- DL manuals

- Badger Meter

- Recording Equipment

- ModMAG M2000

- Installation And Operation Manual

Badger Meter ModMAG M2000 Installation And Operation Manual

Summary of ModMAG M2000

Page 1

® badger meter europa gmbh modmag m2000 installation and operation manual april 2010 mid_m2000_ba_02_1004.

Page 2

Contents page 1. Basic safety precautions .................................................................................................. 1 2. System description ............................................................................................................ 2 3. Installation ...........

Page 3

Basic safety precautions page 1/44 mid_m2000_ba_02_1004 1. Basic safety precautions the electromagnetic flow meter is only suitable for the measurement of conductive fluids. The manufacturer is not liable for damages that result from inproper use or from use that is not in accordance with the requir...

Page 4

System description page 2/44 mid_m2000_ba_02_1004 2. System description the electromagnetic flow meters are intended for the metering of all fluids with electric conductivity of at least 5 μ s/cm (20 μ s/cm for demineralized water). These series of meters is characterized by a high degree of accurac...

Page 5

Installation page 3/44 mid_m2000_ba_02_1004 3. Installation warning: • installation instructions given in the following are to be observed in order to guarantee a perfect functioning and a safe operation of the meter. 3.1 general information 3.1.1 temperature ranges caution: • in order to prevent a ...

Page 6

Installation page 4/44 mid_m2000_ba_02_1004 > 3-5 x dn > 2 x dn ba 20 00- 10 -m id 3.1.3 transport caution: • use lifting lugs when lifting meter flow tubes that are 150 in diameter or larger. • do not lift meter on measuring amplifier or on detector’s neck. • do not lift meter with a fork lift on t...

Page 7

Installation page 5/44 mid_m2000_ba_02_1004 b a 2000-11- m id h > 2 x d n b a 20 00- 12- mid > 3 -5 x d n > 2 x d n ba20 00- 13-m id b a 2000- 14 -m id 3.2.3 meter location caution: • do not install the detector on the suction sides of pumps. This could damage the liner (in particular ptfe liners). ...

Page 8

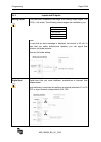

Installation page 6/44 mid_m2000_ba_02_1004 m ax .8 ° ba2 00 0-1 5-m id 3.2.4 pipe reducer requirements with pipe reducers as per din 28545 detectors can be mounted in larger pipelines. You can determine the occurring pressure drop by using the shown nomogram (only applicable to liquids with similar...

Page 9

Installation page 7/44 mid_m2000_ba_02_1004 b a 2000 -16 -mi d 3.2.5 separate version provide a separate version in the following cases: note: • detector protection class ip 68 • fluid temperature > 100 °c • strong vibrations caution: • do not install the signal cable close to power cables, electric...

Page 10

Installation page 8/44 mid_m2000_ba_02_1004 "x" b a 2000 -17m id "x" m4:1 b a 20 00- 18-m id 6 mm² cu 6 mm² cu ba 20 00-19- mi d 3.2.7 plastic or lined pipelines if non-conductive pipelines or pipelines lined with non-conductive material are used, install an additional grounding electrode or groundi...

Page 11

Power connections page 9/44 mid_m2000_ba_02_1004 6 mm² cu ba2 000 -2 0- mi d pe b a 20 00-21-m id 3.2.9 electrically disturbed environment if the pipe material is in an electrically disturbed environment or if metallic pipelines that are not grounded are used, we recommend a grounding as shown in th...

Page 12

Power connections page 10/44 mid_m2000_ba_02_1004 4.2 separate version caution: • connect or separate signal connection cable only when the unit has been switched off. Connection in the measuring amplifier 1. Loosen both fixing screws of the connection cover and remove cover. 2. Loosen upper and low...

