- DL manuals

- Bacharach

- Test Equipment

- Fyrite Pro

- Instruction

Bacharach Fyrite Pro Instruction

Summary of Fyrite Pro

Page 1

Fyrite ® pro combustion gas analyzer instruction 0024-9395 operation & maintenance rev. 12 – october 2010 product leadership • training • service • reliability enter hold i/o light 25 co o % p p m 2 . 52 &.

Page 2: Warranty

Warranty bacharach, inc. Warrants to buyer that at the time of delivery this product will be free from defects in mater ial and manufac ture and will conform substan tially to bach arach inc.’s ap plicable spec i fi ca tions. Bacharach’s li a bil i ty and buyer’s remedy under this warranty are lim i...

Page 3: Contents

Fyrite pro instruction 0024-9395 i contents ordering information .......................................................... Iii 1.0 introduction .............................................................. 1 1.1 the fyrite pro...........................................................................

Page 4

Fyrite pro instruction 0024-9395 ii 4.7 opening and viewing saved test data .......................................25 4.8 printing test data.........................................................................26 4.9 clearing saved test data ..........................................................

Page 5: Ordering Information

Fyrite pro instruction 0024-9395 iii ordering information fyrite pro confi gurations model 100 100 printer kit 105 110 120 125 125 printer kit 125 printer/ oil kit part number 24- 8200 24- 8201 24- 8202 24- 8103 24- 8104 24- 8105 24- 8205 24- 8206 measurements: oxygen stack temperature ambient tempe...

Page 6: Notes:

Fyrite pro instruction 0024-9395 iv notes:.

Page 7: 1.0 Introduction

Instruction 0024-9395 1 fyrite pro 1.0 introduction 1.1 the fyrite pro the fyrite pro series of instruments are hand-held an a lyz ers that are designed for on-demand sampling of residential furnaces and appliances. The more advanced models can also to used to check combustion efficiency by measurin...

Page 8: 1.2 Operational Overview

Instruction 0024-9395 2 fyrite pro 1.2 operational overview pressing the i/o button turns the analyzer on. Note that there is a warm- up period of either 10 or 60 seconds, dependent on the analyzer’s model and setup, that must elapse before the analyzer can be used. When using the analyzer to just m...

Page 9

Instruction 0024-9395 3 fyrite pro 2.0 technical characteristics the analyzer directly measures and displays: • ambient temperature ............................32 to 212 °f (0 to 100 °c) • flue gas o 2 content ................................0.0 to 20.9% o 2 • flue gas temperature .....................

Page 10

Instruction 0024-9395 4 fyrite pro memory (model 105/110/120/125) ..................... Up to 10 sets of readings can be saved in memory. When memory is full, the next reading saved will overwrite the oldest reading. Display ................................................ 4 digit, 2 line, 7-segment...

Page 11: 3.1 Preliminary Steps

Instruction 0024-9395 5 fyrite pro 3.0 setting up the analyzer 3.1 preliminary steps before using the analyzer . . . • check batteries (section 3.2) • connect probe to analyzer (section 3.3) • check setup (section 3.5) 3.2 checking & replacing the bat ter ies install fresh batteries as described bel...

Page 12: Thermocouple

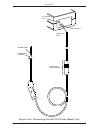

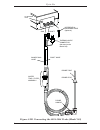

Instruction 0024-9395 6 fyrite pro 3.3 connecting the probe hose and thermocouple the analyzer’s model number determines which hose and thermocouple connections are made at the bottom of the unit. Perform the following steps as required by your particular analyzer model (see figures 3-2a thru d): 1....

Page 13

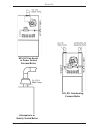

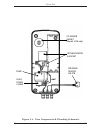

Instruction 0024-9395 7 fyrite pro figure 3-2a. Connecting the 0019-7110 probe (model 100) gas inlet sample-gas hose water trap / filter assembly ac adapter jack probe tube probe stop (optional).

