- DL manuals

- Banner

- Accessories

- iVu Plus BCR

- User Manual

Banner iVu Plus BCR User Manual

Summary of iVu Plus BCR

Page 1

Ivu plus bcr user's manual rev. B 1/25/2012.

Page 2: Contents

Contents 1 product support and maintenance .......................................................................................................5 1.1 product support .......................................................................................................................................

Page 3

5.1 acquiring a good image ..............................................................................................................................................57 5.2 setting up a barcode application ..............................................................................................

Page 4

9.6.1 configuration .................................................................................................................................................132 9.6.2 output registers ...............................................................................................................

Page 5: 1.1 Product Support

1 product support and maintenance this section provides general banner resources and specific documentation for installers and operators of this ivu plus bcr vision sen- sor. Warning: not to be used for personnel protection never use this product as a sensing device for personnel protection. Doing s...

Page 6: 1.2 Maintenance

Factory support call, e-mail, fax, or write your local banner representative or a banner applications engineer for support. Applications engineers are available from 8:00 a.M. To 5:00 p.M. Central time, monday through friday, excluding holidays. Phone local: 763.544.3164 toll free: 1.888.3.Sensor (1...

Page 7: 2 Overview of The Sensor

2 overview of the sensor the ivu plus bcr sensor reads a wide variety of barcodes. The package consists of lighting, sensor, lens, and display. Appropriate cables and mounting brackets can be ordered for each application. Additionally, other lenses, brackets, filters and external lights are availabl...

Page 8

1 led - green: power; red: error 2 led - green: pass; red: fail 3 ethernet i/o led 4 focusing window 5 focusing window locking clip 6 integrated display ivu plus bcr user's manual 8 www.Bannerengineering.Com - tel: 763-544-3164 rev. B.

Page 9

C a b a 8-pin euro-style (m12) female usb cable connector b i/o cable connector c 12-pin euro-style (m12) male power and i/o cable connector mounting bracket mounting holes (uses supplied three m4 x 4 mm screws) ivu with remote display the ivu sensor for use with a remote display comes fully assembl...

Page 10

A b c d a 8-pin euro-style (m12) female remote display connector b 12-pin euro-style (m12) male power and i/o cable connector c 4-pin pico (m8) female connector d i/o cable connector mounting bracket mounting holes (uses supplied three m4 x 4 mm screws) 2.1.2 cable connections ivu plus bcr with inte...

Page 11

Ivu plus bcr with remote display the cable connections on the ivu plus with remote display are shown below, and power i/o connections (b) are defined in the power i/o connections table below. A b c d a remote display connector b power i/o connector c usb connector d ethernet connector note: microlen...

Page 12

Power i/o connections pin # wire color description direction 2 brown 10-30v dc input 7 blue common (signal ground) input 6 pink external trigger input 5 gray remote teach input 1 white output 1 output 8 red ready output 4 yellow strobe out (5v dc only) output 3 green output 2 output 9 orange output ...

Page 13

The sensor triggers from high to low, and remote teach behaves electrically like trigger. Note: if the device used to trigger or remote teach the ivu plus bcr is a sinking device (that is, npn), then there are two options regarding the use of a pull-up resistor: option 1: put a pull-up resistor, rat...

Page 14

Ready (pass) (fail) (pass) (pass) (fail) (pass) strobe out (configure as external & expose based) outputs 1, 2, and 3 (set as active pass) outputs 1, 2, and 3 (set as active fail) function 2.1.3 installing and connecting the sensor the ivu plus bcr sensor requires a bracket for mounting. Three brack...

Page 15

Installing filters on the ivu series sensor note: failure to follow these instructions can cause damage to your ivu series sensor. To install a filter on the ivu series sensor with micro lens, use the illustration as a guide and follow the steps listed below. A lens b focusing window c locking clip ...

Page 16: 2.2 Live Mode Overview

7. Press the focusing window onto the housing to make sure that it seats correctly (that is, there is no gap between the window and housing. Rotate the window counter-clockwise at least two turns. 8. Replace the locking tab screw but do not tighten until you have set up and focused the sensor again....

Page 17

Code > barcode type . The barcode count is selected on the touch screen by going to main menu > inspection > barcode > barcode count . This section describes some general ivu plus bcr concepts. 2.2.1 read/no read, pass/fail, match/no match the following describes what is meant by read/no read, pass/...

Page 18

2.2.3 compare data the ivu plus bcr has a data compare feature for comparing read barcode data against reference data. Data can be manually entered by accessing the main menu > inspection > barcode > data compare > set data screen. Data of up to 3200 characters can be entered. Additionally, the data...

Page 19

The ivu plus bcr rs232 port or ethernet port can be used to output barcode data to other applications. To access the data export screen, go to main menu > system > communications > data export . The user can enable or disable this feature. When enabled: • if the sensor is configured for either exter...

Page 20: 2.3 Ivu Plus Bcr Emulator

2.2.6 remote teach the remote teach function is a method of remotely updating compare data while the ivu sensor is running. The sequence of events for executing a remote teach as follows: 1. With the sensor ready, pulse the remote teach line. 2. The sensor recognizes that the remote teach line has b...

Page 21: 3 Main Menu Reference

3 main menu reference 3.1 main menu the main menu has four sections. Select: inspection to modify inspection settings imager to run the auto exposure routine and to make adjustments to functions like exposure, gain, and strobe. System to set output signals, communication channel parameters and to ma...