Page 13

Power connections page 11/44 mid_m2000_ba_02_1004 b a 17mid weiß (45) braun (46) pink (40) schwarz (44) schwarz (44) gelb/grün (13) gelb (12) grün (11) 5 bis 300 m grün (11) gelb (12) pink (40) weiß (45) braun (46) schwarz (44) schwarz (44) gelb/grün (13) 5 to 300 m pink 4.2.1 signal cable specifica...

Page 14

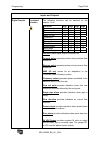

Power connections page 12/44 mid_m2000_ba_02_1004 ba2 00 0- 22m id ln p e jp1 jp2 communication display cs c2 c1 e1 es e2 rs ep es 15 16 1 2 3 4 5 6 7 8 9 10 11 12 13 14 communication 4.3 configuring input/output (i/o) displ input/output description terminal analog output 0 - 20 ma 4 - 20 ma rl 0 - ...

Page 15

Programming page 13/44 mid_m2000_ba_02_1004 5. Programming programming is accomplished by using the three functional buttons ▲ , ► and e . You can move from the measuring mode to the programming mode by pressing twice the button e . While first pressing this button, you activate the backlight and wh...

Page 16

Programming page 14/44 mid_m2000_ba_02_1004 quick setup totalizer unit this parameter establishes the units of measure for the totalizers: full scale flow this parameter sets the maximum flow the system is expected to measure. This parameter has influence on other system parameters. These parameters...

Page 17

Programming page 15/44 mid_m2000_ba_02_1004 5.2 main menu the following menu items are available to you in the main menu: • meter setup • measuring • inputs and outputs • reset of the totalizer • setting of communication port • specific counter settings • counter information • language selection 5.2...

Page 18

Programming page 16/44 mid_m2000_ba_02_1004 meter setup pipe diameter this figure is used for setting pipe’s diameter (size). Several sizes dn 6 to dn 2000 as well as specific sizes in [mm] can be set. Note: pipe diameter is set at the factory. Changes of size have an impact on meter’s accuracy. Det...

Page 19

Programming page 17/44 mid_m2000_ba_02_1004 measurement totalizer unit this parameter establishes the units of measure for the totalizers: full scale flow this parameter sets the maximum flow the system is expected to measure. This parameter has influence on other system parameters. These parametes ...

Page 20

Programming page 18/44 mid_m2000_ba_02_1004 measurement flow direction flow direction lets you set the meter to measure forward flow only (uni- directional) or both forward and reverse flow (bidirectional). Unidirectional means that the flow is totalized in only one direction. The flow direction is ...

Page 21

Programming page 19/44 mid_m2000_ba_02_1004 5.2.3 inputs and outputs analog output this parameter establishes the range of the analog output signal: 0 to 100% (= full scale). The following current ranges are available to you: note: in case that an error message is displayed, set current to 22 ma. In...

Page 22

Programming page 20/44 mid_m2000_ba_02_1004 inputs and outputs digital outputs in the sub-menu “functional operation“ you can configure functional operation of the 4 digital outputs. You can select e.G “forward pulse” for the digital output and define the pulses per totalizer unit via “pulse scale”....

Page 23

Programming page 21/44 mid_m2000_ba_02_1004 inputs and outputs digital outputs digital outputs 3 and 4 the two outputs can be operated as open collector and as relay (solid state relais ssr). You can select operating mode by programming the relative outputs (output hardware)..

Page 24

Programming page 22/44 mid_m2000_ba_02_1004 inputs and outputs digital outputs functional selection the following functions can be selected for the outputs 1 to 4: inactive means digital output is switched off. Forward pulse generates pulses during forward flow conditions. Reverse pulse generates pu...

Page 25

Programming page 23/44 mid_m2000_ba_02_1004 inputs and outputs pulses/unit the pulses/unit parameter lets you set how many pulses per unit of measure will be transmitted. The configurable range is from 0.0001 to 99.999 pulses/volume unit, however the max. Output frequency of 10,000 pulses/sec. (10 k...