Page 14

Instruction 0024-9395 8 fyrite pro figure 3-2b. Connecting the 0024-3004 probe (model 105) differential pressure hose (optional) water trap / filter assembly probe handle gas draft thermocouple connector (not used on the model 105) ac adapter jack draft hose sample-gas hose probe tube probe stop.

Page 15

Instruction 0024-9395 9 fyrite pro figure 3-2c. Connecting the 0019-7111 probe (model 110/120) t-stack gas inlet sample-gas hose thermocouple connector (t-stack) water trap / filter assembly ac adapter jack probe tube probe stop (optional).

Page 16

Instruction 0024-9395 10 fyrite pro figure 3-2d. Connecting the 0024-3004 probe (model 125) t-stack t-air room air / primary air thermocouple connector (t-air) differential pressure hose (optional) gas draft sample gas thermocouple connector (t-stack) ac adapter jack water trap / filter assembly pro...

Page 17

Instruction 0024-9395 11 fyrite pro 3.4 front panel push buttons note that a push button may perform several functions, depending on the analyzer’s model number and what screen is being displayed at the time. I/o • toggles the analyzer on and off. • places the analyzer into either its setup or calib...

Page 18: 3.5 Setup Mode

Instruction 0024-9395 12 fyrite pro 3.5 setup mode the analyzer is preset at the factory for the parameters shown below, but can be changed as described in their associated sec tions. Function parameter to change fuel natural gas (f1) section 4.13.5 temperature unit °f section 3.5.2 co channel auto ...

Page 19: 3.5.3 Co Channel

Instruction 0024-9395 13 fyrite pro 3.5.3 co channel setup the co channel setup screen is labeled “co.” 1. Enter the setup mode per section 3.5.1. If necessary, repeatedly press the enter button until “co” is displayed. 2. Press the ▲ or ▼ button until the desired parameter is dis played. - no senso...

Page 20: 3.5.5 Time Setup

Instruction 0024-9395 14 fyrite pro 3.5.5 time setup there are two time setup screens, one for hours and the other for min- utes. Two bars appear above the segments being changed. The clock is in a 24 hour format, but will appear as am/pm on the printout. 1. Enter the setup mode per section 3.5.1. I...

Page 21: 3.5.7 Year Setup

Instruction 0024-9395 15 fyrite pro 3.5.7 year setup the year setup screen is labeled “year”. 1. Enter the setup mode per section 3.5.1. If necessary, repeatedly press enter until the year setup screen is displayed. 2. Press the ▲ or ▼ button until the correct year is displayed. 3. Press enter to mo...

Page 22: Notes:

Instruction 0024-9395 16 fyrite pro notes:.

Page 23: 4.0 Operation

Instruction 0024-9395 17 fyrite pro 4.0 operation 4.1 performing co and draft testing 4.1.1 analyzer turn on and warm up 1. Connect the probe and make sure that the analyzer is properly set up per sec tion 3.0. 2. Turn on the analyzer in fresh air by pressing is i/o button and observe that the follo...

Page 24: 4.1.2 Measuring Co

Instruction 0024-9395 18 fyrite pro 4.1.2 measuring co (model 100/105/120/125) 1. Turn on the analyzer and allow it to warm-up per section 4.1.1. Important: if the co channel is set up for auto zero, then the analyzer must be turned on in fresh air ; otherwise, incorrect co readings will occur. Refe...

Page 25: The Model 110/120/125

Instruction 0024-9395 19 fyrite pro 4.2 performing a combustion test using the model 110/120/125 4.2.1 analyzer turn on and warm up important: the probe must be at room temperature before performing the following steps. 1. Connect the probe and make sure that the analyzer is properly set up per sec ...

Page 26: 4.2.3 Sampling Point

Instruction 0024-9395 20 fyrite pro atmospheric burner or gravity vented forced air hot water tank 4.2.3 sampling point forced air furnace – when testing atmospheric burner or gravity vented, forced air heating equip ment with a clamshell or sectional heat exchanger design, test each of the exhaust ...

