- DL manuals

- Barker

- Merchandiser

- GMD-R

- Installation & operation manual

Barker GMD-R Installation & operation manual

PTD-RGC

DELI/MEAT/SEAFOOD

09/16

MULTI-DECK MERCHANDISER

I N STA L L AT I O N & O P E R AT I O N S M A N UA L

Energy Data & Case Dimensions ......................2-4

General Information ............................................... 5

Installation ..........................................................6-8

Case Connections ............................................ 9-12

Lighting and Power Supplies ......................... 13-14

Pre-Power Checklist ............................................15

Airfl ow & Defrost ..................................................16

Case Cleaning ................................................ 17-24

Parts Ordering ......................................................25

Appendices

Table of Contents

To ensure proper functionality and optimum performance, it is STRONGLY recommended that Hillphoenix specialty cases be installed/serviced by qualifi ed

technicians who have experience working with commercial refrigerated display merchandisers and storage cabinets. For a list of Hillphoenix-authorized

installation/service contractors, please visit our Web site at www.hillphoenix.com.

Summary of GMD-R

Page 1

Ptd-rgc deli/meat/seafood 09/16 multi-deck merchandiser i n sta l l at i o n & o p e r at i o n s m a n ua l energy data & case dimensions ......................2-4 general information ............................................... 5 installation .......................................................

Page 2

Ii.

Page 3

R-744 (co 2 ) notice for systems utilizing r-744 (co 2 ) refrigerant for refrigeration units that utilize r-744 (co 2 ), pressure relief and pressure-regulating relief valves may need to be installed based on the system capacity. The valves need to be located such that no stop valve is posi- tioned ...

Page 4

Important d a n g e r ▲ indicates an immediate threat of death or seri- ous injury if all instructions are not followed carefully. A t hillphoenix ® , the safety of our customers and employees, as well as the ongo- ing performance of our products, are top priorities. To that end, we include impor- t...

Page 5

Revision history • new manual format_12/13 • energy data_01/14 • energy data_03/14 • endviews_09/14 • support diagram and parts page_02/15 • warranty_04/16 • energy data_09/16 v.

Page 6

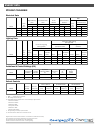

Energy data numbers are based on standard case sizes. Consult engineering. All measurements are taken per ari 1200 - 2002 specifications. Engineered for stores with ambient conditions not to exceed 75 o and 55% relative humidity. Due to engineering improvements specifications may change without noti...

Page 7

Energy data ptd-rgc coolgenix numbers are based on standard case sizes. Consult engineering. All measurements are taken per ari 1200 - 2002 specifications. Engineered for stores with ambient conditions not to exceed 75 o and 55% relative humidity. Due to engineering improvements specifications may c...

Page 8

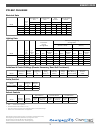

Ptd-rgc coolgenix case dimensions power supply 2 1/16 in [5.2 cm] 18 in [45.7 cm] 51 in [129.6 cm] 6 in [15.2 cm] 12 in [30.5 cm] 1 in [2.5 cm] 1 in [2.5 cm] 15" x 11" mechanical access for elect. ,refrig. ,and drain connections toekick 42 in [106.7 cm] toekick 72 1/2 in [184.2 cm] {6’ case} l c fro...

Page 9

Hillphoenix barker specialty products 703 franklin street, po box 478 keosauqua, ia 52565 tel: (319) 293-3777/fax: (319) 293-3776 web site: www.Hillphoenix.Com general information t hank you for choosing hillphoenix for your food merchandising needs. This handbook contains important technical inform...

Page 10

Case installation floor prep 1. Ask the general contractor if your current copy of the build- ing dimensions are the most recently issued. Also, ask for the points of reference from which you should take dimen- sions to locate the cases. 2. Using chalk lines or a laser transit, mark the fl oor where ...

Page 11

Case installation fig. 2 sealant, piping, and bolt locations multi-case 1. Remove any shelves (discard the shelf clips) and/or loose items from the cases that may interfere with case joining. Keep all loose items as they will be used later in the instal- lation process. 2. Follow the single-case ins...

Page 12

Case installation pan sensors 1. The center deck pan and shelving (if applicable) have a pan sensor connected to the underside (fig. 5). Not every pan will have this sensor. Check the underside of each pan to see which pan(s) have this sensor. Fig. 5 coolgenix pan sensor displaying 1. All display tr...