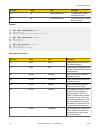

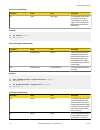

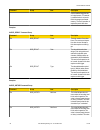

Page 22: 3.2 System Menu

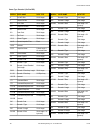

Imager strobe auto exposure exposure gain trigger focus external internal fov maximize fov modify fov locked inspection logs system logs communication logs unlock sensor logs inspection logs system logs communication logs industrial ethernet data export image export locked sensor menus view logs set...

Page 23

3.2.1 sensor mode main menu > system > sensor mode the sensor has two operating modes: • live mode, which is the normal operating mode where the sensor captures live images, scans, and verifies barcodes • demo mode, where inspections are run on stored images and inspection parameters. Note: you may ...

Page 24

Main menu > system > sensor configuration save to usb the save to usb screen provides for saving sensor configuration to a usb flash drive. The saved configuration information can be used as a backup or as a way to clone configuration information for other sensors. Main menu > system > sensor config...

Page 25

3.2.3 sensor information the sensor information screen displays the following sensor information: • serial number • firmware version • boot number • up timer • hour count • model number • sensor name main menu > system > sensor information click the right-arrow next to the sensor name field to displ...

Page 26

3.2.4 lock sensor this option provides for locking the sensor to prevent accidental modification of settings. When locked, the sensor only provides access to pass/fail statistics, as well as the ability to view logs and to save them to a usb device. A lock icon in the upper left corner of the sensor...

Page 27

Port settings for ethernet i/o main menu > system > communications > ethernet i/o in the ethernet i/o screen you can enter the ip address, subnet mask, and gateway. Port settings for serial i/o main menu > system > communications > serial i/o in the serial i/o screen you can select values for baud r...

Page 28

Industrial ethernet main menu > system > communications > industrial ethernet the ivuplus device can be controlled or monitored over industrial ethernet using ethernet/ip, modbus/tcp or pccc protocols. This document will help you to set up the ivu plus in the desired configuration and provide you wi...

Page 29

Delimiters main menu > system > communications > command channel > delimiters in the delimiters screen, there are three delimiter options that you can set: • field delimiter, which determines what is used to separate data that the sensor is sending out to a remote device. • end of frame, which deter...

Page 30

Data to export main menu > system > communications > data export > data to export the options in the data to export screen are used to determine what barcode data is exported via the serial port. Output format main menu > system > communications > data export > output format in the output format scr...

Page 31

Image export channel main menu > system > communications > image export when the image export channel is enabled, the sensor will transmit the acquired image on every trigger. The image is transmitted as a bitmap (bmp) file. This operation is only available over ethernet i/o. 3.2.6 discrete i/o the ...

Page 32

Input pullup main menu > system > discrete i/o > input pullup the npn version of the ivu sensor triggers from high to low, and remote teach behaves electrically like trigger. If using the npn version of the sensor, select enable. The pnp version of the ivu sensor triggers from low to high, and remot...

Page 33

Note: for latched the signal is active until the results of an inspection cause a change in the signal output. Main menu > system > discrete i/o > output 1 output2 and output 3 output 2 and output 3 can be configured in a similar fashion to output 1. The default setting for output 2 is fail and latc...

Page 34

Fail hold time the fail hold time determines how long a failed image is displayed on the lcd so that you can see what failed. The sensor will continue to process any triggers and the inspection will continue normally. This time delay is just for the screen. You can set this parameter from 0 to 3600 ...

Page 35: 3.3 Imager Menu

3.2.9 firmware update the firmware update screen is used to load the latest sensor firmware. The firmware update screen lists the firmware versions it finds in the banner\firmware folder on the usb drive. When you receive a firmware update from banner engineering, be sure to put it in the banner\fir...

Page 36

Main menu > imager > exposure 3.3.3 gain gain is an electronic boost to the image signal. Increasing gain by using the '-' and '+' keys or moving the slider to the right increases image brightness without increasing exposure time. Note that gain brightens both the light pixels and dark pixels and ma...

Page 37

External-single mode in external-single mode, the sensor depends on an external trigger. For each trigger, the sensor captures an image and executes one scan through the configured barcode types looking for the specified number of barcodes. This trigger mode uses the scan time limit parameter ( main...

Page 38

Note: a no read condition will not occur in continuous mode as another image capture and scan automati- cally follows. External-gated mode external-gated mode is similar to continuous mode. While an external trigger input signal is active, the sensor continues to capture images and run barcode scans...

Page 39

Industrial ethernet only when industrial ethernet communication channel is enabled, triggers can be received from the modes mentioned above. Triggers through industrial ethernet will not be executed if selected trigger mode is 'continuous scan'. If it is desired to receive triggers only through indu...

Page 40

3.3.6 strobe the internal strobe configures the operation of the integrated ring light. The external strobe configures the operation of an external light. Main menu > imager > strobe external the external strobe is a 5v output that can be used for an external light. Setting options are always on, al...

Page 41

Internal the internal strobe setting configures the operation of the integrated ring light. Setting options are always on, always off, or exposure based. If exposure based is selected, then the ring light is on during the time the sensor is capturing an image. Main menu > imager > strobe > internal ...