Page 27

Instruction 0024-9395 21 fyrite pro 90% eff. Condensing furnace/boiler atmospheric or gravity vented boiler 80% eff. Fan assist or power vented furnace/boiler.

Page 28

Instruction 0024-9395 22 fyrite pro 4.2.4 performing a com bus tion efficiency test 1. After turning on the analyzer and selecting the appropriate fuel, press the ▲ or ▼ button to display the stack temperature & ef- ficiency screen (refer to section 4.13.10). 2. Position the probe in the flue-gas st...

Page 29: 4.3 Operating Tips

Instruction 0024-9395 23 fyrite pro 4.3 operating tips • when an analyzer is brought in from a cold vehicle, let it warm up slowly to minimize condensation. Temperatures below freezing will not damage the analyzer; however, bringing a cold analyzer into a warm, humid environment may cause condensate...

Page 30: 4.4 Using The Backlight

Instruction 0024-9395 24 fyrite pro 4.4 using the backlight the lcd can be read in dimly-lit areas by pressing the light button. The backlight automatically turns off after 10 minutes of keyboard inactiv- ity, but can be turned off at any time by again pressing the light button. 4.5 using the probe ...

Page 31

Instruction 0024-9395 25 fyrite pro 2. Press the ▼ button once to display the save screen. The number shown in this screen represents the memory location (1 thru 10) to which the current test data will be saved. 3. Press enter to save the test data and return to the hold mode, or press hold to retur...

Page 32: 4.8 Printing Test Data

Instruction 0024-9395 26 fyrite pro 4.8 printing test data tip: to avoid printing errors, it is important to select the correct protocol per section 3.5.8 before saving data. Turn on the printer. Refer to the printer’s instruction manual for detailed operation and maintenance information. If not alr...

Page 33

Instruction 0024-9395 27 fyrite pro figure 4-1. Printer alignment & sample printout 60° max. 45 cm (18 in.) max. Enter hold i/o light bacharach, inc. Fyrite pro analyzer ======================= date: 8/20/2003 time: 2:45 pm fuel: (f1)natural gas efficiency 82.6 % excess air 21.3 % stack temp 374 °f ...

Page 34

Instruction 0024-9395 28 fyrite pro 4.9 clearing saved test data (model 105/110/120/125) clear all saved test data as follows: note: if no test data has been saved, the option to clear memory will not be available. 1. With the analyzer in its run mode, press the hold button twice to display the prin...

Page 35: 4.12 Run Mode Screens

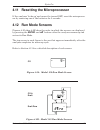

Instruction 0024-9395 29 fyrite pro figure 4-2a. Model 100 run mode screen 9 co ppm co 4.11 resetting the microprocessor if the analyzer ‘locks up’ and cannot be turned off, reset the microproces- sor by removing one of the batteries for 5 seconds. 4.12 run mode screens figures 4-2a thru 4-2e show t...

Page 36

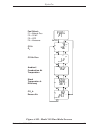

Instruction 0024-9395 30 fyrite pro figure 4-2c. Model 110 run mode screens fuel select: f1 = natural gas f2 = oil #2 f3 = lpg f4 = kerosene o 2 ambient / combustion air temperature stack temperature & efficiency co 2 & excess air f1 el u f 251 92 co2 % . . Excess air f1 787 00 stack f1 eff °f % 5 ....

Page 37

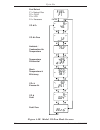

Instruction 0024-9395 31 fyrite pro figure 4-2d. Model 120 run mode screens fuel select: f1 = natural gas f2 = oil #2 f3 = lpg f4 = kerosene co & o 2 co air free ambient / combustion air temperature stack temperature & efficiency co 2 & excess air f1 el u f 251 92 co2 % . . Excess air f1 787 00 stac...

Page 38

Instruction 0024-9395 32 fyrite pro figure 4-2e. Model 125 run mode screens fuel select: f1 = natural gas f2 = oil #2 f3 = lpg f4 = kerosene co & o 2 co air free ambient / combustion air temperature temperature differential stack temperature & efficiency co 2 & excess air co & draft draft zero f1 el...

