En gi mist 1000 dspnm-d manuale istruzioni per l'uso. Instructions for use istruzioni originali (it) 0006080766 - two stages progressive / modulating natural gas / heavy oil mixed burners По вопросам продаж и поддержки обращайтесь: А рхангельск (8182)63-90-72 А стана +7(7172)727-132 Б елгород (4722)...

3 / 38 0006080766 - before using the burner for the first time please carefully read the chapter “warnings notes for the user : how to use the burner safely” in this instruction manual, which is an integral and essential part of the product. The works on the burner and on the esystem have to be carr...

E n g l i s h 2 / 34 0006080766 i warning notes for the user how to use the burner safely foreword these warning notes are aimed at ensuring the safe use of the compo- nents of heating systems for civil use and the production of hot water. They indicate how to act to avoid the essential safety of th...

E n g l i s h 3 / 34 0006080766 i warning notes for the user how to use the burner safely electrical supply • theequipmentiselectricallysafeonlywhenitiscorrectlyconnectedtoan efficientgroundconnectioncarriedoutinaccordancewithcurrentsafety regulations.Itisnecessarytocheckthisessentialsafetyrequireme...

E n g l i s h 4 / 34 0006080766 technical specifications *) the electrical preheaters are not mounted on the burner mod. Gi mist 1000 dspnm gi mist 1000 dspnm-d thermic capacity max kw 10 500 min kw 2 500 flow rate max kw 1 056 min kw 251 min. Pressure (inordertoobtainthemaximumflowrate) max mbar 50...

E n g l i s h 5 / 34 0006080766 mod. A a1 a2 b b1 b2 b3 b4 b5 b6 c d e Ø gi mist 1000 dspnm-d 1465 800 665 1257 855 402 450 575 175 163 2350 440 480 mod. F Ø g g1 l Ø m n Ø p q r s gi mist 1000 dspnm-d 685 dn80 rp1/2 630 m16 495 740 1910 1575 795 n° 00 02 67 05 52 overall dimensions.

E n g l i s h 6 / 34 0006080766 pressure in the combustion chamber burner output operating range heavy oil description of s eries gi 1000 industrial burners the gi 1000 burner is a packaged version made up of separately supplied units; these components must be connected at the bur- ner installation ...

E n g l i s h 7 / 34 0006080766 electrical connections itisadvisabletoeffectallelectricalconnectionswithflexibleelec- trical wire. Electrical lines must be kept away from hot parts. Make sure that the power line to which you intend to connect theunitisofvoltageandfrequencysuitablefortheburner.Make s...

E n g l i s h 8 / 34 0006080766 fuel feed unit the burner pump must receive the fuel from a suitable feed circuit with an auxiliary pump having a pressure that is adjustable between 0.5 and 2 bar; if fuel of a rated viscosity greater than 5° e at 50° c is to be used, it must be preheated to 50 - 60°...

E n g l i s h 9 / 34 0006080766 hydraulic diagram for one or more modulating burners operating with heavy oil (15° e at 50° c) n° 0 00 29 01 19 0 1 main tank 2 steamorhotwaterheatingoiltokeepasufficienttemperaturefortheslideinthepipe-linealsoduringthe pause 3 filter 4 circulation pumps 5 by pass (no...

E n g l i s h 10 / 34 0006080766 n° 0 00 29 01 14 0 hydraulic diagram burners no shut off device may be interposed connection to supply cir- cuits 0002901180, 0002901190, 0002901200 1 - filter 2 - flexible pipe 3 - burner pump 4 - pressure gauge (0 ÷ 40 bar) 5 - modulation servomotor 6 -diskwithscre...

E n g l i s h 11 / 34 0006080766 description of operation with heavy oil (s ee 0002900311) turnthemainisolatingswitch“q1”toon:thepowerindicatorlightwill comeon,aswilltheauxiliaryelementsofthepump,filter,atomising unit and regulating valve (.....N-d version only). Turnthestart/stopswitch“s1”toon:powe...

