- DL manuals

- Baldor

- Inverter

- GLC100

- Installation & Operating Manual

Baldor GLC100 Installation & Operating Manual

Summary of GLC100

Page 1

Glc generator (gaseous liquid cooled) glc30, 35, 45, 50, 60, 80, 100 and 125 installation & operating manual 5/04 mn2408.

Page 2: Warning:

Warning: california proposition 65 warning: engine exhaust from this product contains chemicals known to the state of california to cause cancer, birth defects and other reproductive harm. Warning: california proposition 65 warning: battery posts, terminals and related accessories are known to the s...

Page 3: Table of Contents

Table of contents table of contents i mn2408 section 1 product safety information 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Safety notice 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4

Ii table of contents mn2408 section 4 operation 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Operator control panel (digital engine controller only) 4-1 . . . . . . ...

Page 5: Section 1

Section 1 product safety information product safety information 1-1 mn2408 safety notice be sure that you are completely familiar with the safe operation of this equipment. This equipment may be connected to other machines that have rotating parts or parts that are controlled by this equipment. Impr...

Page 6

1-2 product safety information mn2408 this symbol is shown throughout the manual to indicate a connection to ground reference point. Symbols indicates a potentially hazardous situation which, if not avoided, could result in injury or death. Indicates a potentially hazardous situation which, if not a...

Page 7

Product safety information 1-3 mn2408 operation warning statements continued warning: never connect or disconnect loads during operation. Always connect load circuits before starting the engine and use external branch disconnects etc. To switch loads on/off. Warning: be sure that you understand how ...

Page 8

1-4 product safety information mn2408 warning statements continued installation warning: installation and servicing of batteries is to be performed or supervised by personnel knowledgeable of batteries and the required precautions. Keep unauthorized personnel away from batteries. Warning: disconnect...

Page 9

Product safety information 1-5 mn2408 warning statements continued maintenance warning: disconnect the battery’s ground terminal before working in the vicinity of the battery or battery wires. Contact with the battery can result in electrical shock when a tool accidently touches the positive battery...

Page 10

1-6 product safety information mn2408 caution statements caution: avoid installing the generator set beside heat generating equipment, or directly below water or steam pipes or in the vicinity of corrosive substances or vapors, metal particles and dust. Heat can cause engine problems to develop and ...

Page 11: Section 2

Section 2 general information general information 2-1 mn2408 thank you for purchasing your baldor generator set. This manual contains information you need to safely and efficiently install and operate your generator set. During the preparation of this manual every effort was made to ensure the accur...

Page 12

2-2 general information mn2408.

Page 13

General information 2-3 mn2408 important be sure you are completely familiar with all safety instructions detailed in section 1 of this manual. Do not proceed if you are unsure of any detail. Contact your baldor distributor, they are experienced and are happy to assist you and to answer your questio...

Page 14

2-4 general information mn2408 room location often a separate building located on the site away from the main building is the most simple and cost effective. Major considerations when housing the genset in a separate building are: s maintain the building at a satisfactory temperature year round (to ...

Page 15

General information 2-5 mn2408 foundation design warning: an open bottom stationary engine generator set must be installed over noncombustible materials and shall be located such that it prevents combustible materials from accumulating under the generator set. Foundation checklist a. Evaluate if a s...

Page 16

2-6 general information mn2408 s steel spring isolators are a very effective and commonly used. Steel spring isolators are typically 95–98% efficient (reduces the transmitted vibration 95–98%) while a pad type can be 75–88% efficient. Spring isolators also level the genset sub–base in the event the ...

Page 17

General information 2-7 mn2408 designing an isolated foundation if the genset cannot be mounted directly on a floor slab, or if it is desirable to isolate it from the floor slab, then a separate foundation slab must be designed. A massive concrete foundation is not required. Outside dimensions of th...

Page 18

2-8 general information mn2408 table 2-1 approximate load bearing capacities of various soil types soil type safe bearing capacity soil type lb per ft 2 kilo pascals hard rock – granite etc. 50,000 – 200,000 2,395 – 9,576 medium rock – shale etc. 20,000 – 30,000 958 – 1,436 hardpan 16,000 – 20,000 7...

Page 19

General information 2-9 mn2408 exhaust system exhaust checklist a. Exhaust outlets are not located upwind or near any building air intakes. B. Flexible piping section is used at engine exhaust outlet. C. Exhaust piping material is adequate for expected service. D. Exhaust piping sizing is adequate t...