Page 39: 4.13 Screen

Instruction 0024-9395 33 fyrite pro 4.13 screen descriptions 4.13.1 warm-up screens as soon as the analyzer is turned on, a series of warm-up screens are dis played. These screens show the analyzer’s model number (pro 100/105/110/120/125), the unit’s software revision, and finally the remain- ing wa...

Page 40: 4.13.3 Co & Draft Screen

Instruction 0024-9395 34 fyrite pro 4.13.3 co & draft screen (model 105/125) the co reading is a measurement of how much carbon monoxide in ppm is present in the flue-gas stream. Note, however, that the amount of co dis played may be diluted by secondary air (refer to section 4.13.12 co air free scr...

Page 41: 4.13.5 Fuel Screen

Instruction 0024-9395 35 fyrite pro 4.13.5 fuel screen (model 110/120/125) the fuel screen is displayed after warm-up, and is where an operator chooses which fuel is to be used by the analyzer to calculate com bus tion efficiency. Press ing the ▲ or ▼ button scrolls the dis play through the fuel cod...

Page 42: 4.13.8 Co

Instruction 0024-9395 36 fyrite pro the co reading is a measurement of how much carbon monoxide in ppm is present in the flue-gas stream. Note, however, that the amount of co dis played may be diluted by secondary air (refer to section 4.13.12 co air free screen). The o 2 reading is the measured per...

Page 43

Instruction 0024-9395 37 fyrite pro 4.13.9 temperature differential screen (model 125) the temperature differential reading is the measured difference between the temperatures being measured by the t-stack and t-air thermo- couples. Front panel button functions: ▲ – displays next screen (refer to se...

Page 44

Instruction 0024-9395 38 fyrite pro 4.13.11 ambient air temperature screen (model 110/120/125) the ambient reading is the combustion-air temperature in either °f or °c that is used for efficiency calculations. This temperature is measured by either the t-air thermocouple on a continuous basis ( mode...

Page 45

Instruction 0024-9395 39 fyrite pro 4.13.13 sensor error screen (model 100/105/110/120/125) an o 2 sensor error is displayed if the analyzer determines during the warm-up cycle that the oxygen sensor’s output is too low for it to be usable. However, in the extreme condition when the o 2 sensor has n...

Page 46: Notes:

Instruction 0024-9395 40 fyrite pro notes:.

Page 47: Testing The Display Segments

Instruction 0024-9395 41 fyrite pro 5.0 calibration & maintenance important: fresh batteries should be installed, and the unit allowed to sta bi lize at room temperature for at least two hours before proceeding with calibration. To main tain ac- cu ra cy as listed in the technical characteristics se...

Page 48: Calibration

Instruction 0024-9395 42 fyrite pro 5.2 ambient temperature calibration (model 110/120/125) material required: calibrated thermometer procedure: 1. Enter the calibration mode as described in section 5.1. Observe that “ambient” will appear at the top of the display; if not, re- peatedly press enter u...

Page 49

Instruction 0024-9395 43 fyrite pro 3. Set the simulator to 32.0 °f (0 °c); then use the ▲ and ▼ buttons to set the dis played value to match the simulator’s value. 4. Set the simulator to 212.0 °f (100 °c); then use the ▲ and ▼ but- tons to adjust the dis played value to match simulator’s value. 5....

Page 50: 5.5 Oxygen Sensor Zero

Instruction 0024-9395 44 fyrite pro 6. Press enter to store these calibration values and move to the next cal i bra tion screen, or hold down enter for 2 seconds to store these calibration values and enter the run mode, or press the i/o button to exit the cal i bra tion mode and turn off the an a ly...

Page 51

Instruction 0024-9395 45 fyrite pro 9. Press enter to store the new calibration values and move to the next cal i bra tion screen, or hold down enter for 2 seconds to store the new calibration values and enter the run mode, or press the i/o button to exit the cal i bra tion mode and turn off the an ...