Page 42: 3.4 Inspection Menu

Modify fov use this option to reduce the size of the fov. Main menu > imager > fov > modify fov 3.4 inspection menu the inspection menu icon is located on the main menu. The inspection menu provides options to set inspection parameters on currently running inspection and manage stored inspections. M...

Page 43

The first time the sensor is powered up, the selection checkboxes for datamatrix and all linear barcode types are checked. The best practice is to check only the barcode type(s) applicable for your particular application. Note that, if all linear is unchecked, a single linear barcode type can be sel...

Page 44

• ean8 • upce • postnet • imb checksum verify when checksum is enabled, the sensor uses a checksum to verify the integrity of the barcode being read. Relaxed quietzone the quietzone is a blank margin on either side of a barcode that indicates where the barcode begins and ends. If this quietzone isn'...

Page 45

Use omnidirectional scanning if barcode can appear inverted on part being inspected. If 'compare' is enabled, the sensor attempts to compare that string to decoed data in both scan directions. Inspection is marked as pass if at least one string matches. The data that successfully matched is displaye...

Page 46

Compare use this menu to enable or disable data compare. If data compare is enabled, data can be defined in the compare data screen. The data can be retrieved from a previously scanned barcode, or it can be entered using the software keyboard on the touch screen, and insignificant characters can be ...

Page 47

Edit compare data the edit screen displays data that was previously read or entered in the text field. The position of the cursor within the characters dis- played ([) in the text field is indicated at the top of the screen. Additionally, the number of characters is indicated by length. Use the left...

Page 48

3.4.2 properties properties menu main menu > inspection > properties the properties menu is used to edit an inspection name or set the scan time limit. 3.4.3 stored inspections stored inspections menu main menu > inspection > stored inspections stored inspections is used to manage stored inspections...

Page 49: 3.5 Logs Menu

Add new inspection screen main menu > inspection > stored inspections > add new this screen is used to add a new inspection. The sensor can store up to 30 inspections. When you add a new one, it will begin running. When adding a new inspection, you can specify the name for the new inspection. 3.5 lo...

Page 50

3.5.1 inspection logs this menu provides for configuring and viewing inspection logs. Inspection logs are stored inspection records that include a captured image, the parameters used to inspect it, and the results of that inspection. Up to ten inspection logs can be held in memory on the sensor. The...

Page 51

View logs inspection logs appear as a strip of film. You can select a frame to view a specific image. Use the icon in the lower right of the screen to save the logs to the usb drive. Logs saved to the usb drive can be imported into the emulator. Click the clear button to clear inspection logs. Main ...

Page 52

3.5.2 system logs the system log contains configuration change information, other notifications, and any errors or warnings that may be encountered. • click the icon in the upper left corner of the screen to show/hide the time column. • click clear log button at the bottom of the screen to clear the...

Page 53: 4 Display Modes

4 display modes in the upper left of the screen is an icon for accessing different display modes: • display annotations • hide annotations • display statistics. 4.1 display/hide annotations click the icon in the upper-left of the screen to display annotations. When annotations are on, the display sh...

Page 54

4.1.1 inspection statistics the history screen shows inspection statistics: • total frames - total number of objects counted • passed - running total of parts that passed inspection • failed - running total of parts that failed inspection • missed triggers - running total of missed triggers • time r...

Page 55

4.1.3 barcode viewer to view detailed information about a particular barcode, click the arrow next to the barcode # to access the barcode viewer screen. If data compare is disabled, the barcode viewer screen shows a single text box indicating the index number of the barcode and the data the sensor i...

Page 56

Ivu plus bcr user's manual 56 www.Bannerengineering.Com - tel: 763-544-3164 rev. B.

Page 57: 5.1 Acquiring A Good Image

5 setting up for an inspection in order to set up for an inspection, you need to: 1. Acquire a good image. 2. Set up a barcode application 3. Set data compare parameters 5.1 acquiring a good image the ivu series sensor needs to capture a good image to ensure that it can read the barcode(s) correctly...

Page 58

• main menu > imager > exposure ivu plus bcr user's manual 58 www.Bannerengineering.Com - tel: 763-544-3164 rev. B.

Page 59

4. Go to main menu > imager > focus to adjust the focus while monitoring the focus number: for micro-lens models only: 1. Use the supplied 1/16" hex key to loosen the focusing window locking screw (d), then adjust focus on the ivu series sensor using the clear focusing window (b). 2. Adjust focus wh...

Page 60

Micro-lens models d locking screw e filter cap (optional) f filter (optional) note: filter kits are available separately. Ivu plus bcr user's manual 60 www.Bannerengineering.Com - tel: 763-544-3164 rev. B.

Page 61

For c-mount models only: 1. Remove the lens enclosure 2. Adjust focus while monitoring the focus number. To ensure the best image, adjust the focus until the focus number peaks. 3. Replace the lens enclosure on the camera. C-mount models d c a b e c a c-mount lens b lens enclosure c retainer ring (o...

Page 62

Once the sensor has been set up as described: • each successfully read barcode is marked by a green bounding box. If annotations are on, the barcode data is also displayed. • any case where data does not compare is marked with a solid red bounding box. If the barcode is marked with a dotted red boun...

Page 63

3. Press the yes button. 4. Press the home icon to return to the main screen. For all subsequent triggers, when the sensor reads the barcode data, it will compare it against this reference data. Ivu plus bcr user's manual rev. B www.Bannerengineering.Com - tel: 763-544-3164 63.

