- DL manuals

- Barnstead

- Furnace

- F46110CM

- Operation Manual

Barnstead F46110CM Operation Manual

1

B

ARNSTEAD

|T

HERMOLYNE

C

ORPORATION

High Temperature

Muffle Furnace

OPERATION MANUAL

AND PARTS LIST

Model Numbers

F46110CM

F46230CM

Automatic

F46110CM-33

F46230CM-33

Automatic

F46118CM

F46238CM

Automatic

F46120CM

F46240CM

Multi-Programmable

F46120CM-33

F46240CM-33

Multi-Programmable

F46128CM

F46248CM

Multi-Programmable

F46120CM-75

F46240CM-75

Multi-Programmable

F46120CM-33-75

F46240CM-33-75

Multi-Programmable

F46128CM-75

F46248CM-75

Multi-Programmable

LT1078X2 • 5/9/97

Summary of F46110CM

Page 2

2 important information this manual contains important operating and safety information. The user must carefully read and understand the contents of this manual prior to the use of this equipment. Table of contents safety information .....................................................................

Page 3

3 furnace loading: ......................................................................................................................................... 29 furnace atmospheres ...........................................................................................................................

Page 4

4 safety information your thermolyne furnace has been designed with function, reliability, and safety in mind. It is the user’s responsibility to install it in conformance with local electrical codes. For safe operation, please pay attention to the alert boxes through- out the manual. Because of the...

Page 5

5 warning to avoid electrical shock, this furnace must: 1. Be installed by a competent, qualified electrician who insures compatibility among furnace specifications, electrical source and grounding code requirements. 2. Always be disconnected from the electrical supply prior to maintenance and servi...

Page 6

6 please note the following warnings: warning this warning is presented for compliance with california proposition 65 and other regulatory agencies and only applies to the insulation in this product. This product contains refractory ceramic, refractory ceramic fiber or fiberglass insulation, which c...

Page 7

7 intended use types 461 and 462 are general purpose laboratory furnaces intended for applications requiring temperatures from 800-1700 degrees c. General usage do not use this product for anything other than its intended usage. Principles of operation the chamber section is heated by six (in type f...

Page 8

8 the control section consists of a temperature controller, a current controller, a transformer, a contactor (relay), a circuit breaker, and a pilot light. The temperature controller senses the furnace temperature (by means of the thermocouple) and adjusts electricity to the heating elements by mean...

Page 9

9 general specifications model# f46110cm, f46118 f46120cm f46128 f46120cm-75 f46128cm-75 f46110cm-33 f46120cm,-33 f46120cm-33-75 dimensions overall-in width 28-1/8 28-1/8 28-1/8 28-1/8 28-1/8 28-1/8 (cm) (71.4) (71.4) (71.4) (71.4) (71.4) (71.4) height 18-1/2 18-1/2 18-1/2 18-1/2 18-1/2 18-1/2 (47) ...

Page 10

10 model# f46230cm, f46238 f46240cm f46248 f46240cm-75 f46248cm-75 f46230cm-33 f46240cm,-33 f46240cm-33-75 dimensions overall-in width 34-1/8 34-1/8 34-1/8 34-1/8 34-1/8 34-1/8 (cm) (86.7) (86.7) (86.7) (86.7) (86.7) (86.7) height 22-1/2 22-1/2 22-1/2 22-1/2 22-1/2 22-1/2 (57.2) (57.2) (57.2) (57.2)...

Page 12

12 unpacking visually check for any physical damage to the shipping container. Inspect the equipment surfaces that are adjacent to any damaged area. Open the furnace door and remove packing material from inside the furnace chamber. Vacuum the chamber prior to use to remove the insulation dust due to...

Page 13

13 installation site selection: install furnace on a sturdy surface and allow space for ventilation. The electrical specifications are located on the specifica- tion plate on the back of the furnace. Consult barnstead/ thermolyne if your electrical service is different than those listed on the speci...

Page 14

14 general operation of furnace observe these warnings before operating your furnace: warning to avoid electrical shock, this furnace must: 1. Be installed by a competent, qualified electrician who insures compatibility among furnace specifications, electri- cal source and grounding code requirement...

Page 15

15 circuit breaker a double pole circuit breaker is located at the bottom of the control section. It serves to turn electricity on and off and to protect the electrical circuit. Fans the fans, located in the rear of the heating section and the control section, will run continuously as long as electr...

