- DL manuals

- Baldor

- Servo Drives

- MicroFlex

- Installation Manual

Baldor MicroFlex Installation Manual - 2.1 Microflex Features

Introduction 2-1

MN1919

2.1 MicroFlex features

The MicroFlex is a versatile compact control, providing a flexible and powerful solution for

single axis rotary systems. Standard features include:

H

Single axis AC brushless drive.

H

Range of models with continuous current ratings of 3A, 6A or 9A.

H

Direct connection to 115VAC or 230VAC single-phase or 230VAC three-phase supplies.

H

SSI or incremental encoder feedback.

H

Velocity and current control, with step and direction input for position control.

H

Auto-tuning wizard (including position loop) and software oscilloscope facilities

H

2 optically isolated digital inputs.

H

1 optically isolated digital output.

H

1 general-purpose analog input (can be used as a speed or torque command reference).

H

RS232 communications.

MicroFlex will operate with a large number of brushless servo motors - for information on

selecting Baldor servo motors, please see the sales brochure BR1202 (BR1800 for linear

motors) available from your local Baldor representative.

This manual is intended to guide you through the installation of MicroFlex. The sections should

be read in sequence.

The Basic Installation section describes the mechanical installation of the MicroFlex, the

power supply connections and motor connections. The other sections require knowledge of

the low level input/output requirements of the installation and an understanding of computer

software installation. If you are not qualified in these areas you should seek assistance before

proceeding.

2

Introduction

2

Summary of MicroFlex

Page 1

Microflex servo control servo drive installation manual 4/03 mn1919.

Page 3

Contents i mn1919 contents 1 general information 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 introduction 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1 microflex features 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4

Ii contents mn1919 5 input / output 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1 introduction 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.2 analog i/o 5-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5

Contents iii mn1919 8 specifications 8-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.1 introduction 8-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.1.1 ac input power and dc bus voltage (x1) 8-1 . . . . . . . . . . . . ....

Page 6

Iv contents mn1919.

Page 7

General information 1-1 mn1919 copyright baldor (c) 2003. All rights reserved. This manual is copyrighted and all rights are reserved. This document or attached software may not, in whole or in part, be copied or reproduced in any form without the prior written consent of baldor. Baldor makes no rep...

Page 8: Product Notice

1-2 general information mn1919 product notice only qualified personnel should attempt the start-up procedure or troubleshoot this equipment. This equipment may be connected to other machines that have rotating parts or parts that are controlled by this equipment. Improper use can cause serious or fa...

Page 9

General information 1-3 mn1919 warning: the stop input to this equipment should not be used as the single means of achieving a safety critical stop. Drive disable, motor disconnect, motor brake and other means should be used as appropriate. Warning: improper operation or programming of the drive may...

Page 10

1-4 general information mn1919 caution: baldor does not recommend using “grounded leg delta” transformer power leads that may create earth/ground loops and degrade system performance. Instead, we recommend using a four wire wye. Caution: drives are intended to be connected to a permanent main power ...

Page 11: 2.1 Microflex Features

Introduction 2-1 mn1919 2.1 microflex features the microflex is a versatile compact control, providing a flexible and powerful solution for single axis rotary systems. Standard features include: h single axis ac brushless drive. H range of models with continuous current ratings of 3a, 6a or 9a. H di...

Page 12

2-2 introduction mn1919 2.2 receiving and inspection when you receive your microflex, there are several things you should do immediately: 1. Check the condition of the shipping container and report any damage immediately to the carrier that delivered your microflex. 2. Remove the microflex from the ...

Page 13

Introduction 2-3 mn1919 2.3 units and abbreviations the following units and abbreviations may appear in this manual: v volt (also vac and vdc) . . . . . . . . . . . . . . . Ac alternating current . . . . . . . . . . . . . Dc direct current . . . . . . . . . . . . . W watt . . . . . . . . . . . . . ....

Page 14

2-4 introduction mn1919.

