- DL manuals

- Bard

- Furnace

- WG3S2-A

- Installation Instructions Manual

Bard WG3S2-A Installation Instructions Manual

Page

1 of 59

WALL MOUNTED GAS/ELECTRIC

Models:

INSTALLATION INSTRUCTIONS

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual No.:

2100-587C

Supersedes: 2100-587B

Date: 10-30-14

WG3S2-A

WG4S2-A

WG5S2-A

WG3S2-B

WG4S2-B

WG5S2-B

WG3S2-C

WG4S2-C

WG5S2-C

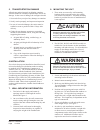

WARNING

READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE

INSTALLATION.

THE INSTALLATION MUST COMPLY WITH THESE INSTRUCTIONS

AND THE REQUIREMENTS OF ALL GOVERNING CODES AND

ORDINANCES FOR THE INSTALLATION LOCATION.

IT IS THE RESPONSIBILITY OF INSTALLER TO KNOW AND

UNDERSTAND ALL OF THESE REQUIREMENTS.

FAILURE TO DO SO COULD CREATE A HAZARD RESULTING IN

PROPERTY DAMAGE, BODILY INJURY, OR DEATH.

Summary of WG3S2-A

Page 1

Page 1 of 59 wall mounted gas/electric models: installation instructions bard manufacturing company, inc. Bryan, ohio 43506 www.Bardhvac.Com manual no.: 2100-587c supersedes: 2100-587b date: 10-30-14 wg3s2-a wg4s2-a wg5s2-a wg3s2-b wg4s2-b wg5s2-b wg3s2-c wg4s2-c wg5s2-c warning read all instruction...

Page 2: Contents

Manual 2100-587c page 2 of 59 contents getting other information and publications................4 wg series model nomenclature ................................5 ventilation options......................................................5 air conditioning module options ..................................

Page 3: Contents

Manual 2100-587c page 3 of 59 contents figures figure 1 unit dimensions ...................................... 8 figure 2a mounting instructions – wg3s2 ............ 11 figure 2b mounting instructions–wg4s2 & wg5s2 ..... 12 figure 3 combustible clearance ......................... 13 figure 4 wall mo...

Page 4

Manual 2100-587c page 4 of 59 getting other information and publications for more information, contact these publishers: acca air conditioning contractors of america 1712 new hampshire avenue, nw washington, dc 20009 telephone: (202) 483-9370 ansi american national standards institute 11 west street...

Page 5

Manual 2100-587c page 5 of 59 wg 4 s 2 – a x c x x x x x x wall mount gas/electric general model number nomenclature low ambient control is required with economizer for low temperature compressor operation. Ventilation options description factory installed code no. Field installed part no. Blank-off...

Page 6: Caution

Manual 2100-587c page 6 of 59 air conditioning module options std = standard equipment ccm compressor control module has adjustable 30 second to 5 minute delay-on-breaktimer. On initial power up, or any time the power is interrupted, the delay-on-make will be 2 minutes plus 10% of the delay-on-break...

Page 7

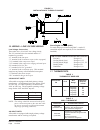

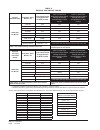

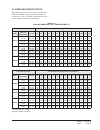

Manual 2100-587c page 7 of 59 * 75 ° c copper wire size ** maximum time delay fuse or circuit breaker table 1 specifica tions models wg3s2-a wg3s2-b wg3s2-c wg4s2-a wg4s2-b wg4s2-c wg5s2-a wg5s2-b wg5s2-c electrical rating - 60 hz 230/208-60-1 230/208-60-3 460-60-3 230/208-60-1 230/208-60-3 460-60-3...

Page 8

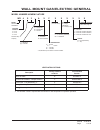

Manual 2100-587c page 8 of 59 m g n p d a ff gg hh y z t c k j bb dd r w s s s s cc f b aa x u i v s b ee o e l ii q h fi lt er se rv ice door ga s pa ne l ve nt op ti on ci rc ui t br ea ke r/ fr on t re tu rn ope ni ng co nd en se r ba ck su pp ly ope ni ng di sc onn ec t a cc es s ri gh t s id e ...