Page 16

16 operation of automatic models (models f46110cm, f46110cm-33, f46118cm, f46230cm, f46230cm-33, f46238cm) control parameters pr = program ramp rate, the rate of heat increase or decrease in °c/minute. Pushing the up or down button will give the current setting of this ramp. Push up or down button t...

Page 17

17 hl = output power limits the average maximum percent- age of electricity that is applied to the heating elements. Depress and release up or down button, if 100 is not displayed, contact barnstead/thermolyne. Sbr = the power that is required to indicate an open thermocouple condition exists. Push ...

Page 18

18 3. To stop tuning function, scroll until sat is displayed and simultaneously push up and down buttons. Single set point operation the automatic control is used as a single set point control, which includes one ramp to set point capability. To use as a single set point control, simply push up or d...

Page 19

19 program ramp rate if you desire to ramp to the set temperature at a specified rate, depress scroll button until “pr” appears. (“pr” = program ramp rate, which is the rate of heat increase or decrease in °c/minutes). Depress up or down button to give current setting of ramp rate. Depress up or dow...

Page 20

20 operation of programmable models (f46120cm, f46120cm-33, f46120cm-33-75, f46120cm- 75, f46128cm, f46128cm-75, f46240cm, f46240cm-33, f46240cm-33- 75, f46240cm-75, f46248cm, f46248-75) control parameters pr1 = program ramp rate is the rate of heat increase or decrease in °c/minute. Pushing the up ...

Page 21

21 st = self tune automatically loads pid values on initial start up. This function does not have a value, it is either on or off. (see furnace operation for function of self tune.) at = adaptive tune analyzes and inputs optimum pid values when temperature has reached setpoint. This function does no...

Page 22

22 tuning your furnace the sat self and adaptive tuning feature starts the controller in the self tune mode, then automatically switches over to the adaptive tuning mode. Self tuning is a one-time function which permits the user to tune the instrument control parameters to suit new process condi- ti...

Page 23

23 caution minimize operation of furnace under 800°c. Element life is reduced when operating below 800°c because the protective layer of silica glass takes longer to form. Note temperature setpoint or output power is indicated on lower display, single depression of scroll button will alternate betwe...

Page 24

24 desired ramp rate (pr). Dwell segments (pd) can be attached to each program level (pl) to hold that tempera- ture for a specified number of minutes. Multi-programmable controller program entry (models f46120cm, f46120cm-33, f46120cm-33-75, f46120cm-75, f46128cm, f46128cm-75, f46240cm, f46240cm-33...

Page 25

25 program entry (all models) set ramp rates 1. With the controller not operating, indicated by the bottom right hand side of the display extinguished, depress scroll button until pr1 is displayed. Push the up or down button to scroll to the desired value, which is degrees per minute. Scrolling down...

Page 26

26 all other dwells in the program can be set in a similar fashion by selecting “pd” followed by the relevant dwell number. Set the number of times to repeat the program 4. Scrolling through the main scroll until the parameter “plc” is displayed and then depressing the up or down button will reveal ...

Page 27

27 implementing programs program execution once the program has been entered it can be set running by depressing the ‘run/hold’ push button on the front. With the run initiated, the program will commence and the legend on the display will indicate if a ramp or dwell is being performed. While a progr...

Page 28

28 segment type and will be flashing. Pushing “run/hold” button again will return the program to a run situation and extinguish the “hold” legend. Program reset a running, held or finished program can be reset by de- pressing the up and down push buttons together. When the reset has been enabled, th...

Page 29

29 furnace loading: be sure to use care in loading and unloading the furnace chamber. Molybdenum disilicide heating elements are extremely fragile and can crack or break with just a slight bump. Be sure not to block the flow of radiant heat from the heating elements to the thermocouple. The thermo- ...

Page 30

30 furnace atmospheres this furnace is designed to be used to 1700°c in pure air only. It may be used with nitrogen, argon, or helium atmospheres to 1600°c. Reducing atmospheres are not recommended. The heating elements in this furnace are attacked by fluorine, chlorine, sodium and potassium compoun...

Page 31

31 warning this warning is presented for compliance with california proposition 65 and other regulatory agencies and only applies to the insulation in this product. This product contains refractory ceramic, refractory ceramic fiber or fiberglass insulation, which can produce respirable dust or fiber...

Page 32

32 general cleaning instructions wipe exterior surfaces with lightly dampened cloth contain- ing mild soap solution. A few simple procedures will help insure that your furnace will give you long service. 1. Keep the chamber clean; this furnace is capable of achieving temperatures which will cause va...