E n g l i s h 12 / 34 0006080766 safety time in seconds 2.5 pre-ventilation and pre-circulation time in seconds 37.5 pre-ignition in seconds 5 post-ignition in seconds 2.5 time between 1st (pilot) flame and start of modulation in seconds 12.5 control box and programmer lfl 1.335 cyclic relay control...

E n g l i s h 13 / 34 0006080766 n° 0 00 29 33 99 0 detail of fuel pressure adjusting valve detail of fuel pressure adjusting valve for auxiliary circuit 1 - valve body 2 - adjusting screw support plug 3 - adjusting screw stop nut 4 - adjusting screw 5 - spring centering bush n° 0 00 29 32 08 0 6 - ...

E n g l i s h 14 / 34 0006080766 wiring diagram for dandoss pump model ksvb 1000 ÷ 6000 r n° 0 00 29 00 43 0 return delivery cock cock pressure gauge intake pressure regulator screw diagram of a dismantled (cb) charles bergonzo nozzle (without pin) n° b t 93 53 /1 nozzleid: flowrateinkg/h spray angl...

E n g l i s h 15 / 34 0006080766 ignition and adjustment with heavy oil 1) checkthatnozzlecharacteristics(flowandsprayangle)are suitable for the combustion chamber (see bt 9353); if they are notreplacethenozzlewithonethatissuitable. 2) check that there is fuel in the tank and that it is, at least on...

E n g l i s h 16 / 34 0006080766 - ignite the burner, adjust the quantity of gas and air for the pilot flame and check for proper ignition several times. - when adjustment is over restore the original connections. Uv cell detectionofthepilotflameiseffectedbyauvcell:the following information should b...

E n g l i s h 17 / 34 0006080766 switch operation (opening of the circuit) must cause burner shutdown:thiscanbecheckedforbyactingontherelevant adjustment devices. 22) now check that modulation works properly in automatic mode. Turn the aut - o - man switch to “aut” and the min - o - max switch to “o...

E n g l i s h 18 / 34 0006080766 n°0002933530 basic diagram of gas train detail of butterfly valve damper regulating gas flow for gi 1000 series burners 1- indicatorpositionofthegasbutterflyvalve 2- gasbutterflyvalve 3 - the slot on the end of the shaft indicates the position of the butterflyvalve(d...

E n g l i s h 19 / 34 0006080766 starting up and regulation with metha- ne gas 1) if not already done at the moment of connecting the burner to the gas pipeline, it is indispensable to carry out a purge of the air contained in the pipeline. As a precaution, special care should be taken and doors and...

E n g l i s h 20 / 34 0006080766 13) afterhavingregulatedgasthroughputfortheminimumflame setting, set the modulation switches to “man” (manual) and “max” (maximum). 14) the modulating servo-motor will now start up. Wait until the modulator disk has moved through an angle of about 12° (cor- respondin...

E n g l i s h 21 / 34 0006080766 air feeding adjustment principle diagram n° 00 02 93 62 30 wrong adjustment correct adjustment air combustion inlet, air gates very closed big air passage opening combustion head air combustion inlet, air gates sensibly open combustion head air passage relatively clo...

E n g l i s h 22 / 34 0006080766 burner gi 1000 dspgn gas pilot adjustment principle diagram burner model gi 1000 dspgn modulation group detail with servomotor 1 - device for the air regulation at the head 2 - modulating disks 4 - air combustion gate adjustment screws 5- butterflyvalve,controllingth...

E n g l i s h 23 / 34 0006080766 skp 15... Complete with valve instructions for setting siemens skp 15.000 e2 gas valve description of how the valve operates single-stage valves when the valve receives the signal to open, the pump cuts in and the magnetic valve closes. The pump transfers the oil fro...

E n g l i s h 24 / 34 0006080766 n° 0002910940 execution servo motor the hydraulic control system consists of a cylinder full of oil and a pump with oscillating piston. There is also a solenoid valve between the aspiration chamber and the pump thrust chamber, forclosure.Thepistonmovesonaliquidtightj...

