- DL manuals

- Bacharach

- Test Equipment

- PCA 2

- Operating & Maintenance Instructions

Bacharach PCA 2 Operating & Maintenance Instructions

Summary of PCA 2

Page 1

Product leadership • training • service • reliability portable combustion analyzer instruction 24-9448 operation & maintenance rev. 1 - october 2006.

Page 2: Warranty

Warranty bacharach, inc. Warrants to buyer that at the time of delivery this product will be free from defects in material and manufacture and will conform substantially to bacharach inc.’s applicable specifications. Bacharach’s liability and buyer’s remedy under this warranty are limited to the rep...

Page 3: Contents

Instruction 24-9448 contents contents 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 1.1 pca 2 general descrpton . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1 1.2 sales combo & model confguratons . . . . . . . . . . . . . . . . . . . . . .1-...

Page 4

Instruction 24-9448 contents 4 operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 4.1 operatng tps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1 4.2 turnng on the analyzer and warm up . . . . . . . . . . . . . . . . . . .4-2 4...

Page 5

Instruction 24-9448 contents 6 maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 6.1 pca 2 dsassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2 6.2 water trap / flter mantenance . . . . . . . . . . . . . . . . . . . . . . . . . 6-6 ...

Page 6: Notes:

Instruction 24-9448 v contents notes:.

Page 7: 1 Introduction

Instruction 24-9448 1-1 introduction 1 introduction 1.1 pca 2 general description the pca 2 s a commercal-grade hand-held combuston and emssons analyzer desgned for on-demand samplng of lght ndustral, nsttu- tonal, commercal and resdental furnaces, applances, and bolers. The basc nstrument s suppled...

Page 8

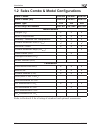

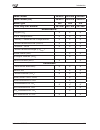

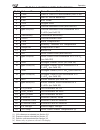

Instruction 24-9448 1-2 introduction 1.2 sales combo & model configurations sales combo 24-8350 24-8351 24-8352 sales combo (kit) 24-8370 24-8371 24-8372 model type 225 235 245 pca2 only part number 24-7301 24-7302 24-7303 measurements oxygen (o 2 ) 3 3 3 stack temperature 3 3 3 prmary / ambent ar t...

Page 9

Instruction 24-9448 1-3 introduction sales combo 24-8353 24-8354 24-8355 sales combo (kit) 24-8373 24-8374 24-8375 model type 255 265 275 pca2 only part number 24-7304 24-7305 24-7306 measurements oxygen (o 2 ) 3 3 3 stack temperature 3 3 3 prmary / ambent ar temperature 3 3 3 carbon monoxde low (co...

Page 10: 1.3 Features & Benefits

Instruction 24-9448 1-4 introduction 1.3 features & benefits • powered by 4 ‘aa’ alkalne batteres, or nmh rechargeable batteres. An optonal ac power adapter provdes contnuous operaton. • internal chargng crcut allows rechargeable batteres to be charged nsde the analyzer wth the use of the optonal ac...

Page 11: 1.4 Operational Overview

Instruction 24-9448 1-5 introduction 1.4 operational overview the pca 2 s powered by ether ts 4 nternal batteres, or by an optonal ac power adapter that operates from any convenent source of 100– 240 vac, 50/60 hz power. The type of batteres used can be ether dspos- able alkalne or rechargeable nmh....

Page 12

Instruction 24-9448 1-6 introduction emsson levels n the stack gas and then dsplay measured and calculated values on ts lcd. Values are lsted n secton 2 specfcatons. Durng a test, the co low sensor s protected from hgh co levels by beng automatcally flushed wth fresh ar when the detected co level ex...

Page 13

Instruction 24-9448 1-7 introduction t-stack t-air figure 1-1. Pca 2 components lcd – 160 x 160 graphic display f1 / f2 / f3 – soft menu buttons, whose functions are defined by labels appearing above them on lcd arrow buttons: – moves cursor up the display, or increments an alphanumerical value – mo...

Page 14: 1.5.3 Power (Ac Adapter)

Instruction 24-9448 1-8 introduction 1.5.3 power (ac adapter) the ac power adapter p/n 24-1404 can be used as an external power sup- ply, whch wll run the analyzer on a contnuous bass. When usng rechargeable nmh batteres, the ac power adapter can also be used to charge the batteres whle nsde the ana...

