- DL manuals

- Baldor

- Portable Generator

- TS130

- Installation & Operating Manual

Baldor TS130 Installation & Operating Manual

Summary of TS130

Page 1

Tier 2/3 towable generators (trailer and skid mounted) (diesel liquid cooled) ts25, 35, 45, 60, 80, 130, 175, 250 and 400 installation & operating manual 8/06 mn2417.

Page 2

Warning: california proposition 65 warning: engine exhaust from this product contains chemicals known to the state of california to cause cancer, birth defects and other reproductive harm. Warning: california proposition 65 warning: battery posts, terminals and related accessories are known to the s...

Page 3

Table of contents table of contents i mn2417 section 1 product safety information 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Safety notice 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4

Ii table of contents mn2417.

Page 5

Section 1 product safety information product safety information 1-1 mn2417 safety notice be sure that you are completely familiar with the safe operation of this equipment. This equipment may be connected to other machines that have rotating parts or parts that are controlled by this equipment. Impr...

Page 6

1-2 product safety information mn2417 this symbol is shown throughout the manual to indicate a connection to ground reference point. Symbols indicates a potentially hazardous situation which, if not avoided, could result in injury or death. Indicates a potentially hazardous situation which, if not a...

Page 7

Product safety information 1-3 mn2417 operation warning statements continued warning: over crank indication can mean a loss of crank disconnect signal during the previous run period. Attempting to restart the engine with no crank disconnect signal can destroy the starter motor, which can cause serio...

Page 8

1-4 product safety information mn2417 warning statements continued burn warning: parts of this generator are extremely hot during and after operation. To prevent severe burns, do not touch any part of the generator until you have first determined if the part is hot. Wear protective clothing and afte...

Page 9

Product safety information 1-5 mn2417 warning statements continued warning: incorrect installation of this generator set could result in property damage, injury or death. Connection of the generator to its fuel source must be done by a qualified professional technician or contractor. Warning: never ...

Page 10

1-6 product safety information mn2417 caution statements caution: avoid installing the generator set beside heat generating equipment, or directly below water or steam pipes or in the vicinity of corrosive substances or vapors, metal particles and dust. Heat can cause engine problems to develop and ...

Page 11

Section 2 general information general information 2-1 mn2417 thank you for purchasing your baldor generator set. This manual contains information you need to safely and efficiently install and operate your generator set. During the preparation of this manual every effort was made to ensure the accur...

Page 12

2-2 general information mn2417.

Page 13

Section 3 receiving & installation receiving & installation 3-1 mn2417 receiving & inspection when you receive your generator, there are several things you should do immediately. 1. Observe the condition of the shipping container and report any damage immediately to the commercial carrier that deliv...

Page 14

3-2 receiving & installation mn2417 several other factors should be carefully evaluated when selecting a location for installation: 1. For effective cooling and maintenance, the system should be mounted on a flat, smooth, noncombustible level surface. A concrete pad is ideal and provides a secure in...

Page 15

Receiving & installation 3-3 mn2417 hot exhaust gasses warning: exhaust fumes/gases are extremely dangerous and can cause severe illness or death. Never breath exhaust fumes produced by a running engine. Only run the engine outdoors where ventilation is plentiful. Exhaust gases contain carbon monoxi...

Page 16

3-4 receiving & installation mn2417 electrical connections class 1 wiring methods must be used for field wiring connections to terminals of a class 2 circuit. It is the responsibility of the owner/operator to arrange for these procedures to be performed by a licensed electrical contractor and ensure...

Page 17

Receiving & installation 3-5 mn2417 single phase connections single phase connections are made at load receptacles located by the operator panel, see figure 3-3. Simply open the rear panel access door and make the connections. When the panel door is closed, the connections are weather tight. Figure ...

Page 18

3-6 receiving & installation mn2417 three phase connections three phase connections are made at l1, l2, l3 and n connections shown in figure 3-4. Figure 3-4 three phase and remote start connections for power to be applied to these terminals, the output voltage selector switch must be in the 120/208v...

Page 19

Receiving & installation 3-7 mn2417 frame ground connection warning: be sure the system is properly grounded before applying power. Do not apply ac power before you ensure that grounds are connected. Electrical shock can cause serious or fatal injury. Nec requires that the frame and exposed conducti...

