- DL manuals

- Barnstead

- Furnace

- F46110CM

- Operation manual and parts list

Barnstead F46110CM Operation manual and parts list

High Temperature

Muffle Furnace

OPERATION MANUAL

AND PARTS LIST

Model Numbers

F46110CM

F46230CM

8 Segment

F46110CM-33

F46230CM-33

8 Segment

F46118CM

F46238CM

8 Segment

F46120CM

F46240CM

4 Program

F46120CM-33

F46240CM-33

4 Program

F46128CM

F46248CM

4 Program

F46120CM-75

F46240CM-75

20 Program

F46120CM-33-75

F46240CM-33-75

20 Program

F46128CM-75

F46248CM-75 20

Program

1

LT1141X1 • 12/21/05

Summary of F46110CM

Page 1

High temperature muffle furnace operation manual and parts list model numbers f46110cm f46230cm 8 segment f46110cm-33 f46230cm-33 8 segment f46118cm f46238cm 8 segment f46120cm f46240cm 4 program f46120cm-33 f46240cm-33 4 program f46128cm f46248cm 4 program f46120cm-75 f46240cm-75 20 program f46120c...

Page 2

Safety information ..................................................................................................................................................................3 alert signals ..........................................................................................................

Page 3

This manual contains important operating and safety information. The user must carefully read and under- stand the contents of this manual prior to the use of this equipment. Your barnstead thermolyne furnace has been de- signed with function, reliability, and safety in mind. It is the user’s respon...

Page 4

7. To avoid burns, do not stand directly in front of the chamber without wearing a heat resistant face shield, gloves and apron. 8. To avoid fire, do not place combustible materials where exposed to heat from open door. 9. Caution: hot surface. Avoid contact. Please note the following warnings: this...

Page 5

Intended use types 461 and 462 are general purpose laboratory furnac- es intended for applications requiring temperatures from 800-1700 degrees c. General usage do not use this product for anything other than its intended usage. Principles of operation the chamber section is heated by six (in type f...

Page 6

The contactor removes electricity from the heating ele- ments if the furnace temperature equals or exceeds the high limit setpoint of the controller or when the door is opened. The circuit breaker is used to turn the furnace on and off and also protects the electrical supply in the event that the fu...

Page 7

7 g eneral d escription typical profile for programmable models. (other profiles may be formed.) programmable/automatic control output 1 auto/man button page button scroll button down arrow button up arrow button run/hold button lower display upper display display window.

Page 8

Model# f46110cm, f46118 f46120cm f46128 f46120cm-75 f46128cm-75 f46110cm-33 f46120cm,-33 f46120cm-33-75 dimensions overall-in width 28-1/8 28-1/8 28-1/8 28-1/8 28-1/8 28-1/8 (cm) (71.4) (71.4) (71.4) (71.4) (71.4) (71.4) height 18-1/2 18-1/2 18-1/2 18-1/2 18-1/2 18-1/2 (47) (47) (47) (47) (47) (47) ...

Page 9

Model# f46230cm, f46238 f46240cm f46248 f46240cm-75 f46248cm-75 f46230cm-33 f46240cm,-33 f46240cm-33-75 dimensions overall-in width 34-1/8 34-1/8 34-1/8 34-1/8 34-1/8 34-1/8 (cm) (86.7) (86.7) (86.7) (86.7) (86.7) (86.7) height 22-1/2 22-1/2 22-1/2 22-1/2 22-1/2 22-1/2 (57.2) (57.2) (57.2) (57.2) (5...

Page 10

Environmental conditions operating: 17°c-27°c; 20% to 80% relative humidity, non-condensing. Installation category ii (over- voltage) in accordance with iec 664. Pollution degree 2 in accordance with iec 664. Altitude limit: 2,000 meters. Storage: -25°c to 65°c; 20% to 80% relative humidity. Declara...

Page 11

Visually check for any physical damage to the shipping container. Inspect the equipment surfaces that are adjacent to any damaged area. Open the furnace door and remove packing material from inside the furnace chamber. Vacuum the chamber prior to use to remove the insulation dust due to shipment. A ...

Page 12

Site selection install furnace on a sturdy surface and allow space for ventilation. The electrical specifications are located on the specifica- tion plate on the back of the furnace. Consult barnstead international if your electrical service is different than those listed on the specification plate....