Page 15: 1.6 Front Panel Buttons

Instruction 24-9448 1-9 introduction 1.6 front panel buttons descrptons of the front panel buttons are gven below. Note that a control may perform multple functons as determned by what screen s beng dsplayed at the tme. The functons of these buttons are defned by labels ap- pearng above them on the ...

Page 16

Instruction 24-9448 1-10 introduction selects a hghlghted menu. In addton, f changes were made to one of the analyzer’s operatng parameters (e.G., date, tme, o 2 reference, etc.), pressng ths button con- frms those changes and saves them n memory. Starts and stops a combuston test when the combus- t...

Page 17: 2 Specifications

Instruction 24-9448 2-1 specifications 2 specifications the pca 2 directly measures and displays: the gases dsplayed depend on the analyzer’s model number. Refer to secton 1.2. Oxygen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 to 20.9% stack tempera...

Page 18: Normal Operating Conditions:

Instruction 24-9448 2-2 specifications normal operating conditions: temperature: analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 to 104 ºf (0 to 40 ºc) probe tp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1,472 ºf (800 ºc) max. Humdty: analyzer . . . . ...

Page 19: Power Requirements:

Instruction 24-9448 2-3 specifications power requirements: four dsposable ‘aa’ alkalne batteres provde at least 15 hours of contnu- ous operaton. Nmh rechargeable batteres can also be used, wth the operatng tme dependent on battery type and condton. An optonal ac power adapter, whch runs from any co...

Page 20: Notes:

Instruction 24-9448 2-4 specifications notes:.

Page 21: 3 Initial Setup

Instruction 24-9448 3-1 initial setup 3 initial setup 3.1 scope before usng the pca 2, you must: • install batteres, or plug n the optonal ac power adapter (secton 3.2) • connect the probe and hose assembly (secton 3.3) • check, and f necessary, make changes to the analyzer’s confguraton (secton 3.4...

Page 22

Instruction 24-9448 3-2 initial setup 3.2.2 using the ac power adapter the ac power adapter s capable of powerng the analyzer on a contnuous bass. The adapter plugs nto an approprate 100–240 vac, 50/60 hz wall outlet, and produces an output of +9 vdc. The adapter’s output connector plugs nto the ana...

Page 23

Instruction 24-9448 3-3 initial setup figure 3-2. Connecting the probe and hose assembly to the pca 2 power p t-stack t-air gas differential pressure hose (— ∆p) (optional) probe handle water trap / filter assembly stack gas thermocouple connector (t-stack) ac power adapter jack (power) option conne...

Page 24: 3.4 Operating Parameters

Instruction 24-9448 3-4 initial setup 3.4 operating parameters the pca 2 s set up at the factory for the followng operatng parameters: fuel . . . . . . . . . . . . . . . . . . . . .Natural gas temperature unts . . . . . . . . .°f pressure unts . . . . . . . . . . . .Inches of water column (nwc) poll...

Page 25

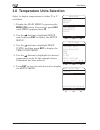

Instruction 24-9448 3-5 initial setup 3.6 temperature units selection select to dsplay temperature n ether °f or °c as follows: 1. Dsplay the main menu by pressng the menu (f2) button. If necessary, press esc untl menu appears above f2. 2. Use the buttons to hghlght setup, and then press ent to dspl...

Page 26

Instruction 24-9448 3-6 initial setup 3.7 pressure units selection select to dsplay pressure n inches of water column (nwc), mllbar (mb), pascals (pa), or hectopascals (hpa) as follows: 1. Dsplay the main menu by pressng the menu (f2) button. If necessary, press esc untl menu appears above f2. 2. Us...

Page 27

Instruction 24-9448 3-7 initial setup 3.8 pollution units selection the pca 2 s capable of convertng the measured ppm levels of co, no, no 2 , and so 2 to varous polluton unts usng cfr40 part 60 emsson factors. Note that the polluton-unt conversons for no, no 2 and nox are based on the molecular weg...

Page 28: 3.9 Date Setup

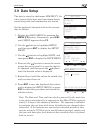

Instruction 24-9448 3-8 initial setup 3.9 date setup the date s stored n the format: mm/dd/yy. Its value s part of the date and tme stamp that s saved along wth each combuston test record. Set the analyzer’s nternal clock to the current date as follows: 1. Dsplay the main menu by pressng the menu (f...