Page 20

3-8 receiving & installation mn2417 warning: a battery presents a risk of fire because they generate hydrogen gas. Hydrogen gas is extremely explosive. Never jump start a battery, smoke in the area around the battery or cause any spark to occur in the area around the battery. The following precautio...

Page 21

Receiving & installation 3-9 mn2417 recommended engine oil and battery type when replacing batteries, use only the recommended battery for your generator, see table 3-5. Table 3-5 oil & battery recommendations model summer winter oil recommended (amps) cold model summer oil winter oil oil capacity r...

Page 22

3-10 receiving & installation mn2417 post installation checks continued 16. Place the voltage output selector switch in the appropriate position. 17. Verify all loads are disconnected. 18. Verify the master control is in the “stop” position. Connect the engine starting battery to the starter. Verify...

Page 23

Section 4 operation operation 4-1 mn2417 towing the generator warning: never allow a person to ride in or on a trailer that is being towed. All states prohibit passengers in towed vehicles. A person can fall off and be struck be another vehicle or run over by the towed trailer. Failure to observe th...

Page 24

4-2 operation mn2417 selecting the proper towing equipment continued electrical trailer wiring all trailers must have taillights, brake lights and turn signals connected to the towing vehicle’s electrical system. It is also recommended that a heavy duty turn signal flasher and emergency flasher (if ...

Page 25

Operation 4-3 mn2417 figure 4-1 trailer component identification jack single or double axle trailer brake safety chains trailer pintle engine compartment lift hook battery compartment jack coupler coupler handle safety chains ball coupler tow vehicle mounted pintle hook caution: large “engine compar...

Page 26

4-4 operation mn2417 towing instructions see figure 4-1 for component identification. 1. Be sure the generator is off. 2. Shut all enclosure doors and latch the locks. 3. Back the tow vehicle to within a few inches of the trailer coupler (pintle or ball). 4. Be sure the coupler handle is in the “up”...

Page 27

Operation 4-5 mn2417 trailer setup see figure 4-1 for component identification. Carefully read all instructions before starting. 1. Locate a suitable, level location. Also be sure there are no overhead wires or obstructions. The trailer is balanced so the majority of the weight rests on the tow bar ...

Page 28

4-6 operation mn2417 table 4-2 three/single phase operation alternator voltage voltage at terminal lugs voltage at plug receptacles switch position alternator winding connection voltage adjust position line to line voltage line to neutral voltage 120vac receptacles 240vac receptacles (twist lock) po...

Page 29

Operation 4-7 mn2417 meters, switches, lights and other operator control components are located in various places on each panel. Figure 4-5 can be used to identify the function and features of each operator control regardless of where it is located on your panel. Figure 4-5 operator control panel co...

Page 30

4-8 operation mn2417 pre−start procedure before attempting to start the generator set, several things must first be verified or performed. These are: 1. Fill system fuel tank with clean, fresh diesel fuel. 2. Fill engine crankcase to full mark with clean, fresh lubricating oil per engine manufacture...

Page 31

Operation 4-9 mn2417 digital engine controller description em0046a21 (mrs17) figure 4-6 operator control panel stop manual run display menu group led indicators operating modes and horn & fault reset led indicators alarm (red) − alarm (shutdown) condition occurred. Annunciates & shuts down generator...

Page 32

4-10 operation mn2417 digital engine controller description em0046a21 (mrs17) continued operating mode press mode or to scroll though the list of operating modes: off, manual and automatic. The control mode is shown in the highlighted area at the top of the display, figure 4-7. When the desired cont...

Page 33

Operation 4-11 mn2417 digital engine controller description em0046a21 (mrs17) continued table 4-4 manual mode sequence description menu status condition of transition action next state start request prestart on, prestart time counter started prestart ready rpm > 2 or oil pressure detected or gen vol...

Page 34

4-12 operation mn2417 alarms following alarms are available: sensor fail (fls) see table 4-5 sensor fail is detected when measured value is 6% out of selected sensor characteristic. Sensor fail is indicated by ##### symbol instead measured value. Warning (wrn) see table 4-5 when warning comes up, on...