Page 52

Instruction 0024-9395 46 fyrite pro 6. Connect the tubing of the calibration kit to the gas inlet of the an- a lyz er. Note that the gas fitting (item 6) is only required on fyrite pro models 105 and 125. 7. Adjust the regulator for ap prox i mate ly 2 scfh of excess flow (see figure 5.1). 8. After ...

Page 53: 5.7 Draft Calibration

Instruction 0024-9395 47 fyrite pro 5.7 draft calibration (model 105/125) material required: • bellows • micromanometer range: ±8 in. H 2 o column (±20 mb) accuracy: ±0.01 in. H 2 o column (±20 mb) procedure: 1. Set the draft units to “wc” per section 3.5.4. 2. Enter the calibrate mode per section 5...

Page 54

Instruction 0024-9395 48 fyrite pro 5.8 water trap / filter maintenance the water trap / filter assembly removes water con den sate from the gas sam ple, and also prevents soot from con tam i nat ing the internal com po- nents of the analyzer. Drain the water condensate after every test. Procedure: ...

Page 55: 5.9 O

Instruction 0024-9395 49 fyrite pro 5.9 o 2 sensor replacement (model 110/120/125) be sure to perform all of the checks listed in sec tion 4.13.13 to ensure that the o 2 sensor needs to be replaced. Material required: • oxygen sensor, p/n 0024-8106 • #1 phillips screwdriver procedure: 1. Disassemble...

Page 56

Instruction 0024-9395 50 fyrite pro 5.10 co sensor replacement (model 100/105/120/125) be sure to perform all of the checks listed in sec tion 4.13.13 to ensure that the co sensor needs to be replaced. Material required: • co sensor, p/n 0024-7265 • co sensor gasket, p/n 0024-1112 • #1 phillips scre...

Page 57

Instruction 0024-9395 51 fyrite pro 5.11 pump assembly replacement material required: • pump, p/n 0024-3048 • #1 phillips screwdriver procedure: 1. Disassemble the analyzer as follows: a. Remove the battery cover and the batteries, uncovering one of the cover hold-down screws. B. Remove and set asid...

Page 58

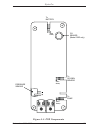

Instruction 0024-9395 52 fyrite pro figure 5-4. Case components & plumbing schematic co sensor gasket (model 125e only) oxygen sensor & socket pressure sensor on pcb pump hold down clamp.

Page 59

Instruction 0024-9395 53 fyrite pro figure 5-5. Pcb components co sensor (model 125e only) to battery to oxygen sensor to pump pressure sensor (red wire) (red wire) (red wire).

Page 60: Notes:

Instruction 0024-9395 54 fyrite pro notes:.

Page 61: 6.0 Parts & Service

Instruction 0024-9395 55 fyrite pro 6.0 parts & service 6.1 replacement parts description part no. Carbon monoxide sensor .................................................................0024-7265 carbon monoxide sensor gasket .....................................................0024-1112 oxygen sen...

Page 62: 6.2.2 Optional Accessories

Instruction 0024-9395 56 fyrite pro 6.2.2 optional accessories ac adapter (battery eliminator) ....................................................0024-1254 calibration kit .................................................................................0024-7059 calibration gas cylinder: 100 ppm co...

Page 63: 6.3 Service Centers

Instruction 0024-9395 57 fyrite pro united states 621 hunt valley circle new kensington, pa 15068 phone: 724-334-5051 fax: 724-334-5723 email: help@mybacharach.Com canada bacharach of canada, inc. 20 amber st. Unit #7 markham, ontario l3r 5p4 canada phone: 905-470-8985 fax: 905-470-8963 email: bachc...

Page 64

Headquarters: 621 hunt valley circle, new kensington, pa 15068 ph: 724-334-5000 • fax: 724-334-5001 • toll free: 800-736-4666 website: www.Mybacharach.Com • e-mail: help@mybacharach.Com printed in u.S.A..