Page 29: 3.10 Time Setup

Instruction 24-9448 3-9 initial setup 3.10 time setup the tme s stored n the format: hh:mm:ss am/pm. Its value s part of the date and tme stamp that s saved along wth each combuston test record. Set the analyzer’s nternal clock to the current tme as follows: 1. Dsplay the main menu by pressng the me...

Page 30: 3.11 O

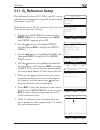

Instruction 24-9448 3-10 initial setup 3.11 o 2 reference setup the measured values of co, nox, and so 2 can be ndvdually referenced to a specfc o 2 percentage of between 0 and 15%. Indvdually set up the o 2 reference value for each of the above gases as follows: 1. Dsplay the main menu by pressng t...

Page 31

Instruction 24-9448 3-11 initial setup 3.12 print pressure selection select whether to prnt or not prnt the pressure measurement on the combuston test prntout as follows (see fgure 4-3 on page 4-31): 1. Dsplay the main menu by pressng the menu (f2) button. If necessary, press esc untl menu appears a...

Page 32

Instruction 24-9448 3-12 initial setup 3.13 zoom-display selection zoom-dsplay provdes an addtonal combuston test screen that shows the test values of o 2 , co, and effcency n extra large characters, thus al- lowng the operator to vew the dsplay of these values from a longer dstance. Pressng the ent...

Page 33

Instruction 24-9448 3-13 initial setup 3.14 battery charger selection when usng rechargeable nmh batteres, the ac power adapter can be used to charge the bat- teres whle nsde the analyzer. The analyzer’s rapd-charger crcut, however, must be frst turned on. Important: when using disposable alkaline b...

Page 34: 3.15 Logging Selection

Instruction 24-9448 3-14 initial setup 3.15 logging selection when the loggng functon s actvated, up to 500 combuston test records wll be automatcally stored n memory at a preset nterval over a pre- determned length of tme. Refer to secton 4.12 for detaled nformaton on how to select the loggng funct...

Page 35: 4 Operation

Instruction 24-9448 4-1 operation 4 operation 4.1 operating tips • when an analyzer s brought n from a cold vehcle, let t warm up slowly to mnmze condensaton. Temperatures below freezng wll not dam- age the analyzer; however, brngng a cold analyzer nto a warm, humd envronment may cause condensate to...

Page 36

Instruction 24-9448 4-2 operation 4.2 turning on the analyzer and warm up 1. Connect the probe and hose assembly, and make sure that the analyzer s properly set up per secton 3 initial setup. Important: do not insert probe into stack before turning on the analyzer! 2. Place the probe n an area that ...

Page 37: 4.3 Selecting A Fuel

Instruction 24-9448 4-3 operation 4.3 selecting a fuel the top lne of the combuston test hold screen shows the fuel currently selected. In the example shown, the current fuel s natural gas. If necessary, change the fuel as follows: 1. Dsplay the main menu by pressng the menu (f2) button. 2. Use the ...

Page 38: 4.4 Sampling Point

Instruction 24-9448 4-4 operation 4.4 sampling point forced air furnace – for atmospherc burner or gravty vented, forced ar heatng equpment wth a clamshell or sectonal heat exchanger de- sgn, test each of the exhaust ports at the top of the heat exchanger. The probe should be nserted back nto each o...

Page 39

Instruction 24-9448 4-5 operation 4.5 performing a combustion test ensure that the followng has been completed, and then proceed wth the combuston test as descrbed below: • turn on analyzer and allow t to warm up (secton 4.2). • select fuel beng burned (secton 4.3). • inset probe nto stack (secton 4...

Page 40

Instruction 24-9448 4-6 operation 4. You can now begn burner-servce procedures. The analyzer readngs wll change quckly to show changes n burner performance. Caution: position the water trap with its gas-flow arrow pointing upward. Do not let water condensate go above the tip of the riser tube. The s...

Page 41

Instruction 24-9448 4-7 operation 4.6 making a draft / pressure measurement the dfference n pressure (∆p) between two areas can be measured by usng the analyzer’s two pressure ports and the pressure screen. By usng the –∆p port as the reference, the pressure appled to the +∆p port wll be dsplayed on...