Page 13

Observe the following warnings before operating your furnace. To avoid electrical shock, this furnace must: 1. Be installed by a competent, qualified elec- trician who insures compatibility among fur- nace specifications, electrical source and grounding code requirements. 2. Always be disconnected f...

Page 14

Power switch controls power to the furnace. Switch to the “on” position to energize the elements and the controller. Cycle indicator (op1) the amber cycle light will illuminate when electricity is being supplied to the elements. Circuit breaker a double pole circuit breaker is located at the bottom ...

Page 15

Accessing controller parameters to enter the main list of controller parameters, press and release the page button until you reach the desired pa- rameter. To scroll through the desired parameter, press and release the scroll button. Within the main list, press and release the scroll button. To quic...

Page 16

8 segment, 4-program and 20-program models buttons and indicators op1 (output 1): illuminates when the heating output of the temperature controller is on. Auto/man (auto/manual mode): when the controller is in the automatic mode the output automatically adjusts to keep the temperature or process val...

Page 17

Controller parameters home display °c: measured temperature in celsius. Temperature units can not be changed without entering the configuration. Contact customer service if a different temperature unit is required. Op: % output power demand; displayed in lower display (cannot be changed). C.Id: cont...

Page 18

Fast: fast run through program (no/yes). The controller will default to “no.” out.N: even output states (off/on), only used on multi-pro- gram models. Sync: synchronization (no/yes), only used on multi-program models. Seg.D: flash active segment type in the lower display of the home display (no/yes)...

Page 19

Used with type include; tgt target setpoint), rate (rate of temperature increase) and dur (time to target setpoint or time to dwell). End.T: end of program. Al list (alarm list) idhi: deviation high alarm. Atun list: (autotune list) tune: one-shot autotune enable. Dra: adaptive tune enable. Dra.T: a...

Page 20

Alarms the controller will flash an alarm message in the home dis- play if an alarm condition is detected. Fsl: pv full scale low alarm. Fsh: pv full scale high alarm. Dev: pv deviation band alarm. Ldhi: pv deviation high alarm. Ldlo: pv deviation low alarm. Lcr: load current load alarm. Hcr: load c...

Page 21

Basic operation when the controller is turned “on,” it will perform a short self-test and then change to the home display. The home display shows the measured temperature (process value) in the upper display and the desired value (setpoint) in the lower display. To operate the controller as a single...

Page 22

To these parameters when the program is in the hold state but permanent changes must be made in the reset state. Follow the steps below to create or edit a program. 1. Press the page button until you reach the pro- gram list (prog list). 2. Press the scroll button until display reads, “prg.N.” 3. Pr...

Page 23

To set the holdback type: 1. Press the page button until you reach the pro- gram list (prog list). 2. Press the scroll button until display reads, “hb.” 3. Press the up or down button to toggle between “band, hi, lo and off.” holdback value to set the holdback value: 1. Press the page button until y...

Page 24

Setting the number of cycles set the number of times a group of segments or pro- grams are to be repeated by following the steps listed below. 1. Press the page button until you reach the pro- gram list (prog list). 2. Press the scroll button until display reads,”cyc.N.” 3. Press the up or down butt...

Page 25

4. Press the scroll button until display reads “hb.” 5. Press the up or down button to toggle between “band, hi, lo and off.” 6. Press the scroll button until display reads, “tgt.” 7. Press the up or down button to set a target set- point. 8. Press the scroll button until display reads,”rate.” 9. Pr...

Page 26

3. Press the up or down button until display reads, “dwell.” 4. Press the scroll button until display reads, “dur.” 5. Press the up or down button to select a time in dwell units (seconds, minutes or hours; set in the “dwl.U” parameter). Step to climb instantaneously from the current temperature to ...

Page 27

4. Press the scroll button until display reads, “prg.N.” 5. Press the up or down button to select a program number to be linked. 6. Press the scroll button until display reads, “cyc.N.” 7. Press the up or down button to select the number of cycles the linked program is to be run. End to end or repea...

Page 28

Running a program 1. Press the page button until you reach the run list (run list). 2. Press the scroll button until display reads, “prg.” 3. Press the up or down button to select the program number you want to run. 4. Press the run/hold button once to start the program. (the run light will illumina...