Page 15: 3.1 Introduction

Basic installation 3-1 mn1919 3.1 introduction you should read all the sections in basic installation to ensure safe installation. This section describes the mechanical and electrical installation of the microflex in the following stages: h location considerations h mounting the microflex h connecti...

Page 16

3-2 basic installation mn1919 h a pc with the following specification: minimum specification recommended specification processor intel pentium 133mhz intel pentium 200mhz or faster ram 32mb 64mb hard disk space 40mb 60mb cd-rom a cd-rom drive serial port one free rs232 serial (com) port screen 800 x...

Page 17

Basic installation 3-3 mn1919 3.2 mechanical installation and cooling requirements it is essential that you read and understand this section before beginning the installation. Caution: to prevent equipment damage, be certain that the input power has correctly rated protective devices installed. Caut...

Page 18

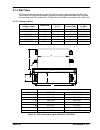

3-4 basic installation mn1919 3.2.1 dimensions 80 (3.2) 63.5 (2.5) 11 (0.4) 167.7 (6 .6 ) 180 (7 .1 ) 6 (0 .24) 6 (0 .24) 5 (0.2) front panel mounting hole and slot detail 5.5 mm dimensions shown as: mm (inches). Depth: 157 mm (6.2 in) weight: 3a: 1.45kg (3.2lb) 6a: 1.50kg (3.3lb) 9a: 1.55kg (3.4lb)...

Page 19

Basic installation 3-5 mn1919 3.2.2 mounting and cooling the microflex ensure you have read and understood the mechanical installation and location requirements in section 3.2. Mount the microflex vertically on its rear side, the side opposite the front panel. M5 bolts or screws should be used to mo...

Page 20

3-6 basic installation mn1919 3.2.3 derating characteristic - 3a model the following derating characteristics are for model fmh2a03tr-en23. 0 1 2 3 30 35 40 45 50 55 ambient temperature (°c) r at ed out put cu rr rent (a rm s ) single-phase ac supply natural cooling 0.6m/s forced air natural cooling...

Page 21

Basic installation 3-7 mn1919 3.2.4 derating characteristic - 6a model the following derating characteristics are for model fmh2a06tr-en23. 0 1 2 3 4 5 6 30 35 40 45 50 55 ambient temperature (°c) single-phase ac supply natural cooling 1m/s forced air 1.5m/s forced air 2.5m/s forced air 0 1 2 3 4 5 ...

Page 22

3-8 basic installation mn1919 3.2.5 derating characteristic - 9a model the following derating characteristics are for model fmh2a09tr-en23. 0 1 2 3 4 5 6 7 8 9 30 35 40 45 50 55 ambient temperature (°c) single-phase ac supply natural cooling 1m/s forced air 1.5m/s forced air 2.5m/s forced air 3.5m/s...

Page 23: 3.3 Connector Locations

Basic installation 3-9 mn1919 3.3 connector locations 8 shield 9 dir 10 step 11 dgnd 12 ain0- 13 ain0+ 14 agnd 1 cha+ 2 chb+ 3 chz+ 4 (nc) 5 dgnd 6 cha- 7 chb- 8 chz- 9 (nc) 1 (nc) 2 rxd 3 txd 4 (nc) 5 0v gnd 6 (nc) 7 rts 8 cts 9 (nc - see section 5.4) x3 input / output x6 rs232 x7 encoder out x8 fe...

Page 24: 3.4 Power Connections

3-10 basic installation mn1919 3.4 power connections this section provides instructions for connecting the ac power supply. The installer of this equipment is responsible for complying with nec (national electric code) guidelines or ce (conformite europeene) directives and application codes that gov...

Page 25

Basic installation 3-11 mn1919 3.4.1 single-phase or three-phase power connections location connector x1 (mating connector: phoenix combicon mstb 2,5hc/11-st-5,08) nominal input voltage 115vac or 230vac, 1Φ or 3Φ line to line range 105-250vac tightening torque for terminal block connections is 0.5-0...

