- DL manuals

- Bard

- Air Conditioner

- FUSION-TEC HR36APA

- Service Instructions Manual

Bard FUSION-TEC HR36APA Service Instructions Manual

Page

1 of 32

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual :

2100-670

Supersedes:

NEW

Date: 6-2-17

NOTE: LV1000 Controller is required for operation when

multiple HR58AP* units are used.

SERVICE INSTRUCTIONS

FUSION-TEC™

WALL-MOUNT

AIR CONDITIONER

Models:

Part of the Bard Free Cooling Unit System

HR58APA

HR58APB

Summary of FUSION-TEC HR36APA

Page 1

Page 1 of 32 bard manufacturing company, inc. Bryan, ohio 43506 www.Bardhvac.Com manual : 2100-670 supersedes: new date: 6-2-17 note: lv1000 controller is required for operation when multiple hr58ap* units are used. Service instructions fusion-tec™ wall-mount air conditioner models: part of the bard...

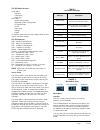

Page 2: Contents

Manual 2100-670 page 2 of 32 contents using the tec-eye tm ...........................................6 tec-eye hand-held diagnostic tool .................. 6 tec-eye menu structure ............................ 7 tec-eye acronyms ..................................... 7 status screen ...................

Page 3

Manual 2100-670 page 3 of 32 refrigerant information ..................................30 general ......................................................... 30 topping off system charge .............................. 30 safety practices ............................................. 30 important insta...

Page 4: General Information

Manual 2100-670 page 4 of 32 general information free cooling unit system this bard free cooling unit system is composed of fusion-tec wall-mounted air conditioners matched with an lv1000 lead/lag controller. The wall mounts are specifically engineered for telecom/motor control center rooms. Note: t...

Page 5: Warning

Manual 2100-670 page 5 of 32 electrical shock hazard. Have a properly trained individual perform these tasks. Failure to do so could result in electric shock or death. ! Warning fire hazard. Maintain minimum 1/4" clearance between the supply flange and combustible materials. Failure to do so could r...

Page 6: Using The Tec-Eye

Manual 2100-670 page 6 of 32 figure 2 tec-eye connection to unit control modular phone connector for tec-eye hand-held diagnostic tool using the tec-eye tm tec-eye hand-held diagnostic tool the microprocessor control used in the fusion-tec wall-mount air conditioners allows for complete control and ...

Page 7

Manual 2100-670 page 7 of 32 tec-eye menu structure quick menu setpoints information alarm log main menu system configuration advanced system configuration i/o configuration on/off alarm logs settings logout in addition to the menu structure above, there are also status and alarm screens. Tec-eye ac...

Page 8

Manual 2100-670 page 8 of 32 to verify or change the wall-mount unit cooling and heating setpoints in stand alone mode: 1. Connect the tec-eye diagnostic tool to the control board located in the unit. 2. From the status screen, press up or down key until quick menu displays setpoints icon. Press ent...

Page 9: Operation

Manual 2100-670 page 9 of 32 unit on/off the wall unit can be turned on and off from the tec- eye. Turning the unit off with the following instructions will disable heating and cooling operation but may not disable the blower. The blower may continue to run if the unit or the lv1000 have the continu...

Page 10

Manual 2100-670 page 10 of 32 figure 6 adjusting return air sensor 2. Press up or down keys and enter key to enter technician password 1313. 3. Press up or down keys to scroll to i/o config ; press enter key. 4. Press up or down keys to scroll to return air sensor (c5) ; press enter key. 5. Verify t...

Page 11

Manual 2100-670 page 11 of 32 figure 8 viewing unit stages figure 9 cooling w/no economizer compressor stage 1 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% -10% 0% 110% 120% compressor stage 2 off deadband on deadband (sometimes called a neutral zone or dead zone) is an interval of a signal domain or ba...

Page 12

Manual 2100-670 page 12 of 32 dehumidification the unit uses a dehumidification sequence that does not require the electric heat to run at the same time as the compressor. Instead, the unit will turn on the compressor to cool down to the heating setpoint. Once the lower setpoint has been reached, th...

Page 13

Manual 2100-670 page 13 of 32 eev operation eev superheat control the electronic expansion valve (eev) will open or close to maintain 10° of superheat while the compressor is running. When the compressor is not running, the valve will close. Low superheat protection will be active once the superheat...

Page 14

Manual 2100-670 page 14 of 32 manually open the eev. To do this, remove the eev stator coil (red color with retaining nut on top), slide the magnetic tool over the shaft where the stator was removed and turn in a clockwise direction to open the valve to the full open position (directional arrows are...

Page 15

Manual 2100-670 page 15 of 32 table 4 rated airflow nominal rated cfm nominal rated esp high low 1800 1400 .10 table 5 indoor blower performance speed high low esp (inch h20) dry coil wet coil dry coil wet coil 0.1 1885 1800 1470 1400 blower status alarm if the blower is commanded on and the fan sta...