Page 42: 4.7 Saving Test Data

Instruction 24-9448 4-8 operation b. Dsconnect any hoses connected to the +∆p and –∆p ports, and then press ent to zero the pressure sensor. C. Reconnect any hoses. When measurng draft, simply leave the –∆p port open to the atmosphere and connect the probe’s draft hose to the +∆p port (see fgure 3-2...

Page 43

Instruction 24-9448 4-9 operation 4.8 ending a combustion test warning! Burn hazard. Do not touch the probe after removing it from the stack. Allow the probe to cool before handling (about 5 minutes). 1. Remove probe from stack. 2. Allow the pump to run untl all combuston gases have been flushed fro...

Page 44: 4.11 Low Battery Alarm

Instruction 24-9448 4-10 operation 4.10 turning off the analyzer & purging turn off the analyzer by pressng the i/o but- ton for at least 2 seconds, or untl two beeps are heard. The unt wll count down 5 seconds before shuttng down, gvng the operator an opportu- nty to keep the analyzer turned on by ...

Page 45: 4.12 Data Logging

Instruction 24-9448 4-11 operation 4.12 data logging when the loggng functon s actvated, up to 500 combuston test records wll be automatcally stored n memory at a preset nterval (1, 5, 10, 15, 30 seconds, 1, 2, 5, 10 mnutes) over a predetermned duraton (5, 10, 15, 30 mnutes, 1, 2, 5, 10, 24, 48 hour...

Page 46

Instruction 24-9448 4-12 operation 4.12.1 turning on data logging important: before turning on data logging and starting the data logging process, the analyzer should already be set up to perform a combustion test per section 4.5. Turn on data loggng as follows: 1. Dsplay the main menu by pressng th...

Page 47

Instruction 24-9448 4-13 operation 4.12.2 setting the logging interval and duration the loggng nterval s the length of tme between measurements, whle the loggng duraton s the tme allocated to the loggng process. Set the loggng nterval and duraton as follows: tip: if the duration is set for more than...

Page 48

Instruction 24-9448 4-14 operation 4.12.3 starting the data logging process after turnng on data loggng and settng the nterval and duraton, the analyzer wll pause at the logging summary screen, where the currently selected nterval and duraton tme perods are dsplayed. Press ent to start the combuston...

Page 49: 4.13 Memory

Instruction 24-9448 4-15 operation 4.12.4 ending the data logging process data loggng wll stop and the pump wll turn off after the prescrbed duraton, or after all 500 memory locatons are flled. To ext the combuston test log screen, press the run/hold button twice to dsplay the com- buston test hold ...

Page 50

Instruction 24-9448 4-16 operation 4.13.1 recalling combustion test data recall ndvdual combuston test data records as follows: 1. Dsplay the main menu by pressng the menu (f2) button. If necessary, press esc untl menu appears above f2. 2. Use the buttons to hghlght memory, and then press ent to dsp...

Page 51

Instruction 24-9448 4-17 operation 4.13.2 recalling logged test data recall ndvdual logged combuston test data records as follows: 1. Dsplay the main menu by pressng the menu (f2) button. If necessary, press esc untl menu appears above f2. 2. Use the buttons to hghlght memory, and then press ent to ...

Page 52: 4.13.3 Clearing Memory

Instruction 24-9448 4-18 operation 4.13.3 clearing memory when all memory (“snap shot”) locatons used to store ndvdual combuston test records have been flled, the next combuston test record saved wll overwrte the oldest. When all loggng memory locatons n the loggng drectory are full, they must be ma...

Page 53

Instruction 24-9448 4-19 operation 4.14 downloading stored data to a computer the combuston test data that was stored n ether the analyzer’s memory drectory (secton 4.7), or loggng drectory (secton 4.12), can be down- loaded to a computer usng the pca 2 data recovery program and usb cable that are s...

Page 54

Instruction 24-9448 4-20 operation 4.14.1 pca 2 data recovery program installation the pca 2 data recovery program s suppled wth the analyzer on a cd (p/n 24-1425). Install ths program as follows: 1. Insert the pca 2 cd nto the computer’s cd-rom drve. 2. Locate the cd-rom drve n wndows explorer and ...

