460 14 fyrite ® insight 3.5.5 o 2 reference the measured value of co can be referenced to a specific o 2 percentage of 0% to 15%. Set up the reference value as follows: 1. Enter the setup menu per section 3.5.1. If necessary, press esc until menu appears above f2. 2.Fromthesetupmen...

Page 19

Instruction 0024-9460 15 fyrite ® insight lated data no matter what zoom level has been selected. Select the desired zoom level as follows: 1. Enter the setup menu per section 3.5.1. If necessary, press esc until menu appears above f2. 2.Fromthesetupmenu,usethe▲▼ buttons to select zoom. Press enter ...

Page 20

Instruction 0024-9460 16 fyrite ® insight 6. Repeat steps 3-5 to edit the remaining lines. 7.Oncetheinputiscomplete,usethe▲▼buttonstoselectedit complete. 8. Press enter to accept the entered information or esc to revert to the previous information and display the setup menu. Helpful hint: use the fy...

Page 21

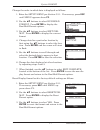

Instruction 0024-9460 17 fyrite ® insight change the order in which data is displayed as follows: 1. Enter the setup menu per section 3.5.1. If necessary, press esc until menu appears above f2. 2.Usethe▲▼buttonstoselectrun/hold format. Press enter to display the run/hold format options. 3.Usethe▲▼bu...

Page 22

Instruction 0024-9460 18 fyrite ® insight 3.5.10 language selection information on the display screen can be shown in english, french, or spanish. Select the desired language as follows: 1. Enter the setup menu per section 3.5.1. If necessary, press esc until menu appears above f2. 2.Usethe▲▼buttons...

Page 23

Instruction 0024-9460 19 fyrite ® insight note: thedefaultcalreminderperiodissettonever. Set the calibration reminder period as follows: 1. Enter the setup menu per section 3.5.1. If necessary, press esc until menu appears above f2. 2.Usethe▲▼buttonstoselectcalre- minder period. Press enter to dis- ...

Page 24

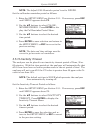

Instruction 0024-9460 20 fyrite ® insight 3.5.14 post-purge period the analyzer can be setup to purge the sensors following the combustion test. It can be programmed to purge for none, 5 seconds, 1, 5, or 10 min- utes. Set the post-purge period as follows: 1. Enter the setup menu per section 3.5.1. ...

Page 25

Instruction 0024-9460 21 fyrite ® insight 3.5.16 auto/manual zero feature manual zero: when the co channel is set to manual zero, the analyzer does not zero the co sensor to ambient conditions during start up. In this mode, the “fresh air zero” established during manual mode setup is stored in memor...

Page 26

Instruction 0024-9460 22 fyrite ® insight auto-zero versus manual zero.

Page 27: 4.0 Operation

Instruction 0024-9460 23 fyrite ® insight 4.0 operation 4.1 operating tips • when an analyzer is brought in from a cold vehicle, let it warm up slowly to minimize condensation. Temperatures below freezing will not damage the analyzer; however, bringing a cold analyzer into a warm, humid environment ...

Page 28: 4.3 Fuel Selection

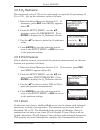

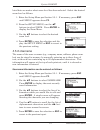

Instruction 0024-9460 24 fyrite ® insight 4.2 analyzer power on & warm up 1. Connect the probe and make sure that the analyzer is properly set up per section 3. Important! Do not insert probe into stack before powering on the analyzer. 2. Place the probe in an area that contains fresh air. This ensu...

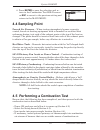

Page 29: 4.4 Sampling Point

Instruction 0024-9460 25 fyrite ® insight 4. Press enter to save the selection and re- turn to the combustion test hold screen or esc to revert to the previous setting and return to the main menu. 4.4 sampling point forced air furnace – when testing atmospheric burner or gravity vented, forced air h...

Page 30

Instruction 0024-9460 26 fyrite ® insight 1. Press the run/hold button to start the test. You should hear the pump start running and see the word run appear at the top of the combustion test screen. Sensor indicators: the following indicators appear in the sensor's data field depending on certain co...

Page 31

Instruction 0024-9460 27 fyrite ® insight atmospheric burner or gravity vented forced air 80% eff. Fan assist or power vented furnace/boiler 90% eff. Condensing furnace/boiler atmospheric or gravity vented boiler hot water tank undiluted flue gas sample taken under draft diverter in top of fire tube...

Page 32

Instruction 0024-9460 28 fyrite ® insight 4.6 making a draft / pressure measurement thedifferenceinpressure(Δp)betweentwoareascanbemeasuredby using the analyzer's two pressure ports and the pressure screen. By usingthe-Δpportasthereference,thepressureappliedtothe+Δpport will be displayed on the pres...

Page 33: 4.8 Saving Test Data

Instruction 0024-9460 29 fyrite ® insight sured. The differential pressure between the two areas is now displayedonthepressurescreen.Ifthepressureatthe+Δp portishigherthanthe-Δpport,thepressurereadingwillbe positive. If it is lower, the reading will be negative. 4.7 temperature measurement the diffe...