Page 26

3-12 basic installation mn1919 3.4.2 input power conditioning certain power line conditions must be avoided; an ac line reactor, an isolation transformer or a step up/step down transformer may be required for some power conditions: h if the feeder or branch circuit that provides power to the microfl...

Page 27

Basic installation 3-13 mn1919 3.4.3 power disconnect and protection devices a power disconnect should be installed between the input power supply and the microflex for a fail-safe method to disconnect power. The microflex will remain in a powered condition until all input power is removed from the ...

Page 28

3-14 basic installation mn1919 3.4.4 wire sizes and protection device ratings table 2 describes the wire size to be used for power connections and the ratings of the protection devices. Continuous nominal input fuse minimum catalog number continuous output a nominal input v lt input fuse (a) minimum...

Page 29

Basic installation 3-15 mn1919 3.4.5 power supply filters to comply with eec directive 89/336/eec, an ac power filter of the appropriate type must be connected. This can be supplied by baldor and will ensure that the microflex complies with the ce specifications for which it has been tested. Table 3...

Page 30

3-16 basic installation mn1919 3.4.6 24v control circuit supply a 24vdc supply must be provided to power the controlling electronics. This is useful for safety reasons where ac power needs to be removed from the power stage but the controlling electronics must remain powered to retain position and i...

Page 31: 3.5 Motor Connections

Basic installation 3-17 mn1919 3.5 motor connections the motor can be connected directly to the microflex or through a motor contactor (m-contactor). Location connector x1 ac supply voltage 115vac, 1Φ 230vac, 1Φ 230vac, 3Φ output voltage range 0-115vac, 3Φ 0-230vac, 3Φ 0-230vac, 3Φ v w u motor to ea...

Page 32

3-18 basic installation mn1919 3.5.1 motor circuit contactors if required by local codes or for safety reasons, an m-contactor (motor circuit contactor) may be installed to provide a physical disconnection of the motor windings from the microflex (see section 3.5). Opening the m-contactor ensures th...

Page 33

Basic installation 3-19 mn1919 3.5.3 motor cable pin configuration - baldor linear motors the following table shows the pin colors used in a typical baldor linear motor cable set, part number ay1763a00: signal name motor cable wire color motor u black motor v red motor w white motor ground green the...

Page 34

3-20 basic installation mn1919 3.6 regeneration resistor (dynamic brake resistor) an external regeneration resistor may be required to dissipate excess power from the internal dc bus during motor deceleration. The regeneration resistor must have a resistance of at least 39Ω, and an inductance of les...

Page 35: 4.1 Introduction

Feedback 4-1 mn1919 4.1 introduction two feedback options are available for use with linear and rotary motors; incremental encoder, or encoder with ssi (synchronous serial interface). There are some important considerations when wiring the feedback device: h the feedback device wiring must be separa...

Page 36

4-2 feedback mn1919 4.1.1 encoder feedback - x8 the encoder connections (abz channels and hall signals) are made using the 15-pin d-type female connector x8. Twisted pair cables must be used for the complementary signal pairs e.G. Cha+ and cha-. The overall cable shield (screen) must be connected to...

Page 37

Feedback 4-3 mn1919 4.1.1.1 encoder cable configuration - baldor rotary motors cha+ cha- chb+ chb- +5v dgnd 1 9 2 10 3 11 12 x8 chz+ (index) chz- (index) 6 5 15 14 8 7 13 hall u+ hall u- hall w+ hall w- hall v+ hall v- 4 sense hall feedback connect overall shield to connector backshells. Twisted pai...

Page 38

4-4 feedback mn1919 4.1.1.3 halls-only feedback devices feedback devices using only hall sensors may be connected to the microflex. +5v dgnd 12 x8 6 5 15 14 8 7 13 hall u+ hall u- hall w+ hall w- hall v+ hall v- 4 sense hall feedback connect overall shield to connector backshells. Connect internal s...