Page 55

Instruction 24-9448 4-21 operation 5. Clck install to confrm the destnaton folder and user nformaton. 6. Clck finish after all fles have been coped nto the destnaton folder. 7. At ths tme the pca2 data recovery program con should appear under "start all programs menu. 8. Ths completes the nstallaton...

Page 56

Instruction 24-9448 4-22 operation 4.14.2 computer to pca 2 connection & usb device driver installation connect the usb cable (p/n 104-4032) that was suppled wth the pca 2, and, f necessary, nstall the analyzer’s usb devce drver as follows: 1. Wth both the pca 2 and computer turned on, nsert the app...

Page 57

Instruction 24-9448 4-23 operation 3. Select “install from a lst or specfc locaton (advanced)” and clck next>. 4. Select to search for the best drver and then browse to folder c:\program fles\pca2data. Clck next>. 5. At the hardware installaton wndow, clck continue anyway. Our driver has been thorou...

Page 58: 4.14.3 Recovering Data

Instruction 24-9448 4-24 operation 6. After the found new hardware wzard has fnshed nstallng the software, clck finish to close the wzard. 4.14.3 recovering data before data can be recovered from the analyzer, nstall the pca 2 data recovery program, usb cable, and usb devce drver as descrbed n sec- ...

Page 59

Instruction 24-9448 4-25 operation status line showing pca 2 is successfully connected to the computer use this section of window to recover logging data use this section of window to recover combustion data start the download process by clicking the desired open log / data file button select a pre-...

Page 60

Instruction 24-9448 4-26 operation note: the filename is automatically given a csv (comma separated value) extension, allowing the file to be directly opened by most spreadsheet programs for analysis. 3. After selectng a folder and enterng the flename, clck open and then clck start to begn the downl...

Page 61

Instruction 24-9448 4-27 operation 4.14.4 unplugging the usb cable caution: to avoid possible electronic damage to the ana- lyzer, it is not advisable to unplug the usb cable without first turning off the pca 2 usb connection using the “safely remove hardware” icon in the windows xp system tray. Do ...

Page 62

Instruction 24-9448 4-28 operation 4.15 importing saved data into a spreadsheet data that was recovered and saved as an ascii text fle wth a “csv” extenson, as descrbed n secton 4.14, can easly be opened for vewng n most spreadsheet programs by smply double-clckng the flename. For example: double-cl...

Page 63

Instruction 24-9448 4-29 operation table 4-2 . Downloaded data fields field column name data name or value 1 tme tme of test n 12 hour format (am / pm) 2 date date of test n mm/dd/yy 3 fuel fuel name 4 %o2 oxygen level 5 co carbon monoxde level (see feld 26) 6 ppm co(o2) carbon monoxde level referen...

Page 64: 4.16 Printing Test Data

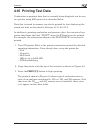

Instruction 24-9448 4-30 operation 4.16 printing test data combuston or pressure data that s currently beng dsplayed can be sent to a prnter usng irda protocol as descrbed below. Data that s stored n memory can also be prnted by frst dsplayng the stored test data as descrbed n sectons 4.13.1 & 4.13....

Page 65

Instruction 24-9448 4-31 operation figure 4-3. Printer alignment & sample printout bacharach, inc. Pca 2 sn: xxxxxx ===================== time 01:00:00 pm date 10/06/06 fuel natural gas o2 4.0 % co 12 ppm eff 82.6 % co2 9.5 % t-stack 374 °f t-air 68.0 °f ea 21 % no 18 ppm no temp 70.5 °f no2 6 ppm n...

Page 66: Notes:

Instruction 24-9448 4-32 operation notes:.

Page 67: 5 Calibration

Instruction 24-9448 5-1 calibration 5 calibration important: before performing any calibration procedure, ensure that fresh batteries are installed or use the optional ac power adapter. Also ensure that the analyzer is at room temper- ature and will be sampling fresh air when turned on. 5.1 smart se...

Page 68

Instruction 24-9448 5-2 calibration any errors detected durng warm-up wll be lsted on the dsplay mmedately fol- lowng warm-up. For example, the screen to the rght shows that the battery s low. Correct any errors before proceedng. Refer to secton 7.3 for a lstng of error messages and ther meanng. 2. ...

