- DL manuals

- Barco

- Projector

- iD H250

- Service Manual

Barco iD H250 Service Manual

Summary of iD H250

Page 1

Id h250 / h500 service manual r9010570 r9010520 r59770097/00 15/05/2007.

Page 2

Barco nv presentations noordlaan 5, 8520 kuurne phone: +32 56.36.82.11 fax: +32 56.35.86.51 e-mail: presentations.Bid@barco.Com visit us at the web: www.Barco.Com printed in belgium.

Page 3

Changes barco provides this manual ’as is’ without warranty of any kind, either expressed or implied, including but not limited to the implied war- ranties or merchantability and fitness for a particular purpose. Barco may make improvements and/or changes to the product(s) and/or the program(s) desc...

Page 4

As a special exception, if other files instantiate templates or use macros or inline functions from this file, or you compile this file and link it with other works to produce a work based on this file, this file does not by itself cause the resulting work to be covered by the gnu general public lic...

Page 5: Table Of Contents

Table of contents table of contents 1. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1.1 safety instructions . ...

Page 6

Table of contents 6.5.1 description of the folding mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 6.5.2 removing the folding mirror . . . . . . . . ....

Page 7: 1. Safety

1. Safety 1. Safety overview • safety instructions 1.1 safety instructions w arning : before removing/replacing any projector components, turn off the main power switch and un- plug the main ac power cable. R59770097 id h250 / h500 15/05/2007 3.

Page 8

1. Safety safety instructions 1. Before returning an instrument to the customer, always make a safety check of the entire instrument, including, but not limited to, the following items: a) be sure that no built-in protective devices are defective and/or have been defeated during servicing. (1) prote...

Page 9

1. Safety 5. Hot chassis warning - this projector chassis has two ground systems: the primary ground system is formed by the negative voltage of the rectified mains (power) and is only used as a reference in primary circuits; the secondary ground system is connected to earth ground via the earth con...

Page 10

1. Safety 6 r59770097 id h250 / h500 15/05/2007.

Page 11: 2. General Information

2. General information 2. General information overview • conventions • abbreviations • connector instructions • removing the cable basket • removing the lens • mounting the lens • removing the rear cover • removing the top cover • spares overview about this manual this manual describes id h250 and i...

Page 12

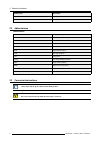

2. General information abbreviation description fr factory repairable lr locally repairable 2.2 abbreviations abbreviations lps lamp power supply smps switched mode power supply pb power box pfc power factor corrector pmp pixel map processor dlp tm digital light processor uhp ultra high pressure cw ...

Page 13

2. General information board to board connector • board to board connectors are mounted directly on the board, do not use any tools when disconnecting these connectors. • to disconnecting carefully lift the board on top. Image 2-2 disconnect by carefully lifting the board on top r59770097 id h250 / ...

Page 14

2. General information flat cable connector • do not use any tools when (dis)connecting a flat cable connector, otherwise damage may occur on the mini locks. • disconnect by simultaneously pulling out the 2 mini locks on both sides of the flat cable connector. Image 2-3 pull out the 2 mini locks on ...

Page 15

2. General information atx connector • to disconnect an atx connector, push on the lip as shown in the image. Image 2-6 lamp power connector • these connectors are used to connect the lamp drivers to the power box. • to disconnect, push on both lips as shown in the image. Image 2-7 2.4 removing the ...

Page 16

2. General information image 2-8 2.5 removing the lens necessary tools no tools. How to remove the lens? 1. Support the lens with one hand. 2. Unlock the lens by pulling the handle which is located on the right side of the projector. 3. Pull the lens out of the lens holder. Image 2-9 removal of the ...

Page 17

2. General information 2.6 mounting the lens necessary tools no tools. How to mount the lens? 1. Make sure the lens locking handle is not pulled out 2. Gently push the lens into the lens holder until it is locked (click!) caution: when the projector is not fixed onto its support, hold it back while ...

Page 18

2. General information image 2-11 rear cover fixing screw 2. Tilt the rear cover and remove it. Image 2-12 tilt rear cover to remove it 2.8 removing the top cover necessary tools phillips n° 2 screwdriver how to remove the top cover? 1. Loosen and remove the screws a (3pc) and b (2pc) retaining the ...