Page 39

Feedback 4-5 mn1919 4.1.1.4 encoder cable pin configuration - baldor linear motors baldor linear motors use two separate cables (encoder and hall). The cores of these two cables must be wired to the appropriate pins of the 15-pin d-type mating connector (supplied): signal name microflex x8 pin encod...

Page 40

4-6 feedback mn1919 4.1.2 ssi feedback - x8 the ssi (synchronous serial interface) encoder interface supports 17-bit and 18-bit single-turn encoders. The ssi encoder connections are made using the 15-pin d-type female connector x8. Twisted pair cables must be used for the complementary signal pairs ...

Page 41

Feedback 4-7 mn1919 4.1.3 encoder output - x7 location connector x7 pin name 1 cha+ 2 chb+ 3 chz+ 4 (nc) 5 dgnd 6 cha- 7 chb- 8 chz- 9 (nc) description encoder output on a 9-pin female d-type connector this output can be used for position feedback to a host positioner, or in master/slave situations ...

Page 42

4-8 feedback mn1919.

Page 43: 5.1 Introduction

Input / output 5-1 mn1919 5.1 introduction this section describes the various digital and analog input and output capabilities of the microflex, with descriptions of each of the connectors on the front panel. The following conventions are used to refer to the inputs and outputs: i/o input / output ....

Page 44: 5.2 Analog I/o

5-2 input / output mn1919 5.2 analog i/o the microflex provides as standard: h 1 analog input on the connector block x3 (demand input) 5.2.1 analog input - x3 (demand) location connector x3, pins 12 & 13 (mating connector: weidmüller minimate b2l 3.5/14) name ain0 mint keyword adc.0 description sing...

Page 45

Input / output 5-3 mn1919 ain0 ( adc.0 ) x3 gnd ain0 ( adc.0 ) 13 12 14 x3 ain0- differential connection single ended connection ain0+ ain0+ 13 12 14 figure 16 - ain0 analog input wiring ain0 1kΩ, 0.25w potentiometer ( adc.0 ) x3 1.5kΩ, 0.25w 0v +24vdc 13 12 14 figure 17 - typical input circuit to p...

Page 46: 5.3 Digital I/o

5-4 input / output mn1919 5.3 digital i/o the microflex provides as standard: h 1 dedicated drive enable input. H 1 general purpose digital input. H dedicated step and direction inputs. H 1 dedicated drive status output. The general purpose digital input can be configured for many typical input func...

Page 47

Input / output 5-5 mn1919 5.3.1 drive enable input - x3 location connector x3, pins 6 & 7 (mating connector: weidmüller minimate b2l 3.5/14) name drive enable description dedicated drive enable input. Nominal input voltage: +24vdc (input current not to exceed 50ma) the drive enable input is buffered...

Page 48

5-6 input / output mn1919 5.3.2 general purpose digital input - x3 location connector x3, pins 4 & 5 (mating connector: weidmüller minimate b2l 3.5/14) name din0 mint keyword resetinput / errorinput / stopinput description general purpose optically isolated digital input. Nominal input voltage: +24v...

Page 49

Input / output 5-7 mn1919 5.3.3 step (pulse) and direction inputs - x3 location connector x3, pins 9 & 10 (mating connector: weidmüller minimate b2l 3.5/14) names step and dir description dedicated step and direction inputs. Input voltage: +5vdc maximum input frequency: 1 mhz maximum when the microf...

Page 50

5-8 input / output mn1919 5.3.4 drive status output - x3 location connector x3, pins 2 & 3 (mating connector: weidmüller minimate b2l 3.5/14) name status mint keyword outputactivelevel description opto-isolated drive status output output current: 100ma maximum user supply 30vdc maximum update interv...

Page 51: 5.4 Serial Port - X6

Input / output 5-9 mn1919 5.4 serial port - x6 location connector x6 pin name 1 (nc) 2 rxd 3 txd 4 (nc) 5 0v gnd 6 (nc) 7 rts 8 cts 9 (nc) description rs232 connections on a single 9-pin d-type connector the microflex has a full-duplex rs232 serial port with the following preset configuration: h 57....