Page 69

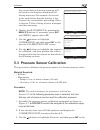

Instruction 24-9448 5-3 calibration play the calibrate pressure screen. “measured” is the pressure value currently being detected by the pressure sensor, while “applied” is a known value of pressure that will be applied for calibration purposes. 4. With both the –∆p and +∆p ports open to the atmosph...

Page 70: 5.4 T-Stack Calibration

Instruction 24-9448 5-4 calibration 5.4 t-stack calibration ths procedure frst zeros and then spans the stack-temperature channel to known temperature values. The use of an electronc thermocouple smulator s the preferred method of producng the desred calbraton temperatures. Alternatvely, contaners o...

Page 71

Instruction 24-9448 5-5 calibration 5. Wat untl the measured readng stablzes, and then press ent to calbrate the ts-zero measured value to that of the appled value; after whch the message “good calbraton” should brefly appear followed by the calibrate ts-span screen. Ts-span procedure: 6. Set thermo...

Page 72: 5.5 T-Air Calibration

Instruction 24-9448 5-6 calibration 5.5 t-air calibration ths procedure frst zeros and then spans the ambent-temperature chan- nel to known temperature values. The use of an electronc thermocouple smulator s the preferred method of producng the desred calbraton temperatures. Alternatvely, contaners ...

Page 73

Instruction 24-9448 5-7 calibration the calibration range is from 32 to 41 °f (0 to 5 °c). An attempt to calibrate outside this range will cause the message “bad calibration wrong cal entry” to appear in the following step. 5. Wat untl the measured readng stablzes, and then press ent to calbrate the...

Page 74

Instruction 24-9448 5-8 calibration 5.6 co-lo sensor calibration note that the co-lo sensor also measures h 2 for the purpose of com- pensatng the co readng for the presence of h 2 n the gas sample. Ths procedure frst spans the co-lo sensor and, optonally, spans the h 2 part of the sensor to known g...

Page 75

Instruction 24-9448 5-9 calibration if the sensor’s output is too low to be usable, then the message “bad calibration sensor end of life, entry not saved” will appear. The sen- sor will now be marked as being bad in the diagnostics screen. Note: h 2 calibration can be bypassed by pressing the esc bu...

Page 76: 5.7 So

Instruction 24-9448 5-10 calibration 5.7 so 2 sensor calibration ths procedure spans the optonal sulfur doxde sensor to a known gas level. Material required: calbraton kt, p/n 24-7059 gas cylnder: 100 ppm so 2 n ntrogen, p/n 24-1158 procedure: 1. If not already done, turn on the analyzer and dsplay ...

Page 77: 5.8 No Sensor Calibration

Instruction 24-9448 5-11 calibration if the sensor’s output is too low to be usable, then the message “bad calibration sensor end of life, entry not saved” will appear followed by the calibration list screen being re-displayed. The sensor will now be marked as being bad in the diagnostics screen. 6....

Page 78: 5.9 No

Instruction 24-9448 5-12 calibration brefly appear followed by the calibration list screen beng re-dsplayed. If the sensor’s output is low, but still usable, then the message “good calibration warning low sensor” will appear. The sensor will now be marked as being low in the diagnostics screen. If t...

Page 79

Instruction 24-9448 5-13 calibration cause the message “bad calibration wrong cal entry” to appear in the following step. 5. Adjust regulator for a flowmeter ndcaton of approxmately 2 scfh. Wat untl the measured readng stablzes (approxmately 3 mnutes), and then press ent to calbrate the no 2 measure...

Page 80

Instruction 24-9448 5-14 calibration 4. Use the and buttons to enter an appled value that exactly equals the concen- traton stamped on the co cylnder. The calibration range is from 250 to 11,000 ppm. An attempt to calibrate out- side this range will cause the message “bad calibration wrong cal entry...

Page 81: 6 Maintenance

Instruction 24-9448 6-1 maintenance 6 maintenance customer mantenance of the pca 2 s lmted to the followng: battery replacement or chargng usng ac power adapter (secton 3.2) sensor re-calbraton (secton 5) water trap / flter assembly mantenance (secton 6.2) sensor replacement (secton 6.3) probe therm...