Page 19

2. General information image 2-13 remove the 3 screws on the left image 2-14 remove the 2 screws on the right 2. Unplug the connector on the keypad / ir receiver r59770097 id h250 / h500 15/05/2007 15.

Page 20

2. General information image 2-15 unplug the touchpad/ir connector 3. Remove the top cover note: unplugging the ir receiver will not interrupt the ir communication with the rcu since an additional ir receiver is mounted on the pmp board. 2.9 spares overview consumables overview description category ...

Page 21

2. General information description category order number color wheel rgwb (id h500) nr r852628k lps filter nr r764665k back plane fr r765023k dmd nr b401216k infitec switcher left nr r854872k infitec switcher right nr r854873k covers description category order number top cover nr r8454271k rear cove...

Page 22

2. General information 18 r59770097 id h250 / h500 15/05/2007.

Page 23: 3. Software

3. Software 3. Software the software is also referred to as firmware. 3.1 description of the software firmware the firmware is the software that controls the projector. It is stored on the pmp. 3.2 upgrading the software the software is also referred to as firmware. How to upgrade the software, usin...

Page 24

3. Software 20 r59770097 id h250 / h500 15/05/2007.

Page 25

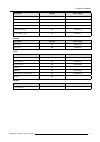

4. Board and component location 4. Board and component location 4.1 board location front left view image 4-1 left front view of the projector (the server on the image is replaced by a network layer in the id h400) indication description part number 1 input module contains several boards 2 backplane ...

Page 26

4. Board and component location indication description part number 6 power box r852585k 7 formatter r765020k 8 fan connector board r764395 9 motor connector board r763592 top cover view image 4-3 top cover: view of the inside indication description part number 10 infra red and touch pad board r76357...

Page 27

4. Board and component location 4.2 component location right top view image 4-4 right top view of the projector indication description part number 1 lamp cover (outlet) - 2 engine frame (tir prism location) - 3 folding mirror - 4 lens holder - rear view image 4-5 rear view of the projector r59770097...

Page 28

4. Board and component location indication description part number 5 main lamp fans 6 lamp top fans 7 uhp lamps view on the optical frame 8 14 12 10 13 11 3 image 4-6 optical path (view 1) indication description part number 3 folding mirror r8428901 8 uv / ir filter r842894k 10 color wheel - 11 ligh...

Page 29

4. Board and component location 3 9 11 10 14 image 4-7 optical path (view 2) indication description part number 3 folding mirror r8428901 9 prism - 10 color wheel - 11 light rod - 14 a-spheric lens r59770097 id h250 / h500 15/05/2007 25.

Page 30

4. Board and component location 4.3 remote control unit rcu image 4-8 remote control unit indication description part number - remote control unit (rcu) r763794k 26 r59770097 id h250 / h500 15/05/2007.

Page 31: Procedures

5. Electronic spares and servicing procedures 5. Electronic spares and servicing procedures overview • introduction • interconnection diagram • lamp cover removal • the input module • the pixel map processor (pmp) • the formatter • the power box • the lamp power supply c aution : wear a wrist band w...

Page 32

5. Electronic spares and servicing procedures simplified power control fans motors to lamp 1 to lamp 2 pfc smps controller power box mains lps1 lps2 filter 2 filter 1 image 5-2 simplified power architecture 28 r59770097 id h250 / h500 15/05/2007.

Page 33

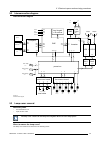

5. Electronic spares and servicing procedures 5.2 interconnection diagram interconnection diagram pmp dmd local keypad + ir receiver formatter backplane amb. Temp sensor ° t lamp 1 temp sensor lamp 2 temp sensor rgb /video dvi hdsdi* 30 4 2 10 10 6 2 2 6 2 2 4 3 j20 10 j10 10 10 5 5 2 2 3 j1 3 4 2 1...

Page 34

5. Electronic spares and servicing procedures • power box removal • lamp power supply removal • color wheel removal how to remove the lamp cover? 1. Remove the three screws as indicated on the images below image 5-4 remove the screw of the lamp cover image 5-5 remove the screw of the lamp cover imag...

Page 35

5. Electronic spares and servicing procedures image 5-7 release the wires from the clamps. 3. Now you can flip over the lamp cover so as to reach the parts underneath. 5.4 the input module overview • description of the input module • removing the input module • disassembling the input module 5.4.1 d...