E n g l i s h 25 / 34 0006080766 details of the modulation control mo- tor sqm 10 and sqm 20 for regulation of cams tomodifytheregulationofthe3camsutilized,operatethe respective red rings ( a - z - m ). By pushing with enough force, in the direction desired, each red ring will rotate with respect to...

E n g l i s h 26 / 34 0006080766 electrical connections the burner manufacturer’s diagram is valid for the relief valve connections. Legend for the entire catalogue sheet a limit switch commutation contact for air damper open position al remote signalling of lock-out stop (alarm) ar main relay (oper...

E n g l i s h 27 / 34 0006080766 notes on the programmer programmer sequence output signals on terminal times legend time (50 hz) in seconds 31.5............T1 pre-ventilation time with air damper open 3.................T2 safety time - .................T2’ safety time or safety time with burners th...

E n g l i s h 28 / 34 0006080766 t2’, t3’, t3’: these times are valid only for series 01 or lfl1.335, lfl1.635, lfl1.638 burner control and command equipment. They are not valid for types of series 032, since they involve simultaneous activation of cams x and viii. Working the above diagrams illustr...

E n g l i s h 29 / 34 0006080766 ldu 11.. Gas valve tightness control equipment use ldu 11 equipment is used to verify tightness of valves on natural gas burners. The ldu 11 combined with a normal pressure switch automatically verifies tightness of natural gas burners valves, before every start up a...

E n g l i s h 30 / 34 0006080766 al remote alarm signalling ar main relay with “ar” contacts as equipment fuse br blocking relay with “ar” contacts dw outer pressure switch (tightness control) ek... Unblocking button gp outer pressure switch (for mains gas pres- sure) hr auxiliary relay with “ar” co...

E n g l i s h 31 / 34 0006080766 instructions for ascon electronic tem- perature controller m odel ms 30/099 for heavy oil in burner preheater(s) the “ms 30” electronic controller cab be used in various ways and mustbecorrectlyprogrammed(configured)asafunctionoftheuse thatistobemadeofit.Useandconfig...

E n g l i s h 32 / 34 0006080766 1) press ▲ key and theflashingfigurewillchange,presskey again until obtaining 3. Press ◄toconfirmtheflashing3 that becomesfixed.Itisnowpossibletoeditthefigurefurtherto theleftthatbeginstoflash.Press▲ key in order to change thefigurenowflashingto3andthen◄inordertoconf...

E n g l i s h 33 / 34 0006080766 opening the burner - dismounting of the atomizing group and flame disk n° 0002933430 1 - take out the burner cover 2 - disconnect the atomising group and head tie rods 3 - disconnect the heating element connector 4 - disconnect the ignition electrode cable 5 - unscre...

E n g l i s h 34 / 34 0006080766 6 - take out the hinge pivot 7 - take out the hinge upper screw and open the burner 8 - take out the blocking screw of the atomising group 9-takeouttheatomisinggrouptodismountthenozzle 10-takeoutthefourfixingscrewsofthegroupholder 11-takeoutthegroupholderandflamedisk...

75 / 84 0006080766.

76 / 84 0006080766.

77 / 84 0006080766.

78 / 84 0006080766.

79 / 84 0006080766.

80 / 84 0006080766.

81 / 84 0006080766.

82 / 84 0006080766 din / iec it gb fr es gnye verde / giallo green / yellow ver t / jaune verde / ama - rillo bu blu blue bleu azul bn bruno brown marron marrÓn bk nero black noir negro bk* connett ore nero con sovrast amp a black wire with inprint conducteur noir avec surimpres - sion conduct or ne...

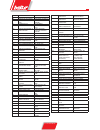

83 / 84 0006080766 sigla it gb a1 apparecchiatura control box a2 termostato eletronico electronic thermostat a3 controllo tenuta val- vole valves tightness control b1 fotocellula uv uv photocell b2 termoresistenza pt100 thermoresistance pt100 dw pressostato controllo tenuta valvole pressure switch f...

- il presente catalogo riveste carattere puramente indicativo. La casa, pertanto, si riserva ogni possibilità di modifica dei dati tecnici e quant’altro in esso riportato. - technical data in this brochure are given as information only. Baltur reserves the right to change specification, without noti...