Page 34: 4.9 Ending A Combustion Test

Instruction 0024-9460 30 fyrite ® insight 2. Press the save (f3) button to save the test data in the next available memory location. Note: when memory is full, the next read- ing will not be saved until space is made available by clearing previ- ously saved data. (section 4.13) 4.9 ending a combusti...

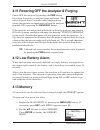

Page 35: 4.12 Low Battery Alarm

Instruction 0024-9460 31 fyrite ® insight 4.11 powering off the analyzer & purging power off the analyzer by pressing the pwr button for at least 2 seconds, or until two beeps are heard. The unit will count down 5 seconds before shutting down, giving the operator an opportunity to keep the analyzer ...

Page 36: 4.14 Printing Test Data

Instruction 0024-9460 32 fyrite ® insight 3.Usethe▲▼buttonstoselectmemorydirec- tory. Press enter to display the saved data contained in the memory directory. Tip: when displaying the contents of the memorydirectory,theoperatorcanquickly page through the screens by pressing the page– (f1) and page+ ...

Page 37

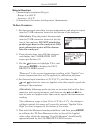

Instruction 0024-9460 33 fyrite ® insight f1 f2 f3 esc run hold pwr bacharach, inc. Fyrite insight sn: 12345678 time: 01:28:27 pm date: 09/22/11 fuel nat gas o 2 4.0 % co 12 ppm eff 82.6 % co 2 9.5 % t-stk 374 o f t-air 68.0 o f ea 21.3 % co (3) 13 ppm comments: fig. 4.2 1. Power up the printer. Ref...

Page 38: 4.15 Fyrite

Instruction 0024-9460 34 fyrite ® insight 4.15 fyrite ® user software for information on the installation of the fyrite® user software, refer to the installation document (provided in .Pdf format) on the software disk. The fyrite® user software installation manual may also be downloaded from the fyr...

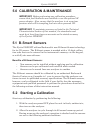

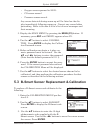

Page 39: 5.1 B-Smart Sensors

Instruction 0024-9460 35 fyrite ® insight 5.0 calibration & maintenance important: before performing any calibration procedure, ensurethatfreshbatteriesareinstalledorusetheoptionalac power adapter. Also, ensure that the analyzer is at room tem- perature and will be sampling fresh air when powered on...

Page 40: 5.3

Instruction 0024-9460 36 fyrite ® insight • oxygen sensor spanned to 20.9% • co sensor zeroed • pressure sensor zeroed. Any errors detected during warm-up will be listed on the dis- play immediately following warm-up. Correct any errors before proceeding. Refer to section 6.8 for a list of error mes...

Page 41

Instruction 0024-9460 37 fyrite ® insight note: if the correct code was entered, the analyzer accepts it and returns to the calibration menu. If an incorrect code was entered, the screen will display "invalid code". Check to make sure the correct code has been entered. If problem persists, contact y...

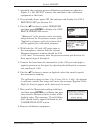

Page 42

Instruction 0024-9460 38 fyrite ® insight 1. Assemble the pressure sensor calibration equipment as shown in figure 5.1, but do not connect the analyzer to the calibration equipment at this time. 2. If not already done, power on the analyzer and display the cali- bration list per section 5.2. 3.Useth...

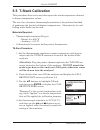

Page 43: 5.5 T-Stack Calibration

Instruction 0024-9460 39 fyrite ® insight 5.5 t-stack calibration this procedure first zeroes and then spans the stack-temperature channel to known temperature values. The use of an electronic thermocouple simulator is the preferred method of producing the desired calibration temperatures. Alternati...

Page 44: 5.6 T-Air Calibration

Instruction 0024-9460 40 fyrite ® insight alternatively: submerge probe tip into an ice-water bath with a ther- mometer, wait several minutes, and then use the and buttons to enter an applied value that exactly equals the thermometer read- ing. Thecalibrationrangeisfrom32to41°f(0to5°c).Anattemptto c...

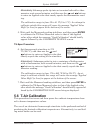

Page 45

Instruction 0024-9460 41 fyrite ® insight material required: • thermocouple simulator (k-type) - range: 0 to 600 °f - accuracy: ±0.5 °f • (alternatively) ice-water, boiling water, thermometer ta-zero procedure: 1. Set thermocouple simulator to room temperature and plug its output into the t-air conn...

Page 46: 5.7 Co Sensor Calibration

Instruction 0024-9460 42 fyrite ® insight ta-span procedure: 6. Set thermocouple simulator to 212 °f (100 °c), and then use the and buttons to enter an applied value that exactly equals the set- ting of the simulator. Alternatively: submerge probe tip into a container of boiling water with a thermom...

Page 47

Instruction 0024-9460 43 fyrite ® insight “measured”isthecurrentcoreading,while“applied”isa knowncolevelthatwillbeappliedforcalibrationpurposes. 3. Attach a 500 ppm co cylinder to the regulator of the calibration fixture. 4. Use the and buttons to enter an applied value that exactly equals the conce...