Page 36

5. Electronic spares and servicing procedures image indication partnumber description optional/standard layer 1 r765024k dvi input layer (pmp) standard layer 2 r764499k rgb / video input standard layer 3 r765195k dvi / d15 input standard layer 2 or 3 r764442k hdsdi input optional layer 4 r765226 eth...

Page 37

5. Electronic spares and servicing procedures - j419 (6 wires): power from the power box (connector 6) image 5-10 input module: connector 4. Lift the input module to remove it 5.4.3 disassembling the input module overview • the backplane • the dvi input • the rgb and video input • the dvi and d15 in...

Page 38

5. Electronic spares and servicing procedures 5.4.3.1 the backplane 5.4.3.1.1 description of the backplane what does the backplane do? Image 5-11 • preprocessor (can handle two input channels) - amds: automatic mode detection system - apa: automatic pixel alignment - prescaling • deinterlacer • ethe...

Page 39

5. Electronic spares and servicing procedures image 5-12 input module: removing the backplane image 5-13 input module: backplane released 5.4.3.2 the dvi input description of the dvi input (layer 1) this layer contains a dvi input connector, a wired rc connector, a rs232 input connector and a dvi ou...

Page 40: Adc

5. Electronic spares and servicing procedures adc decoder (agc) clamp amp clamp amp clamp clamp r g b h v video buffer ctrl +led driver 1 80 1 80 j401 j402 rgb 48 bits hs(42) vs(2) video 8bits +5v(4) +3.3v(7) -5v(10) analog video input s-video srce sel .. . .. . Image 5-15 5.4.3.3.2 replacing the rg...

Page 41

5. Electronic spares and servicing procedures image 5-16 input module: side screw fixing the rgb / video input layer 4. Remove the three front screws image 5-17 input module: front screws fixing the rgb / video input layer 5. Take out the rgb / video input r59770097 id h250 / h500 15/05/2007 37.

Page 42: 3X Adc

5. Electronic spares and servicing procedures 5.4.3.4 the dvi and d15 input 5.4.3.4.1 description of the dvi / d15 input what does the dvi / d15 input do? Image 5-18 the dvi / d15 input • the signal from the d15 connector goes to an adc and is converted into 48 bits • the signal from the dvi connect...

Page 43

5. Electronic spares and servicing procedures 5.4.3.4.2 replacing the dvi / d15 input necessary tools • torx screwdriver t10 • nut spanner 4mm how to replace the dvi / d15 input? 1. Remove the input module — see "removing the input module", page 32 2. Remove the backplane — see "replacing the backpl...

Page 44

5. Electronic spares and servicing procedures 5.4.3.5 the sdi / hdsdi input (optional) 5.4.3.5.1 description of the sdi / hdsdi input what does the sdi / hdsdi input do? Image 5-22 sdi/hdsdi input layer a serial digital video signal is detected (sdi or hdsdi) and converted to a 10 bits or 20 bits pa...

Page 45

5. Electronic spares and servicing procedures 5.4.3.6 the ethernet board 5.4.3.6.1 description of the ethernet board what does the ethernet board do? Image 5-24 input module: ethernet board the ethernet communication can be used to: • download new software on the projector (upgrading) • set up seria...

Page 46

5. Electronic spares and servicing procedures 2. Push the cursor key ← or → to highlight installation in the menu bar. 3. Push the ↓ key to pull down the installation menu. 4. Push the cursor key ↑ or ↓ to highlight network settings and press enter to select. Image 5-25 a dialog box will be displaye...

Page 47

5. Electronic spares and servicing procedures image 5-29 input module: side screw fixing the ethernet board 4. Remove the two front screws image 5-30 input module: front screws fixing the ethernet board 5. Take out the ethernet board 5.5 the pixel map processor (pmp) overview • description of the pm...

Page 48

5. Electronic spares and servicing procedures 5.5.1 description of the pmp description • the pmp receives the input signals in two ways: - the input connectors on the pmp board: dvi connector - the separate input layers via the backplane: 10 bits for video image, 48 bits for data image • in the scal...

Page 49

5. Electronic spares and servicing procedures pmp: board layout image 5-32 pmp: board layout 5.5.2 diagnostics of the pmp field programmable gate array network of logical gates which can be customized (programmed for a particular use) led diagnostics during the startup of the projector image 5-33 pm...