Page 9: Warning

Manual 2100-587c page 9 of 59 a one-inch clearance to combustible material for the first three feet of duct attached to the outlet air frame is required. See wall mounting instructions and figures 2, 2a, 3 and 3a for further details. Ducts through the walls must be insulated and all joints taped or ...

Page 10: Caution

Manual 2100-587c page 10 of 59 5. Transportation damage all units are packed securely in shipping container. All units should be carefully inspected upon arrival for damage. In the event of damage, the consignee should: 1. Note on delivery receipt of any damage to container. 2. Notify carrier prompt...

Page 11

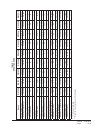

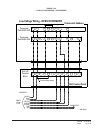

Manual 2100-587c page 11 of 59 figure 2a mounting instructions for wg3s2.

Page 12

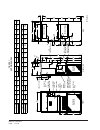

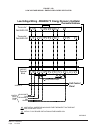

Manual 2100-587c page 12 of 59 figure 2b mounting instructions for wg4s2 and wg5s2.

Page 13: Warning

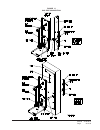

Manual 2100-587c page 13 of 59 figure 3 combustible clearance warning a minimum of one (1) inch clearance must be maintained between the supply air duct and combustible materials. This is required for the first three (3) feet of ducting. It is important to insure that the one (1) inch minimum spacin...

Page 14

Manual 2100-587c page 14 of 59 figure 4 wall mounting instructions figure 5 wall mounting instructions.

Page 15

Manual 2100-587c page 15 of 59 figure 6 common wall mounting installations.

Page 16: Warning

Manual 2100-587c page 16 of 59 9. Clearances minimum clearances, as specified in table 2, must be maintained from adjacent structures to provide adequate fire protection, adequate combustion air, and room for service personnel. While minimum clearances are acceptable for safety reasons, they may not...

Page 17: Caution

Manual 2100-587c page 17 of 59 10. Vent terminal and combustion air inlet hood the vent terminal is shipped in the burner compartment. See figure 7. Remove the two shipping screws and separate the two-piece assembly. Install the vent terminal by using the four screws provided. Make sure gasket is in...

Page 18

Manual 2100-587c page 18 of 59 12. Vent resizing instructions when an existing furnace is removed from a venting system servicing other appliances, the venting system is likely to be too large to properly vent the remaining attached appliances. The following steps shall be followed with each of the ...

Page 19: Warning

Manual 2100-587c page 19 of 59 electrical grounding when installed, the furnace must be electrically grounded in accordance with local codes or in the absence of local codes, with the national electrical code, ansi/nfpa 70, or canadian electrical code, csa22.1, latest edition. Use a copper wire from...

Page 20

Manual 2100-587c page 20 of 59 note: the voltage should be measured at the field power connection point in the unit and while the unit is operating at full load (maximum amperage operating condition). 17. Thermostats 16. Wiring – low voltage wiring low voltage connection these units use a 24-volt ac...

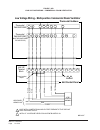

Page 21: Unit Control Panel

Manual 2100-587c page 21 of 59 figure 10a low voltage wiring - no vent g part #8403-058 thermostat low voltage wiring - no ventilation package 1 o/b y thermostat r unit control panel block w2 r c w1 w2 e y2 y1 2 3 r c w y2 rc w2 y g l y1 d/yo y2 a w1/e c g terminal part #8403-060 thermostat subbase ...

Page 22

Manual 2100-587c page 22 of 59 figure 10b low voltage wiring - commercial room ventilator (must be configured re d mis-2433 f low voltage wiring - multi-position commercial room ventilator 1 g y c bl ac k install if you require ventilation anytime blower is on. Block r c w1 a w2 e y2 purple 2 3 r c ...

Page 23: Unit Control Panel

Manual 2100-587c page 23 of 59 figure 10c low voltage wiring - economizer w2 orange thermostat thermistor from low voltage wiring - eifm economizer 1 wgseifm-5 red o/b g red unit control panel block r c w1 w2 e y2 y1 2 3 r c w y2 rc w2 y g l y1 d/yo y2 a plug y unit 24v terminal part #8403-058 w1/e ...