Page 13

Semi-self-contained hillphoenix ssc (semi-self-contained) cases utilize an open- loop secondary system, supplying independent circuits to the coolgenix pans, shelves and the gravity top coils. All circuits return to a common reservoir tank that is maintained at atmo- spheric pressure. All cases are ...

Page 14

Case connections electrical electrical hookups are made through the power supply box that can be accessed by removing the back panel. For case-to-case wiring, run conduit between the power supply boxes or run wiring through the raceway. When connecting to the power supply on the case, fi eld wiring s...

Page 15

C a u t i o n dowfrost propylene glycol is used for pressure testing and system charging. If another approved glycol is utilized, the case must be fl ushed with pure water to remove any residual glycol before fi lling. Failure to do so will void the manufacturer warrarnty. Never mix manufacturers of g...

Page 16

Mechanical access locations case connections power supply 2 1/16 in [5.2 cm] 18 in [45.7 cm] 51 in [129.6 cm] 6 in [15.2 cm] 12 in [30.5 cm] 1 in [2.5 cm] 1 in [2.5 cm] 15" x 11" mechanical access for elect. ,refrig. ,and drain connections toekick 42 in [106.7 cm] toekick l c front of case 72 1/2 in...

Page 17

Lighting & power supplies general lighting information hillphoenix cases are equipped with either t-8 lights or led luminaires and feature specially designed light reflectors in the cornice to improve the illumination of products. Depending on case configuration, t-8 electronic ballasts or led power...

Page 18

Lighting & power supplies replacing led lights once store power is connected and the light circuit is ener- gized, the clearvoyant led system should operate without the need for any signifi cant maintenance for several years. Should a power supply need to be removed and/or replaced, turn off the powe...

Page 19

Pre-power checklist have you thoroughly examined the case for shipping damage? (see pg. 5) have you checked the vertical plumb of the case? The horizontal level? (see pg. 6) have you applied the sealant to the end breakers of adjoining cases? (see pg. 7) have you sealed the case-to-case joints by ap...

Page 20

Airflow & defrost cut-in/cut-out cut-in temp ( o f) cut-out temp ( o f) pans 33 29 top coil 36 31 airflow & product load hillphoenix cases provide maximum product capacity within the refrigerated air envelope. Please keep products within the ap- propriate load limit. It is important that you do not ...

Page 21

Defrost & temperature control thermostat the defrost termination control thermostat and the temperature control thermostat are located in one of two places depending on the rear sill. For cases with a standard fl at rear sill the thermostat is located in the sliding ballast tray on the bottom. For ca...

Page 22

Coolgenix pans 1. Slowly raise the front lift glass to its full open position. 2. Remove the pan sensor (fig. 13) located on the center deck pan by sliding the sensor out of the bracket attached to the bottom side of the coolgenix pan. 3. Lift and remove the coolgenix deck pans from the front of the...

Page 23

The coolant lines under each pan. 4. To disconnect the pans from the case, push the button located on the quick connects to release (fig. 14 & 15). 5. The pan sensor should slide off the mounting bracket be- fore cleaning and must always be reattached to the center pan after cleaning. 6. Remove the ...

Page 24

Case cleaning fig. 17 pressure plate (underside) fig. 16 pressure plate (topside) pressure plate coil cover c a u t i o n always be sure to move the pressure plate and screw the coil cover back to their original posi- tion after the cleaning and/or inspection is com- plete . Failure to do so may res...

Page 25

Rear load doors 1. Remove the rear sliding doors on the back of the case and clean. To remove: push up and pull out (fig. 21). Fig. 21 rear load door removal 2. Use a spray bottle fi lled with an approved mild detergent and warm water. 3. Use a clean, disposable cloth (approved item) to thorough- ly ...

Page 26

Pre-cleaning checklist • identify the cases that need to be cleaned (note: multiple cases usually run on the same refrig eration circuit, so plan on cleaning all cases on that circuit at one time) • post safety signs in the area of the cases that are going to be cleaned • remove the product from the...

Page 27

• gather all necessary cleaning materials mild cleaning solution sanitizer clean towels or paper towels soap and hot water (cleaning tank only) non-abrasive cleaning pads glass cleaner case cleaning checklist 1. Clean the top sill • spray the top sill with a mild cleaning solution and wipe it down w...

Page 28

3. Clean the coolgenix display pans and interior components • depending on the case design, the front glass will lift or swingout to access the coolgenix pans • make sure the surface of the pan is room temperature before cleaning • if you have not done so already, remove the pan sensor located on th...