Page 64

Ivu plus bcr user's manual 64 www.Bannerengineering.Com - tel: 763-544-3164 rev. B.

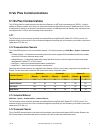

Page 65: 6 Ivu Plus Communications

6 ivu plus communications 6.1 ivu plus communications the ivu plus provides for communicating with other devices via ethernet or a uart serial communications port (rs-232 ). In order to establish an ethernet connection to the sensor, the external device must be configured with the correct ip address...

Page 66

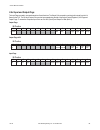

A b c d do trigger\x0d\x0a ok\x0d\x0a a control device, which can be a plc, pc program, or a terminal c response frame b request frame d ivu plus sensor the following are some of the functionality available via the command channel: • get sensor information (such as version and sensor name) • control...

Page 67

6.1.5 data export the ivu plus sensor provides for exporting user-selected inspection data via either ethernet or the rs-232 serial interface. Inspection data that can be exported includes: • pass/fail output • inspection name • inspection results • frame # • inspection time (ms) 6.1.5 sample applic...

Page 68

6.1.6 image export image export is only supported on ethernet ports. Inspection images are a maximum 752x480 8-bits per pixel grayscale images in win- dows bmp format that represent all the data in a full field of view (fov). Each exported image is comprised of a header (64 bytes) followed by the im...

Page 69: 6.2 Enabling Communications

6.2 enabling communications 6.2.1 setting up ethernet communications the following is the general flow for setting up for ethernet communications between the ivu plus sensor and a remote device: on the windows pc, configure the ip address as follows: windows xp windows 7 1. Open network properties o...

Page 70

Windows xp windows 7 4. In the internet protocol (tcp/ip) properties dialog, select use the following ip address and make sure that the ip address is 192.168.0.2, and the subnet mask is 255.255.255.0. 4. In the internet protocol (tcp/ipv4) properties dialog, se- lect use the following ip address and...

Page 71

2. To enable the command channel over ethernet: a. Go to main menu > system > communications > command channel > connection , and select ethernet [ip port # 32000]. B. Configure the field and end-of-frame delimiters. Go to main menu > system > communications > command channel > delimiters . Ivu plus...

Page 72

Valid end-of-frame delimiters are: , , , , , , or . C. Verify that the ivu receives and transmits data correctly. 3. To enable data export over ethernet: a. Go to main menu > system > communications > data export > connection and select serial i/o from the drop-down. B. Go to main menu > system > co...

Page 73

C. Go to main menu > system > communications > data export > output format and select the start string, delimiter, and end string. D. Go to main menu > system > communications > data export > advanced . Ivu plus bcr user's manual rev. B www.Bannerengineering.Com - tel: 763-544-3164 73.

Page 74

During the data and image export operation the sensor's output channels might become full. This can occur if the sensor is producing export data (frames) faster than the data can be exported from the device (due to bandwidth limitations) or faster than the client is reading the channel export data. ...

Page 75

3. To enable the command channel over the serial connection: a. Go to main menu > system > communications > command channel > connection and select serial i/o. B. Configure the field and end-of-frame delimiters. Go to main menu > system > communications > command channel > delimiters . Valid end-of-...

Page 76

D. Verify that the ivu receives and transmits data correctly. 4. To enable data export over the serial connection: a. Go to main menu > system > communications > data export > connection and select serial i/o from the drop-down. B. Go to main menu > system > communications > data export > data to ex...

Page 77

C. Go to main menu > system > communications > data export > output format and select the start string, delimiter, and end string. D. Go to main menu > system > communications > data export > advanced . Ivu plus bcr user's manual rev. B www.Bannerengineering.Com - tel: 763-544-3164 77.

Page 78

During the data and image export operation the sensor's output channels might become full. This can occur if the sensor is producing export data (frames) faster than the data can be exported from the device (due to bandwidth limitations) or faster than the client is reading the channel export data. ...

Page 79

7 testing and troubleshooting ivu plus communications 7.1 understanding the communication log the ivu plus sensor includes the following communication logs: • command channel log that can be used to ensure that commands are properly formed (syntax is correct), and provides a history of commands issu...

Page 80: 7.2 Ethernet I/o

Icon description if the command takes a long time to process, the last long entry will change to an hourglass (for example, during trigger of long inspections). For ethernet channels: • the channel's log will show an enabled entry that indicates which port is being listened to. • when a client conne...

Page 81

Port errors the port errors screen can help to debug communications channel issues: parity, break, and framing indicate mismatched port settings or, in the case of break, incorrect cabling. 7.3.2 using the ivu command channel sample application or a terminal program for test- ing the easiest way to ...

Page 82

2. On the requesting device, transmit one or more bytes to the ivu sensor. • if the data byte values appear correct and the number sent by the requesting device matches the number received by the ivu sensor, then the transmit/receive functionality is working properly. • if the connection is incorrec...

Page 83

3. If the byte count does not match, re-verify that the settings on both devices match exactly. If no bytes are received, re-check the wiring. If the correct response frame is received, then basic electrical and port settings are correct. Ivu plus bcr user's manual rev. B www.Bannerengineering.Com -...

Page 84: 8 Command Channel Primer

8 command channel primer 8.1 command channel commands all ivu command channel request command frames use the following syntax: >> command group item value notes is the end-of-frame delimiter. See below for a description. All commands are in ascii and are case-insensitive command an action to be perf...