Page 33

33 the following pages are intended to help you resolve functional problems with your furnace. Thermolyne is always available to assist you with problems. If this guide does not direct you to your specific problem, call or write barnstead/thermolyne at (1-800-553-0039). Problem possible causes corre...

Page 34

34 warning to avoid electrical shock, this furnace must always be disconnected from the electrical supply prior to maintenance and servicing. Refer servicing to qualified personnel. Warning this warning is presented for compliance with california proposition 65 and other regulatory agencies and only...

Page 35

35 to avoid premature burnout of a replacement heating element, be sure that the insulation tail supplied with the replacement element is inserted between the two legs of the element as shown in the drawing. Also be sure that the heating element projects sufficiently into the cham- ber. Insert eleme...

Page 36

36 the heating element until the element ceramic holder rests on top the main insulation. Check the heating element on the inside of the chamber. The large diameter section of the element must be flush with or slightly projecting from the surface of the insulation (if not, reposition element ceramic...

Page 37

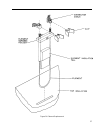

37 figure 1a element replacement.

Page 38

38 wiring diagramwiring diagram f46110cm, f46118cm, f46120cm, f46128cm, f46120cm-75, f46128cm-75 wiring diagram controller supplied with current controller. Fuse and fuse holder are notes: heating element indicator lamp hr1 to hr6 ds1 3 7 o b 17 13 internal communication cable wiring connector 2 1 r...

Page 39

39 wiring diagramwiring diagram f46110cm-33, f46120cm-33, f46120cm-33-75 w iring d iagram diagram component list part no. Description cn1 cn2 cb1 b1 b2 k1 t1 tc1 ds1 hr1 to hr6 controller, temperature controller, current circuit breaker fan fan contactor, mechanical transformer thermocouple indicato...

Page 40

40 wiring diagram wiring diagram f46230cm, f46238cm, f46240cm, f46248cm, f46240cm-75, f46248cm-75 diagram component list part no. Description cn1 cn2 cb1 b1 b2 & 3 k1 t1 tc1 ds1 hr1 to hr8 controller, temperature controller, current circuit breaker fan fan contactor, mechanical transformer thermocou...

Page 41

41 wiring diagram wiring diagram f46230cm-33, f46240cm-33, f46240cm-33-75 series elements controller supplied with current controller. Fuse and fuse holder are notes: heating element indicator lamp hr1 to hr8 ds1 3 7 o b 17 13 internal communication cable wiring connector 2 1 r w 15 2 emi line filte...

Page 42

42 description series 1077 series 1078 (chamber) small (models) large (models) (6"x6"x6") (10"x10"x10") circuit breaker switch swx54 swx54 connector cable 30" long ce557x1 (2 req’d) ce557x1 (1 req’d) connector cable 36" long ce558x1 (1 req’d) current controller cnx125 cnx125 elements el461x1 (6 req’...

Page 43

43 warning replace fuses with the same type and rating. Please refer to the specification plate for the complete model number, serial number, and series number when requesting service, replacement parts or in any correspondence concerning this unit. All parts listed herein may be ordered from the ba...

Page 44: Thermal Ceramics

44 date revised: 7/2/91 product identification trade name(s): cerafiber generic name: refractory ceramic fiber insulation cas #: 65997-17-3 chemical name: alumina silica formula: mixture manufacturer: thermal ceramics telephone: (404) 796-4200 address: p.0. Box 923, 2102 old savannah road city: augu...

Page 45

45 may be aggravated. Target organ(s): lungs, skin and eyes . Acute health effects: product is a mechanical irritant to skin, eyes and upper respiratory system. Chronic health effects: excessive exposure to rcf dusts and after service fibers may cause lung damage (fi- brosis). Iarc states there is s...

Page 46

46 special precautions *** always segregate materials by major hazard class *** this product contains a chemical known to the state of california to cause cancer. Storage segregation hazard classes: irritant special handling/storage: keep material dry. Special workplace engineering controls: adequat...

Page 48

48 barnstead thermolyne 2555 kerper blvd. P.O. Box 797 dubuque, ia 52004-0797 usa phone: 319-556-2241 • 800-553-0039 fax: 319-556-0695 web address: http://www.Barnsteadthermolyne.Com a subsidiary of 9001 iso registered.