Summary of ValueLam 4500

Page 1

Operating instructions valuelam 4500

Page 2: Read Before Operating

2 read before operating caution... To avoid any damage, please do not use razors or sharp objects near the rollers. Do not leave machine on when not in use or you will damage your rollers!.

Page 3: Table of Contents

3 table of contents i. For your safety...................................... 4 ii. Electrical safeguards ............................. 4-5 iii. Specifications......................................... 5 iv. Set-up .................................................... 5-8 inspection.......................

Page 4: Operating Instructions

4 operating instructions valuelam 4500 i. For your safety... Do not connect the laminator to electrical power or attempt to operate it until you have read these instructions completely. Keep these instructions in a convenient location for future reference. Read all safety messages located in this in...

Page 5

5 do not leave the laminator power on for extended periods while not in use. Unplug the machine at the end of the day as a precaution against a possible fire hazard. Do not operate the laminator with a damaged power supply cord or plug. Replace fuses only with same type rated 20, 250v and 1a, 250v f...

Page 6

6 loading film onto mandrels: when the film is loaded properly the core gripper blade will prevent the film from turning on the supply mandrel. With the gripper spring away from you, pull the core gripper blade toward you and place the roll of film onto the mandrel. Turn the roll on the mandrel to l...

Page 7

7 thumb screws in the mandrel holders. Turn clockwise to increase tension. This action clamps the brake on the mandrel axle creating tension necessary to achieve good results. Threading the film: your valuelam 4500 was delivered with sample rolls of film. When changing film rolls, thread the film ac...

Page 8

8 8. Turn the speed control knob far enough to allow the rollers to sufficiently pull the poster board or cardboard into the laminator. Keep in mind that varying media and temperatures will require different speeds. 9. Feed the poster board or cardboard between the rollers. 10.If you are loading col...

Page 9

9 v. Thermal laminating... 1. Be sure all laminator parts (i.E. Safety shield, feed table, etc.) are in their proper positions and the laminating film is loaded correctly. 2. Set the temperatures according to the film manufacturer’s recommendations for the film you have chosen. A low-melt film is re...

Page 10

10 6. Allow the valuelam 4500 to run a small amount of film before feeding the print into the laminator to avoid a dwell line across your print. Feed the print slowly and evenly, smoothing it as the rollers pull it through. 7. You may laminate subsequent prints now, leaving ample space between each ...

Page 11

11 5. Turn the motor switch on and perform a test mount to ensure proper settings for successful mounting. If any adjustments are necessary make them now and run another test. Repeat this step until you obtain desired results. 6. Position the print to be mounted on a section of mount board up to ¼” ...

Page 12

12 cleaning rubber rollers: excessive build-up of adhesive on the rollers may cause poor lamination quality and erratic film movement. Use the following procedure to remove any adhesive from the laminating rollers. 1. Turn the heated rollers off and allow the laminator to cool. 2. Cut the film where...

Page 13

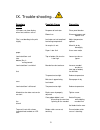

13 ix. Trouble-shooting... Symptom possible cause corrective action lcd does not show display no power to laminator close panel breaker when heat switches are on. Blown fuse disconnect power and replace fuse film is not bonding to the print laminator not set to optimal adjust temperature slightly la...

Page 14

14 x. Do’s and don’ts... • read the instruction manual before operating your laminator. • always run test samples before laminating valuable items. • feed the print through slowly and evenly, smoothing it as it is pulled into the • laminator. • operate the laminator with two rolls of the same width ...

Page 15

15 xii. Parts list item part number description quantity 1 645003 roller, silicone, 35-40 2 2 645033 top idler roller rod 1 3 645032 top idler roller tube 1 4 645034 housing, rod 45110 1 5 11125 rod, lower idler 1 6 11126 rod, lower idler 1 7 645026 run-off table, back 45110 1 8 645027 run-off table...

Page 16

16 51 6546 switch, emergency stop 2 52 10085 motor, ezii, 80mm 1 53 11045 variable speed control 1 54 10398 chain, #35 bulk 2 55 2325 chain, link, #35 master 1 56 1172 fuse holder, htb-34i 1 57 11480 on/off switch 25a dp 43 1 58 645040 pin, roller adjustment 2 59 645039 spring, roller pressure 2 60 ...