Page 26

Programming page 24/44 mid_m2000_ba_02_1004 inputs and outputs hardware selection the hardware type parameter lets you select the type of hardware used to drive the two digital outputs 3 and 4: either passively as open collector or relay (solid state relais ssr). Frequency this parameter establishes...

Page 27

Programming page 25/44 mid_m2000_ba_02_1004 5.2.5 communications port a the port configuration lets you configure how the rs232 communication port will be used: • modbus rtu • remote menu (remote control) • disable port (deactivate port ) the remote menu port will check for display updates once a se...

Page 28

Programming page 26/44 mid_m2000_ba_02_1004 5.2.5 communications data bits the following data bits are supported: • 8 bits • 7 bits • 5 bits default settting is [8 bits] stop bits the following stop bits are supported: • 1 stop bit • 2 stop bits default setting is [1 stop bit] port b this port canno...

Page 29

Programming page 27/44 mid_m2000_ba_02_1004 5.2.6 advanced unit multiplier this function lets you define totalizers’ formatting. You can select among the following formats: formatting is normally [aus/off]. With this function, the best possible resolution is automatically chosen. Backlight control y...

Page 30

Programming page 28/44 mid_m2000_ba_02_1004 advanced factory setting the analog output was already set at the factory to exactly 4.00 ma (zero) and 20.00 ma (margin). In case that you wish to adapt your external system, use the item “corrective factor“. Software filter this filter is intended to hel...

Page 31

Programming page 29/44 mid_m2000_ba_02_1004 advanced empty pipe cal. Note: to compensate different fluid conductivity, signal cable lengths or sizes during measurements, you can calibrate them accordingly. This is important in case that fluid monitoring has been activated and “empty pipe” is signali...

Page 32

Programming page 30/44 mid_m2000_ba_02_1004 5.2.7 info/help error counts the following list gives you an overview about the kind and frequency of various messages and hence provides a diagnostic of the counter or the measuring point. Prior to any diagnostic, we suggest to reset the individual parame...

Page 33

Programming page 31/44 mid_m2000_ba_02_1004 5.2.7 info/help powerup counter the number of times that the unit has been powered on. Power off time the length of time that the unit has been without power. This parameter “tpwroff“ can be set with the menu “reset totalizer“. Version info the current sof...

Page 34

Troubleshooting page 32/44 mid_m2000_ba_02_1004 6. Troubleshooting error messages can be displayed via the 4 digital outputs. By means of the error list type and frequency of the errors can be logged and analyzed, also see chapter programming: info/help. The following error messages can be displayed...

Page 35

Troubleshooting page 33/44 mid_m2000_ba_02_1004 ba 200 0-22mid ln p e jp1 jp2 communication display cs c2 c1 e1 es e2 rs ep es 15 16 1 2 3 4 5 6 7 8 9 10 11 12 13 14 6.1 replacing the fuse warning: • disconnect main power to the unit before replacing the fuse. Fuse type: t2 h 250 v (2a idle) 6.2 rep...

Page 36

Technical data page 34/44 mid_m2000_ba_02_1004 a 122 80 b1 120 k d d2 x n m2000- 3 dn 99 180 180 m2 0 (x 3) 281 60 Ø5. 2 65 a b2 k d d2 x n dn m2 000 -2 180 180 m20 (x 3) 83 7. Technical data 7.1 detector type ii technical data size dn 6 – 2000 (1/4“...80“) process connections flange: din, ansi, jis...

Page 37

Technical data page 35/44 mid_m2000_ba_02_1004 dn a std* a iso** b1 b2 ansi flanges din flanges ∅ d ∅ k ∅ d2xn ∅ d ∅ k ∅ d2xn 6 1/4” 170 --- 228 288 88,9 60,3 15,9 x 4 90 60 14 x 4 8 3/10” 170 --- 228 288 88,9 60,3 15,9 x 4 90 60 14 x 4 10 3/8” 170 --- 228 288 88,9 60,3 15,9 x 4 90 60 14 x 4 15 1/2”...