Page 35

Operation 4-13 mn2417 inputs and outputs any binary input or output can be configured to any controller terminal inputs are bi1 − bi6, outputs are bo1 − bo6) or changed to different function by liteedit software. There is fixed 1 sec delay when any binary input is configured as protection. Table 4-6...

Page 36

4-14 operation mn2417 table 4-7 binary outputs continued genparamsok the output is same as generator status led on panel. Output is closed if genset is running and all genset electric values are in limits. Commonwrnsd output is closed if : any warning or shutdown are active or the gen−set malfunctio...

Page 37

Operation 4-15 mn2417 table 4-7 binary outputs continued common wrn output closes when any warning alarm appears. The output opens, if alarm is not active and fault reset is pressed. Common sd output closes when any shut−down alarm appears. The output opens, if alarm is not active and fault reset is...

Page 38

4-16 operation mn2417 analog inputs three analog inputs for resistive sensor 0 to 2400 Ù measuring are available on il controller. Use liteedit software to modify configuration. The analog inputs values assignment (ai1 = oil press, ai2 = water temp, ai3 = fuel level) is fix. It is possible to config...

Page 39

Operation 4-17 mn2417 table 4-9 setpoints continued start rpm “firing” speed when il controller stops cranking (starter goes off). Step: 1% of nominal rpm; range: 5 − 50 % starting poil when reached controller stops cranking (starter goes off). Step: 0,1 psi; range: −100 − 10000 note: there are thre...

Page 40

4-18 operation mn2417 table 4-9 setpoints continued gcb closedelay gcb can be closed earliest gcb closedelay after stabil time when all electric values are in overunder voltage and over−under frequency limits. Step: 1 s; range: 0 − 300 s stabil time generator nominal voltage is detected during gense...

Page 41

Operation 4-19 mn2417 table 4-9 setpoints continued overload threshold for generator overload (in % of nominal power) step: 1% of nominal power; range: 0 − 200% overload wrn threshold for generator overload warning (in % of nominal power) step: 1% of nominal power; range: 0 − 200% overload del delay...

Page 42

4-20 operation mn2417 table 4-9 setpoints continued anliniom1 lev1 the level for iom analog input 1 alarm detection. Step: 1; range: −100 to +10000 anliniom1 lev2 the level for iom analog input 1 alarm detection. Step: 1; range: −100 to+10000 anliniom1 del delay for iom analog input 1 alarm. Step: 1...

Page 43

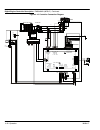

Operation 4-21 mn2417 digital engine controller description em0046a21 (mrs17) continued figure 4-9 controller connection diagram load diesel/gas engine oil pressure w a ter temp fuellevel starter battery − + fuel so l e no id generator g st a r t e r f u el so le n o id l1 l2 l3 n generator c.B. Ana...

Page 44

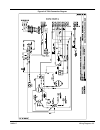

4-22 operation mn2417 digital engine controller description em0046a21 (mrs17) continued figure 4-10 controller connection diagram load em erg ency sto p access l o c k control signals rem o t e s/ s di ese l /gasengin e start er battery − + fuel so l e no id generator g +24 v binary outputs gen c. B...

Page 45

Section 5 troubleshooting and maintenance troubleshooting and maintenance 5-1 mn2417 warning: never “jump start” a generator to start the engine. If the battery charge is insufficient to start the engine, charge or replace the battery and try to restart. Jump starting a battery can cause the battery...

Page 46

5-2 troubleshooting and maintenance mn2417 problems and solutions some of the more common problems are listed in table 5-1. This information is intended to be a check or verification that simple causes can be located and fixed. It is not an exhaustive “how to” for all types of problems. Procedures t...

Page 47

Troubleshooting and maintenance 5-3 mn2417 table 5-1 troubleshooting guide continued problem possible cause remedy genset will not pull load incorrect engine speed load not connected properly load too large for unit remove electrical load, output should be 61−62 hertz adjust engine speed if necessar...

Page 48

5-4 troubleshooting and maintenance mn2417.

Page 49

Appendix a wiring diagrams wiring diagrams a-1 mn2417 replacement parts replacement parts information is provided in replacement parts catalog ca2401. Engine parts are identified in the engine manual that was provided with your generator set. Important: fuses are installed in the control box to prot...