Page 20

2-10 general information mn2408 figure 2-6 exhaust system calculations exhaust piping caution: the weight of the exhaust system must never be imposed on the turbo–charger outlet. Damage to the turbo–charger and other components may result. An exhaust system must withstand the vibration and thermal e...

Page 21

General information 2-11 mn2408 cooling system cooling system checklist a. Have noise considerations been taken into account? B. Has system piping been properly sized? C. Has system been properly protected from freeze up and corrosion? D. Have standby equipment heaters been specified? E. Have all el...

Page 22

2-12 general information mn2408 the remote radiator may be mounted either vertically or horizontally. In general, the radiator will have an electric fan to provide cooling air and may be able to utilize the engine mounted coolant pump to provide coolant flow. The piping system friction and head loss...

Page 23

General information 2-13 mn2408 remote radiator cooling remote radiator airflow generally assumed there will be no external restrictions to airflow. If this is not true, restriction must be considered in sizing and selection of a cooling fan and drive motor. Typical examples of restrictions include ...

Page 24

2-14 general information mn2408 figure 2-11 valves & fittings and fluid flow in pipe figure 2-12 hot well installation.

Page 25

General information 2-15 mn2408 other considerations general: 1. Deaeration of the coolant. This can be accomplished through the use of the system deaerators in very large systems, or simply ensuring the radiator top tank or surge tank is at the highest point in the piping system. Unvented piping sy...

Page 26

2-16 general information mn2408 coolant treatment: see figure 2-13. 1. Engine coolant should be treated with a diesel coolant additive (dca) to minimize corrosion of the engine and cooling system components. A 50/50 ethylene glycol antifreeze solution is recommended for all genset engines. This will...

Page 27

General information 2-17 mn2408 air system air system checklist a. Air inlet faces the direction of prevailing winds. B. Air outlet does not face noise sensitive areas without noise attenuating devices. C. All heat loads have been taken into consideration in sizing air flow. D. Gravity louvers face ...

Page 28

2-18 general information mn2408 figure 2-15 radiator cooling with ducted air handling other engine cooling systems remote radiator and heat exchanger cooled engine cooling systems will not have an engine driven fan. As a result, the consultant must provide a means of supplying air to the room, and e...

Page 29

General information 2-19 mn2408 transfer switch transfer switch checklist a. Locate transfer switch in a clean, dry place, near the emergency load. B. Provide a circuit breaker between the genset and the transfer switch. C. Put a flexible connection between the conduit and genset. D. Observe applica...

Page 30

2-20 general information mn2408 6. Conduit, wire, circuit protective device sizes, insulation etc. Must conform to applicable local and national codes and regulations. 7. Be certain to seal around conduits that penetrate the walls of the genset room to reduce the amount of noise that is transmitted ...

Page 31

General information 2-21 mn2408 battery charger an engine mounted alternator to charge the batteries during operation is an available option. Standby gensets require a solid state battery charger that is connected to utility power so the battery is charged continuously while the genset is not runnin...

Page 32

2-22 general information mn2408.

Page 33: Section 3

Section 3 receiving & installation receiving & installation 3-1 mn2408 receiving & inspection when you receive your generator, there are several things you should do immediately. 1. Observe the condition of the shipping container and report any damage immediately to the commercial carrier that deliv...

Page 34

3-2 receiving & installation mn2408 warning: an open bottom stationary engine generator set must be installed over noncombustible materials and shall be located such that it prevents combustible materials from accumulating under the generator set. Several other factors should be carefully evaluated ...

Page 35

Receiving & installation 3-3 mn2408 secure the generator six (eight for the glc125) mounting bolts in the base frame secure the generator to the shipping pallet. Remove these bolts, lift the generator and remove the shipping pallet. Secure the generator to the concrete pad using 3 / 8 ″ anchor hardw...

Page 36

3-4 receiving & installation mn2408 hot exhaust gasses warning: exhaust fumes/gases are extremely dangerous and can cause severe illness or death. Never breath exhaust fumes produced by a running engine. Only run the engine outdoors where ventilation is plentiful. Exhaust gases contain carbon monoxi...

Page 37

Receiving & installation 3-5 mn2408 8. As much of the exhaust piping as possible should be located near the power ventilation exhaust. This will reduce the radiant exhaust heat inside the building. 9. Keep all fuel and its associated piping away from all components of the engine exhaust system. 10. ...

