- DL manuals

- Bacharach

- Security Sensors

- MGD-100

- Installation And Operation Manual

Bacharach MGD-100 Installation And Operation Manual

Summary of MGD-100

Page 1

Gas detector and controllers installation and operation manual instruction 6109-9000 revision 3 – june 2013 product leadership • training • service • reliability.

Page 2

Mgd-100 manual 2 6109-9000 rev 3 warranty policy bacharach, inc. Warrants this instrument, excluding sensors, to be free from defects in materials and workmanship for a period of two years from the date of purchase by the original owner. The sensors have a warranty period of one year from the date o...

Page 3

Mgd-100 manual 6109-9000 rev 3 3 performing all needed repa irs to restore the instrument to full opera ting condition. Prior to shipping equipment to ba cha ra ch, conta ct our office for a n rma # (returned mercha ndise a uthorization). All returned goods m ust be a ccompa nied with an rma number....

Page 4: Table Of Contents

Mgd-100 manual 4 6109-9000 rev 3 table of contents section 1. Overview.............................................................................................. 5 1.1. General information.......................................................................................... 5 1.2. Technical s...

Page 5: Section 1. Overview

Mgd-100 manual 6109-9000 rev 3 5 section 1. Overview 1.1. General information the mgd-100 is the ideal gas detection solution for installations requiring a quality and affordable stand-alone gas detector. It consists of 1 to 6 remote gas sensors connected to and powered by a controller. The controll...

Page 6: (Single Level Alarm)

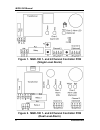

Mgd-100 manual 6 6109-9000 rev 3 figure 1. Mgd-100 1- and 2-channel controller pcb (single level alarm) figure 2. Mgd-100 1- and 2-channel controller pcb (dual level alarm).

Page 7: (Single Level Alarm)

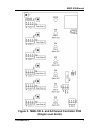

Mgd-100 manual 6109-9000 rev 3 7 figure 3. Mgd-100 4- and 6-channel controller pcb (single level alarm).

Page 8: (Dual Level Alarm)

Mgd-100 manual 8 6109-9000 rev 3 figure 4. Mgd-100 4- and 6-channel controller pcb (dual level alarm).

Page 9

Mgd-100 manual 6109-9000 rev 3 9 figure 5. Examples mgd-100 pcbs.

Page 10

Mgd-100 manual 10 6109-9000 rev 3 1.2. Technical specifications specification description pow er supply 120 vac 60 hz, 220 vac 50 hz, or 12 vdc (specified at time of order); max power 20w 1- and 2-channel systems 4- and 6-channel systems audible alarm (buzzer) internal, continuous internal, intermit...

Page 11

Mgd-100 manual 6109-9000 rev 3 11 specification description 1- and 2-channel systems 4- and 6-channel systems standard enclosure ratings mgd-100: ip41 controller: ip51 mgd-100: ip41 controller: ip51 dimensions and weight: controller 8.4” x 4.1” x 3.15” 214 x 105 x 80 mm 2.9 lbs / 1.3 kg 10.3” x 10.4...

Page 12

Mgd-100 manual 12 6109-9000 rev 3 supported cfm and duct sizes for the duct mount housing units duct size inches 12 x 12 12 x 24 18 x 18 24 x 24 24 round feet 1 x 1 1 x 2 1.5 x 1.5 2 x 2 pi x 1 x 1 area (ft 2 ) 1 2 2.25 4 3.14 cfm ft/min (based on cfm and duct size) 2800 2800 n/a n/a n/a n/a 3000 30...

Page 13: 2.2. General Guidelines

Mgd-100 manual 6109-9000 rev 3 13 section 2. Placing sensors 2.1. Installation warnings note: this instrument can be equipped with a semiconductor sensor for the detection of refrigerant, combustible and voc gases. Semiconductor sensors are not gas specific and respond to a variety of other gases in...

Page 14

Mgd-100 manual 14 6109-9000 rev 3 avoid routing sensor cabling outside of premises, or between buildings via overhead cables. Also, sensor wiring should be kept to a minimum of 20 in (500mm) from the main power supply and telephone cables. When connecting the main power supply and/or sensor cables e...

Page 15: 2.3. Machinery Rooms

Mgd-100 manual 6109-9000 rev 3 15 2.3. Machinery rooms there is no absolute rule in determining the number of sensors and their locations. However, a number of simple guidelines will help to make a decision. Sensors monitor a point as opposed to an area. If the gas leak does not reach the sensor the...

