- DL manuals

- Barnstead

- Distilling equipment

- Mega-Pure Series 798

- Operation Manual And Parts List

Barnstead Mega-Pure Series 798 Operation Manual And Parts List

Summary of Mega-Pure Series 798

Page 1

Mega-pure ® one liter water still operation manual and parts list series 798 lt798x1 • 9/8/05 model number voltage description a440266 120v without bottle a440267 120v with bottle a7981 240v without bottle a7982 240v with bottle.

Page 2

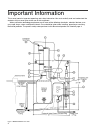

2 important information this manual contains important operating and safety information. You must carefully read and understand the contents of this manual prior to the use of this equipment. Water purification technology employees one or more of the following: chemicals, electrical devices, mer- cu...

Page 3

3 table of contents important information....................................................................................................................................2 table of contents ..............................................................................................................

Page 4

4 your barnstead mega-pure one liter water still has been designed with function, reliability, and safety in mind. It is your responsibility to install it in conformance with local electrical codes. For safe operation, please pay attention to the alert signals throughout the manual. Warnings to avoi...

Page 5

5 5. Always depressurize chemical lines before disas- sembly. 6. To avoid exposure to chemical fumes, ensure ade- quate ventilation when using chemicals for clean- ing. 7. Follow carefully the manufacturers’ safety instruc- tions on labels of chemical containers and material safety data sheets (m.S....

Page 6

6 your barnstead mega-pure one liter water still is a com- pact, all glass unit with ptfe connectors designed to provide 1.4 liter per hour of high purity distilled water. The product water is non-pyrogenic per usp xix. Resistivity will be greater than 1.0 megohm-cm at the condenser outlet using mos...

Page 7

7 tools required: diagonal cutting pliers. 1. Remove parts box and still from shipping carton and place on workbench. 2. Check glassware inside the main cabinet for damage. Check parts in the accessory box for damage. Identify any broken or damaged parts and report them to your dealer immediately. R...

Page 8

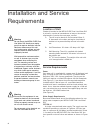

8 installation and service requirements location of unit choice of location for the mega-pure one liter water still is primarily a matter of convenience as long as the service requirements, listed on the next page, are met. A. The still may be bench or wall mounted. Allow 4"- 6" clearance at the sid...

Page 9

9 figure 2 240 volt receptacle figure 3 15a - 250v breaker box ground line line with option #1, approximately 4 gallons of untreated water will be used per hour in the cooling section of the still, 1 gal- lon of this water will be used as boiler feed. Water connec- tions are discussed on pages 11-15...

Page 10

10 tools required for assembly: 7/16" open end wrench, diagonal cutting pliers, common screwdriver. 1. Unwrap the condenser “b” and thoroughly flush all of the salt out. 2. Reattach the condenser “b” to the still and then attach the two ptfe connectors “d” and “p” to the condenser “b” as shown in fi...

Page 11

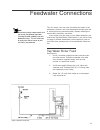

11 this still always uses tap water for cooling the steam in the condenser. However, you have the option of feeding your boil- er with higher purity pretreated water, thereby reducing the need to drain and clean your boiler. If you will be using tap water as your boiler feedwater, pro- ceed to the t...

Page 12

12 4. Plug the solenoid valve power cord (not shown) into the receptacle on the bottom of the control box "h." (see figure 5.) 5. Go to the still output connections section to com- plete your still's setup. Pretreated boiler feed when a supply of distilled, deionized or reverse osmosis water is to b...

Page 13

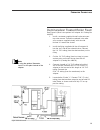

13 demineralizer treated boiler feed see figure 8. (must have optional still adapter kit: catalog no. 440376) 1. Install a customer supplied shutoff valve onto your tap water source. Thread the solenoid valve onto your customer supplied shutoff, with the side marked “in" toward the shutoff. 2. Insta...

Page 14

14 6. Route 3/8" i.D. Vinyl drain tubing to atmospherically vented drain. 7. Plug solenoid valve power cord (not shown) into receptacle in control box "h." 8. Plug still adapter kit cable into right side of dem- ineralizer and receptacle in control box "h." 9. Go to the still output connections sect...

Page 15

15 3. Connect the 3/8" fitting and 3/8" i.D. Vinyl tubing from the double solenoid valve kit to the “out” side of the solenoid valve on your treated water supply. 4. Locate the boiler fill tube "l." connect 3/8" i.D. From treated water supply solenoid to the end of the boiler fill tube. Route as sho...

Page 16

16 if you are using one of the optional storage bottles, go to the storage bottle installation section. If you are connecting your still to an automatic collection system, go to the automatic collection system installation section. Storage bottle installation to install the optional 6 or 9 liter sto...

Page 17

17 s till o utput c onnections automatic collection system installation before connecting your mega-pure one liter water still to the barnstead automatic collection system, move the still to its final location. 1. Locate acs tube "q" and ptfe connector "e" in the acs parts box. Locate distillate out...

Page 18

18 plug electrical power cord into appropriate receptacle. Refer to figure 1, page 2 for referenced locations. 1. Close drain clamp "g" on bottom of boiler "i." 2. Open valve at tap water source and treated water source if so installed. 3. Switch on the main power breaker on control at customer powe...

Page 19

19 high temperature cut-off switch your mega-pure one liter water still is protected against overheating by a thermal switch located in the control box at the right hand side of the boiler. Should the boiler overheat, the switch will open causing the heater and water supply to shut off. When the boi...

Page 20

20 cleaning for top performance and efficiency, the mega-pure one liter water still should be kept clean and free of scale. It is recommended that the boiler be drained and refilled with fresh water daily to flush the boiler of the concentration of contaminants from the previous day’s run. When usin...

Page 21

21 troubleshooting general m aintenance and s ervicing problem causes solution leaks. The most common leak is one occurring in the vinyl drain tubing. Hot water causes softening and pulling loose at the plastic barbed connectors. Runs of vinyl tubing should be supported to reduce the pull on the pla...

Page 22

22 general (con't) problem causes solution steam at condenser vent. A slight wisp of steam exiting at the condenser vent is normal. Gases in the steam are also being removed. If there is an excessive amount of steam leaving the condenser vent, increase the cooling water flow rate. No steam at conden...

Page 23

23 electrical before troubleshooting can begin, the problem component must be determined. That is accomplished as follows: 1. Disconnect the demineralizer and acs jacks from the still control box and attempt to run the still. If still fails, see “still troubleshooting.” if still runs, go to step #2....

Page 24

24 automatic collection system troubleshooting m aintenance and s ervicing problem cause solution will not turn still on or off as it should. Float stuck. Switch not working. Input jack not plugged in. Jack board defective. Remove level control cover and free-up. Replace switch. Check and reconnect....

Page 25

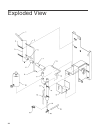

Parts list all replacement parts must be ordered through your laboratory dealer. Parts arranged by exploded view key number exploded view figure 1 item key key number description part number 1 a steam vent tubing tu674x6 2 c boiler/condenser spring (set of 4) 416104 3 b condenser 401203 4 p ptfe con...

Page 26

26 exploded view.

Page 27

27 wiring diagram.

Page 28

28 please refer to the specification plate for the complete model number, serial number, and series number when requesting service, replacement parts or in any correspondence concerning this unit. All parts listed herein may be ordered from the barnstead international dealer from whom you purchased ...

Page 29

29.

Page 30

30

Page 31

31.

Page 32

Barnstead international (“barnstead”) warrants that a product manufactured by barnstead shall be free of defects in materials and workmanship for one (1) year from the first to occur of (i) the date the product is sold by barnstead or (ii) the date the product is purchased by the original retail cus...