Page 24

Manual 2100-587c page 24 of 59 figure 10d low voltage wiring - energy recovery ventilator mis-2434 c wgserv-*5 r have occupancy output. Thermostat panel y control install if you require ventilation anytime blower is on. Block r c w1 a w2 e y2 y1 2 3 r c w y2 rc w2 y g l y1 d/yo low voltage wiring - ...

Page 25

Manual 2100-587c page 25 of 59 figure 11 gas pipe connection.

Page 26

Manual 2100-587c page 26 of 59 18. Gas supply and piping general recommendations 1. Be sure the gas line complies with the local codes and ordinances, or in their absence with the national fuel gas code, ansi z223.1, or natural gas installation code, can/cga b149.1, or propane installation code b149...

Page 27: Warning

Manual 2100-587c page 27 of 59 19. Manifold pressure adjustment a 0 to 15 inch water manometer with 0.1 inch resolution and a 1/8” npt manual shut off valve is needed to measure actual manifold pressure. Depending on your local gas heating value and elevation, you may need to adjust manifold pressur...

Page 28: Warning

Manual 2100-587c page 28 of 59 natural gas input rate natural gas heating value (btu/cu. Ft.) can vary significantly. Before starting natural gas input check, obtain gas heating value at your location from local supplier. You will need a stopwatch to measure actual gas input. 1. Gas supply pressure ...

Page 29

Manual 2100-587c page 29 of 59 21. Standard orifice sizing and high altitude derate this furnace is shipped with fixed gas orifices for use with natural gas and sized for 1000 btu/cubic foot gas. Make sure actual gas input does not exceed rating plate input. The orifices may need to changed to get t...

Page 30

Manual 2100-587c page 30 of 59 all other orifice sizes shown are available as individual items. See orifice tables below for part numbers and number required. Table 8 natural gas orifice tables factory standard input gas heat* value btu/cu. Ft. Up to 6,000 feet no changes except for btu content 6,00...

Page 31: Warning

Manual 2100-587c page 31 of 59 23. Measuring air temperature rise air temperature rise (supply air temperature minus return air temperature) must be within allowable air temperature rise range specified on furnace rating plate and in table 1. You will need 2 thermometers with 1 degree resolution cap...

Page 32

Manual 2100-587c page 32 of 59 24. Filters a 2” thick throwaway filter is supplied with each unit. This filter is installed by removing the filter access panel. (see figure 13.) replacement filters are available through your dealer. 25. Compressor control module the compressor control module is stan...

Page 33

Manual 2100-587c page 33 of 59 alarm output alarm terminal is output connection for applications where alarm signal is desired. This terminal is powered whenever compressor is locked out due to hpc or lpc sequences as described. Note: both high and low pressure switch controls are inherently automat...

Page 34

Manual 2100-587c page 34 of 59 26. Lighting and shutdown instructions figure 14 instruction label bend & peel “here” to remove label liner a. This appliance does not have a pilot. It is equipped with an ignition device which automatically lights the burner. Do not try to light the burner by hand. B....

Page 35: Caution

Manual 2100-587c page 35 of 59 27. Service agency procedures main burner observe the main burners in operation. The flame should be mostly “blue” with possibly a little orange (not yellow) at the tips of the flame. The flames should be in the center of the heat exchanger tubes and not impinging on t...

Page 36: Warning

Manual 2100-587c page 36 of 59 routine maintenance 1. Air filters – check the condition at least monthly when the unit is in use, and replace as necessary. 2. Lubrication requirements – the indoor circulating air blower motor and outdoor circulating air fan motor are permanently lubricated and requi...

Page 37

Manual 2100-587c page 37 of 59 30. Sequence of operation – heating on a call for heat from the thermostat, the induced draft blower is energized. Once sufficient draft is established, the pressure switch contacts close and the ignition system is energized. The direct spark ignitor will be energized ...

Page 38

Manual 2100-587c page 38 of 59 32. Indoor blower operation the indoor blower motor is a constant cfm variable speed direct drive motor. The motor is programmed to respond to individual thermostatic inputs that will determine the speed/airflow at which the motor operates. The motor software maintains...