Page 85

For example, the following is a series of command requests and responses. The first request sets the trigger mode to command and, once the sensor responds with an "ok," the next command request is issued to do (or execute) the trigger. >> set trigger mode command\x0d\x0a ok\x0d\x0a >> do trigger\x0d...

Page 86: 8.3 Examples

Command channel command status the command status is either ok or error. If ok, then the command has fully and successfully completed. If an error is returned it is in the form error nnnnn_error_identifier (for example error 10001_command_not_recognized). Refer to command channel error codes on page...

Page 87

2. Set the compare data. >> set bcr_input comparedata "0043000011201"\x0d\x0a ok\x0d\x0a 3. Trigger the sensor. >> do trigger\x0d\x0a ok\x0d\x0a 4. Check that the inspection passed. >> get inspection status\x0d\x0a ok\x0d\x0a pass\x0d\x0a 5. Get the barcode data read by the ivu sensor. >> get bcr_re...

Page 88

Command group item description get info remotemodelnumber the model number of the re- mote display as a string. Get info remoteserialnumber the serial number of the remote display as a string. Examples >> get info companyname\x0d\x0a ok\x0d\x0a "banner engineering corp."\x0d\x0a >> get info bootnumb...

Page 89

Command group item description set ethernet gateway set new gateway ip address. A 're- boot' command is required to be sent from the command channel to make the new address effective. Examples >> do system save\x0d\x0a ok\x0d\x0a 8.4 status command group command group item description get status rea...

Page 90

Command group item description eration is required to persist this value. Set trigger mode the sensor's triggering mode. This value must match the modes supported by the sensor. This value can be modified us- ing the sensor's touchscreen. This remotely modified value is not persisted to the sensors ...

Page 91

Command group item description pixels this value can be modi- fied using the sensor's touchscreen. This remotely modified value is not persisted to the sensors permanent mem- ory. The 'save' operation is re- quired to persist this value. Set imager gain the sensor's value used to electronically brig...

Page 92

8.4 teach command group command group item description do teach nexttrigger this commands forces the sen- sor to perform the remote teach operation on the next trigger. This command can be performed using the sensor's touchscreen. Examples >> do teach\x0d\x0a ok\x0d\x0a 8.4 productchange command gro...

Page 93

Command group item description cleared (reset) whenever history is cleared. This value is cleared (reset) when the device starts up or is rebooted. Get history missedtriggers this value indicates the number of missed triggers for the active inspection. This value is cleared (reset) whenever history ...

Page 94

Command group item description er history is cleared. This value is cleared (reset) when the de- vice starts up or is rebooted. Get history maxbarcodecount this value indicates the maxi- mum number of barcodes read for the active inspection this value is cleared (reset) whenev- er history is cleared...

Page 95

Fail\x0d\x0a >> get inspection executiontime\x0d\x0a ok\x0d\x0a 37.739\x0d\x0a 8.4 bcr_input command group command group item description get bcr_input comparedata the barcode inspection com- pare data string. This string must start and end with the dou- ble quote character. This value can be modifi...

Page 96

Command group item description can be modified using the sen- sor's touchscreen. This remote- ly modified value is not persis- ted to the sensors permanent memory. The 'save' operation is required to persist this value. Examples 8.4 bcr_result command group command group item description get bcr_res...

Page 97

Command group item description is cleared (reset) when the de- vice starts up or is rebooted. Examples 8.5 command channel error codes numeric id text id description 00000 success command processed successfully 10000 empty_frame_received indicates that the request was empty. The command channel requ...

Page 98

Numeric id text id description 10920 sensor_type_not_active command specified belongs to a different sensor type. 15000 value_invalid text value is invalid / unknown 15050 value_invalid text value is invalid - expecting true or false 15100 string_too_long string value specified exceeds maximum allow...

Page 99: 9.1 Device Setup

9 industrial ethernet overview 9.1 device setup 9.1.1 set ip address when shipped, the device is assigned a default ip address - 192.168.0.1, a default subnet mask - 255.255.255.0, and a default gateway - 0.0.0.0. To change these defaults, click on main menu > system > communications > ethernet i/o....

Page 100: 9.2 Supported Functions

9.2 supported functions the ivu plus series sensor is controlled over ethernet/ip and modbus/tcp using the input and output data it makes available as a slave device for those protocols. Here are some of the sensor operations that can be performed using input and output values: • product change • te...

Page 101

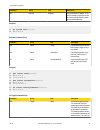

Input commands the following commands need to be executed using command id and the command bit stated above. Command command id description data type do set get trigger trigger mode 1 10001 the sensor's triggering mode. This value must match the modes supported by the sensor int16 product change pro...

Page 102: 9.3 Sensor Operation

Command command id description data type do set get bcr inputs compare string 11001 the barcode inspection compare data string. This string must start and end with the double quote character byte array compare mask 11002 the barcode inspection compare string mask in binary format; that is, masked ch...

Page 103: 9.4 Ethernet/ip

Start (optional) if using command id, set it and its parameter value as required done read error code. Handle error condition. Clear all output flags is execution error flag set? Command execution successful. Read value and input status flags as required ack flag set? Set command output flag yes no ...

Page 104

Ivu plus bcr user's manual 104 www.Bannerengineering.Com - tel: 763-544-3164 rev. B.