Page 52

5-10 input / output mn1919 5.5 connection summary - typical system wiring as a guide, figure 23 shows an example of the typical wiring required to allow the microflex to control a motor. Com host pc ac power motor power u v w serial communication control circuit supply motor +24v * microflex require...

Page 53: 6.1 Introduction

Configuration 6-1 mn1919 6.1 introduction before powering the microflex you will need to connect it to the pc using a serial cable and install the supplied pc software workbench v5. This software includes a number of tools to allow you to configure and tune the microflex. If you do not have experien...

Page 54

6-2 configuration mn1919 6.1.3 starting the microflex if you have followed the instructions in the previous sections, you should now have connected all the power sources, inputs and outputs, and the serial cable linking the pc to the microflex. 6.1.4 preliminary checks before you apply power for the...

Page 55: 6.2 Workbench V5

Configuration 6-3 mn1919 6.2 workbench v5 workbench v5 is a fully featured application for controlling the microflex. The main workbench v5 window contains a menu system, the toolbox and other toolbars. Many functions can be accessed from the menu or by clicking a button - use whichever you prefer. ...

Page 56

6-4 configuration mn1919 6.2.2 starting workbench v5 1. On the windows start menu, select programs, workbench v5, workbench. Workbench v5 will start, and the tip of the day dialog will be displayed. You can prevent the tip of the day dialog appearing next time by removing the check mark next to show...

Page 57

Configuration 6-5 mn1919 3. In the select controller dialog, go to the drop down box near the top and select the pc serial port to which the microflex is connected. (if you are unsure which pc serial port is connected to the microflex, select scan all serial ports). Click scan to search for the micr...

Page 58

6-6 configuration mn1919 6.2.3 commissioning wizard each type of motor and drive combination has slightly different performance characteristics. Before the microflex can be used to control the motor accurately, the microflex must be “tuned”. This is the process where the microflex powers the motor i...

Page 59: 6.3 Further Configuration

Configuration 6-7 mn1919 6.3 further configuration workbench v5 provides a number of tools, each of which has an icon on the left of the screen. Click once on an icon to select the tool. Three of the main tools used for tuning and configuring the microflex are described in the following sections. Ev...

Page 60

6-8 configuration mn1919 6.3.1.1 fine-tuning - step tab the step tab allows you to adjust position loop settings and perform test moves. The commissioning wizard may have already set some of these values, depending on the type of system selected on the mode screen. Enter new values in the required b...

Page 61

Configuration 6-9 mn1919 6.3.2 parameters tool the parameters tool can be used to setup many important parameters, such as a scaling factor for the feedback input, and the action to take when errors occur. 1. Click the parameters icon in the toolbox on the left of the screen. The main area of the wo...

Page 62

6-10 configuration mn1919 6.3.3 other tools and windows each tool and window is explained fully in the help file, so is not described here in detail. H edit & debug tool this tool provides a work area including the command window and output window. The command window can be used to send immediate mi...

Page 63: 7.1 Introduction

Troubleshooting 7-1 mn1919 7.1 introduction this section explains common problems that may be encountered, together with possible solutions. 7.1.1 problem diagnosis if you have followed all the instructions in this manual in sequence, you should have few problems installing the microflex. If you do ...

Page 64: 7.2 Status Led

7-2 troubleshooting mn1919 7.2 status led the status led indicates general microflex status information. Solid green: drive enabled (normal operation). Flashing green: firmware download in progress. Solid red: drive disabled, but no errors are latched. Flashing red: powerbase fault or error(s) prese...

Page 65

Troubleshooting 7-3 mn1919 7.2.1 communication problem check status led is off check that the 24vdc control circuit supply is connected correctly to connector x2 and is switched on. Workbench v5 fails to detect the microflex - it detects “no controller found. Communication fault on comx”. Ensure tha...