Page 82: 6.1 Pca 2 Disassembly

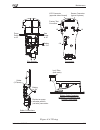

Instruction 24-9448 6-2 maintenance 6.1 pca 2 disassembly the followng procedure descrbes how to dsassemble the analyzer, whle fgures 6-1 thru 6-4 llustrate how the analyzer s put together. Tools requred: medum phllps screwdrver procedure: 1. Unplug all thermocouples from bottom of analyzer. 2. Remo...

Page 83

Instruction 24-9448 6-3 maintenance figure 6-2. Inside view with rear case removed sensor positions 225 24-7301 235 24-7302 245 24-7303 255 24-7304 265 24-7305 275 24-7306 #1 o 2 o 2 o 2 o 2 o 2 o 2 #2 co lo co lo co lo co lo co lo co lo #3 so 2 no 2 so 2 #4 no co hi no no model p/n position sensor ...

Page 84

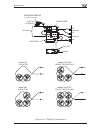

Instruction 24-9448 6-4 maintenance figure 6-3. Tubing connections models 235 & 245 p/ns 24-7302 & 24-7303 model 255 p/n 24-7304 models 265 & 275 p/ns 24-7305 & 24-7306 model 225 p/n 24-7301 pressure sensor on printed circuit board –∆p +∆p –∆p (bottom) +∆p (top) pressure purge air gas gas in gas pum...

Page 85

Instruction 24-9448 6-5 maintenance figure 6-4. Wiring solder (2 places) red dot on pump indicates positive (red wire) connection battery to j14 battery to j14 gas pump to j8 purge pump to j9 sensor connector (typical 4 places) factory test connector lcd connector (opposite side of board) ribbon cab...

Page 86

Instruction 24-9448 6-6 maintenance figure 6-5. Disassembling the water trap / filter assembly filter element “a” “b” pry apart filter chamber using a small flat-blade screwdriver inserted into notch when reassem- bling filter chamber, make sure surfaces “a” and “b” contact each other water trap cha...

Page 87

Instruction 24-9448 6-7 maintenance 6.3 smart sensor replacement bacharach’s smart sensor technology allows new sensors to be nstalled wthout needng to be calbrated nsde the analyzer. Note: sensors may be purchased with and without the smart sensor technology pcb. See section 6.4 on how to change ju...

Page 88

Instruction 24-9448 6-8 maintenance 6.4 sensor only replacement all sensors are replaced n a smlar manner. Do the followng to replace ether the o2, co-lo, co-hi, no, no2, or so2 sensor. Refer to section 8.1 replacement parts for list of sensors and part numbers. Turn off the analyzer. Remove the bat...

Page 89

Instruction 24-9448 6-9 maintenance 12. Plug the sensor nto analyzer; and then reattach tubng to gas cup. 13. Install the sensor retaner and battery cover. 12. Allow the sensor that was just nstalled tme to stablze n the crcut before contnung wth ths procedure. Stablzaton tme for all sen- sors (exce...

Page 90

Instruction 24-9448 6-10 maintenance 6.5 nitric oxide sensor battery replacement a sngle lthum battery, located on the no smart sensor assembly, apples a bas voltage to the no sensor to prevent the sensor from destablzng when the analyzer s turned off. The no bas battery s expected to last at least ...

Page 91

Instruction 24-9448 6-11 maintenance 6.6 thermocouple replacement usng the approprate thermocouple replacement kt lsted below, replace the probe’s thermocouple as follows: thermocouple replacement kits: part number replaces thermocouple in a probe with a tube length of . . . 24-8413 6 nches 24-8414 ...

Page 92

Instruction 24-9448 6-12 maintenance 3. Pull old thermocouple from probe body and dscard. 4. The new thermocouple has been coled for shppng purposes. Straghten the thermocouple usng your thumb and ndex fnger. 5. If not already done, nstall suppled o-rngs onto thermocouple. 6. Insert thermocouple nto...

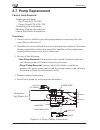

Page 93: 6.7 Pump Replacement

Instruction 24-9448 6-13 maintenance 6.7 pump replacement parts & tools required: replacement pump: gas pump p/n 24-1393 purge pump p/n 3015-1716 solderng iron and solder medum phllps screwdrver small flat blade screwdrver procedure: 1. Gan access to both the gas and purge pumps by removng the rear ...