Page 105

2. Select module. • • ivu plus bcr user's manual rev. B www.Bannerengineering.Com - tel: 763-544-3164 105.

Page 106

3. Configure module properties. See assembly objects on page 112 for more information on each specific assembly instance. Input assembly (100) input assembly (101) ivu plus bcr user's manual 106 www.Bannerengineering.Com - tel: 763-544-3164 rev. B.

Page 107

Input assembly (102) select or deselect unicast connection as desired. Note: the data type in the comm format must be changed to an int. Note: the minimum allowed rpi is 50 ms. Ivu plus bcr user's manual rev. B www.Bannerengineering.Com - tel: 763-544-3164 107.

Page 108

4. If the module configuration was successful, the following information should be displayed: if the module configuration was not successful, the rslogix 5000 software will indicate errors similar to the ones displayed below: error: assembly instance number and/or size incorrect. Error: ivu plus not...

Page 109

5. Locate the memory map setup from banner module to plc memory map. C = configuration (not used) i = inputs to plc (outputs from ivu plus) o = outputs from plc (inputs to ivu plus) ivu plus bcr user's manual rev. B www.Bannerengineering.Com - tel: 763-544-3164 109.

Page 110

The ivu plus memory map expanded. I = inputs to plc (outputs from ivu plus). Ivu plus bcr user's manual 110 www.Bannerengineering.Com - tel: 763-544-3164 rev. B.

Page 111

Sample map demonstrating string values: memory map: default note: controllogix string format. "ivu plus image sensor" memory map: "style" changed to ascii all data is initially transferred as "int" data type. An ascii string looks like gibberish in this format. Changing the "style" to ascii instead ...

Page 112

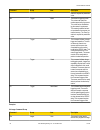

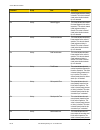

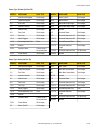

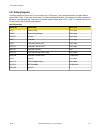

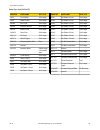

9.4.2 assembly objects outputs from plc ivu_output1 instance 0x70 (112) - 6 registers word # word name data type 0 input bits register 16-bit integer 1-2 product change number 32-bit integer 3-5 reserved ivu_output2 0x71 (113) - 240 registers word # word name data type 0 inputs bit register 16-bit i...

Page 113

Inputs to the plc ivu_input1 0x64 (100) - 30 registers word # word name data type 0 input bits ack register 16-bit integer 1 output bits register 16-bit integer 2-3 error code 32-bit integer 4-5 inspection number 32-bit integer 6-7 iteration count 32-bit integer 8-9 pass count 32-bit integer 10-11 f...

Page 114

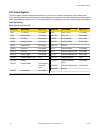

Sensor type - blemish (ivu plus tg) word # word name data type 0 input bits ack register 16-bit integer 1 output bits register 16-bit integer 2-3 error code 32-bit integer 4-5 inspection number 32-bit integer 6-7 iteration count 32-bit integer 8-9 pass count 32-bit integer 10-11 fail count 32-bit in...

Page 115

Sensor type - sort (ivu plus tg) word # word name data type 0 input bits ack register 16-bit integer 1 output bits register 16-bit integer 2-3 error code 32-bit integer 4-5 inspection number 32-bit integer 6-7 iteration count 32-bit integer 8-9 pass count 32-bit integer 10-11 fail count 32-bit integ...

Page 116

Sensor type - barcode (ivu plus bcr) word # word name data type 0 input bits ack register 16-bit integer 1 output bits register 16-bit integer 2-3 error code 32-bit integer 4-5 inspection number 32-bit integer 6-7 iteration count 32-bit integer 8-9 pass count 32-bit integer 10-11 fail count 32-bit i...

Page 117

Ivu_input 3 0x66 (102) sensor type (ivu plus bcr) word # word name data type 0 input bits ack register 16-bit integer 1 output bits register 16-bit integer 2-3 error code 32-bit integer 4-5 inspection number 32-bit integer 6-7 iteration count 32-bit integer 8-9 pass count 32-bit integer 10-11 fail c...

Page 118

Flags output bit flags command ack set bcr mask ack set bcr string ack trigger ack teach latch ack product change ack gated trigger ack bit position 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 0 input ack bits command set bcr mask set bcr string trigger teach latch product change gated trigger bit position ...

Page 119

9.4.3 configuration assembly object the ivuplus eip implementation does not support an assembly object configuration instance. However, one is required for creation of implicit class 1 connections on a controllogix family plc. Therefore, a configuration instance is defined as instance number 0x80 (1...

Page 120

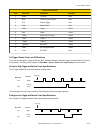

9.4.6 sample timing diagram x, y, z: represent snapshot in time verify : ready = 1 productchange ack = 0 ready product change productchange ack = ‘1’ new inspection is loaded rpi 0 1 x x+y x+y+z product change ack set productchange = 1 verify : ready = 1 productchange ack = 0 set productchange = 0 p...

Page 121

Verify : ready = 1 teachlatch ack = 0 ready teach latch teachlatch ack = ‘1’ teach will execute on next trigger rpi 0 1 x x +y x +y +z teach latch ack set teachlatch = 1 verify : ready = 1 teachlatchack = 0 set teachlatch = 0 teach latch ivu plus bcr user's manual rev. B www.Bannerengineering.Com - ...