Page 66

7-4 troubleshooting mn1919 7.2.2 power on problem check the status led is flashing. The microflex has detected a motion error. Click the error button on the motion toolbar to view a description of the error. Alternatively, type these commands in the command window: print axiserror print driveerror c...

Page 67: 8.1 Introduction

Specifications 8-1 mn1919 8.1 introduction this section provides technical specifications for the microflex. 8.1.1 ac input power and dc bus voltage (x1) all models unit 230vac 1Φ or 3Φ nominal input voltage vac 230 minimum input voltage 105 maximum input voltage 250 nominal dc-bus voltage vdc 320 m...

Page 68

8-2 specifications mn1919 8.1.3 motor output power (x1) unit 3a 6a 9a nominal phase current a rms 3 6 9 peak phase current for 0.5s a rms 6 12 18 nominal output @ 230v, 3Φ va 1195 2390 3585 efficiency % >95 output frequency hz 0 - 2000 nominal switching frequency khz 8.0 8.1.4 regeneration (x1) unit...

Page 69

Specifications 8-3 mn1919 8.1.6 digital inputs - drive enable and general purpose (x3) unit all models type opto-isolated inputs input voltage nominal minimum maximum vdc 24 12 30 input current (@ vin=24v) ma 6.7 sampling interval ms 0.5 maximum pulse input frequency mhz 1 minimum pulse width ns 250...

Page 70

8-4 specifications mn1919 8.1.9 incremental encoder feedback option (x8) all models unit all models encoder input a/b differential, z index maximum input frequency (quadrature) mhz 8 hall inputs single ended, 5v logic output power supply to encoder 5v, 200ma max. Maximum recommended cable length 30....

Page 71

Specifications 8-5 mn1919 8.1.13 environmental all models unit all models operating temperature range °c °f minimum maximum derate +0 +45 2.5% / °c between 45°c and 55°c (max) +32 +113 2.5% / 1.8°f between 113°f and 131°f (max) storage temperature range -40 to +85 -40 to +185 humidity % 10-90 non-co...

Page 72

8-6 specifications mn1919.

Page 73: A.1 Introduction

Accessories a-1 mn1919 a.1 introduction this section describes accessories and options that you may need to use with your microflex. Shielded (screened) cables provide emi / rfi shielding and are required for compliance with ce regulations. All connectors and other components must be compatible with...

Page 74

A-2 accessories mn1919 a.1.1 motor power cables cable cable assembly baldor catalog length cable rated current cable assembly description baldor catalog number ft m 10 amps power cable assembly ce style threaded connector cbl015sp-mhce cbl030sp-mhce cbl061sp-mhce cbl091sp-mhce cbl152sp-mhce cbl229sp...

Page 75

Accessories a-3 mn1919 a.1.4 emc filters ac filters remove high frequency noise from the ac power supply, protecting the microflex. These filters also prevent high frequency signals from being transmitted back onto the power lines and help meet ce requirements. To select the correct filter, see sect...

Page 76

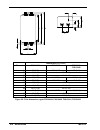

A-4 accessories mn1919 l k j h g f e d c b a dimensions mm (inches) dimension fi0014a00 fi0015a00 fi0015a01 fi0015a02 a 85 (3.35) 113.5 (4.47) 156 (6.14) b 54 (2.13) 57.5 (2.26) c 40 (1.57) 46.6 (1.83) d 65 (2.56) 94 (3.70) 130.5 (5.14) e 75 (2.95) 103 (4.06) 143 (5.63) f 27 (1.06) 25 (0.98) g 12 (0...

Page 77

Accessories a-5 mn1919 a.1.5 regeneration resistors microflex may require an external regeneration resistor to be fitted, using the r1 and r2 pins of connector x1. The regeneration resistor dissipates energy during braking to prevent an over-voltage error occurring. Baldor part number rg39 is recomm...

Page 78

A-6 accessories mn1919.