Page 38

3-6 receiving & installation mn2408 installation the generator is completely assembled, tested and adjusted at the factory before it is shipped to you. The procedures presented in this manual are suggestions and it is the responsibility of the owner/operator to arrange for these procedures to be per...

Page 39

Receiving & installation 3-7 mn2408 example: determining pipe size for natural gas a generator has a 16hp engine 60 feet from the supply. Determine the supply pipe size for natural gas fuel. 16 x 10,000 = 160,000 btu’s / per hour for proper operation. 160, 000 1, 096 + 146 cubic feet per hour. From ...

Page 40

3-8 receiving & installation mn2408 example: determining pipe size for lpg a generator has a 16hp engine 60 feet from the supply. Determine the supply pipe size for natural gas fuel. 16 x 10,000 = 160,000 btu’s / per hour for proper operation. 160, 000 2, 516 + 63.5 cubic feet per hour. From table 3...

Page 41

Receiving & installation 3-9 mn2408 electrical connections class 1 wiring methods must be used for field wiring connections to terminals of a class 2 circuit. It is the responsibility of the owner/operator to arrange for these procedures to be performed by a licensed electrical contractor and ensure...

Page 42

3-10 receiving & installation mn2408 figure 3-4 three phase wye and delta connections.

Page 43

Receiving & installation 3-11 mn2408 battery charger considerations 1. Mount the battery charger on the generator or as close to the generator as possible. 2. If you mount the battery charger inside the building, mount it near the main breaker box or disconnect box. 3. If you mount the battery charg...

Page 44

3-12 receiving & installation mn2408 battery connections the generator is shipped with no battery installed. Warning: installation and servicing of batteries is to be performed or supervised by personnel knowledgeable of batteries and the required precautions. Keep unauthorized personnel away from b...

Page 45

Receiving & installation 3-13 mn2408 figure 3-6 battery installation washers & nut battery battery hold down rod washers & nut battery tray the + and – terminals of your battery may be different than shown. Be sure that the positive lead is connected to the positive (+) terminal of your battery. Bat...

Page 46

3-14 receiving & installation mn2408 2. Verify that the transfer switch is in utility power mode. No power must be present at the generator or transfer switch connections. Verify with a voltmeter. 3. Verify that the engine starting battery is disconnected so accidental starting is not possible. 4. V...

Page 47: Section 4

Section 4 operation operation 4-1 mn2408 operator control panel (digital engine controller only) the operator control panel is shown in figure 4-1. Warning: never connect this generator to any buildings electrical system unless a licensed electrician has installed an approved transfer switch. The na...

Page 48

4-2 operation mn2408 operator control panel continued auto switch - when pushed, initiates automatic operation of the engine (generator set). Starting and stopping of the engine is controlled by a remote contact (transfer switch). When the remote start signal is removed the engine will continue to r...

Page 49

Operation 4-3 mn2408 5. When the cool down time delay period expires (typically 5 minutes), the controllers run output will be immediately terminated which will initiate the engine to stop. Automatic fault shutdown when a fault circuit is programmed as a shutdown, the engine will immediately stop wh...

Page 50

4-4 operation mn2408 when the controller is applied in an auto mains failure (amf) application with a transfer switch, it must be wired as shown in figure 4-2. Programmable output #3 must be selected for utility ready to load and programmable output #4 must be selected for gen ready to load. After t...

Page 51

Operation 4-5 mn2408 no load test to allow a timed no load test of the engine/generator set while using the amf control application, a digital input contact from an external timer must be programmed for no load test the sequence of operation for a no load test condition is as follows: 1. With the ut...

Page 52

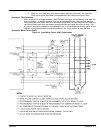

4-6 operation mn2408 figure 4-3 engine controller inputs & outputs.

Page 53

Operation 4-7 mn2408 analog faults eight analog fault inputs are user programmable for 12 fault conditions. Each analog fault input requires a specific analog signal type. Fault name fault action inputs signal low engine temperature alarm engine temperature high engine temperature #1 alarm engine te...

Page 54

4-8 operation mn2408 output contacts all output contacts are non–powered (i.E. Dry contacts) and are rated 10a/240vac, 8a/28vdc resistive (3a inductive, 0.4pf). Output contacts are not fused therefore external overcurrent protection (maximum 10a) is required for all control circuits using these cont...