Page 94: 6.8 Cleaning The Probe

Instruction 24-9448 6-14 maintenance 6.8 cleaning the probe the probe tube and gas-sample hose wll become drty under normal use. Note that the water trap’s flter element should prevent soot from reachng the analyzer’s nternal components. If the probe s not kept clean, t could become clogged and rest...

Page 95: Notes:

Instruction 24-9448 6-15 maintenance notes:.

Page 96: 7 Troubleshooting

Instruction 24-9448 7-1 troubleshooting 7 troubleshooting 7.1 analyzer repair it s recommended that feld repar of the pca 2 be lmted to: checks of prnted crcut board connectors replacng the probe assembly replacng the flter element n the water trap / flter assembly replacng sensors replacng ether th...

Page 97

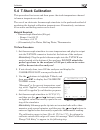

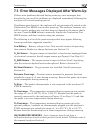

Instruction 24-9448 7-2 troubleshooting 7.3 error messages displayed after warm-up if there were problems detected durng warm-up, error messages that descrbe the nature of the problems are dsplayed mmedately followng the analyzer’s 60 second warm-up perod. If problems were detected, the analyzer wll...

Page 98

Instruction 24-9448 7-3 troubleshooting 7.4 diagnostics and status screens the diagnostics screen lsts the current status of all the smart gas sensors nstalled and the o 2 sensor status and mv output. The status screen provdes a quck reference of key tems when troubleshootng. Diagnostics o2 value: 4...

Page 99: Notes:

Instruction 24-9448 7-4 troubleshooting notes:.

Page 100: 8 Parts & Service

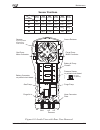

Instruction 24-9448 8-1 parts & service 8 parts & service 8.1 replacement parts item (fig. 8-1) description part no. 1 man pcb assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .24-1371 2 lcd module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24-1374 3 rear case...

Page 101

Instruction 24-9448 8-2 parts & service item (fig. 8-1) description part no. 18 sensors (not-calbrated): 18a o 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24-0788 o 2 sensor pcb only * . . . . . . . . . . . . . . . . . . . . . . . . . . .24-1364 18b co-h 2 . ...

Page 102

Instruction 24-9448 8-3 parts & service figure 8-1. Parts (1 of 2) 22 22 25 25 9 22 –∆p +∆p –∆p (bottom) pressure sensor +∆p (t op) pressure purge air gas in (bottom) out (top) out in 23 25 26 24 16 (typical 4 places) 15 (typical 2 places) 14b (typical 2 places) 14a 14c (typical 3 places) 23 14 11 1...

Page 103

Instruction 24-9448 8-4 parts & service 4 10 7 6 2 1 9 18 17 13 3 5 8 19 12 14 20 21 11 19 figure 8-1. Parts (2 of 2).

Page 104: 8.2 Accessories

Instruction 24-9448 8-5 parts & service 8.2 accessories standard accessories part no. Carryng case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-0865 batteres, 'aa' alkalne (4 requred) . . . . . . . . . . . . . . . . . . . . . . . . 204-0004 12" probe, hose, ...

Page 105: Optional Accessories

Instruction 24-9448 8-6 parts & service optional accessories part no. Ac power adapter (input: 100–240 vac, 50/60 hz; output: 9 vdc @ 1 a) . . . . . . . .24-1404 pca 2 protectve boot wth magnet . . . . . . . . . . . . . . . . . . . . . . . . . .24-1409 ambent ar thermocouples (t-air), k-type: 10 ft....

Page 106: 8.3 Service Centers

Instruction 24-9448 8-7 parts & service 8.3 service centers united states bacharach inc. 621 hunt valley crcle new kensngton, pa 15068 phone: 724-334-5051 fax: 724-334-5723 emal: help@bacharach-nc.Com canada bacharach of canada, inc. 250 shelds court unt #3 markham, ontaro l3r 9w7 canada phone: 905-...

Page 107: Notes:

Notes:.

Page 108

Headquarters: 621 hunt valley circle, new kensington, pa 15068 ph: 724-334-5000 • fax: 724-334-5001 • toll free: 800-736-4666 website: www.Bacharach-inc.Com • e-mail: help@bacharach-inc.Com printed in u.S.A. Iso 9001:2000