Page 29

• apply sanitizer solution to the tank • dry interior glass with clean, dry paper towels or cloth • allow the remainder of the case to air dry 5. Clean the front glass • for standard glass, use a mild glass cleaner and a clean paper towel or cloth to wipe the glass • for non-glare glass, refer to sp...

Page 30

• clean up any spills on the fl oor • make sure that all components have completely air dried • turn on the electrical circuit and verify operation of electrical components • turn on the refrigeration to the cases either at the power supply, through the controller or it will automatically turn back o...

Page 31

Sovis ultravision ® tempered glass specialized anti-reflective coatings on each surface of the glass. These coatings reduce the glare from lighting so that the products on display are more visible to your customers. While the anti-reflective coatings are durable, they are susceptible to scratching i...

Page 32

Contact the service parts department at: 319-293-3777 provide the following information about the part you are ordering: • model number and serial number* of the case for which the part is intended. • length of the part (if applicable). • color of part (if painted) or color of polymer part. • whethe...

Page 33

A1-a4 .............................................................................................. Wiring information b1-b4 .............................................................................. Dixell operating instructions c1 .................................................................

Page 34

A1: wiring dia gram ground sol junction box ground to case wire information wire information ground to receptacles ground to sv3 black to outlet black outlet power white to outlet white outlet power wire information wire information black to outlet white to outlet black led driver white led driver g...

Page 35

A2: wiring dia gram ground sol junction box ground to case wire information wire information ground to receptacles ground to sv3 black to outlet black outlet power white to outlet white outlet power wire information wire information black to outlet white to outlet black led driver white led driver b...

Page 36

A3: wiring dia gram black to iso black iso power white to iso wire information wire information black fan power white fan power wire information wire information white iso power green iso ground green to iso white power from 7 - 2 white to block 6 - g - 2 gray to 2 - f red shelf light red driver wir...

Page 37

A4: wiring dia gram red driver white to 4 - d red top light white driver wire information wire information black top light gray to 4 - c black driver blue driver red driver red dome light blue driver wire information wire information black dome switch black power from 5 - h wire information wire inf...

Page 38

B1: dixell operating instructions dixel installing and operating instructions 1592020070 1592020070 xr70cx gb m&m r1.130.11.2007.Doc xr70cx 1/4 digital controller with defrost and fans management xr70cx 1. General warning 1.1 please read before using this manual x this manual is part of the product ...

Page 39

B2: dixell operating instructions dixel installing and operating instructions 1592020070 1592020070 xr70cx gb m&m r1.130.11.2007.Doc xr70cx 2/4 6.3 how to start a manual defrost push the def key for more than 2 seconds and a manual defrost will start. 6.4 how to change a parameter value to change th...

Page 40

B3: dixell operating instructions dixel installing and operating instructions 1592020070 1592020070 xr70cx gb m&m r1.130.11.2007.Doc xr70cx 3/4 au2 high temperature alarm of condenser:(-55÷150°c) when this temperature is reached the ha2 alarm is signalled, possibly after the ad2 delay. Ah2 different...

Page 41

B4: dixell operating instructions dixel installing and operating instructions 1592020070 1592020070 xr70cx gb m&m r1.130.11.2007.Doc xr70cx 4/4 14.1 alarm recovery probe alarms p1”, “p2”, “p3” and “p4” start some seconds after the fault in the related probe; they automatically stop some seconds afte...

Page 42

C1: sporlan pressure-temperature chart temperature pressure chart - at sea level t o d e te rm in e s u b co o lin g f o r r -4 0 4 a u se b u b b le p o in t v a lu e s (t e m p e ra tu re s a b o v e 5 0 °f — g ra y b a ck g ro u n d ); t o d e te rm in e s u p e rh e a t fo r r -4 0 4 a , u se d ...

Page 43

A drain trough b case top c front fixed glass d interior end panel e die board plex f die board g front toekick h air return i product stop j insulated drain pan k remote bottom deck l end panel trim m end panel n fixed end glass o end toekick p electrical raceway q outside back r lower rear storage...

Page 44

4844-3514-3187.2 hill phoenix, inc. Hereinafter referred to as manufacturer limited warranty general warranty manufacturer’s products are warranted to be free from defects in materials and workmanship under normal use and maintenance for fourteen months from date of shipment from manufacturer (the “...

Page 45

Warning maintenance & case care when cleaning cases the following must be performed prior to cleaning: to avoid electrical shock, be sure all electric power is turned off before cleaning. In some installations, more than one switch may have to be turned off to completely de-energize the case. Do not...