Page 55

Operation 4-9 mn2408 display modes the controller is in the display mode at all times except when in the programming mode. The display screens and menus may be selected by pressing the enter or exit keys to access operating status display, fault display, timer countdown, generator ac metering or pro...

Page 56

4-10 operation mn2408 timer countdown timer countdown menus are automatically displayed when a specific time delay function occurs during a control sequence. When a time delay begins, the lcd display will show the time delay function name (i.E. Engine start delay) and the current time remaining in t...

Page 57

Operation 4-11 mn2408 generator ac metering the controller is in the display mode at all times except when in the programming mode. The display screens and menus may be selected by pressing the enter or exit keys to access operating status display, fault display, timer countdown, generator ac meteri...

Page 58

4-12 operation mn2408 engine parameter display two engine operating parameter screens are provided. Battery voltage/engine speed (tachometer) battery speed 27.0 vdc 1800 rpm battery displays battery voltage in dc volts. The voltage is displayed with a resolution of 1/10 of a volt. Speed displays eng...

Page 59

Operation 4-13 mn2408 navigation hints programming parameters are displayed in the same order as the programming sheets (see figures 4-5 to 4-8). To skip over parameters that do not require changes, push and hold the enter push–button until the desired parameter is displayed. The exit push–button ma...

Page 60

4-14 operation mn2408 main menu loop continued loss of speed signal select the desired action (i.E. Alarm or shutdown) when a loss of speed signal is detected during operation. Note: a loss of speed signal must be detected for longer than 2 seconds to initiate the desired action. Common fail for no...

Page 61

Operation 4-15 mn2408 digital fault menu loop the controller’s digital fault settings are described as follows: caution: the digital fault label selection must agree with the external control wiring prior to energizing the controller. Failure to do so may cause severe equipment damage. Digital fault...

Page 62

4-16 operation mn2408 span calibration energize the generator supply voltage to the controller at nominal level. Note: it may be necessary to program the optional under and over voltage shutdowns as alarms to ensure the generator will continue to operate during calibration. Caution must be taken to ...

Page 63

Operation 4-17 mn2408 engine temperature & oil pressure calibration to accurately calibrate the controller’s temperature sensor, an external temporary engine mounted temperature gauge is required. The external temperature gauge should be connected as close as possible to the temperature sender. To a...

Page 64

4-18 operation mn2408 figure 4-4 configuration data sheet j j j j j j j j j.

Page 65

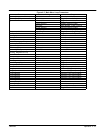

Operation 4-19 mn2408 figure 4-5 main menu loop parameters parameter setting range system voltage (line to line) xxxxx vac 120–15000vac system frequency 50hz/60hz toggle between 50/60 hz system phases 1 phase/3 phase toggle between 1 & 3 phase y neutral connected toggle between yes/no voltage sensin...

Page 66

4-20 operation mn2408 figure 4-6 analog fault menu loop parameters fault name input analog type fault e enable setpoint level (pick up) setpoint level action s shutdown alarm latch y yes bypass on start transient delay (sec) type e=enable d=disable (pick-up) (drop-out) s=shutdown a=alarm y=yes n=no ...

Page 67

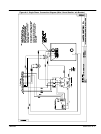

Operation 4-21 mn2408 figure 4-9 engine control connections 1 2 3 4 5 6 7 8 9 10 11 12 17 16 15 14 13 38 37 grd cr mp2 mp1 19 18 24 23 b – b + + – crank run 25 26 27 28 29 30 31 32 33 34 24 35 36 22 21 20 programmable contact #4 programmable contact #3 programmable contact #2 programmable contact #1...

Page 68

4-22 operation mn2408 operator control panel (analog engine controller only) figure 4-10 analog operator control panel – + off 1 2 3 panel lights switch (on-off ) turns on two lamps to illuminate the operator panel. Panel light fuse fuse for panel lights. Master control switch (manual run-stop - aut...

Page 69

Operation 4-23 mn2408 manual start/stop to manually start the gen–set, set the master control switch to the “manual run” position. The following happens: 1. When the “manual run” push–button is pressed, an engine start delay timer is initiated. (the start sequence will not be initiated if any shutdo...

Page 70

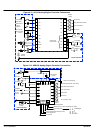

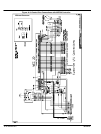

4-24 operation mn2408 figure 4-12 a121h analog engine controller connections external components high water temperature low oil pressure overspeed high water temperature low oil pressure overcrank osl htl lpl ocl display led’s lc + lt hti lpi cci rr tdi ground b+ auto off run auto off run remote sta...