Page 50

5. Electronic spares and servicing procedures • first stage of startup: led 1 (red) and led 5 (red) are on in case of system failure during this stage, led 1 stays on and led 5 starts blinking. • second stage of startup: led 1 (red), led 3 (red) and led 5 (red) lare on • third stage of startup (user...

Page 51

5. Electronic spares and servicing procedures 5.5.3 removing the pmp necessary tools • torx screwdriver t10 • nut spanner 4mm how to remove the pmp? 1. Remove the connectors: - j400 (2 wires): power from the power box (connector 6) - j550 (6 wires): control signals from the local key pad / ir receiv...

Page 52

5. Electronic spares and servicing procedures image 5-37 pmp: screw and nuts fixing the pmp / input layer 1 4. Gently lift the pmp, while disconnecting the board-to-board connectors to remove it image 5-38 pmp: lift to remove it 5.6 the formatter overview • description of the formatter • replacing t...

Page 53

5. Electronic spares and servicing procedures • image processing: the input data is converted into a bit plane output format to drive the dmd image bus • control to and feedback from the color wheel • control of the lamp power supply • brilliant color mode: increase brightness through the use of the...

Page 54

5. Electronic spares and servicing procedures 3. Remove the bottom nut. Be careful not to drop the spring! Tip: look at the position of the nut: it must be in the same position when remounting a new formatter (focus !). Image 5-41 lens holder and formatter: bottom view 4. Gently remove the formatter...

Page 55

5. Electronic spares and servicing procedures image 5-43 power box: left-rear view with mains connector this universal 12v power box is delivered as a complete unit in a metal shielded box. All the power supply electronics for the boards are mounted inside this box. There is a cpld containing the so...

Page 56

5. Electronic spares and servicing procedures board description smps supplies the various voltages: ++12v, +12v, +12va generates the control voltages for (in defined groups): • lamp fans • dmd fan • lps fan • lamp top fans • light pipe fan • pb (power box) fan • pmp (pixel map processor) fan control...

Page 57

5. Electronic spares and servicing procedures connector description 17 & 18 control signals for lps (via formatter board) 19 & 20 lens motor control 21 power supply to lamp filters the connectors which are not mentioned are not used in this projector! Image 5-46 connector on the left side of the pow...

Page 58

5. Electronic spares and servicing procedures 1 8 7 9 12 13 14 19 21 15 17 18 16 2 3 4 5 6 red orange orange green 1 2 3 4 image 5-48 diagnostic led’s on the power box led number led color description 1 orange on when +12v is active (active state of the projector) 2 green on when ++12v is active (st...

Page 59

5. Electronic spares and servicing procedures image 5-49 loosen the left rear screw image 5-50 loosen the right rear screw image 5-51 loosen both front screws 5. Disconnect the mains power connectors on the left side of the power box image 5-52 disconnect the mains power cables 6. Unplug the colored...

Page 60

5. Electronic spares and servicing procedures image 5-53 fan connector board 7. Remove the cable strap of the lamp power cable at the rear side of the power box image 5-54 remove the cable strap of the lamp power cable 8. Shift the power box a bit forward and upward and unplug the following connecto...

Page 61

5. Electronic spares and servicing procedures image 5-55 9. Remove the earth cable from the fan connector board image 5-56 remove the earth wire 10.Lift the power box out of the projector. 11.Unplug the connectors which are going to the fan connector board: - 3: power supply to fan connector board -...

Page 62

5. Electronic spares and servicing procedures image 5-57 12. Remove the four screws of the fan connector board image 5-58 remove the four screws 13.Remove the fan connector board 14.Unplug the mains power connector image 5-59 disconnect the mains power connector 58 r59770097 id h250 / h500 15/05/200...

Page 63

5. Electronic spares and servicing procedures 5.8 the lamp power supply overview • description • replacing the lamp power supply • replacing the lamp filter 5.8.1 description parts of the lps the lps gets its power supply from the universal 12v power box via the lamp filters and generates the driver...

Page 64

5. Electronic spares and servicing procedures image 5-61 remove the indicated connectors on the formatter 4. Loosen the two screws fixing the lps cover to the projector bottom image 5-62 loosen the front screw of the lps cover image 5-63 loosen the rear screw of the lps cover 5. Gently release the w...