Page 39

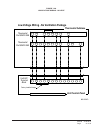

Manual 2100-587c page 39 of 59 table 10 integrated furnace and blower control operation ignition sequence control ignition source 24 vac dsi flame sensing remote timings - prepurge - postpurge - inter-trial purge - pressure switch proving period - trials for ignition - trial for ignition - ignition ...

Page 40: Start Up

Manual 2100-587c page 40 of 59 start up these units require r-410a refrigerant & polyol ester oil. Application: 1. Use separate service and manufacturing equipment to avoid cross contamination of oil and refrigerants. 2. Use recovery equipment rated for r-410a refrigerant. 3. Use manifold gauges rat...

Page 41

Manual 2100-587c page 41 of 59 three phase scroll compressor start up information scroll compressors, like several other types of compressors, will only compress in one rotational direction. Direction of rotation is not an issue with single phase compressors since they will always start and run in t...

Page 42: Troubleshooting

Manual 2100-587c page 42 of 59 compressor solenoid (see sequence of operation on page 37 for function.) a nominal 24-volt direct current coil activates the internal compressor solenoid. The input control circuit voltage must be 18 to 28 volt ac. The coil power requirement is 20 va. The external elec...

Page 43: Troubleshooting Ecm

Manual 2100-587c page 43 of 59 troubleshooting ecm ™ motors caution: disconnect power from unit before removing or replacing connectors, or servicing motor. To avoid electric shock from the motor’s capacitors, disconnect power and wait at least 5 minutes before opening motor. Symptom cause/procedure...

Page 44: Troubleshooting Ecm

Manual 2100-587c page 44 of 59 troubleshooting ecm ™ motors cont’d. Replacing ecm control module to replace the control module for the ge variable-speed indoor blower motor you need to take the following steps: 1. You must have the correct replacement module. The controls are factory programmed for ...

Page 45

Manual 2100-587c page 45 of 59 33. Pressure service ports high and low pressure service ports are installed on all units so that the system operating pressures can be observed. Table 12 outlines expected pressures at various indoor and outdoor temperatures. Low side pressure ± 4 psig high side press...

Page 46: * *

Manual 2100-587c page 46 of 59 35. Low-nox burner assembly “n” suffix models only – u.S. Installations only natural gas models only model numbers designated with an “n” are designed for low nox emissions which comply with all california air quality management district regulations for nitrogen oxide ...

Page 47

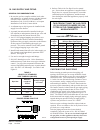

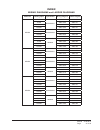

Manual 2100-587c page 47 of 59 index wiring diagrams and ladder diagrams model no. Heating input input power wiring diagram ladder diagram wg3s2 50,000 208/230/60/1 4085-154a 4085-155 75,000 4085-156a 4085-157 100,000 4085-154a 4085-155 125,000 4085-156a 4085-157 50,000 208/230/60/3 4085-254a 4085-2...

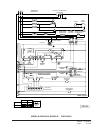

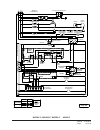

Page 48

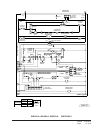

Manual 2100-587c page 48 of 59 wg3s2-a, wg4s2-a, wg5s2-a 208/230/60/1 t2 nc c l2 l3 au x. L1 t1 t3 lpc cc hpc y alr c lpc mi nu tes 4 2 3 5 r 1 switch pressure high compressor compressor high speed motor crankcase 16 replaced, it must be replaced with wiring material having a temperature rating of a...

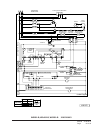

Page 49

Manual 2100-587c page 49 of 59 wg3s2-a, wg4s2-a, wg5s2-a 208/230/60/1 if option not a wires connect used 4085-155 indoor blower motor 14 12 10 6 2 13 3 1 16 pin plug for 15 w1 c heat unused g high voltage optional low voltage factory induced draft a y2 contactor compressor l2 t2 c s r compressor pow...

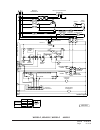

Page 50

Manual 2100-587c page 50 of 59 wg3s2-a, wg4s2-a, wg5s2-a 208/230/60/1 t2 nc c l2 l3 au x. L1 t1 t3 32 a 62 induced draft blower compressor contactor 51 gas valve 20 32 32 37 35 35 40 40 35 35 32 32 32 32 32 32 34 32 62 28 28 28 37 28 27 27 42 43 41 38 36 47 41 33 28 28 28 flame limit spark ignitor r...