Page 71

Operation 4-25 mn2408 garretson model kn fuel valve considerations general the kn is designed for sensitivity and simple operation. It is used with low–pressure vaporized gaseous fuels, where dependable starting is a requirement. Because of its extreme sensitivity, the kn offers excellent results in...

Page 72

4-26 operation mn2408 installation the kn should be mounted as close to the carburetor as possible with the arrow on the cover pointing up and the diaphragm in a vertical position. This helps to minimize the effects of gravity on diaphragm travel. This unit should also be placed for easy access to t...

Page 73: Section 5

Section 5 troubleshooting and maintenance troubleshooting and maintenance 5-1 mn2408 maintenance this manual contains only very minimal engine maintenance instructions. Refer to the engine manufacturer’s owner’s manual for specific engine maintenance instructions for your generator set. Any maintena...

Page 74

5-2 troubleshooting and maintenance mn2408 problems and solutions some of the more common problems are listed in table 5-1. This information is intended to be a check or verification that simple causes can be located and fixed. It is not an exhaustive “how to” for all types of problems. Procedures t...

Page 75

Troubleshooting and maintenance 5-3 mn2408 table 5-2 troubleshooting guide (digital controller only) problem possible cause remedy controller does not power up even with correct dc power applied wiring mistake overload condition check that there are no wiring errors/short circuits connected to the c...

Page 76

5-4 troubleshooting and maintenance mn2408 note: see engine controller manual for additional information. Table 5-3 troubleshooting guide (analog controller only) problem possible cause remedy controller cannot be reset" engine not stopped controller not in off mode verify the engine is at a comple...

Page 77: Appendix A

Appendix a series glc parts & wiring diagrams series glc a-1 mn2408 replacement parts replacement parts information is provided in this section of the manual. Engine parts are identified in the engine manual that was provided with your generator set. 10.95030 important: fuses are installed in the co...

Page 78

A-2 series glc mn2408 replacement parts continued description part no. Description glc 80 glc 100 glc125 weldment, base ba0236a06l2b ba0236a06l2b ba0236a06l2b isolator, gen end rm1088a18 rm1088a18 rm1088a18 isolator, control box rm1088a01 rm1088a01 rm1088a01 solenoid, engine 12v se0057a01 se0057a01 ...

Page 79

Series glc a-3 mn2408 replacement parts continued description part no. Description glc 80 glc 100 glc125 decal bonded neutral" lb0300a00 lb0300a00 lb0300a00 decal fuse type & warning" lb0300a01 lb0300a01 lb0300a01 decal, control panel lb0094b60 lb0094b60 lb0094b60 placard, remote start" lb0095a42...

Page 80

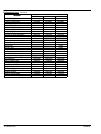

A-4 series glc mn2408 glc circuit breaker & electrical data glc alternator engine output glc model model leads/ winding fuel type size kw rated phase voltage config vac (l - l) vac (l - n) fla 115% fla circuit breaker c.T. Ratio wire size (qty) awg glc125 uci274e 4/06 nat gas gm/8.1l 115 1 series 24...

Page 81

Series glc a-5 mn2408 glc data continued glc alternator engine output glc model model leads/ winding fuel type size kw rated phase voltage config vac (l - l) vac (l - n) fla 115% fla circuit breaker c.T. Ratio wire size (qty) awg glc100 uci274e 4/06 nat gas gm/8.1l 84 1 series 240 120 350 403 400 40...

Page 82

A-6 series glc mn2408 glc data continued glc alternator engine output glc model model leads/ winding fuel type size kw rated phase voltage config vac (l - l) vac (l - n) fla 115% fla circuit breaker c.T. Ratio wire size (qty) awg glc60 uci224f 4/06 nat gas gm/5.7l 54 1 series 240 120 225 259 300 300...

Page 83

Series glc a-7 mn2408 glc data continued glc alternator engine output glc model model leads/ winding fuel type size kw rated phase voltage config vac (l - l) vac (l - n) fla 115% fla circuit breaker c.T. Ratio wire size (qty) awg glc45 uci224d 4/06 nat gas gm/4.3l 37 1 series 240 120 154 177 175 200...