Page 65

5. Electronic spares and servicing procedures image 5-64 guide the wires through the hole image 5-65 release the wires image 5-66 release the wires 6. Unplug the connectors as described below: - cj1: power supply from the lamp filters - cj2: control signals form the formatter - cj4: power supply to ...

Page 66

5. Electronic spares and servicing procedures image 5-67 1: connectors to unplug 2: screws to remove 7. Remove the four screws fixing the lps to the projector. See image 5-67 8. Take out the lps 5.8.3 replacing the lamp filter necessary tools screwdriver torx t10 how to replace the lamp filter 1. Re...

Page 67

5. Electronic spares and servicing procedures image 5-69 lamp filter connectors 4. Remove the fixing screws image 5-70 lamp filter screws 5. Remove the lamp filter r59770097 id h250 / h500 15/05/2007 63.

Page 68

5. Electronic spares and servicing procedures 64 r59770097 id h250 / h500 15/05/2007.

Page 69

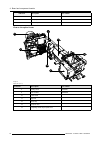

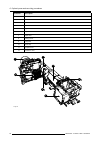

6. Optical spares and servicing procedures 6. Optical spares and servicing procedures overview • introduction • the uhp lamp • the uv/ir filter • the dlp chip • the folding mirror • the aspheric lens • the light rod 6.1 introduction optical path description 2 1 2 2 3 2 4 5 7 6 2 8 9 1 12 12 10 11 im...

Page 70

6. Optical spares and servicing procedures indication description 1 uhp lamp 2 uv/ir filter 3 prism 4 color wheel 5 light rod 6 aspheric lens 7 triplet lens 8 folding mirror 9 tir prism 10 dlp chip 11 projector lens 12 condenser lens 2 10 4 11 5 6 8 image 6-2 66 r59770097 id h250 / h500 15/05/2007.

Page 71

6. Optical spares and servicing procedures 8 3 5 6 4 image 6-3 6.2 the uhp lamp w arning : risk of burns: wait for the projector and lamp to cool down before changing a lamp! W arning : risk of explosion: changing a lamp can only be done by a barco authorized technician. W arning : risk of electrica...

Page 72

6. Optical spares and servicing procedures 8. Use the numeric keys on the remote or ↑, ↓, ←, → to input the serial number of the lamp 9. Use ← or → to select accept. The runtime will be reset and the serial number will be saved w arning : lamp runtime reset can only be done by a barco authorized tec...

Page 73

6. Optical spares and servicing procedures reverse this procedure to mount a lamp. C aution : do not touch the glass part of the lamp. 6.3 the uv/ir filter introduction the uv/ir filter consists of a glass plate with a uv coating on one side and a ir coating on the other side. The side with uv coati...

Page 74

6. Optical spares and servicing procedures image 6-10 uv/ir filter: indication of coated side tip: the uv coated side is indicated with a black dot in the corner. 2. Tighten the two screws slightly. Tightening them too hard may damage the filter. 6.4 the dlp chip overview • dlp / formatter mounting ...

Page 75

6. Optical spares and servicing procedures 7 8 9 10 11 12 2 1 3 4 5 6 image 6-11 indication description 1 dlp fix plate 2 dlp aperture 3 dlp aperture gasket (to prevent dust from falling on the dlp chip) 4 dlp interposer 5 dlp chip 6 insulation plate 7 formatter board 8 insulation plate 9 heatsink 1...

Page 76

6. Optical spares and servicing procedures c aution : never touch the gold contacts on the chip, on the interposer or on the formatter! Fingerprints may damage the chip! C aution : never power up the projector unless you are sure that the settings of the formatter match the dmd! It is advised to cle...

Page 77

6. Optical spares and servicing procedures image 6-14 6.5.2 removing the folding mirror necessary tools torx screwdriver t10 how to remove the folding mirror? 1. Remove the top cover of the projector 2. Remove the pmp 3. Remove the three screws fixing the folding mirror image 6-15 fixing screws of t...

Page 78

6. Optical spares and servicing procedures image 6-17 examples of misalignment of the folding mirror c aution : bad alignment of the folding mirror can cause damage to the lens or to the seals on the dmd! Overview of adjusting possibilities of the folding mirror this overview only applies to a front...