Page 16: 2.4. Refrigerated Spaces

Mgd-100 manual 16 6109-9000 rev 3 otherwise, a gas leak might pass by in a high-speed jet and not be detected by the sensor. • make sure that pits, stairwells and trenches are monitored since they may fill with stagnant pockets of gas. • if a pressure relief vent (prv) pipe is fitted to the system, ...

Page 17

Mgd-100 manual 6109-9000 rev 3 17 • with air-cooled chillers or air-cooled condensers with non- enclosed condenser sections it is difficult to effectively monitor leaks in the coil sections. With some designs it will be possible using an airflow sensor to monitor airflow to the start–up fans in the ...

Page 18

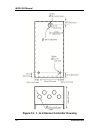

Mgd-100 manual 18 6109-9000 rev 3 section 3. Housing dimensions figure 6. Mgd-100 standard housing.

Page 19

Mgd-100 manual 6109-9000 rev 3 19 figure 7. Mgd-100 exd housing figure 8. Mgd-100 ip66 housing (with splash guard).

Page 20: Mount

Mgd-100 manual 20 6109-9000 rev 3 figure 9. Mgd-100 ip66 housing with remote sensor figure 10. Mgs-100 ip66 housing with airflow duct mount see figure 8 for mounting locations. Cut out in duct for pitot 22mm.

Page 21

Mgd-100 manual 6109-9000 rev 3 21 figure 11. 4- & 6-sensor controller housing.

Page 22

Mgd-100 manual 22 6109-9000 rev 3 figure 12. 1- to 2-sensor controller housing.

Page 23: 4.1. Wiring Mgd-100S

Mgd-100 manual 6109-9000 rev 3 23 section 4. Wiring instructions 4.1. Wiring mgd-100s step wiring mgd-100s 1 connect a 4-conductor cable (18 awg recommended) to a terminal block on the mgd-100 controller (cn1, cn2, etc). 2 route the cable to an mgd-100. 3 for standard (ip41) mgd-100 housings, remove...

Page 24

Mgd-100 manual 24 6109-9000 rev 3 important: ensure that connections 1 to 4 on the sensor connect to their corresponding numbers on the terminal block in the main control unit, otherwise it could cause damage to the mgd-100. Note: you may use different cables and longer distances provided the corres...

Page 25: 4.3. Relays

Mgd-100 manual 6109-9000 rev 3 25 4.3. Relays connect leads to terminal block for common (com) and n/o and/or n/c connections as required. Note that relays are rated as 10a @ 120/230 vac. Relay wiring type two-alarm units one-alarm units 1-2 channel units cn5: low-level alarm cn4: high-level alarm c...

Page 26

Mgd-100 manual 26 6109-9000 rev 3 note: the main power supply cable should be of an approved type based on local regulations. Note: the blanking plugs for cable entries should only be removed if being replaced by conduit fittings. Note: if replacement of the main power fuse is required, use only the...

Page 27: Diagram

Mgd-100 manual 6109-9000 rev 3 27 figure 13. 1- & 2-sensor, one-alarm installation diagram.

Page 28: Diagram

Mgd-100 manual 28 6109-9000 rev 3 figure 14. 1- & 2-sensor, two-alarm installation diagram.

Page 29

Mgd-100 manual 6109-9000 rev 3 29 figure 15. 4- & 6-sensor, one-alarm installation.

Page 30

Mgd-100 manual 30 6109-9000 rev 3 figure 16. 4- & 6-sensor, two-alarm installation.

Page 31

Mgd-100 manual 6109-9000 rev 3 31 section 5. Operation and stabilization when power to the unit is switched on, there is a 3-minute delay before the system activates. This allows the sensors to warm up to the correct temperature for gas detection. • on a two-alarm unit the green light on the alarm p...

Page 32

Mgd-100 manual 32 6109-9000 rev 3 operation state description idle only the green light on the panel is on. No gas is present. Power interrupted if the green light is off, power to the unit has been interrupted. Refer to section 7. Alarm conditions one-alarm units: one or more red lights on the pane...

Page 33: 6.1. Introduction

Mgd-100 manual 6109-9000 rev 3 33 section 6. Functional tests and calibration 6.1. Introduction to comply with the requirements of en378 and the european f-gas regulation, sensors must be tested annually. However, local regulations may specify the nature and frequency of this test. Caution: check lo...

Page 34

Mgd-100 manual 34 6109-9000 rev 3 important: before testing the sensors on-site, the mgd- 100 must have been powered up and allowed to stabilize for at least 24 hours. See section 5. Important: failure to test or calibrate the unit in accordance with applicable instructions and with industry guideli...