Page 50

A-2 wiring diagrams mn2417 figure a-1 ts25 connection diagram.

Page 51

Wiring diagrams a-3 mn2417 figure a-2 ts25 connection diagram.

Page 52

A-4 wiring diagrams mn2417 figure a-3 ts25 connection diagram.

Page 53

Wiring diagrams a-5 mn2417 figure a-4 ts25 connection diagram.

Page 54

A-6 wiring diagrams mn2417 figure a-5 ts25 connection diagram.

Page 55

Wiring diagrams a-7 mn2417 figure a-6 ts25 connection diagram.

Page 56

A-8 wiring diagrams mn2417 figure a-7 ts35 connection diagram.

Page 57

Wiring diagrams a-9 mn2417 figure a-8 ts35 connection diagram.

Page 58

A-10 wiring diagrams mn2417 figure a-9 ts35 connection diagram.

Page 59

Wiring diagrams a-11 mn2417 figure a-10 ts35 connection diagram.

Page 60

A-12 wiring diagrams mn2417 figure a-11 ts35 connection diagram.

Page 61

Wiring diagrams a-13 mn2417 figure a-12 ts35 connection diagram.

Page 62

A-14 wiring diagrams mn2417 figure a-13 ts35 power connection diagram.

Page 63

Wiring diagrams a-15 mn2417 figure a-14 ts60 connection diagram.

Page 64

A-16 wiring diagrams mn2417 figure a-15 ts60 connection diagram.

Page 65

Wiring diagrams a-17 mn2417 figure a-16 ts60 connection diagram.

Page 66

A-18 wiring diagrams mn2417 figure a-17 ts60 connection diagram.

Page 67

Wiring diagrams a-19 mn2417 figure a-18 ts60 connection diagram.

Page 68

A-20 wiring diagrams mn2417 figure a-19 ts60 connection diagram.

Page 69

Wiring diagrams a-21 mn2417 figure a-20 ts60 connection diagram.

Page 70

A-22 wiring diagrams mn2417 figure a-21 ts80 connection diagram.

Page 71

Wiring diagrams a-23 mn2417 figure a-22 ts80 connection diagram.

Page 72

A-24 wiring diagrams mn2417 figure a-23 ts80 connection diagram.

Page 73

Wiring diagrams a-25 mn2417 figure a-24 ts80 connection diagram.

Page 74

A-26 wiring diagrams mn2417 figure a-25 ts80 connection diagram.

Page 75

Wiring diagrams a-27 mn2417 figure a-26 ts80 connection diagram.

Page 76

A-28 wiring diagrams mn2417 figure a-27 ts80 connection diagram.

Page 77

Wiring diagrams a-29 mn2417 figure a-28 ts80 connection diagram.

Page 78

A-30 wiring diagrams mn2417 figure a-29 ts80 connection diagram.

Page 79

Wiring diagrams a-31 mn2417 figure a-30 ts80 connection diagram.

Page 80

A-32 wiring diagrams mn2417 figure a-31 ts400 connection diagram.

Page 81

Wiring diagrams a-33 mn2417 figure a-32 ts400 connection diagram.

Page 82

A-34 wiring diagrams mn2417 figure a-33 ts400 connection diagram.

Page 83

Wiring diagrams a-35 mn2417 figure a-34 ts400 connection diagram.

Page 84

A-36 wiring diagrams mn2417 figure a-35 ts400 connection diagram.

Page 85

Wiring diagrams a-37 mn2417 figure a-36 ts400 connection diagram.

Page 86

A-38 wiring diagrams mn2417 figure a-37 ts400 connection diagram.

Page 87

Wiring diagrams a-39 mn2417 figure a-38 ts400 connection diagram.

Page 88

A-40 wiring diagrams mn2417 figure a-39 ts400 connection diagram.

Page 89

Baldor district offices.

Page 90

© baldor electric company mn2417 printed in usa 8/06 warning: california proposition 65 warning: engine exhaust from this product contains chemicals known to the state of california to cause cancer, birth defects and other reproductive harm. Warning: california proposition 65 warning: battery posts,...