Page 29

The g.Sp gain schedule setpoint) is factory set at 1210°c. If tuning within 200°c above or below the g.Sp. You must adjust your g.Sp value up or down to maintain at least a 200°c span between the g.Sp and the sp. Setting the transfer point if gain scheduling has been enabled, “g.Sp will appear at th...

Page 30

6. Simultaneously press the page and scroll buttons to return to the home display. The display will flash “tune” while tuning is in progress. Adaptive tuning adaptive tuning continuously evaluates tuning parame- ters. Adaptive tuning automatically installs new values if better accuracy is possible. ...

Page 31

During tuning, the lower display flashes between “tune” and the setpoint temperature. The setpoint temperature can be changed during tuning by pressing the up or down buttons. The lower display will continue to flash until the tuning is completed. Be sure to use care in loading and unloading the fur...

Page 32

Warning this warning is presented for compliance with california proposition 65 and other regulatory agencies and only applies to the insulation in this product. This product con- tains refractory ceramic, refractory ceramic fiber or fiber- glass insulation, which can produce respirable dust or fibe...

Page 33

The insulation, or other materials you have placed in the chamber. In many instances this reaction is detrimental to operation. 2. Clean exterior surfaces with lightly damp- ened cloth containing mild soap solution 3. Occasionally check the electrical connections in the control section. Repeated hea...

Page 34

Problem possible causes corrective action inaccurate temperatures. Contaminated thermocouple. Replace thermocouple. Repeated element burnout. Continuous operation do not continuously below 800°c. Operate below 800°c. Contact barnstead international. Heating element contamination. “or” displayed. Ope...

Page 35

Warning this warning is presented for compliance with califor- nia proposition 65 and other regulatory agencies and only applies to the insulation in this product. This prod- uct contains refractory ceramic, refractory ceramic fiber or fiberglass insulation, which can produce respirable dust or fibe...

Page 36

To replace a heating element (refer to fig. 1a): 1. Remove top cover from heating chamber side of furnace. 2. Remove the clips holding the connector cable (4) to the defective heating element. Unwrap the connector cable from the element. 3. Slide the heating element with element ceram- ic holder att...

Page 37

(if not, reposition element ceramic holder). Carefully wrap the connector cable around the element ends; fasten with clips. Replace top cover. To replace thermocouple: 1. Remove top cover from the heating cham- ber side of furnace. 2. Loosen diagonal screw holding ceramic con- nection block. 3. Lift...

Page 38

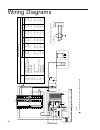

38 wiring diagrams fuse and holder are supplied with current controller. Notes: hr1 --- 240 vol t s t1 hr2 ry 1 ...208 vol t s sw1 hr3 series elements hr4 hr5 hr6 all other models l2 l1 -33 models onl y l2 l1 12 7 6 5 34 on 4 3 te10 a + eurotherm i limit 12 - 2d 3c 3d 3b 3a jb je jf jc jd ab black v...

Page 39

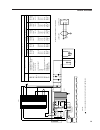

39 w iring d iagrams controller 3 w b o hf he hd connect or internal communica tion cable wiring 7 2 sg rd td te10 a 34 4 3 on 2 1 i limit eurotherm 2 1 567 fuse + - 1a 1b 1c 1d 2a 2b 2c 2d 3a 3b 3c 3d jf je jd jc jb ja hf he hd hc hb ha v- v+ vi ac ab aa lc lb la n l hr1 hr2 hr3 hr4 hr5 hr6 hr7 hr8...

Page 40

Description series 1140 series 1141 (chamber) small (models) large (models) (6"x6"x6") (10"x10"x10") circuit breaker switch swx54 swx54 connector cable 30" long ce557x1 (2 req’d) ce557x1 (1 req’d) connector cable 36" long ce558x1 (1 req’d) current controller cn71x68 cn71x68 controller (8 segment) cn...

Page 41

Please refer to the specification plate for the complete model number, serial number, and series number when requesting service, replacement parts or in any corre- spondence concerning this unit. All parts listed herein may be ordered from the barnstead international deal- er from whom you purchased...

Page 42

42.

Page 43

43.

Page 44

One year limited warranty barnstead international (“barnstead”) warrants that if a product manufactured by barnstead shall be free of defects in materials and workmanship for one (1) year from the first to occur of (i) the date the product is sold by barnstead or (ii) the date the product is purchas...