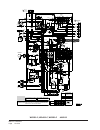

Page 51

Manual 2100-587c page 51 of 59 wg3s2-a, wg4s2-a, wg5s2-a 208/230/60/1 if option not a wires connect used indoor blower motor 14 12 10 6 2 13 3 1 16 pin plug for 15 w1 c heat unused g high voltage optional low voltage factory compressor a r contactor compressor l2 t2 c s power source blower motor for...

Page 52

Manual 2100-587c page 52 of 59 wg3s2-b, wg4s2-b, wg5s2-b 208/230/60/3 t2 nc c l2 l3 au x. L1 t1 t3 pink pi nk 5 blue blue 5 4 3 gr blue blue 1 2 3 4 l3 6 8 9 7 12 10 11 blue blue l2 l1 blue purple purple purple c mv no mv yellow orange yellow yellow/black yellow ye ll ow /b la ck br ow n/ w hi te ye...

Page 53

Manual 2100-587c page 53 of 59 wg3s2-b, wg4s2-b, wg5s2-b 208/230/60/3 if option not a wires connect used indoor blower motor 14 12 10 6 2 13 3 1 16 pin plug for 15 w1 c heat unused g high voltage optional low voltage factory phase monitor ladder diagram lo w vo lta ge te rm .B loc k r control module...

Page 54

Manual 2100-587c page 54 of 59 wg3s2-b, wg4s2-b, wg5s2-b 208/230/60/3 t2 nc c l2 l3 au x. L1 t1 t3 pink pi nk l1 blue blue 5 4 3 gr blue blue 1 2 3 4 5 6 8 9 7 12 10 11 blue blue l2 blue purple purple purple c mv no mv yellow orange yellow yellow/black yellow ye ll ow /b la ck br ow n/ w hi te ye ll...

Page 55

Manual 2100-587c page 55 of 59 wg3s2-b, wg4s2-b, wg5s2-b 208/230/60/3 if option not a wires connect used indoor blower motor 14 12 10 6 2 13 3 1 16 pin plug for 15 w1 c heat unused g high voltage optional low voltage factory phase monitor ladder diagram lo w vo lta ge te rm .B loc k r control module...

Page 56

Manual 2100-587c page 56 of 59 wg3s2-c, wg4s2-c, wg5s2-c 460/60/3 t2 nc c l2 l3 au x. L1 t1 t3 lp c cc hp c y al r c lp c m in ut es 4 2 3 5 r 1 46 0v 23 0v pink pi nk blue blue blue 5 4 3 gr blue blue 1 2 3 4 5 6 8 9 7 12 10 11 blue blue purple purple purple c mv no mv yellow orange yellow yellow r...

Page 57

Manual 2100-587c page 57 of 59 wg3s2-c, wg4s2-c, wg5s2-c 460/60/3 if option not a wires connect used indoor blower motor 14 12 10 6 2 13 3 1 16 pin plug for 15 w1 c heat unused g high voltage optional low voltage factory phase monitor ladder diagram lo w vo lta ge te rm .B loc k r control module com...

Page 58

Manual 2100-587c page 58 of 59 wg3s2-c, wg4s2-c, wg5s2-c 460/60/3 460v 230v t2 nc c l2 l3 au x. L1 t1 t3 lpc cc hpc y alr c lpc mi nu tes 4 2 3 5 r 1 6 1 3 2 4 pink pi nk blue blue 5 4 3 gr blue blue 1 2 3 4 5 6 8 9 7 12 10 11 bl ue bl ue blue purple purple purple mv no c mv yellow orange ye ll ow /...

Page 59

Manual 2100-587c page 59 of 59 wg3s2-c, wg4s2-c, wg5s2-c 460/60/3 if option not a wires connect used 4085-393 indoor blower motor 14 12 10 6 2 13 3 1 16 pin plug for 15 w1 c heat unused g high voltage optional low voltage factory compressor ladder diagram lo w vo ltage te rm. Bl ock r control module...