Page 35

Mgd-100 manual 6109-9000 rev 3 35 caution: before you carry out the bump test or calibration: • advise occupants, plant operators, and supervisors. • check if the mgd-100 is connected to external systems such as sprinkler systems, plant shut down, external sirens and beacons, ventilation, etc. And d...

Page 36

Mgd-100 manual 36 6109-9000 rev 3 step electrical reset of one-alarm systems 2 connect a voltmeter between pins 4 (-ve) and 2 (+ve) of the sensor terminal connector block for each channel in turn (cn1, cn2, etc.) and adjust the corresponding calibration pot (p1, p2, etc.) to the sensor standby volta...

Page 37: 6.4. Bump Testing

Mgd-100 manual 6109-9000 rev 3 37 step electrical reset of two-alarm systems 1 for the sensor standby voltage, connect a dc voltmeter between tp5 (0v) and tp4 (+v) as shown in figure 14 and figure 16. Adjust pot rv1. 2 for low-level alarm voltage, connect your dc voltmeter between tp5 (0v) and tp2 (...

Page 38

Mgd-100 manual 38 6109-9000 rev 3 step bump testing using calibration gas cylinders 1 remove the enclosure lid of the gas sensor and controller (not applicable to exd remote sensor and vent pipe model as monitoring of voltage can be done on controller). 2 connect the voltmeter to the channel under t...

Page 39

Mgd-100 manual 6109-9000 rev 3 39 figure 18. Gas ampoules for bump testing step bump testing using gas ampoules 1 make sure that both the ampoules and the calibration beaker are clean and dry. 2 unscrew the beaker wing nut and place the ampoule so that it sits in the base of the beaker (see figure 1...

Page 40: 6.6. Calibration Options

Mgd-100 manual 40 6109-9000 rev 3 step bump testing using gas ampoules 9 remove the beaker from the sensor. Carefully remove any ampoule remains from the gas detector and beaker. 6.5. Calibration overview to comply with the requirements of en378 and the european f-gas regulation, sensors must be tes...

Page 41

Mgd-100 manual 6109-9000 rev 3 41 step sensor board exchange 1 power off the unit and remove lid of sensor enclosure. 2 note the color code of the cable in positions 1,2,3 and 4 of the connector block. 3 undo the cable and 2 screws securing the sensor board and remove the board. 4 fit the new pre-ca...

Page 42

Mgd-100 manual 42 6109-9000 rev 3 first disable the 3-minute alarm delay on a one-alarm system by moving the jumper link at jp1 to the off position. Two adjustments are required and they are both performed on the controller unit. The alarm threshold voltage (atv) is the voltage at which the alarm an...

Page 43

Mgd-100 manual 6109-9000 rev 3 43 6.9. Gas calibration (two-alarm units) note: this calibration procedure is for a two-alarm unit. For one-alarm units, refer to the previous section. Note: the delay on a two-alarm system is approximately 25 seconds and cannot be deactivated. All adjustments are perf...

Page 44

Mgd-100 manual 44 6109-9000 rev 3 section 7. Troubleshooting symptom possible cause(s) no lights displayed on panel • power failure (check supply) • tripped circuit breaker or blown fuse on electrical supply • blown fuse at the electrical supply on the controller pcb board red light is on, but no al...

Page 45

Mgd-100 manual 6109-9000 rev 3 45 place the negative probe on terminal position 4 and with the positive on 1, 3, 2, check the values. The readings are lower at the sensor due to power drop in the line. The terminals should have the values shown in the table below. You can monitor this as follows: • ...

Page 46

Mgd-100 manual 46 6109-9000 rev 3.

Page 47: Eclaration

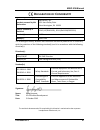

Mgd-100 manual 6109-9000 rev 3 47 d eclaration of c onformity the manufacturer of the products covered by this declaration: bacharach, inc. 621 hunt valley circle new kensington, pa 15068 year(s) conformity is declared: 2012 (iec/en61010), 2011 (en61326/en55011) product(s): mgd model(s): mgd-100 the...

Page 48

Mgd-100 manual 48 6109-9000 rev 3 world headquarters 621 hunt valley circle, new kensington, pennsylvania 15068 phone: 724-334-5000 • toll free: 1-800-736-4666 • fax: 724-334-5001 website: www.Mybacharach.Com • e-mail: help@mybacharach.Com.