Page 122

Verify : ready = 1 triggerack = 0 ready trigger triggerack = ‘1’ read results set trigger = 0 rpi 0 1 x x +y x +y +z triggerack set trigger = 1 verify : ready = 1 triggerack = 0 trigger ivu plus bcr user's manual 122 www.Bannerengineering.Com - tel: 763-544-3164 rev. B.

Page 123

Verify : ready = 1 gatedtriggerack = 0 ready gated trigger gatedtriggerack = ‘1’ read results rpi 0 1 x x +y x +y +z m n gated trigger ack set gatedtrigger = 1 verify : ready = 1 triggerack = 0 set gatedtrigger = 0 set gatedtrigger = 1 set gatedtrigger = 0 (abort ) inspection could not be completed ...

Page 124: 9.5 Modbus/tcp

9.5 modbus/tcp the modbus/tcp protocol provides device control using register and coil banks defined by the slave device. This section defines the ivu plus modbus/tcp register and coil banks. From the point of view of the slave device (plc), there is one output coil registers and two input coil regi...

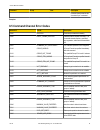

Page 125

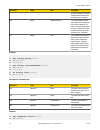

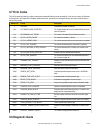

9.5.1 holding registers the holding registers are used by the plc to push values to the ivu plus sensor. These values are accessed in the register address range of 40001 - 40240. To write, use function codes 6/16 (preset single/multiple registers). Also available in this range of registers are the r...

Page 126

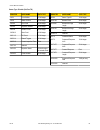

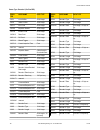

9.5.2 output registers the output registers are used to send output values from the ivu plus to the plc. Note that some devices (such as modicon family plcs) cannot access data using the 30000 range of register addresses. For these devices, the output values are also available using the 40000 range ...

Page 127

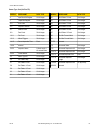

Sensor type - blemish (ivu plus tg) register word name data type 30001 coil ack bits 16-bit integer 30002 status coil bits 16-bit integer 30003-4 error code 32-bit integer 30005-6 inspection number 32-bit integer 30007-8 iteration count 32-bit integer 30009-10 pass count 32-bit integer 30011-12 fail...

Page 128

Sensor type - match (ivu plus tg) register word name data type 30001 coil ack bits 16-bit integer 30002 status coil bits 16-bit integer 30003-4 error code 32-bit integer 30005-6 inspection number 32-bit integer 30007-8 iteration count 32-bit integer 30009-10 pass count 32-bit integer 30011-12 fail c...

Page 129

Sensor type - sort (ivu plus tg) register word name data type 30001 coil ack bits 16-bit integer 30002 status coil bits 16-bit integer 30003-4 error code 32-bit integer 30005-6 inspection number 32-bit integer 30007-8 iteration count 32-bit integer 30009-10 pass count 32-bit integer 30011-12 fail co...

Page 130

Sensor type - barcode-1 (ivu plus bcr) regis- ter word name data type 30001 coil ack bits 16-bit integer 30002 status coil bits 16-bit integer 3003-4 error code 32-bit integer 30005-6 inspection number 32-bit integer 30007-8 iteration count 32-bit integer 30009-10 pass count 32-bit integer 30011-12 ...

Page 131

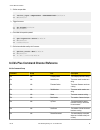

9.5.3 input and output coils the modbus tg / bcr output coils are used to push single bit commands from the plc/hmi to the ivu plus sensor. To access the modbus/tcp output and input coils use function code 02 (read input status). Output coils command set bcr mask set bcr string trigger teach latch p...

Page 132: 9.6 Plc5 and Slc 5 (Pccc)

9.6 plc5 and slc 5 (pccc) allen-bradley’s plc5 and slc 500 family of devices use pccc communications over ethernet/ip. Ivu plus supports these plcs using input and output register arrays. The output flags, ack flags and input flags bit definitions are the same as defined in the eip assem- bly object...

Page 133

2. Read. Ip address of the ivu plus is entered here. 3. Write. Message command_writing to n14 table on ivu plus ivu plus bcr user's manual rev. B www.Bannerengineering.Com - tel: 763-544-3164 133.

Page 134

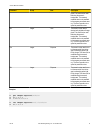

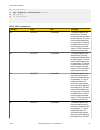

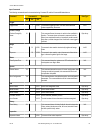

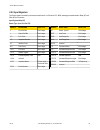

4. Write. Ip address of the ivu plus is entered here. 9.6.2 output registers the input registers are used by the plc to push values to the ivu plus sensor. Msg (message) commands used to read (n7) and write (n14) to the sensor. Output registers map (n14) word # word name data type 0 input coil bits ...

Page 135

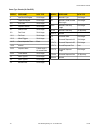

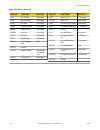

9.6.3 input registers the output registers are used to push output values from the ivu plus to the plc. Msg (message) commands used to read (n7) and write (n14) to the sensor. Input registers map (n7) sensor type - area (ivu plus tg) word # word name data type 0 coil ack bits 16-bit integer 1 output...

Page 136

Sensor type - blemish (ivu plus tg) word # word name data type 0 coil ack bits 16-bit integer 1 output coil bits 16-bit integer 2-3 error code 32-bit integer 4-5 inspection number 32-bit integer 6-7 iteration count 32-bit integer 8-9 pass count 32-bit integer 10-11 fail count 32-bit integer 12-13 mi...