Page 16

Manual 2100-670 page 16 of 32 figure 18 verifying differential airflow status filters the unit is equipped with two (2) 20" x 30" x 2" merv 8 filters. The filters slide into position making them easy to service. The filters can be serviced from the outside by removing either the right or left filter...

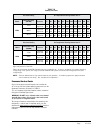

Page 17

Manual 2100-670 page 17 of 32 unit filter blockage % 0% 10% 20% 30% 40% 50% 60% 70% hr58apa (default) high s/t switch static setting 0.40 0.50 0.60 0.70 0.75 0.80 0.90 1.00 evaporator airflow % 100% 98.7% 98.1% 97.5% 91.7% 81.3% 79.1% 78.6% hr58apa standard airflow switch static setting 0.30 0.35 0....

Page 18

Manual 2100-670 page 18 of 32 figure 21 adjusting freezestat alarm delay 6. Press up or down keys to change to the desired value. 7. Press enter key to save the value. Indoor airflow operation blower speed control the blower is capable of changing speeds to best match the requirements of the system ...

Page 19

Manual 2100-670 page 19 of 32 high pressure transducer the unit has a high side pressure transducer installed on the liquid line between the condenser and electronic expansion valve (eev). The transducer is used for system monitoring of high side system pressures. This information is used to indicat...

Page 20

Manual 2100-670 page 20 of 32 mode speed % controller output volts cfm high ambient 71 – 100 7.1 v – 10.0 v 2726 – 3703 low ambient 25 – 71 2.5 v – 7.1 v 1130 – 2726 normal 71 7.1 v 2726 table 8 condenser fan speeds high pressure control condenser fan speed when the discharge pressure reaches 590 ps...

Page 21

Manual 2100-670 page 21 of 32 figure 27 adjusting dirty condensor coil alarm settings compressor compressor components compressor three phase scroll compressor start up information scroll compressors, like several other types of compressors, will only compress in one rotational direction. Direction ...

Page 22

Manual 2100-670 page 22 of 32 upon receiving the alarm, the wall unit will remove the “y” call from the ccm, resetting the status of the ccm. The alarm will stay present on the wall unit until manually cleared. In addition to the ccm, the discharge pressure transducer is used to prevent a high press...

Page 23

Manual 2100-670 page 23 of 32 figure 29 adjusting low pressure alarm settings 8. Press up or down keys to adjust the delay value. 9. Press enter key to save. 10. Press the escape key several times to return to main menu screen. Economizer economizer components actuator the actuator rotates up to 90°...

Page 24

Manual 2100-670 page 24 of 32 figure 31 dust sensor dust sensor failure alarm when the sensor reads a value that is outside of the acceptable 0 to 100% rh range, an alarm will be generated indicating the sensor has failed. This alarm is just a notification and will not disable any other features on ...

Page 25

Manual 2100-670 page 25 of 32 figure 34 adjusting damper alarm delay damper failed to open alarm when the controller commands the economizer damper actuator to a position other than 0% and the damper switch indicates the damper is not open, after a delay of 20 seconds the controller will generate a ...

Page 26

Manual 2100-670 page 26 of 32 figure 36 outdoor humidity sensor 5. Reference the value to see the input of the sensor (see figure 36). 6. To apply an offset, press enter key to scroll to offset . 7. Press up or down keys to change to the desired value. 8. Press enter key to save the value. Outdoor t...

Page 27

Manual 2100-670 page 27 of 32 figure 38 adjusting supply air temperature differential low supply air temperature alarm when the supply air temperature is below 45°f for 120 seconds, an alarm will be generated and the economizer will be disabled until the cooling call has been removed. This alarm wil...

Page 28

Manual 2100-670 page 28 of 32 (see figure 41). The following menu shows the enthalpy content which also contains parameters that would be shown on temphum . 18. Press enter key to scroll to oa humid set (see figure 40). 19. Press up or down keys to change the humidity setpoint to desired value. 20. ...

Page 29

Manual 2100-670 page 29 of 32 bard guard anti-theft system option the unit has the option to be shipped from the factory with a low pressure switch, panel sensors and a speaker. These devices are used with the bard guard bg1000 anti-theft controller to provide an anti-theft measure. These sensors an...

Page 30: Refrigerant Information

Manual 2100-670 page 30 of 32 refrigerant information general 1. Use separate service equipment to avoid cross contamination of oil and refrigerants. 2. Use recovery equipment rated for r-410a refrigerant. 3. Use manifold gauges rated for r-410a (800 psi/250 psi low). 4. R-410a is a binary blend of ...

Page 31

Manual 2100-670 page 31 of 32 pressure service ports high and low pressure service ports are installed on all units so that the system operating pressures can be observed. Pressures are shown in table 9. This unit employs high-flow coremax valves instead of the typical schrader type valves. Warning!...

Page 32: Maintenance

Manual 2100-670 page 32 of 32 maintenance standard maintenance procedures 4. Manually spin fan and blower motors to ensure they turn freely. All motors are permanently lubricated, so no oil is necessary. 5. Inspect free cooling damper actuator and linkage. 6. Install new air filter; check for additi...