Page 79

6. Optical spares and servicing procedures if you shift the image up and left, dark borders will appear at the bottom and at the right side. Image 6-19 screws to adjust the folding mirror • screw 1: - clockwise: image shifts down and left - counterclockwise: image shifts up and right • screw 2: - cl...

Page 80

6. Optical spares and servicing procedures 6.6.2 adjusting the aspheric lens necessary tools allen key 1.5 mm how to adjust the aspheric lens? 1. Select a full white pattern to be projected 2. Adjust screw 3 of the folding mirror to shift down and right the image, until a black corner becomes visibl...

Page 81

6. Optical spares and servicing procedures image 6-24 securing screw and adjustment handle of the a-spheric lens 5. Tighten the securing screw of the aspheric lens 6. Readjust the folding mirror to make the black area disappear 6.7 the light rod 6.7.1 description of the light rod description the lig...

Page 82

6. Optical spares and servicing procedures image 6-26 5. Mount the lamp cover and the lamp caution: if you do not mount the lamp cover before starting the projector, the lamps can explode! 6. Select a full white pattern to be projected 7. Turn the adjustment screw until the light beam is aligned on ...

Page 83

6. Optical spares and servicing procedures image 6-28 8. Switch off the projector 9. Remove the lamp cover and the right lamp 10.Tighten the securing screws 11.Mount the lamp cover and the lamp back again r59770097 id h250 / h500 15/05/2007 79.

Page 84

6. Optical spares and servicing procedures 80 r59770097 id h250 / h500 15/05/2007.

Page 85: Procedures

7. Mechanical spares and servicing procedures 7. Mechanical spares and servicing procedures overview • the color wheel and sensor • the lens shift motor • fans and temperature sensors • the lens holder • dust filters 7.1 the color wheel and sensor overview • description • replacing the color wheel •...

Page 86

7. Mechanical spares and servicing procedures image 7-1 the color wheel 7.1.2 replacing the color wheel necessary tools screwdriver torx t10 how to remove the color wheel? 1. Remove the lamp cover 2. Disconnect the color wheel from the interconnection unit. Image 7-2 disconnect the flat cable cautio...

Page 87

7. Mechanical spares and servicing procedures image 7-3 disconnect the color wheel sensor 4. Remove the two screws fixing the color wheel to the optical frame image 7-4 fixing screws of color wheel 5. Gently lift the color wheel assembly to remove it. Do not touch the glass parts. Image 7-5 lift the...

Page 88

7. Mechanical spares and servicing procedures image 7-6 the color wheel removed 7.1.3 color wheel index c aution : changing these settings may seriously affect the performance of the projector, return to the factory setting by pressing factory preset cwi. What can be done? This adjustment has to be ...

Page 89

7. Mechanical spares and servicing procedures 7.1.4 replacing the color wheel sensor necessary tools • screwdriver philips ph1 • nutspanner 5mm how to remove the color wheel sensor? 1. Remove the color wheel — see "replacing the color wheel", page 82 2. Remove the two bolts fixing the sensor to the ...

Page 90

7. Mechanical spares and servicing procedures image 7-11 connectors on the color wheel connection board 3. Remove the two screws fixing the color wheel connection board image 7-12 screws fixing the color wheel connection board 4. Remove the color wheel connection board 7.2 the lens shift motor descr...

Page 91

7. Mechanical spares and servicing procedures image 7-13 location of the lens shift motor how to remove the lens shift motor? 1. Unplug connector j5 on the motor connector board image 7-14 connector to the lens shift motor 2. Remove the two screws (“a”) fixing the lens shift motor to the lensholder ...

Page 92

7. Mechanical spares and servicing procedures 7.3 fans and temperature sensors overview • fans • replacing the lamp fans • replacing the lamp top fans • replacing the power box fan • removing the lps fan • replacing the light pipe fan • replacing the dmd fan • replacing the pmp fan • temperature sen...

Page 93

7. Mechanical spares and servicing procedures fan location image 7-16 location of fan lamp and fan lamp top image 7-17 location of fan lps image 7-18 location of fan power box r59770097 id h250 / h500 15/05/2007 89.

Page 94

7. Mechanical spares and servicing procedures image 7-19 location of fan light pipe image 7-20 location of the light pipe fan connector 90 r59770097 id h250 / h500 15/05/2007.