Page 38

Technical data page 36/44 mid_m2000_ba_02_1004 b1 12 0 122 80 a d dn m 2 00 0-6 99 180 180 m 20 ( x3 ) 281 60 Ø5. 2 65 b1 a 12 0 122 80 d dn m 2 000-7 99 180 180 m20 (x3) 281 60 Ø5. 2 65 7.2 detector type food technical data size dn 10 – 100 (3/8“...4“) process connections tri-clamp ® , din 11851, i...

Page 39

Technical data page 37/44 mid_m2000_ba_02_1004 b2 a 180 d dn m200 0-8 m 20 (x3) 83 180 a b2 d dn m 2000 -9 m20 (x 3) 83 18 0 180 process connection tri-clamp ® process connection din 11851 m2000 ® mounted version m2000 ® mounted version type food tri-clamp ® type food milk pipe din 11851 dn a b1 b2 ...

Page 40

Technical data page 38/44 mid_m2000_ba_02_1004 b1 122 120 80 dn m 200 0-5 d a 99 180 18 0 m 20 (x3) 281 60 Ø5. 2 65 a b2 dn m 2 000-4 d 180 180 m20 (x 3) 83 7.3 detector type iii technical data size dn 25 – 100 (1“...4“) process connections sandwich connection, (intermediate flange mounting) nominal...

Page 41

Technical data page 39/44 mid_m2000_ba_02_1004 99 180 180 m20 (x3) 281 m 2000-1 60 Ø5. 2 65 7.4 meter type m2000 ® technical data type m2000 ® auxiliary power 85 – 265 vac, 45 – 65 hz optional 24 vdc (-10% … +20%), 900 ma analog output 0/4 – 20 ma, ≤ 800 ohm flow direction is displayed via separate ...

Page 42

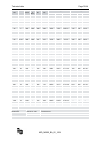

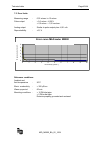

Technical data page 40/44 mid_m2000_ba_02_1004 7.5 error limits measuring range : 0,03 m/sec. To 12 m/sec. Pulse output : ≥ 0,5 m/sec. ± 0,25% ± 1,25 mm/sec. Analog output : similar to pulse output plus ± 0,01 ma reproducibility : ± 0,1% fehlerkurve mid m2000 0% 1% 2% 3% 4% 5% 0 1 2 3 4 5 6 7 8 9 10...

Page 43

Technical data page 41/44 mid_m2000_ba_02_1004 7.6 size select 0,01 0,1 1 10 100 0,01 0,1 1 10 100 1.000 10.000 l/min m/s dn 6 - dn 100 0,01 0,1 1 10 100 dn 125 - dn 1400 1 10 100 1000 10.000 100.0 m³/h.

Page 44

Program structure page 42/44 mid_m2000_ba_02_1004 8. Program structure quick setup flow unit totalizer unit full scale flow low flow cut-off main menu meter setup scale factor empty pipe detect on power line freq off excitation freq pipe diameter detector factor detector offset measurem flow unit to...

Page 45

Program structure page 43/44 mid_m2000_ba_02_1004 start menu main menu inputs/outputs digital output #3 full scale freq preset amount set point min. Set point max. Normally open output type normally closed hardware select relay open collector select function none frequency output flow set point empt...

Page 46: Harmlessness Declaration

Return of goods for repair page 44/44 mid_m2000_ba_02_1004 9. Return of goods for repair please copy, fill in and sign hereafter harmlessness declaration and enclose it for any return of goods you may send back for repair. No repair will be performed prior to receiving the harmlessness declaration d...

Page 48: Hotline

Hotline phone +49-7025-9208-0 or -30 fax +49-7025-9208-15 ® badger meter europa gmbh subsidiary of badger meter, inc., usa nürtinger strasse 76 72639 neuffen (germany) e-mail: badger@badgermeter.De www.Badgermeter.De (passiv) tsrelais 1 skalen- endwert.