Page 84

A-8 series glc mn2408 glc data continued glc alternator engine output glc model model leads/ winding fuel type size kw rated phase voltage config vac (l - l) vac (l - n) fla 115% fla circuit breaker c.T. Ratio wire size (qty) awg glc30 bci184g 4/06 nat gas gm/4.3l 30 1 series 240 120 125 144 150 150...

Page 85

Series glc a-9 mn2408 glc wire size revision b 5–12–04 circuit breaker size quantity per phase minimum wire gauge edi plant ampacity @125c 15 1 #16 1 - #14 epdm per phase 40 20 1 #16 1 - #14 epdm per phase 40 30 1 #14 1 - #8 epdm per phase 90 40 1 #12 1 - #8 epdm per phase 90 50 1 #10 1 - #8 epdm pe...

Page 86

A-10 series glc mn2408 figure a-2 customer interface connection diagram mec20 mec2.

Page 87

Series glc a-11 mn2408 figure a-3 customer interface (w/o breaker) power connection diagram.

Page 88

A-12 series glc mn2408 figure a-4 single phase – (w/o breaker) connection diagram.

Page 89

Series glc a-13 mn2408 figure a-5 single phase – one breaker connection diagram.

Page 90

A-14 series glc mn2408 figure a-6 single phase – two breaker connection diagram.

Page 91

Series glc a-15 mn2408 figure a-7 single phase connection diagram (wire 1/0 and larger w/breaker).

Page 92

A-16 series glc mn2408 figure a-8 single phase connection diagram (wire 1/0 and smaller w/breaker).

Page 93

Series glc a-17 mn2408 figure a-9 single phase connection diagram (wire 1/0 and smaller w/o breaker).

Page 94

A-18 series glc mn2408 figure a-10 single phase connection diagram (wire larger than 1/0 w/o breaker).

Page 95

Series glc a-19 mn2408 figure a-11 three phase connection diagram.

Page 96

A-20 series glc mn2408 figure a-12 three phase connection diagram with pmg.

Page 97

Series glc a-21 mn2408 figure a-13 three phase connection diagram (wire 1/0 and larger).

Page 98

A-22 series glc mn2408 figure a-14 three phase connection diagram (wire larger than 1/0 w/breaker).

Page 99

Series glc a-23 mn2408 figure a-15 three phase connection diagram (wire 1/0 and smaller w/breaker).

Page 100

A-24 series glc mn2408 figure a-16 three phase connection diagram (wire larger than 1/0 w/o breaker).

Page 101

Series glc a-25 mn2408 figure a-17 three phase connection diagram (wire 1/0 and smaller w/o breaker).

Page 102

A-26 series glc mn2408 figure a-18 control box connections with mec20 controller without governor.

Page 103

Series glc a-27 mn2408 figure a-19 control box connections with mec20 controller & governor with governor.

Page 104

A-28 series glc mn2408 figure a-20 control box connections with mec2 controller.

Page 105

Series glc a-29 mn2408 figure a-21 engine wiring, woodward 4.3l gm.

Page 106

A-30 series glc mn2408 figure a-22 engine wiring, woodward 5.7l gm.

Page 107

Series glc a-31 mn2408 figure a-23 engine wiring, woodward 8.1l gm.

Page 108

A-32 series glc mn2408.

Page 109

Series glc a-33 mn2408 start–up inspection form it is required that both sides of this form be completed, signed where indicated and returned to baldor generators within 30 days of initial start–up and test. It is your responsibility to deliver copies to: n baldor generators factory n baldor distrib...

Page 110

A-34 series glc mn2408 n pre start-up check list n start-up procedure no freight damage (components tight, straight, etc.). Check that all applicable warning decals are in their proper place and are legible. Proper belt alignment and tensions. The ats engine start wires and other dc wires, if any, m...

Page 111

Baldor district offices united states arizona phoenix 4211 s 43rd place phoenix, az 85040 phone: 602-470-0407 fax: 602-470-0464 california los angeles 6480 flotilla commerce, ca 90040 phone: 323-724-6771 fax: 323-721-5859 hayward 21056 forbes street hayward, ca 94545 phone: 510-785-9900 fax: 510-785...

Page 112: Warning:

Baldor generators 3815 oregon street oshkosh, wi 54902 (920) 236–4200 or (800) 872–7697 fax (920) 236–4219 www.Baldor.Com © baldor electric company mn2408 printed in usa 5/04 far200 warning: california proposition 65 warning: engine exhaust from this product contains chemicals known to the state of ...