Page 79: B.1 Introduction

Control system b-1 mn1919 b.1 introduction the microflex can be configured for three basic control modes: h current (torque) control. H velocity (speed) control. H step and direction following/gearing. The mode you require is selected in workbench v5 using the commissioning wizard. You can subsequen...

Page 80

B-2 control system mn1919 b.1.1 current (torque) control setting the control mode to current control configures the microflex or microflex as a torque amplifier, as shown in figure 28. Here, a torque reference is obtained from a specified source: h workbench v5 h a host using the activex control h a...

Page 81

Control system b-3 mn1919 b.1.2 velocity (speed) control setting the control mode to velocity control configures the microflex as a speed amplifier, as shown in figure 29. Here, a speed reference is obtained from a specified source: h workbench v5 h a host using the activex control h analog input th...

Page 82

B-4 control system mn1919 b.1.3 position (step and direction) control setting the control mode to position control (step and direction) configures the microflex as a positioning system, as shown in figure 30, capable of following a position command signal. The up down counter and gearing interpret t...

Page 83: C.1 Outline

Ce guidelines c-1 mn1919 c.1 outline this section provides general information regarding recommended methods of installation for ce compliance. It is not intended as an exhaustive guide to good practice and wiring techniques. It is assumed that the installer of the microflex is sufficiently qualifie...

Page 84

C-2 ce guidelines mn1919 c.1.2 use of ce compliant components the following points should be considered: h using ce approved components will not guarantee a ce compliant system! H the components used in the drive, installation methods used, materials selected for interconnection of components are im...

Page 85

Ce guidelines c-3 mn1919 c.1.4 emc installation suggestions to ensure electromagnetic compatibility (emc), the following installation points should be considered to help reduce interference: h earthing/grounding of all system elements to a central earth/ground point (star point) h shielding of all c...

Page 86

C-4 ce guidelines mn1919 c.1.5 wiring of shielded (screened) cables remove the outer insulation to expose the overall shield. Clamp should provide 360° contact with the cable. Flat or p-type conductive clamp or figure 31 - earthing/grounding cable shields 1 9 2 10 3 11 12 13 microflex x8 encoder con...

Page 87

Index mn1919 a abbreviations. See units and abbreviations accessories, a-1 emc filters, a-3 feedback cables, a-2 motor power cables, a-2 regeneration resistors, a-5 analog i/o, 5-2 analog input - x3 (command), 5-2 b basic installation, 3-1 c catalog number, identifying, 2-2 ce guidelines, c-1 commis...

Page 88

Index mn1919 connection summary, 5-10 digital i/o, 5-4 digital input - x3, 8-3 digital output - x3, 5-8 drive status output - x3, 8-3 encoder output - x7, 4-7, 8-4 general purpose digital input - x3, 5-6 serial port - x6, 5-9, 8-4 simulated encoder output, 4-7 step & direction, 8-3 installation see ...

Page 89

Index mn1919 u units and abbreviations, 2-3 w wire sizes, 3-14 workbench v5, 6-3 commissioning wizard, 6-6 fine-tuning tool, 6-7 help file, 6-3 other tools and windows, 6-10 parameters tool, 6-9 starting, 6-4.

Page 90

Index mn1919.

Page 91

Comments mn1919 if you have any suggestions for improvements to this manual, please let us know. Write your comments in the space provided below, remove this page from the manual and mail it to: manuals baldor uk ltd mint motion centre 6 bristol distribution park hawkley drive bristol bs32 0bf unite...

Page 92

Comments mn1919 thank you for taking the time to help us..

Page 94

Printed in uk e baldor uk ltd europe (southern) baldor asr ag, switzerland tel: +41 52 647 4700 fax: +41 52 659 2394 europe baldor asr gmbh, germany tel: +49 (0) 89 905 080 fax: +49 (0) 89 905 08490 australia australian baldor pty ltd tel: +61 2 9674 5455 fax: +61 2 9674 2495 mexico baldor de mexico...