Page 95

7. Mechanical spares and servicing procedures image 7-21 location of the fan dmd image 7-22 location of the fan pmp on top of the power box r59770097 id h250 / h500 15/05/2007 91.

Page 96

7. Mechanical spares and servicing procedures image 7-23 location of the fan connector board, on top of the power supply 7.3.2 replacing the lamp fans necessary tools • screwdriver torx t10 • slotted screwdriver 6mm how to remove the lamp fans? 1. Remove the lamp cover 2. Unplug the fan connector (j...

Page 97

7. Mechanical spares and servicing procedures image 7-25 nuts fixing the lamp top fans 3. Remove the fan 7.3.4 replacing the power box fan necessary tools screwdriver philips ph2 how to remove the fan of the power box? 1. Remove the power box — see "replacing the power box", page 54 2. Unplug the fa...

Page 98

7. Mechanical spares and servicing procedures image 7-27 screws fixing the lps fan to the lps cover 4. Slide out the fan to remove it 7.3.6 replacing the light pipe fan necessary tools • screwdriver philips ph2 • screwdriver torx t10 how to remove the light pipe fan? 1. Remove the power box — see "r...

Page 99

7. Mechanical spares and servicing procedures image 7-30 fixing screw of optical frame (next to power box) 6. Remove the light pipe fan connector (j31 on the small fan connector board on the bottom of the projector) image 7-31 connector of the light pipe fan (between lamp and power box) 7. Remove co...

Page 100

7. Mechanical spares and servicing procedures image 7-33 fixing screws of the condenser lens behind the uv/ir filter 11.Remove both screws fixing the light pipe fan to the optical frame image 7-34 screws fixing the light pipe fan (the left screw is behind the condenser lens) 12.Remove the light pipe...

Page 101

7. Mechanical spares and servicing procedures image 7-35 screws fixing the dmd fan (behind the lens holder, next to the lps) 4. Remove the dmd fan 7.3.8 replacing the pmp fan necessary tools screwdriver torx t10 how to remove the pmp fan? 1. Unplug the connector of the fan (j7 on the fan connector b...

Page 102

7. Mechanical spares and servicing procedures image 7-37 lamp temperature sensors these sensors guard the lamp temperature: in case of overtemperature, the corresponding lamp will not be lit. Image 7-38 location of the lamp temperature sensors dmd temperature sensor this sensor records the temperatu...

Page 103

7. Mechanical spares and servicing procedures image 7-39 location of the temperature sensor of the dmd 7.4 the lens holder 7.4.1 removing the lens holder necessary tools • slotted screwdriver 4mm • philips 2 screwdriver • torx 10 screwdriver • open ended spanner 8mm • allan key 2mm how to remove the...

Page 104

7. Mechanical spares and servicing procedures image 7-41 fixing screws of the lens holder 6. Remove the folding mirror — see "removing the folding mirror", page 73 7. Gently lift the folding mirror to remove it. Do not touch the mirror part! 8. Loosen the screw holding the shaft of the lens locking ...

Page 105

7. Mechanical spares and servicing procedures image 7-43 fixation nuts on left side of lens holder image 7-44 use an open ended spanner to remove the nuts 12. Release the wires from the lens holder image 7-45 release the wires from the lens holder 13.Unplug the following connectors on the motor conn...

Page 106

7. Mechanical spares and servicing procedures image 7-46 unplug j239 and j249 on the motor connector board 14.Unplug the connectors on the formatter board: - j5 (to j38 on the color wheel connector board) - j8 (to cj2 on the lps) - j10 (to cj2 on the lps) - j9 (to 18 on the pb) - j11 (to 17 on the p...

Page 107

7. Mechanical spares and servicing procedures image 7-48 connectors j1, j2, j4 on the formatter (part 2) 15.Loosen the two screws fixing the lens holder to the bottom of the projector (loosen them, no need to remove them) image 7-49 r59770097 id h250 / h500 15/05/2007 103.

Page 108

7. Mechanical spares and servicing procedures 16.Now you can remove the lens holder by gently sliding it a bit foward and lifting it out of the projector image 7-50 lens holder: front side 7.5 dust filters information there are no dust filters to be cleaned! Parts which are sensitive to dust are pro...