Page 137

Sensor type - sort (ivu plus tg) word # word name data type 0 coil ack bits 16-bit integer 1 output coil bits 16-bit integer 2-3 error code 32-bit integer 4-5 inspection number 32-bit integer 6-7 iteration count 32-bit integer 8-9 pass count 32-bit integer 10-11 fail count 32-bit integer 12-13 misse...

Page 138

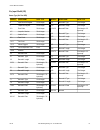

Sensor type - barcode-1 (ivu plus bcr) word # word name data type 0 coil ack bits 16-bit integer 1 output coil bits 16-bit integer 2-3 error code 32-bit integer 4-5 inspection number 32-bit integer 6-7 iteration count 32-bit integer 8-9 pass count 32-bit integer 10-11 fail count 32-bit integer 12-13...

Page 139

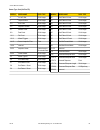

9.6.4 input and output flags the input flags are used to command execution of basic functions. The output coils are used to push single bit outputs from the ivu sensor to the plc. The 32 bits of output coils can also be accessed using the bits of the first two output registers ( ack flags and output...

Page 140: 9.7 Error Codes

9.7 error codes the ivuplus sensor provides error codes in cases when commands failed to execute successfully. If such an error occurs, the execution error flag is set in the output bit/coil register. When this bit is set, read the error code register to know the reason of failure. Below is the list...

Page 141

Ivuplus sensor provides several tools to help diagnose communication issues when using industrial ethernet channel. 9.8.1 ethernet diagnostics to verify ethernet connectivity, please follow these steps: • verify that all the cables are connected and properly seated. • examine the small orange ethern...

Page 142

• if the link status indicates that there is no link, please inspect the wiring, and verify that your ethernet switch is powered up. • if the link parameters are not as expected (wrong baud rate or duplex) try the following: • log into your managed switch and verify that the port to which ivu camera...

Page 143

• type in a ping command, specifying the sensor ip address as an argument. You should see a series of responses from the camera: • you should also see the packets received and packets sent count on the ethernet i/o status page in the camera increment by at least 4. • if the output of the ping comman...

Page 144

9.8.3 industrial protocols troubleshooting modbus protocol modbus protocol relies on the fundamental tcp/ip connectivity to establish connections and transport data. Once you have verified networking and tcp/ip connectivity, you should have little or no problems establishing a modbus connection. Ivu...

Page 145

Ethernet/ip and pccc protocols ethernet/ip and pccc protocols rely on cip protocol to establish communications and exchange data. Cip protocol, in turn, utilizes tcp/ ip. In addition, ethernet/ip implements i/o messaging. I/o messaging allows two devices, ivu sensor and the plc, to continuously syn-...

Page 146

Once the cip and i/o connections are established, the industrial protocols status page will show the details of the connection: most of the errors in establishing the cip and i/o connections have to do with specifying the proper input and output assembly ids and sizes. Please refer to the appropriat...

Page 147: 10 Debugging Inspections

10 debugging inspections 10.1 how to round-trip debug using the emulator the ivu emulator is a windows application that allows you to operate in a windows environment exactly as you would on the sensor itself. In general, the emulator is an inspection debugging tool: you can import stored inspection...

Page 148

A. Go to main menu > imager > trigger , and select internal. B. Set the trigger interval as desired. The ivu emulator will run with the saved configuration from step 6 using the saved inspection logs from step 7 as images. 8. Make the desired adjustments. 9. Close the ivu emulator program. All confi...

Page 149: 11.1 Update Process

11 ivu series: updating the sensor 11.1 update process banner engineering may release new versions of the sensor firmware in the future. New firmware releases can be downloaded from banner's website or can be obtained by ordering the latest product cd. The following steps will guide you through the ...

Page 150

Note: if you have not set the sensor previously, then folders will be named using the first 8-characters of the sensor serial number. 1. Plug a usb thumb drive into the sensor. 2. Save sensor configuration to the usb thumb drive ( main menu > system > sensor configuration > save to usb ). The locato...

Page 151

6. Click the generate reset key button. 7. Write down the four-digit password reset key—identified as step 2 in the password reset utility. 8. On the ivu series sensor, check the next button on the password reset screen. 9. Enter the 4-digit reset key on the enter reset key screen. 10. Click apply. ...

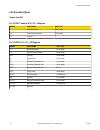

Page 152: 12.1 Errors

12 led indicator troubleshooting in normal operation, the power led is steady green, and the pass/fail is green or red depending on the triggered inspection. The ether- net i/o led will be lit or off depeding on connection status. - 1 power led green: power red: error 2 pass/fail led green: pass red...

Page 153

Warnings are atypical conditions that the sensor detects and fixes. Warning are highlighted in yellow in the system log, and can typically be ignored. Ivu plus bcr user's manual rev. B www.Bannerengineering.Com - tel: 763-544-3164 153.

Page 154: Index

Index a advanced 34 auto exposure 35 c command channel image export 68 command channel log 79 command channel sample application 66 command group info 87 inspection 94 productchange 92 status 89 system 88 communication channel command channel 65 data export 65 image export 65 industrial ethernet 65 ...

Page 155

T touchscreen calibration 34 u usb loading from 24 saving to 24 rev. B www.Bannerengineering.Com - tel: 763-544-3164 155.