Page 48: 6.0 Maintenance

Instruction 0024-9460 44 fyrite ® insight 6.0 maintenance 6.1 fyrite ® insight disassembly the following section describes how to disassemble the fyrite insight to perform necessary periodic maintenance. (see figure 6.1 for diagram.) tools required: •mediumphillipsscrewdriver procedure: 1. Unplug al...

Page 49

Instruction 0024-9460 45 fyrite ® insight 1. O2 sensor 4. Sample pump 2. Co sensor 5. Lcd screen 3. Co sensor base fyrite ® insight end plate connectors 6. Ac power adapter jack (power) 7. Sample gas thermocouple connector (t-stack) 8. Primary air thermocouple (t-air) 9. Usb connector 10. Differenti...

Page 50: 6.2 Water Trap / Filter

Instruction 0024-9460 46 fyrite ® insight 6.2 water trap / filter 6.2.1 emptying the water trap chamber the water trap chamber should be emptied after every test, or when the water condensate approaches the tip of the riser tube. 1. Remove water trap chamber per figure 6.3. 2. Pour out liquid conden...

Page 51: 6.3 O

Instruction 0024-9460 47 fyrite ® insight 6.3 o 2 sensor replacement note: the o 2 sensor life is approximately 2 years. Material required: •o 2 sensor (p/n 0024-0788) fyrite ® rear panel pry tab upward to remove the battery door from the unit. Co sensor o 2 sensor fig. 6.4 procedure: 1. After batte...

Page 52: 6.4 Co Sensor Replacement

Instruction 0024-9460 48 fyrite ® insight 6.4 co sensor replacement note: thecosensorlifeisgreaterthan3years. Material required: •cosensor(p/n0024-7265) or b-smart sensor (p/n 0024-1467). Fig. 6.6 fyrite ® rear panel pry tab upward to remove the battery door from the unit. Co sensor o 2 sensor proce...

Page 53

Instruction 0024-9460 49 fyrite ® insight 6.5 thermocouple replacement using the appropriate thermocouple replacement kit listed below, replace the probe’s thermocouple as follows: each kit contains a thermocouple assembly, two o-rings, and two wire- splice connectors. Tools required: •smallflatblad...

Page 54: 6.6 Gas Pump Replacement

Instruction 0024-9460 50 fyrite ® insight 7. Strip 1 / 4 inch of insulation from each of the probe’s thermocouple connector wires. Important: instep8,thethermocouplewiresmustfirstbetwisted together and then crimped. 8. Twist both red thermocouple wires together; insert them into the supplied wire-sp...

Page 55

Instruction 0024-9460 51 fyrite ® insight parts & tools required: • replacement pump (p/n 0024-3049 or p/n 0024-3073) • medium phillips screwdriver procedure: 1. Gain access to the gas pump by removing the rear case. Refer to sec- tion 6.1. 2. Disconnect j9 (pump) and j11 (battery) connectors. 3. Li...

Page 56: 6.7 Cleaning The Probe

Instruction 0024-9460 52 fyrite ® insight 6.7 cleaning the probe the probe tube and gas-sample hose will become dirty under normal use. Note that the water trap’s filter element should prevent soot from reaching the analyzer’s internal components. If the probe is not kept clean, it could become clog...

Page 57: 6.9 Diagnostics Screen

Instruction 0024-9460 53 fyrite ® insight bad sensor - o 2 sensor is too low and can not be calibrated in the instru- ment and needs replaced. Low sensor- o 2 or co sensor outputs were low but still usable. Sensor(s) may need to be replaced in the near future. Message will indicate which sensor(s) w...

Page 58: 6.10 Status Screen

Instruction 0024-9460 54 fyrite ® insight fresh air diagnostics - fresh air diagnostics will cycle the instrument through the 60 second warm-up to check on the status of the sensors. The probe must be in fresh air to perform a valid check. Access the diagnostic menu as follows: 1. Display the main m...

Page 59: 7.0 Parts & Service

Instruction 0024-9460 55 fyrite ® insight 7.0 parts & service 7.1 replacement parts description part no. O 2 sensor ......................................................................................... 0024-0788 co sensor .............................................................................

Page 60: 7.3 Service Centers

Instruction 0024-9460 56 fyrite ® insight 7.3 service centers replacement parts and service can be obtained by contacting one of the fol- lowing bacharach service centers. United states pennsylvania 621 hunt valley circle new kensington, pa 15068 phone: 724-334-5051 fax: 724-334-5723 email: help@myb...

Page 61: Eclaration

Instruction 0024-9460 57 fyrite ® insight 8.0 declaration of conformity d eclaration of c onformity the manufacturer of the products covered by this declaration: bacharach, inc. 621 hunt valley circle new kensington, pa 15068 year conformity is declared: 2010 product(s): combustion analyzer model(s)...

Page 62

Instruction 0024-9460 58 fyrite ® insight.

Page 63

Instruction 0024-9460 59 fyrite ® insight.

Page 64

Headquarters: 621 hunt valley circle, new kensington, pa 15068 ph: 724-334-5000 • fax: 724-334-5001 • toll free: 800-736-4666 website: www.Mybacharach.Com • e-mail: help@mybacharach.Com printed in u.S.A..